A kind of preparation method of special modified activated carbon for mercury removal

An activated carbon and modified technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of complex process, high cost and high use cost, and achieve the effect of simple operation process, high mercury removal performance and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] A method for preparing modified activated carbon specially used for high-efficiency mercury removal, the specific steps are as follows:

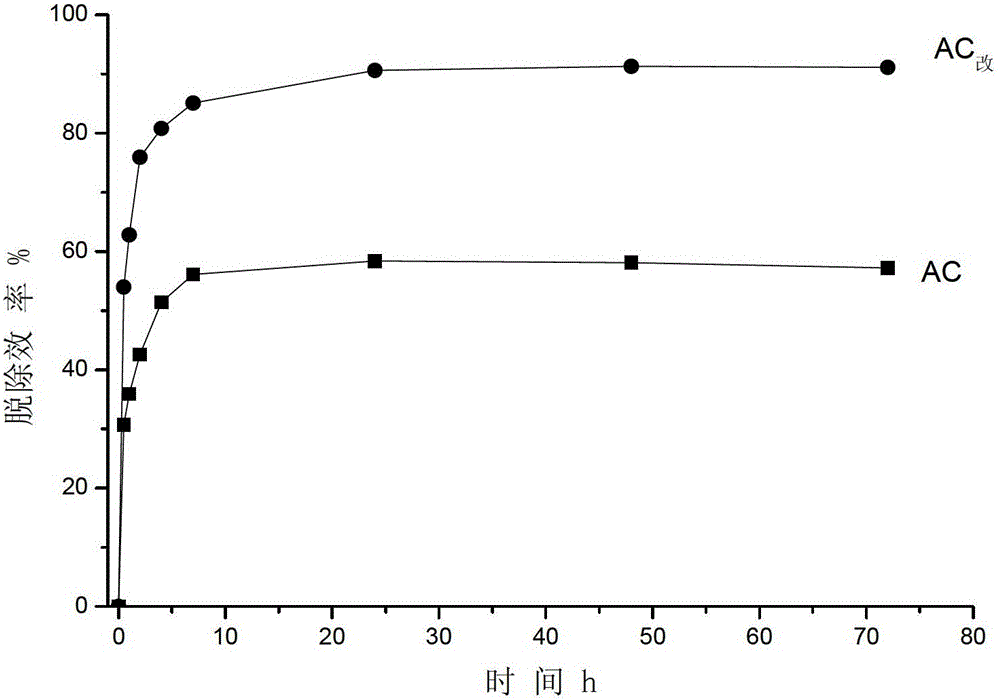

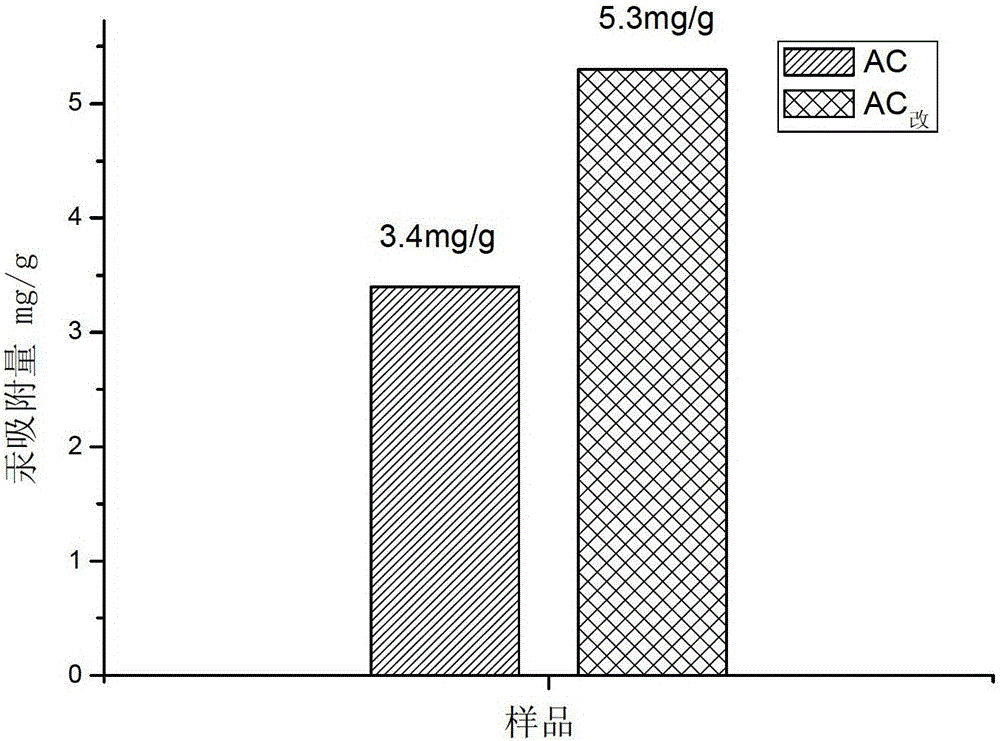

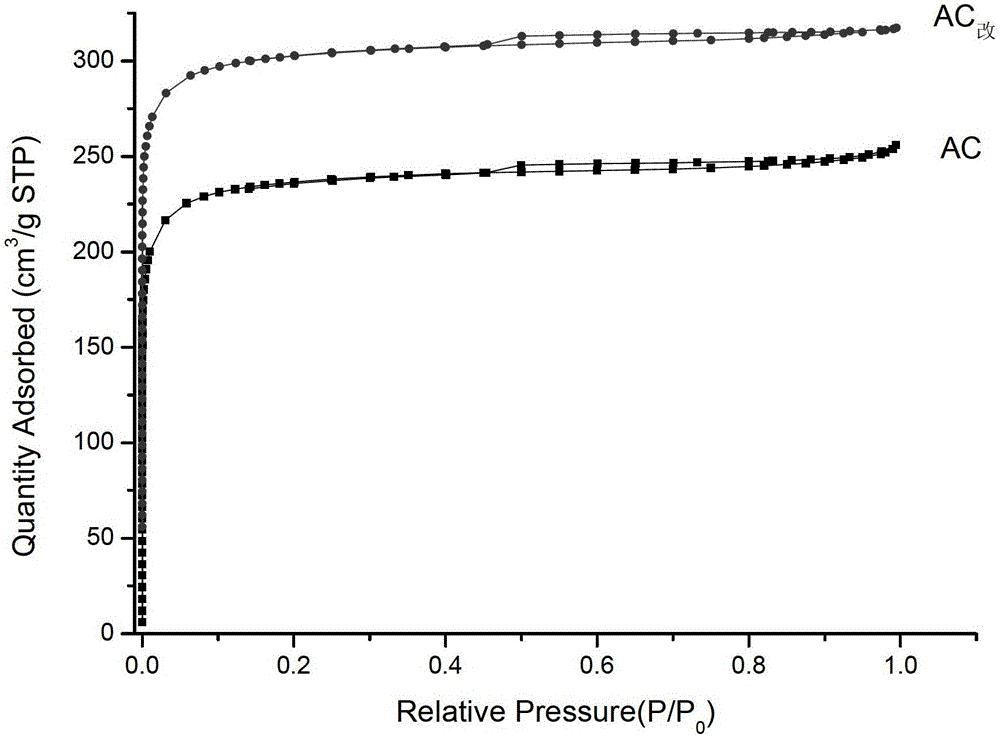

[0019] Wooden granular activated carbon (coconut shell activated carbon) was pickled with hydrochloric acid and washed with distilled water, and then dried at 105°C for later use. Accurately weigh a certain amount of activated carbon, add a certain concentration of hydrogen peroxide according to different volume and mass ratios (hydrogen peroxide volume: mass of activated carbon), heat at 50-70°C for 2-4h, and then ultrasonic for 20-40min, with an ultrasonic frequency of 25 ~40Hz, ultrasonic power 80~100KWH. After standing still for 24 hours, it was filtered and then dried at 105°C. The sample obtained by drying was washed with deionized water until neutral, and dried at 105°C for 4 hours to obtain a modified activated carbon specially used for mercury removal. The modified activated carbon for mercury removal has high mercury remov...

Embodiment 1

