Additive capable of simultaneous desulphurization and demercuration and preparation method thereof

An additive and mercury removal technology, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve the problems of failure to significantly improve flue gas mercury removal efficiency, failure to popularize and apply, and high price of adsorbents. Desulfurization and mercury removal efficiency, good economic and social benefits, and the effect of enhancing mercury removal capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

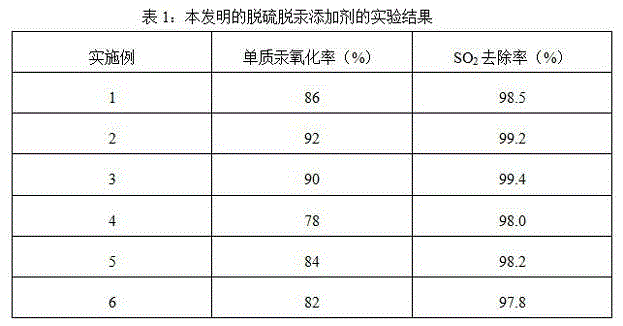

Examples

Embodiment 1

[0020] Sodium benzoate, iron sulfate, adipic acid and o-phthalaldehyde are mixed according to a certain weight ratio, wherein, sodium benzoate is 40wt%, iron sulfate is 20wt%, adipic acid is 30wt%, and o-phthalaldehyde is 10wt%. Add water and stir to mix, heat in a water bath at 60°C with constant stirring to fully dissolve each component to obtain a composite solution, dry at 105°C for 24 hours, and cool to room temperature to obtain a desulfurization and mercury removal additive.

Embodiment 2

[0022] Sodium benzoate, iron sulfate, adipic acid and o-phthalaldehyde are mixed according to a certain weight ratio, wherein, sodium benzoate is 35wt%, iron sulfate is 22wt%, adipic acid is 32wt%, and o-phthalaldehyde is 11wt%. Add water and stir to mix, heat in a water bath at 60°C and keep stirring to fully dissolve each component to obtain a composite solution, dry at 105°C for 12 hours, and cool to room temperature to obtain a desulfurization and mercury removal additive.

Embodiment 3

[0024] Sodium benzoate, iron sulfate, adipic acid and o-phthalaldehyde are mixed according to a certain weight ratio, wherein, sodium benzoate is 42wt%, iron sulfate is 22wt%, adipic acid is 28wt%, and o-phthalaldehyde is 8wt%. Add water and stir to mix, heat in a water bath at 60°C with constant stirring to fully dissolve each component to obtain a composite solution, dry at 105°C for 20 hours, and cool to room temperature to obtain a desulfurization and mercury removal additive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com