A flue gas desulfurization and mercury removal agent and its preparation method

A technology for mercury removal and flue gas removal, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of acid rain returning to surface rivers, lakes, corrosion of industrial equipment, damage to animals and plants, etc., to improve oxidation and adsorption. effect, improve the desulfurization and mercury removal efficiency, and improve the desulfurization and mercury removal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] In some embodiments, the preparation method of flue gas desulfurization and mercury removal agent comprises the following steps:

[0037] (1) heating the pyrolusite at a temperature of 300-600° C., and spraying water on its surface, so that pulverization occurs, and pyrolusite powder is obtained;

[0038] (2) Combine pyrolusite powder with Li 2 MnTiO 4 1. Manganese titanate is mixed evenly, and water is added to prepare a slurry with a liquid-solid ratio of 3-5:1;

[0039] (3) Soak the carrier in the slurry for 2-3 hours, place it at a temperature of 70-130°C for 20-30 minutes, and dry it.

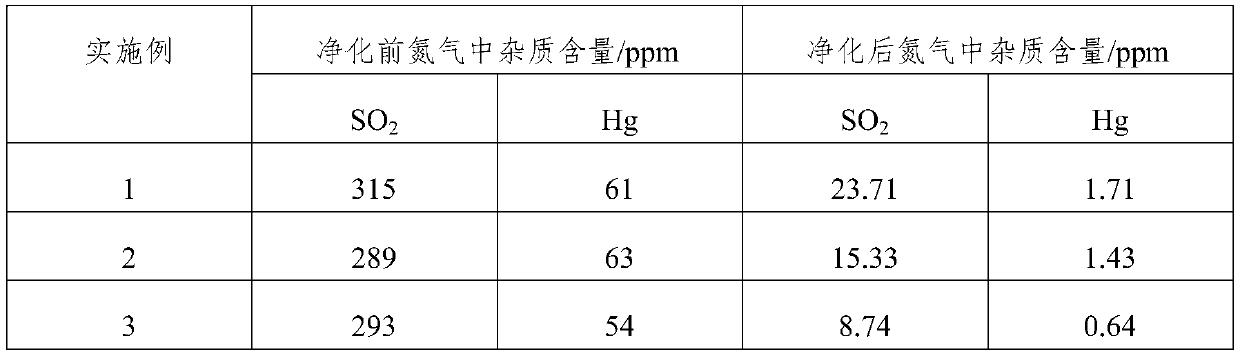

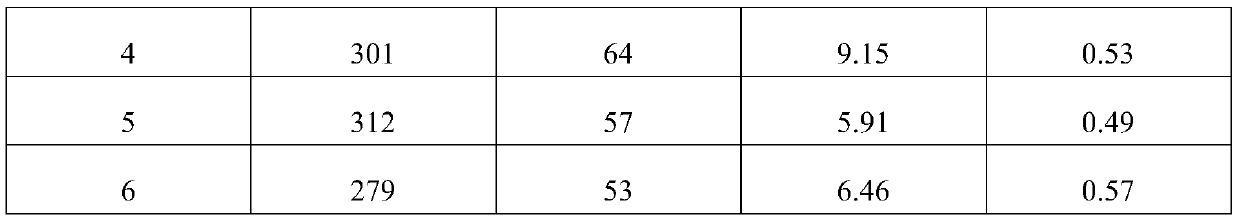

Embodiment 1

[0041] Grind pyrolusite into powder and combine it with Li 2 MnTiO 4 , manganese titanate mixed evenly to obtain the active ingredient, the mixed mass percentage is 80% of pyrolusite powder, Li 2 MnTiO 4 5%, manganese titanate 15%, take active ingredient 10g, add water to prepare slurry, and γ-Al with a diameter of 0.02mm 2 o 3 80g was added and soaked for 2h, treated at 70°C for 30min, and dried.

Embodiment 2

[0043] Heat pyrolusite to 600°C, add water to pulverize pyrolusite to obtain pyrolusite powder; mix pyrolusite powder with Li 2 MnTiO 4 , manganese titanate mixed evenly to obtain the active ingredient, the mixed mass percentage is 60% of pyrolusite powder, Li 2 MnTiO 4 20%, manganese titanate 20%, take 5g of the active ingredient, add water to prepare a slurry, and add 95g of silicon dioxide particles with a diameter of 0.06mm to soak for 3h, place the temperature at 130°C for 20min, and dry to obtain.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com