Modified fly ash adsorbent for mercury removal from flue gas and preparation method thereof

An adsorbent and fly ash technology, which is applied in the field of modified fly ash adsorbent and its preparation, can solve the problems that the mercury removal efficiency of power plants cannot meet the emission standards of co-pollutants, the efficiency of fly ash mercury removal is not high, and the injection cost is increased. , to achieve the effect of improved mercury removal effect, high efficiency advantage, and reduced injection cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

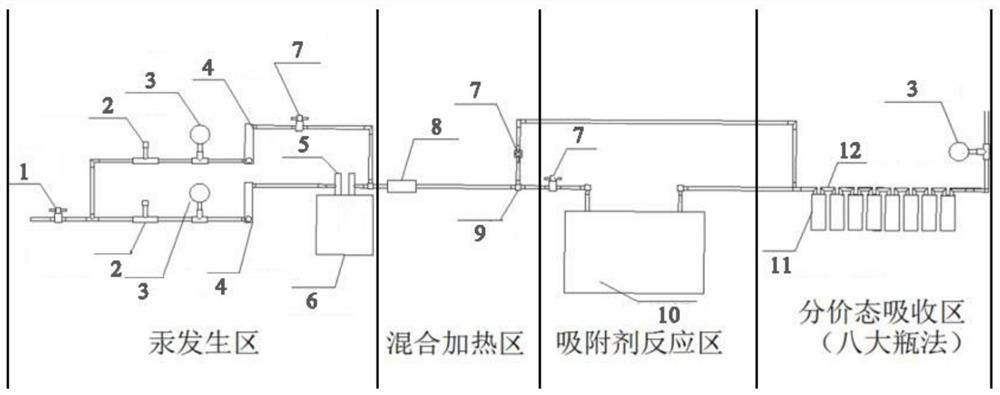

Method used

Image

Examples

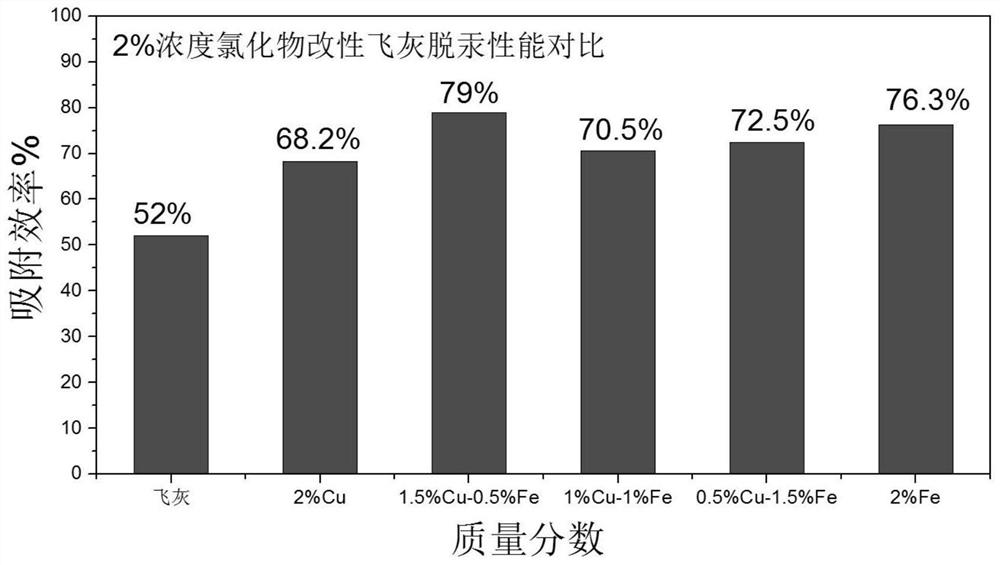

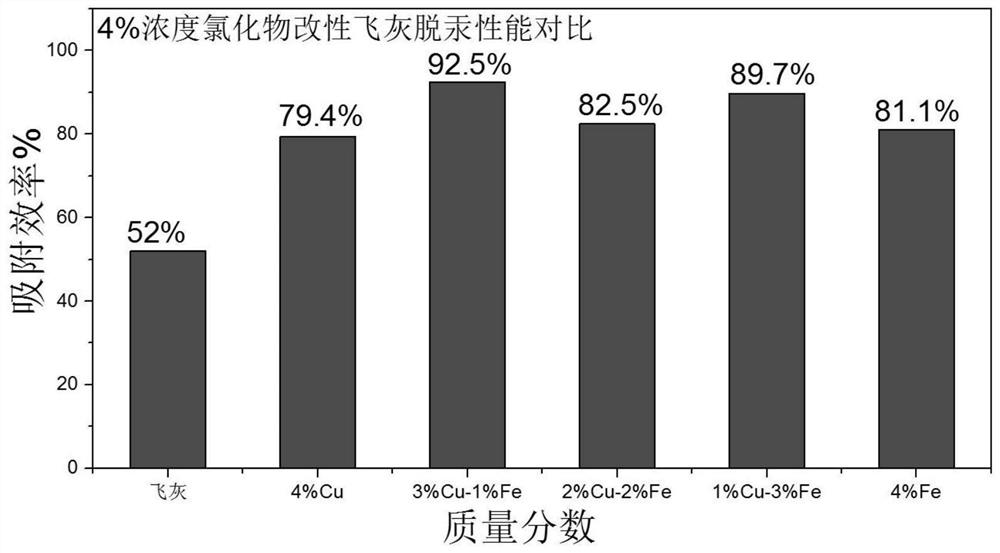

Embodiment 1

[0026] Weigh 1.5g CuCl 2 2H 2 O into the beaker, and then weighed 0.5gFeCl 3 ·6H 2 O and CuCl 2 2H 2 O mixed, adding 100 g of deionized water, after the chloride was completely dissolved, a mixed chloride solution was obtained. Weigh 5g of fly ash into a beaker, stir in an electromagnetic stirrer for 3h, let it stand for 10h, filter off the supernatant, put the remaining solid in a drying oven, and dry it in a drying oven at 50°C for 12h. The dried solid is ground into powder to obtain 1.5% CuCl 2 -0.5% FeCl 3 Modified fly ash adsorbent.

Embodiment 2

[0028] Weigh 1gCuCl 2 2H 2 O into the beaker, and then weigh 1gFeCl 3 ·6H 2 O and CuCl 2 2H 2 O mixed, adding 100 g of deionized water, after the chloride was completely dissolved, a mixed chloride solution was obtained. Weigh 5g of fly ash into a beaker, stir in an electromagnetic stirrer for 5h, let it stand for 12h, filter off the supernatant, put the remaining solid in a drying oven, and dry it in a drying oven at 60°C for 10h. The dried solid is ground into powder to obtain 1% CuCl 2 -1% FeCl 3 Modified fly ash adsorbent.

Embodiment 3

[0030] Weigh 0.5gCuCl 2 2H 2 O put into a beaker, and weigh 1.5g FeCl 3 ·6H 2 O and CuCl 2 2H 2 O mixed, adding 100 g of deionized water, after the chloride was completely dissolved, a mixed chloride solution was obtained. Weigh 5g of fly ash into a beaker, stir in an electromagnetic stirrer for 7h, let stand for 13h, filter off the supernatant, put the remaining solid in a drying oven, and dry it in a drying oven at 80°C for 9h. The dried solid is ground into powder to obtain 0.5% CuCl 2 -1.5% FeCl 3 Modified fly ash adsorbent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com