Method for preparing tin-doped spinel lithium-rich lithium manganate cathode material by using two-stage sintering process

A technology of lithium-rich lithium manganese oxide and positive electrode materials, which is applied in the direction of manganate/permanganate, battery electrodes, structural parts, etc., can solve the problems of cycle performance attenuation, weak stability, and poor discharge performance, and achieve Improved stability, low raw material cost, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Weigh lithium hydroxide, manganese hydroxide, and tin carbonate respectively according to the molar ratio of lithium ion, manganese ion, and tin ion being 1: 1.12: 0.15.

[0035] Mix the weighed lithium hydroxide, manganese hydroxide, and tin carbonate, add ethanol 10 times the volume of the total solid volume, and use a super energy ball mill for wet grinding and mixing for 11 hours to prepare precursor 1. Precursor 1 was vacuum-dried at 190° C. and 100 Pa to prepare Precursor 2 . Precursor 2 was placed in an oxygen-enriched air atmosphere with an oxygen volume content of 66%, sintered at 230°C for 9 hours, then heated from 230°C to 490°C at a heating rate of 7°C / min, and sintered at the temperature for 18 hours to prepare the tip. Spar lithium-rich lithium manganese oxide cathode material.

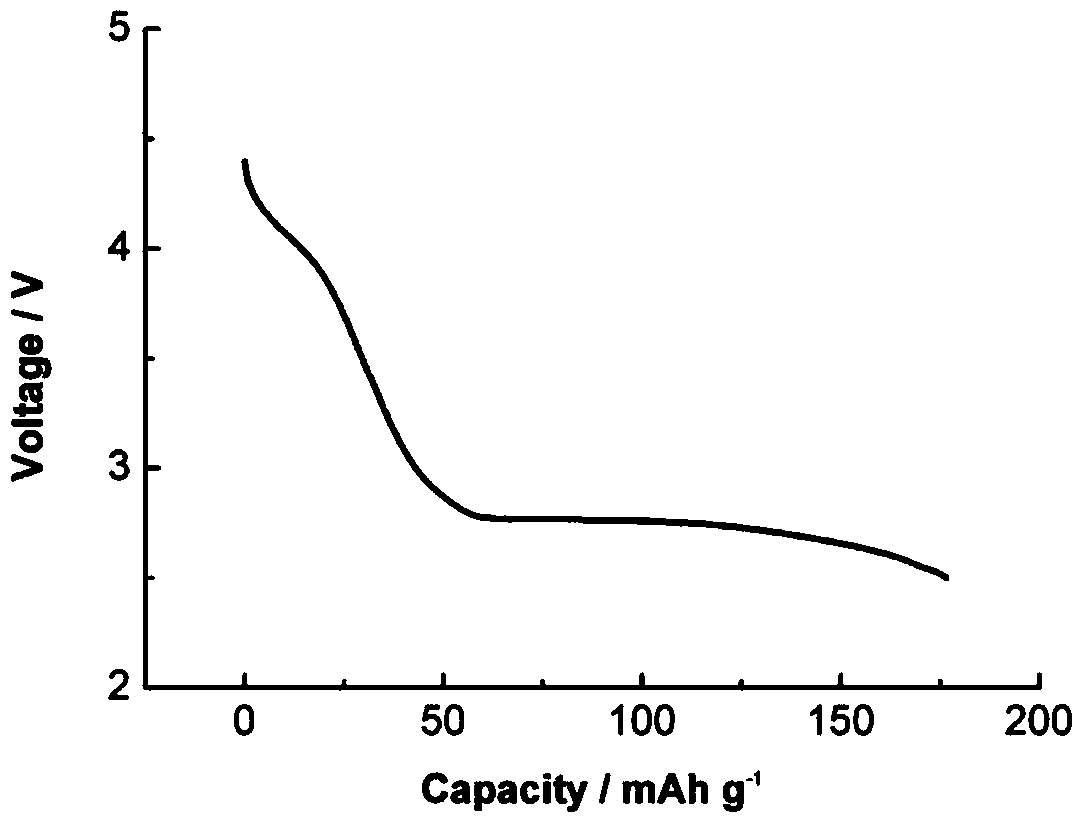

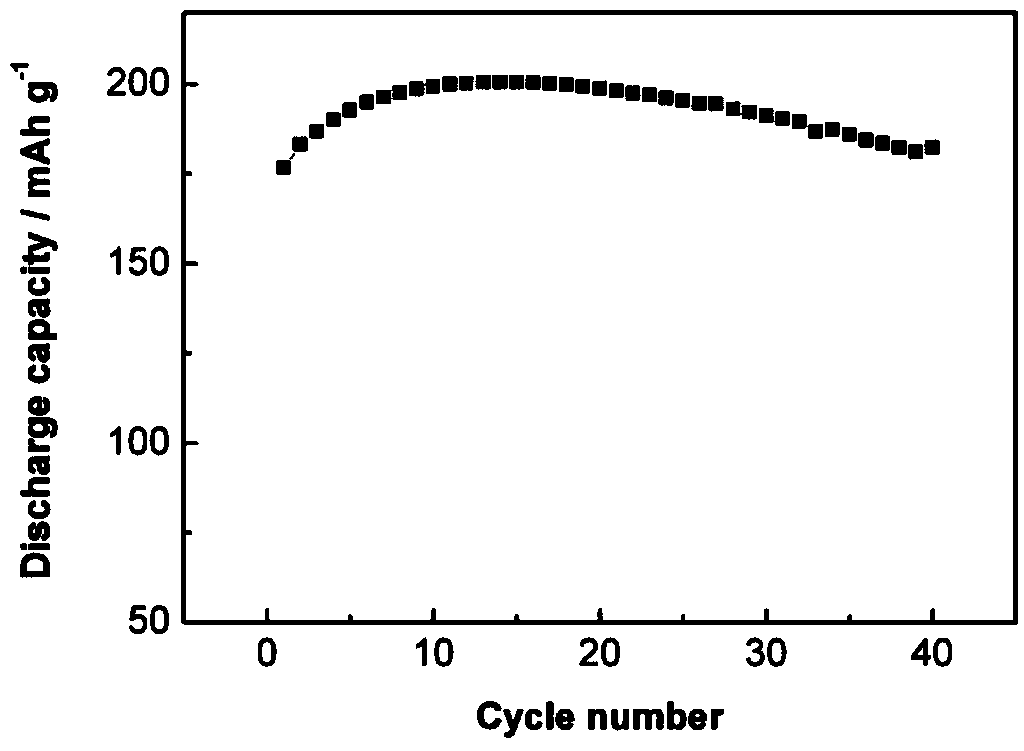

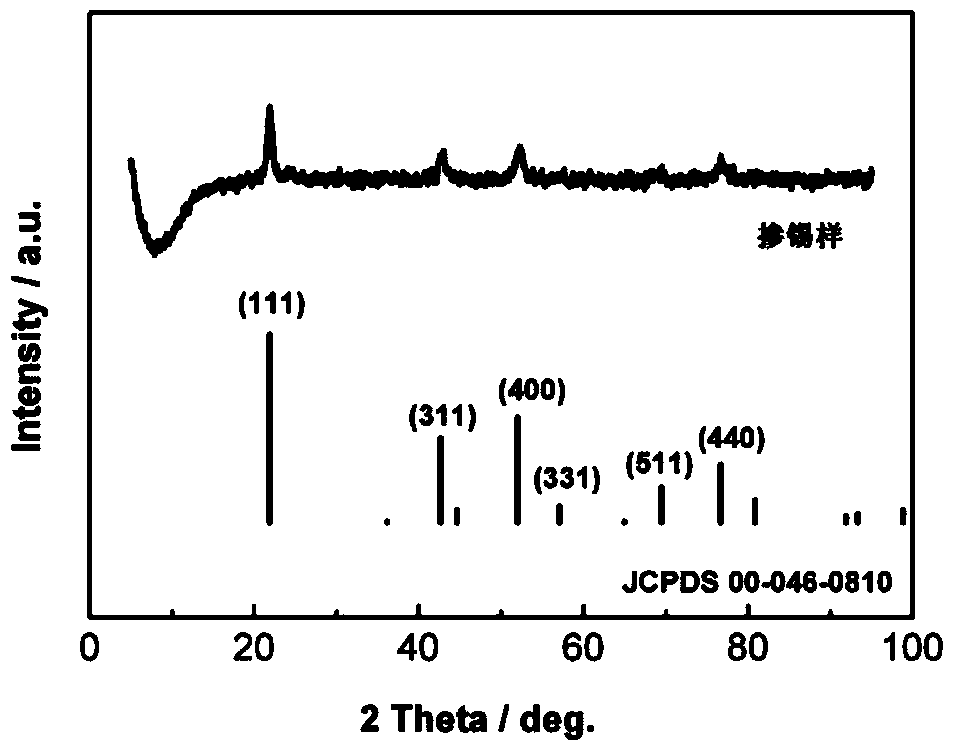

[0036] Compared with other inventive methods, the raw material cost of the present invention is lower, and tin doping improves the prepared spinel Li 4 mn 5 o 12 The stability...

Embodiment 2

[0038] Lithium carbonate, basic manganese carbonate and SnO were weighed according to the molar ratio of lithium ion, manganese ion and tin ion being 1.06 : 1.25 : 0.05, respectively.

