Production processing method and device for regenerating waste material slag in wastepaper papermaking

A technology for papermaking and processing method of waste paper, applied in the field of papermaking, can solve the problems of environmental pollution, waste of waste resources and land resources, and difficult disposal of waste slag, and achieve the effects of reducing environmental pollution, recycling resources and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below with reference to the embodiments and the accompanying drawings.

[0041] The following examples are non-limiting examples of the invention.

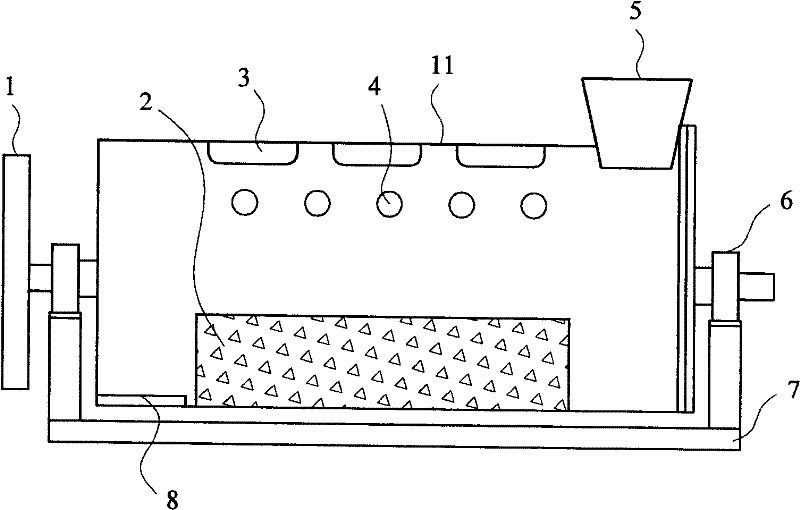

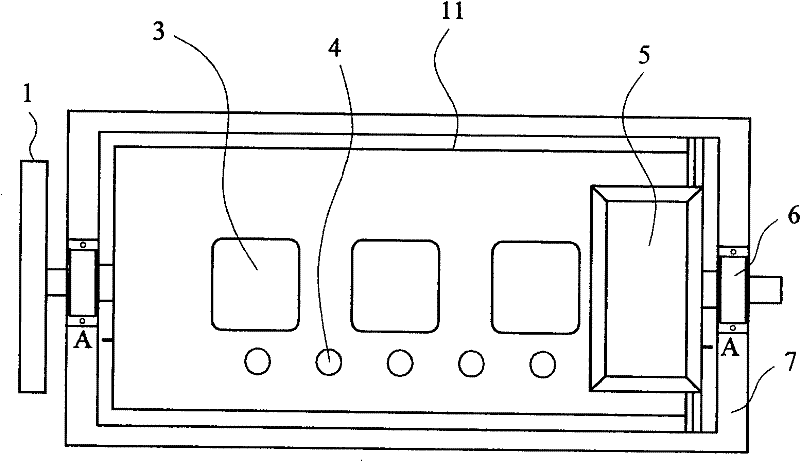

[0042] In this embodiment, the waste plastic and waste paper recycling equipment of the present invention includes a pulverizer, a paper-plastic separator whose inlet is connected to the outlet of the pulverizer, and a water container (in this embodiment, a water container connected to the outlet of the paper-plastic separator) Plastic sinking and floating pool 80), the water wheel separation pusher erected on the pool and in contact with the water surface, the water wheel scavenger, jumping screen and conveyor belt erected on the pool at the opposite end of the paper-plastic separator and in contact with the water body .

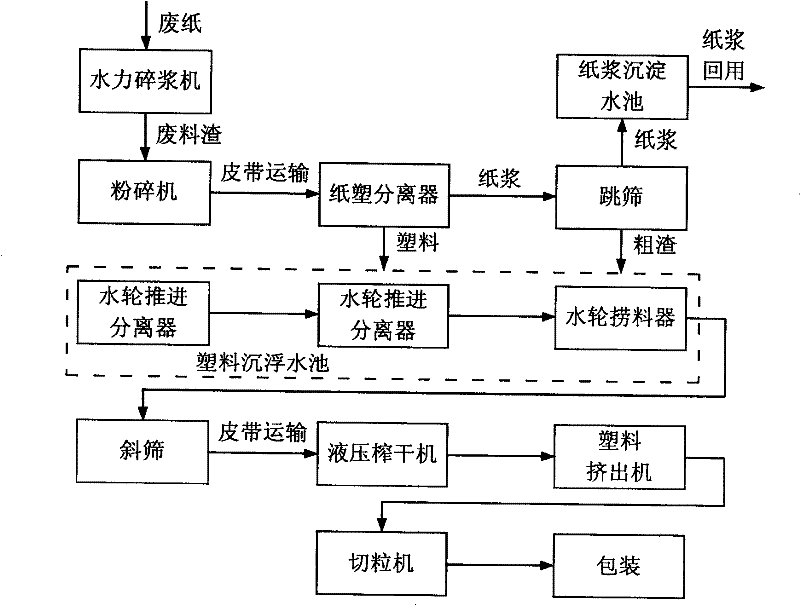

[0043] like figure 1 As shown in the figure, it is the whole processing flow of the present invention. First, the coarse slag containing pulp a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com