A waste liquid treatment and recovery system for stainless steel pickling line

A technology of waste liquid treatment and recovery system, which is applied in metallurgical wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. It can solve the problems of destroying living conditions, waste of resources, and failure to meet discharge standards, etc. , to achieve the effect of high recycling rate, simple structure and resource saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

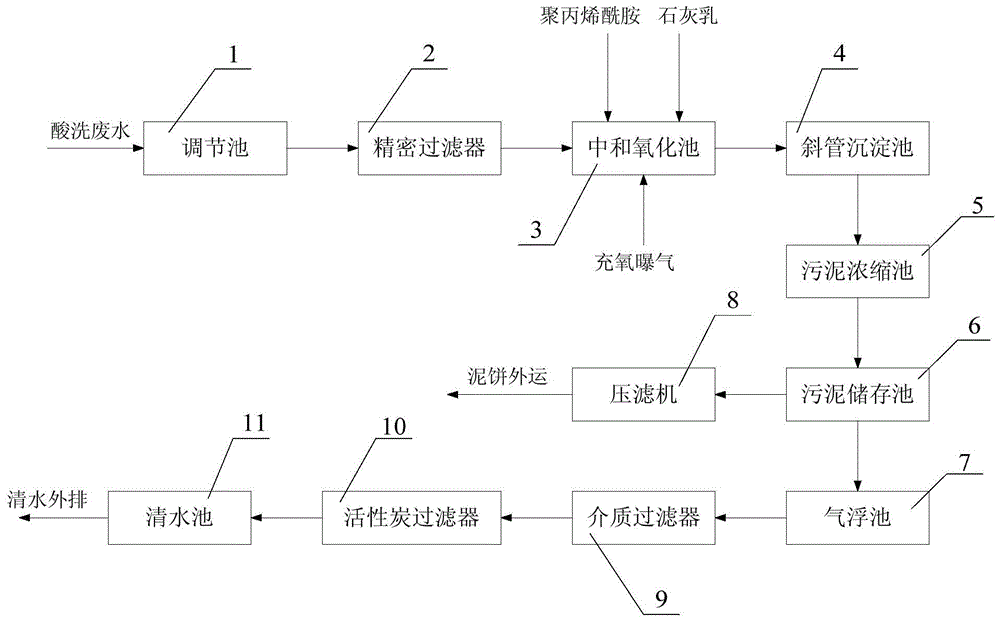

[0015] Examples, see attached figure 1 , a waste liquid treatment and recovery system for a stainless steel pickling line, including a regulating tank 1, a precision filter 2, a neutralization oxidation tank 3, an inclined tube sedimentation tank 4, a sludge concentration tank 5, a sludge storage tank 6, and an air flotation tank 7. Filter press 8, medium filter 9, activated carbon filter 10 and clear water tank 11, it is characterized in that, pickling waste water flows into described adjustment tank 1, and described adjustment tank 1 is connected with precision filter 2, and described precision Filter 2 is connected with neutralization oxidation tank 3, and described neutralization oxidation tank 3 is connected with inclined tube sedimentation tank 4, and described inclined tube sedimentation tank 4 is connected with sludge thickening tank 5, and described sludge thickening tank 5 is connected with sewage The mud storage tank 6 is connected, and the sludge storage tank 6 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com