Polycarbonate resin composition and molded plate obtained therefrom

A technology of polycarbonate resin and polycarbonate, which is applied in the field of polycarbonate resin composition and its forming board, can solve the problems of impracticality, polycarbonate resin composition can not meet the transparency, etc., and achieve excellent thermal stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0101] [Manufacture of polymer-based dispersant-treated ITO]

[0102] In 100 g of 15 mass % ITO toluene dispersion (manufactured by C.I. Chemical Industry Co., Ltd., ITO average particle diameter: 30 nm), 230 g of 20 mass % PMMA toluene solution was added to make polymethyl methacrylate (PMMA) relative to 1 part by mass of ITO was 3 parts by mass, mixed and stirred at room temperature (25° C.), and then heated and concentrated at 120° C. to obtain a viscous liquid. Then, after drying, it was pulverized to obtain 60 g of ITO treated with PMMA.

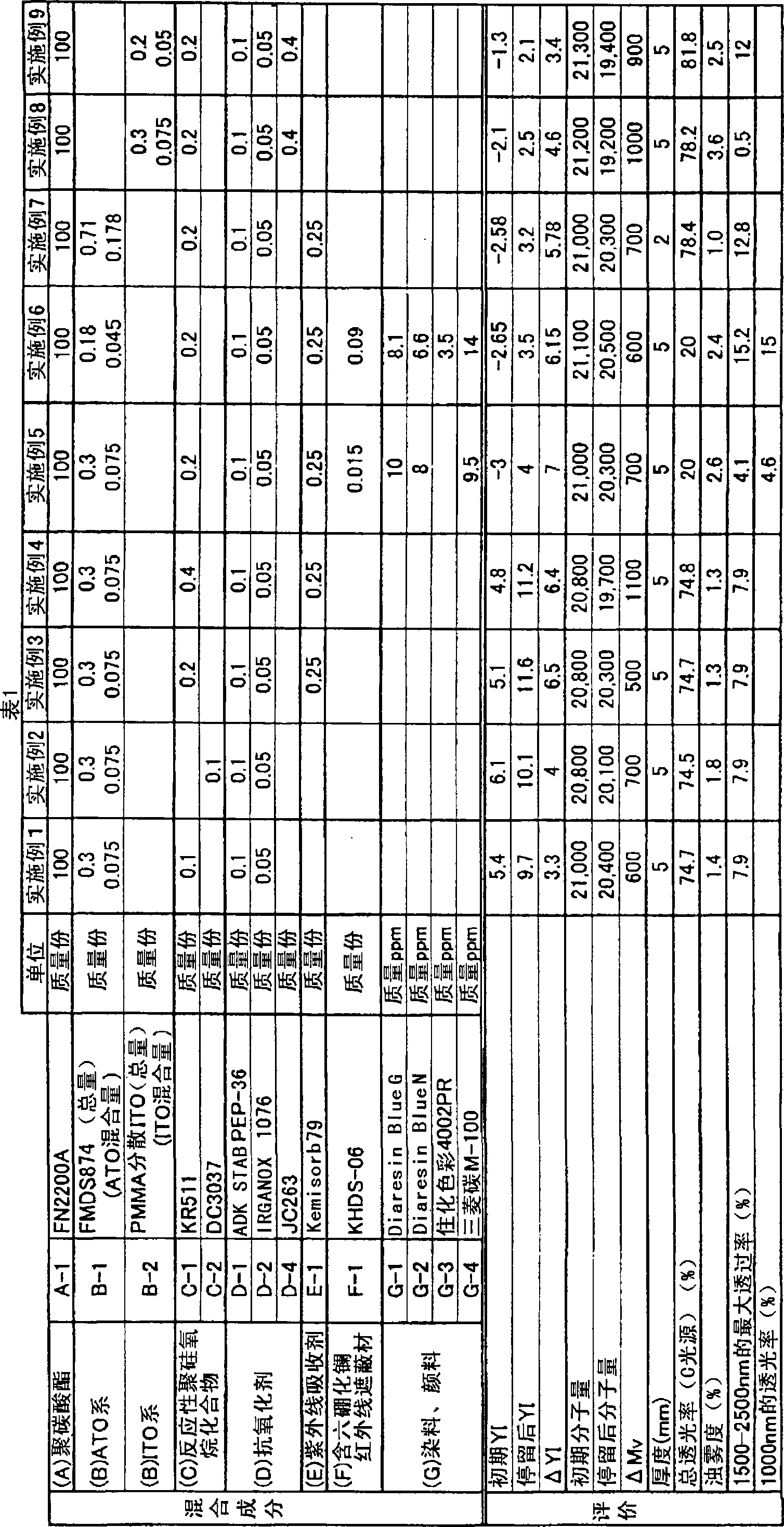

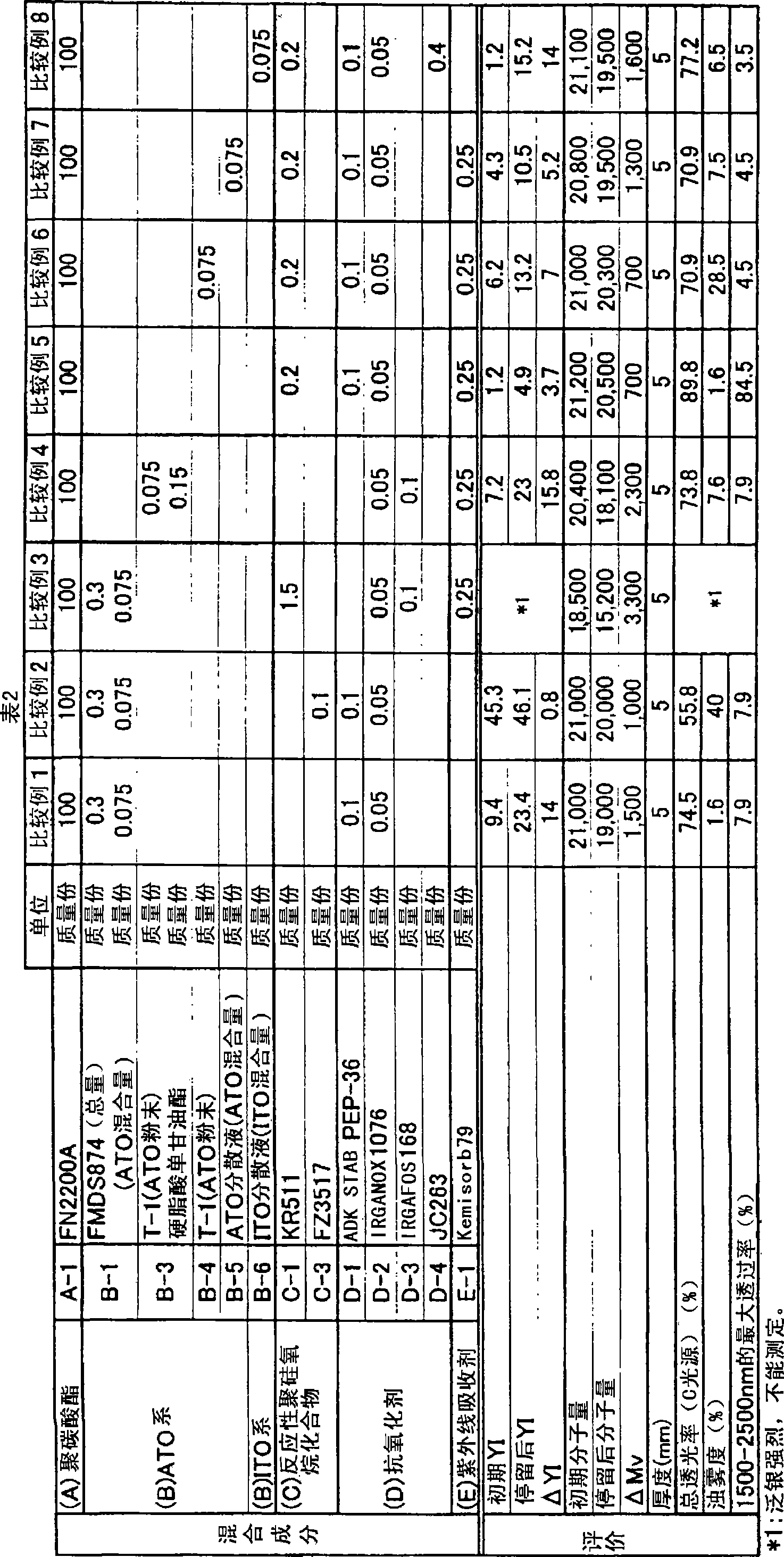

Embodiment 1~9、 comparative example 1~8

[0104] [mixed ingredients]

[0105] The types of materials used in Examples and Comparative Examples are as follows.

[0106] (A) polycarbonate

[0107] (A-1): Polycarbonate (trade name: Toughlon FN2200, manufactured by Idemitsu Kosan Co., Ltd., viscosity average molecular weight: 22,000)

[0108] (B) ATO or ITO

[0109] (B-1): ATO processed with a polymeric dispersant [trade name: FMDS-874, manufactured by Sumitomo Metal Mining Co., Ltd., made of 3 parts by mass of polymethacrylic acid relative to 1 part by mass of ATO Infrared shielding material composed of methyl ester dispersant, ATO average particle size: 80nm, antimony content in ATO: 10% by mass]

[0110] (B-2): ITO treated with a polymeric dispersant (PMMA) obtained in Production Example 1 above

[0111] (B-3): ATO powder [trade name: T-1, JEMCO type, ATO average particle diameter: 31nm (average particle diameter of dispersion liquid)) and stearic acid monoglyceride (low molecular system dispersant) (commodity Nam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com