Method for producing cement-based composite material for injection reinforcement from waste incineration fly ash

A technology for waste incineration fly ash and composite materials, which is applied in the field of cement-based composite materials for injection reinforcement using waste incineration fly ash, can solve problems such as the decrease in strength of magnesium phosphate cement, and achieve the effects of efficient disposal and temperature reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

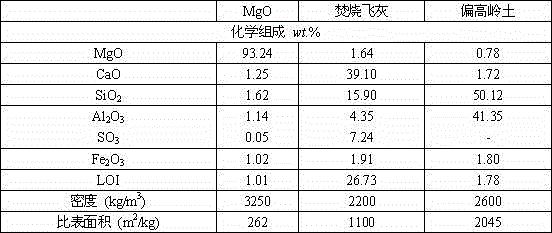

[0039] The main raw materials used in the test are magnesite (MgCO 3 ) It is calcined and ground in a high-temperature furnace at 1100℃. The relevant chemical composition and specific surface area are shown in Table 1. The chemistry and specific surface area of waste incineration fly ash, metakaolin are shown in Table 1. Potassium dihydrogen phosphate, ammonium dihydrogen phosphate, and boric acid are chemical reagents.

[0040] Table 1 Chemical composition of raw materials / %

[0041]

[0042] 1. The setting time is carried out according to GB / T 1346-2011 "Cement Standard Consistency Water Consumption, Setting Time, Stability Test Method". Since the development of high-performance cement-based composites has the characteristics of fast setting and early strength, the final setting time is recorded as the test result ; The compressive strength test process of cement-based materials is carried out in accordance with GB / T 17671-1999 "Cement Mortar Strength Test Method", the sample ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com