[0039] Mix the weighed lithium carbonate, basic manganese carbonate and SnO, add acetone 18 times the volume of the total solid volume, and use a super energy ball mill for wet grinding and mixing for 15 hours to prepare precursor 1. Precursor 1 was vacuum-dried at 280° C. and 10132 Pa to prepare Precursor 2 . Precursor 2 was placed in an oxygen-enriched air atmosphere with an oxygen volume content of 99%, sintered at 300°C for 15 hours, then heated from 300°C to 600°C at a heating rate of 30°C / min, and kept at the temperature for sintering for 24 hours to prepare the tip. Spar lithium-rich lithium manganese oxide cathode material.

[0040] Compared with other inventive methods, the raw material cost of the present invention is lower, and the preparation process is simple, and tin doping impro...

Embodiment 3

[0042]Weigh lithium carbonate, manganese nitrate, and tin hydroxide respectively according to the molar ratio of lithium ion, manganese ion, and tin ion being 1.01: 1.05: 0.21. Mix the weighed lithium carbonate, manganese nitrate, and tin hydroxide, add ethanol that is 1 times the volume of the total solid volume, and wet grind and mix for 3 hours with an ordinary ball mill to prepare precursor 1. Precursor 1 was vacuum-dried at 80 °C and 10 Pa to prepare Precursor 2. Precursor 2 was placed in an oxygen-enriched air atmosphere with an oxygen volume content of 99%, sintered at 150°C for 3 hours, and then heated from 150°C to 400°C at a heating rate of 1°C / min, and kept at the temperature for sintering for 3 hours to prepare the tip. Spar lithium-rich lithium manganese oxide cathode material.

[0043] Compared with other inventive methods, the raw material cost of the present invention is lower, and tin doping improves the prepared spinel Li 4 mn 5 o 12 The stability of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com