[0021] Wooden granular activated carbon was pickled with hydrochloric acid and washed with distilled water, and then dried at 105°C for later use. Accurately weigh 6.0g of granular activated carbon, add 10ml of 30% hydrogen peroxide, heat at 70°C for 2h in an airtight state, then sonicate for 40min, let stand for 24 hours, filter and dry at 105°C. The dried sample was washed several times with deionized water until neutral, and dried at 105°C for 4 hours to prepare a modified activated carbon specially used for mercury removal. At 25°C, for HgCl with a concentration of 17.46mg / L 2 The adsorption experiment shows that the mercury removal efficiency is 83.9%, and the mercury adsorption amount is 4.88mg / g.

Embodiment 2

[0023] Wooden granular activated carbon was pickled with hydrochloric acid and washed with distilled water, and then dried at 105°C for later use. Accurately weigh 6.0g of granular activated carbon, add 10ml of 30% hydrogen peroxide, heat at 70°C for 4h in a closed state, then sonicate for 40min, let stand for 24 hours, filter and dry at 105°C. The dried sample was washed several times with deionized water until neutral, and dried at 105°C for 4 hours to prepare a modified activated carbon specially used for mercury removal. At 25°C, for HgCl with a concentration of 17.46mg / L 2 The adsorption experiment shows that the mercury removal efficiency is 82.2%, and the mercury adsorption amount is 4.96mg / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com