A waste acid purification device and process

A technology of purification device and system device, applied in chemical instruments and methods, multi-stage water/sewage treatment, dehydration/drying/concentrated sludge treatment, etc., can solve the problems of environmental pollution, waste of resources, and low utilization rate of waste gas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

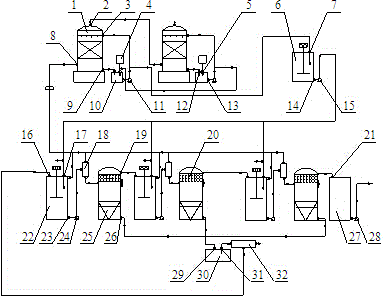

Image

Examples

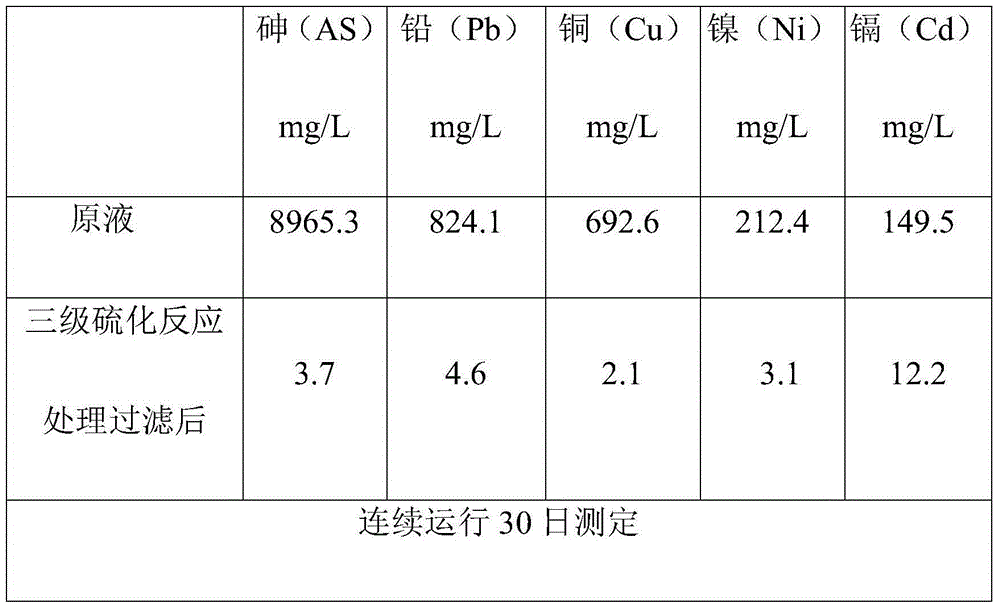

Embodiment 1

[0090] This example purifies sulfuric acid from a copper smelting flue gas in Jinchang, Gansu Province. A part of dirty acid will be produced in the purification section. Originally, the plant used conical settling tanks to treat this part of the dirty acid, and the settled dirty acid was neutralized with lime. This will consume a large amount of lime, and this part of sulfuric acid resources will be wasted.

[0091] The company uses three-stage vulcanization reaction treatment and three-stage filter filtration. After dilute acid treatment and filtration, the indicators are very good. Most of them are reused in the purification section, and a small part is used in the dry suction section to prepare acid. Among them, the stock solution of waste acid is 100 kg, and the total mass of arsenic and heavy metals is 10.91 kg.

[0092] The operation steps are as follows:

[0093] Introduce 100 kg of waste acid stock solution into the first-stage stirring tank 22, add 30.73 kg of sodiu...

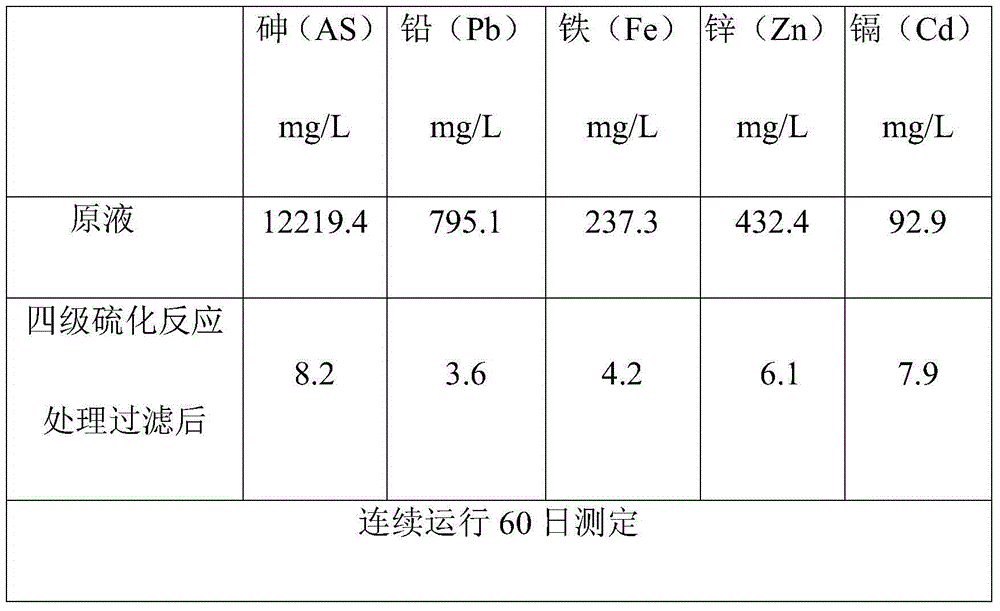

Embodiment 2

[0104] For the waste acid of a lead-zinc smelting acid factory in Jiyuan, Henan Province, a part of dirty acid will be produced in the purification section. Originally, the plant used ordinary settling tanks to treat this part of the dirty acid, and the settled dirty acid was neutralized with lime. A large amount of lime is consumed, and this part of the sulfuric acid resource is wasted.

[0105] The company uses the four-stage vulcanization reaction treatment in the present invention, four-stage filtration, and dilute acid treatment and filtration for reuse in the monoammonium phosphate production section. Among them, the stock solution of waste acid is 200 kg, and the total mass of arsenic and heavy metals is 16.37 kg.

[0106] The specific operation steps are as follows:

[0107] Introduce 100 kg of waste acid stock solution into the first-stage stirring tank 22, add 49.11 kg of sodium sulfide to the waste acid stock solution while stirring the waste acid stock solution, a...

Embodiment 3

[0120] A sulfur iron ore acid plant in Shayang, Hubei Province will produce some dirty acid in the purification section. Originally, the factory used inclined tube settler to treat this part of dirty acid, and the settled dirty acid was neutralized with lime. This will consume a large amount of lime, and this part of sulfuric acid resources will be wasted.

[0121] The company uses two-stage vulcanization reaction treatment, adopts two-stage FBL filter for filtration, and applies dilute acid treatment and filtration to acid distribution in the dry suction section. Among them, the stock solution of waste acid is 120 kg, and the total mass of arsenic and heavy metals is 8.62 kg.

[0122] The operation steps are as follows:

[0123] Introduce 100 kg of waste acid stock solution into the first-stage stirring tank 22, add 25.86 kg of sodium sulfide to the waste acid stock solution while stirring the waste acid stock solution, and simultaneously turn on the waste gas recovery syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com