Hazard-free environment-friendly treatment process for reducing and recycling waste rubber, plastic and domestic garbage

A domestic waste and environmental protection treatment technology, which is applied in the field of domestic waste treatment, waste rubber and plastics, can solve air pollution, odorous waste liquid pollution of soil and water sources, failure to reduce, recycle, and harmless environmental protection Treatment and other issues to achieve the effect of solving secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

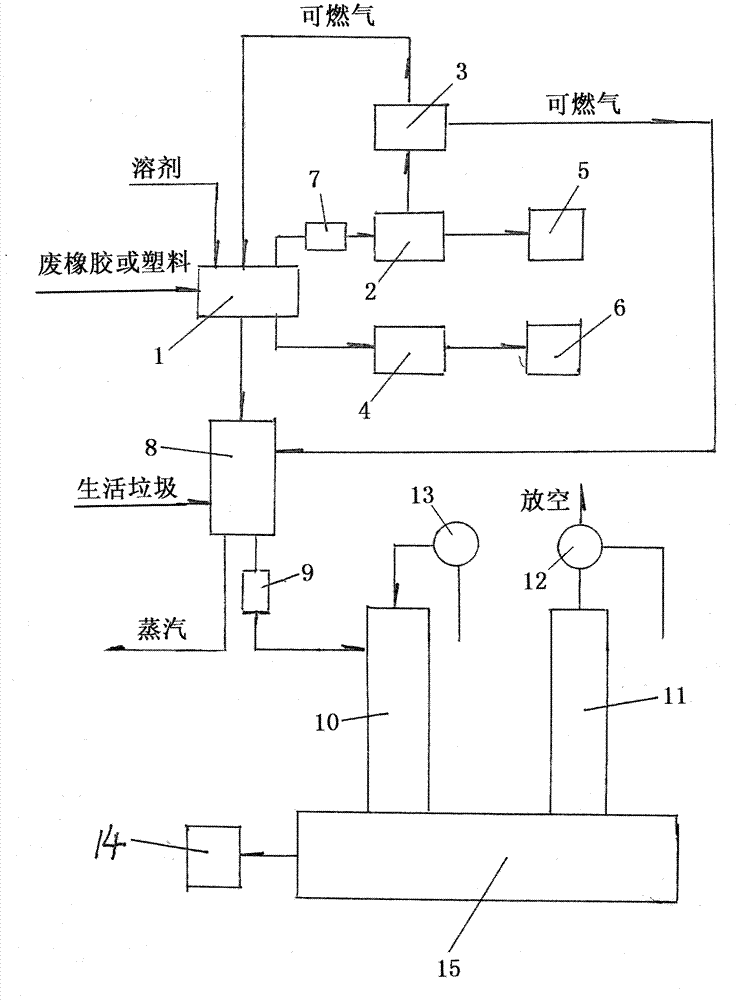

[0032] A waste rubber, plastic, domestic garbage reduction, recycling, harmless and environmentally friendly treatment process, such as figure 1 shown, including the following steps:

[0033] 1) put waste rubber or plastic into the pyrolysis device 1 for pyrolysis, and put domestic waste into the waste heat boiler 8 for incineration;

[0034] 2) The gaseous product produced in the pyrolysis device 1 is sent to the separation device 2 to separate the fuel oil and combustible gas through the upgrading device 7 to improve the quality, and the fuel oil and combustible gas are sent to the oil storage tank 5 and the storage tank respectively. In the gas tank 3 ; the remaining carbon black in the pyrolysis device 1 is recovered, and the remaining carbon black in the pyrolysis device 1 is sent into the melting pool 6 through the vacuum exhaust device 4 .

[0035] 3) sending the flue gas discharged from the pyrolysis device 1 in step 1) to the inlet of the waste heat boiler 8;

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com