Demercuration adsorbent based on pillared montmorillonite, preparation method and application thereof

A technology of pillared montmorillonite and adsorbent, which is applied in the direction of chemical instruments and methods, other chemical processes, alkali metal oxides/hydroxides, etc., can solve the problems of complex preparation methods of modified kaolinite, and achieve improved The effect of mercury's ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

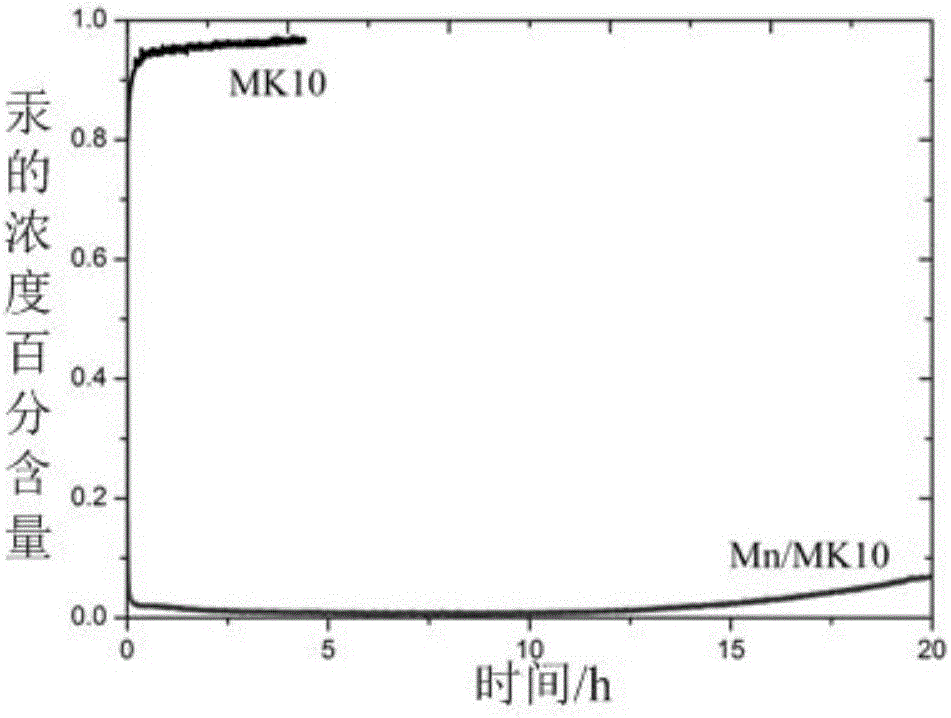

[0065] A mercury removal adsorbent based on pillared montmorillonite, the adsorbent includes aluminum pillared montmorillonite and manganese oxide loaded on aluminum pillared montmorillonite, the mass of manganese element in the manganese oxide is the same as that of pillared montmorillonite The ratio of destoned mass is 1:100, and the particle size of the adsorbent is 60-80 mesh.

[0066] The preparation method of the mercury removal sorbent based on pillared montmorillonite comprises the following steps:

[0067] (1) At 40°C, it will be AlCl 3 ·6H 2 NaOH with 1 times the molar concentration of O is slowly dropped into AlCl 3 ·6H 2 O solution, fully stirred for 2 hours, and then stood still for 2 hours; then slowly added dropwise the obtained solution to the montmorillonite powder at a ratio of 1 mmol / g to the amount of the pillar precursor at 40°C, and stirred thoroughly for 1 hour before Stand for 1 hour, then filter, wash, and dry to form pillared montmorillonite;

[...

Embodiment 2

[0070] A mercury removal adsorbent based on pillared montmorillonite, the adsorbent includes aluminum pillared montmorillonite and manganese oxide loaded on aluminum pillared montmorillonite, the mass of manganese element in the manganese oxide is the same as that of pillared montmorillonite The ratio of destoned mass is 1:10, and the particle size of the adsorbent is 60-80 mesh.

[0071] The preparation method of the mercury removal sorbent based on pillared montmorillonite comprises the following steps:

[0072] (1) At 100°C, it will be AlCl 3 ·6H 2 NaOH with 5 times the molar concentration of O is slowly dropped into AlCl 3 ·6H 2 O solution, fully stirred for 6 hours, and then stood still for 6 hours; then slowly added dropwise the obtained solution to the montmorillonite powder with a ratio of 10 mmol / g to the amount of the pillar precursor at 120 ° C, and stirred thoroughly for 5 hours before Stand still for 5 hours, then filter, wash, and dry to form pillared montmor...

Embodiment 3

[0075] A mercury removal adsorbent based on pillared montmorillonite, the adsorbent includes aluminum pillared montmorillonite and manganese oxide loaded on aluminum pillared montmorillonite, the mass of manganese element in the manganese oxide is the same as that of pillared montmorillonite The ratio of destoned mass is 2:100, and the particle size of the adsorbent is 60-80 mesh.

[0076] The preparation method of the mercury removal sorbent based on pillared montmorillonite comprises the following steps:

[0077] (1) At 50°C, it will be AlCl 3 ·6H 2 NaOH with 4 times the molar concentration of O is slowly dropped into AlCl 3 ·6H 2 O solution, fully stirred for 4 hours, and then stood still for 4 hours; then slowly added dropwise the obtained solution to the montmorillonite powder with a ratio of 3 mmol / g to the amount of the pillar precursor at 60 ° C, and fully stirred for 4 hours before Stand for 4 hours, then filter, wash, and dry to form pillared montmorillonite;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Mercury removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com