Sulfur and mercury removing agent

A mercury-removal agent and mercury-removal technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of low desulfurization and mercury removal efficiency, low sulfur capacity and mercury capacity, etc., so as to improve the desulfurization and mercury removal. efficiency, improve dispersion, and improve the effect of desulfurization and mercury removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

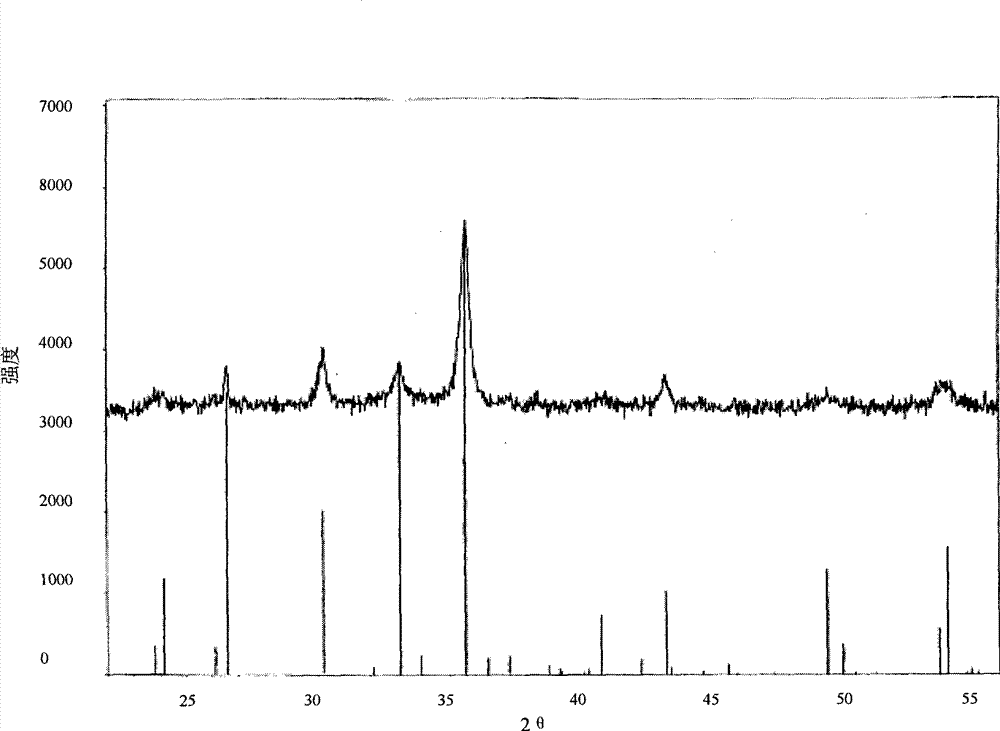

Image

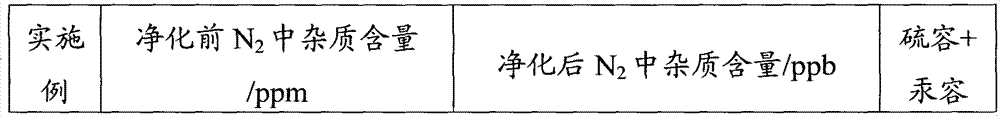

Examples

Embodiment 1

[0025] Choose 80 mesh, specific surface area is 20m 2 / g, the pore volume is 0.1cm 3 / g microspheres γ-Al 2 o 3 Carrier 5g is put into the manganese acetate solution of 10ml 2.88mol / L (Mn(CH 3 COO) 2 4H 2 (0), soak for 1 hour, after the impregnating solution is completely immersed in the carrier, take out the carrier, and dry it at 100°C for 5 hours to remove the moisture in the carrier; then the dried γ-Al loaded with manganese nitrate 2 o 3 The carrier is activated by roasting at 500°C for 6 hours under aerobic conditions to decompose manganese nitrate, and then obtain γ-Al loaded with manganese dioxide active components 2 o 3 carrier. In the above process, an oxygen environment is preferred when the carrier impregnated with the impregnating solution is dried and calcined.

[0026] 54g of ferric chloride hexahydrate and 32g of sodium carbonate were mixed and kneaded for 1 hour. The kneading time could be selected between 1 and 5 hours. After the kneading was finished,...

Embodiment 2

[0029] Choose 80 mesh, specific surface area is 150m 2 / g, the pore volume is 1.0cm 3 / g microspheres γ-Al 2 o 3 Carrier 5g is put into the manganese nitrate solution of 1ml 0.014mol / L (Mn(NO 3 ) 2 4H 2 (0), soak for 1 hour, after the impregnating solution is completely immersed in the carrier, take out the carrier, and dry it at 100°C for 5 hours to remove the moisture in the carrier; then the dried γ-Al loaded with manganese nitrate 2 o 3 The carrier is activated by roasting at 300°C for 10 hours under aerobic conditions to decompose manganese nitrate, and then obtain γ-Al loaded with manganese dioxide active components 2 o 3 carrier. In the above process, an oxygen environment is preferred when the carrier impregnated with the impregnating solution is dried and calcined.

[0030] Mix 8.4g of ferric chloride hexahydrate and 5g of sodium carbonate and knead for 1.5 hours. The kneading time can be selected between 1 and 5 hours. After the kneading is completed, the ab...

Embodiment 3

[0033] Select 80 mesh, specific surface area is 250m 2 / g, the pore volume is 1.5cm 3 / g microspheres γ-Al 2 o 3 Carrier 5g is put into the manganese nitrate solution of 10ml 1.047mol / L (Mn(NO 3 ) 2 4H 2 (0), soak for 0.5 hours, after the above impregnating solution is completely immersed in the carrier, take out the carrier, dry it at 105°C for 4 hours, remove the moisture in the carrier; then put the dried γ-Al loaded with manganese nitrate 2 o 3 The carrier is activated by roasting at 300°C for 9 hours under aerobic conditions to decompose manganese nitrate, and then obtain γ-Al loaded with manganese dioxide active components 2 o 3 carrier. In the above process, an oxygen environment is preferred when the carrier impregnated with the impregnating solution is dried and calcined.

[0034] 24.5g ferric chloride hexahydrate and 14.5g sodium carbonate were mixed and kneaded for 2 hours, the kneading time can be selected between 1 to 5 hours, after the kneading is finish...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com