Ecological potassium magnesium phosphate cement-based repairing material

A technology of magnesium potassium phosphate cement and repair materials, which is applied in the field of building materials, can solve problems such as poor fluidity, large color difference, and short initial setting time of MKPC, and achieve good compatibility, prevent cracks, and enhance mechanical strength and adhesion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The preparation method of the waterworks sludge powder in this example: select the sludge from the sedimentation tank of the waterworks, and obtain the sludge particles as they are through industrialized centralized centrifugal dehydration, and prepare them through the process of microwave autoclave curing-drying treatment-graded calcination-mechanical grinding To obtain sludge powder from waterworks, specifically, (1) uniformly raise the temperature of sludge particles from waterworks as they are for 0.5 hours, fill in steam during the heating process, and at the same time turn on the microwave at full power for 20 minutes, and stabilize the temperature in the kettle between 180°C and 195°C During the period, the pressure is controlled at 1.20MPa to 1.30MPa, and the constant temperature is 4.5h; (2) all the microwaves are turned off, and the temperature is turned off for about 1h, and then the kettle door is opened to dry, and the sludge particles larger than 5.5mm in si...

Embodiment 1

[0044] Calculated by weight components, including 215 parts of overburned magnesium oxide powder, 133 parts of potassium dihydrogen phosphate, 13 parts of sludge powder from waterworks, 13 parts of silica fume, 13 parts of nano-scale white corundum powder, 13 parts of titanium dioxide, ten 8.6 parts of disodium hydrogen phosphate dihydrate, 3.1 parts of borax, 4.3 parts of calcium chloride, and 88 parts of water.

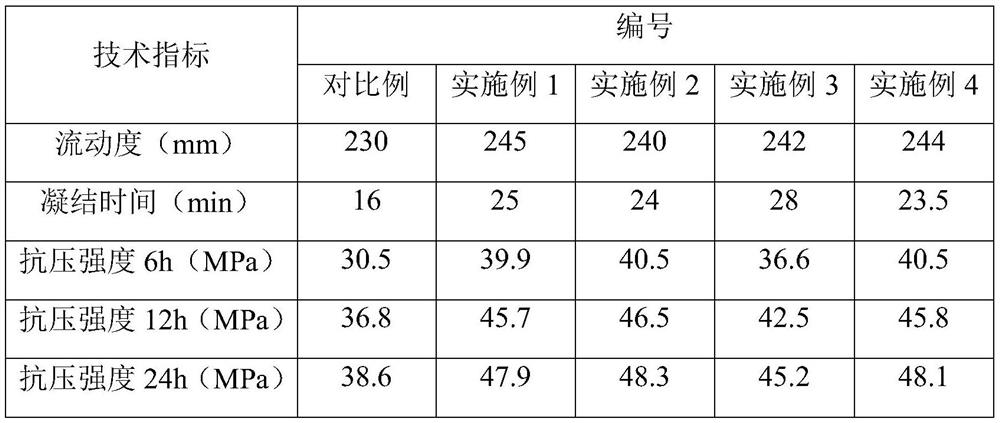

[0045] Performance testing: fluidity, coagulation time and compressive strength are shown in Table 1.

Embodiment 2

[0047] Calculated by weight components, including 202 parts of overburned magnesium oxide powder, 133 parts of potassium dihydrogen phosphate, 26 parts of sludge powder from waterworks, 13 parts of silica fume, 13 parts of nano-scale white corundum powder, 13 parts of titanium dioxide, ten 8.6 parts of disodium hydrogen phosphate dihydrate, 3.1 parts of borax, 4.3 parts of calcium chloride, and 88 parts of water.

[0048] Performance testing: fluidity, coagulation time and compressive strength are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com