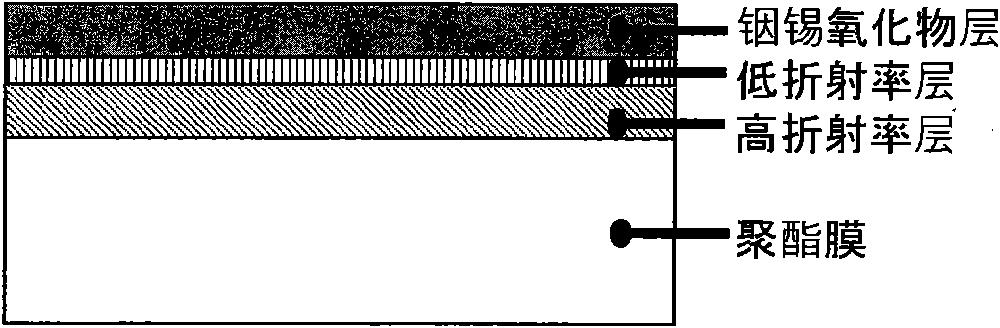

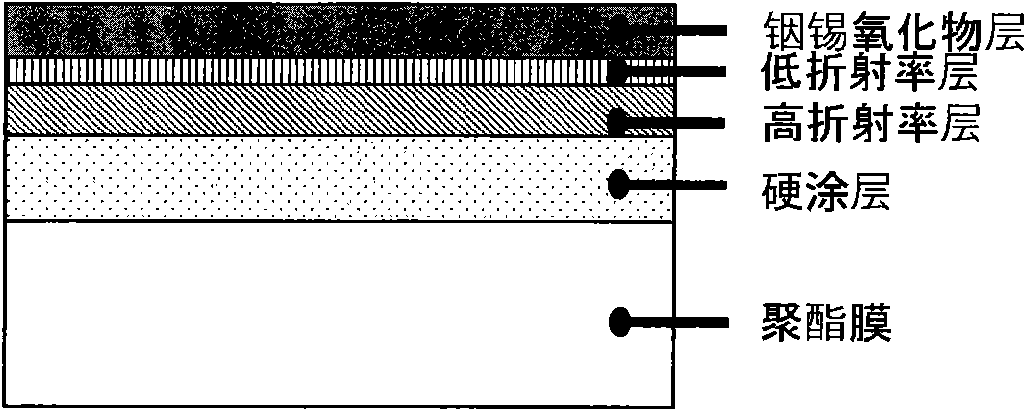

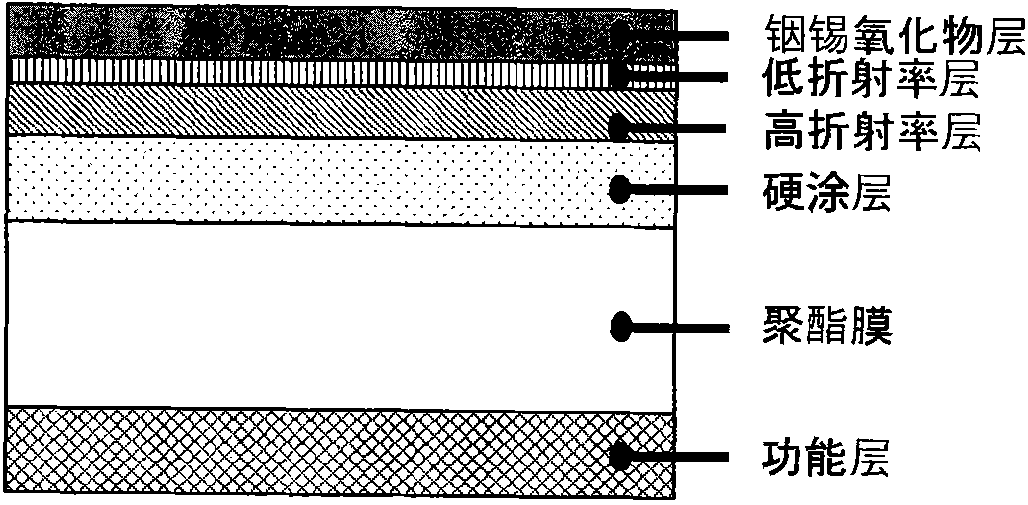

Transparent conductive film

A technology of transparent conductive film and film thickness, which is applied to the conductive layer on the insulating carrier, electrical digital data processing, instruments, etc., and can solve the problems that cannot be suppressed and reduce the haze value of the transparent conductive laminated body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0078] [Production Example 1, Preparation of Coating Solution for Hard Coat (HC-1)]

[0079] 80 parts by mass of dipentaerythritol hexaacrylate, 20 parts by mass of pentaerythritol triacrylate, 20 parts by mass of 1,6-bis(3-acryloyloxy-2-hydroxypropoxy) hexane, photopolymerization initiator (commercial product Name: IRGACURE 184, manufactured by Ciba Seika Co., Ltd.) 4 parts by mass and 100 parts by mass of isobutanol were mixed to prepare a coating liquid (HC-1) for a hard coat layer.

manufacture example 2

[0080] [Production Example 2, Preparation of Coating Liquid (H-1) for High Refractive Index Layer]

[0081] 79 parts by mass of zirconia fine particles with an average particle diameter of 0.02 μm, 21 parts by mass of urethane acrylate (molecular weight 1400, manufactured by Nippon Synthetic Chemical Industry Co., Ltd., Violet UV7600B) having 6 acryloyl groups in one molecule, and photopolymerization initiator (trade name "IRGACURE 184", manufactured by Ciba Specialty Chemicals Co., Ltd.) 5 parts by mass were mixed, diluted with methyl ethyl ketone so that the above-mentioned solid content became 10 mass%, and a coating liquid (H-1) for a high refractive index layer was prepared.

manufacture example 3

[0082] [Production Example 3, Preparation of Coating Liquid (H-2) for High Refractive Index Layer]

[0083] 72 parts by mass of zirconia microparticles with an average particle diameter of 0.02 μm, 28 parts by mass of urethane acrylate (molecular weight 1400, manufactured by Nippon Synthetic Chemical Industry Co., Ltd., Violet UV7600B) having 6 acryloyl groups in one molecule, and photopolymerization initiator (trade name "IRGACURE184", manufactured by Ciba Specialty Chemicals Co., Ltd.) 5 parts by mass were mixed, and then diluted with methyl ethyl ketone so that the above-mentioned solid content became 10 mass % to prepare a high refractive index layer coating solution (H-2).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com