Method and testing device for catalytic pyrolysis treatment of oil-based drilling cuttings produced in shale gas exploitation

A technology for shale gas exploitation and oil-based drilling cuttings, which is applied in the field of catalytic pyrolysis treatment method and test device for oil-based drilling cuttings for shale gas exploitation, and can solve the problem of low recovery rate of valuable products, large energy consumption, reduction of the cost, etc. problems, to achieve the effect of recycling resources, reducing pollution and reducing content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

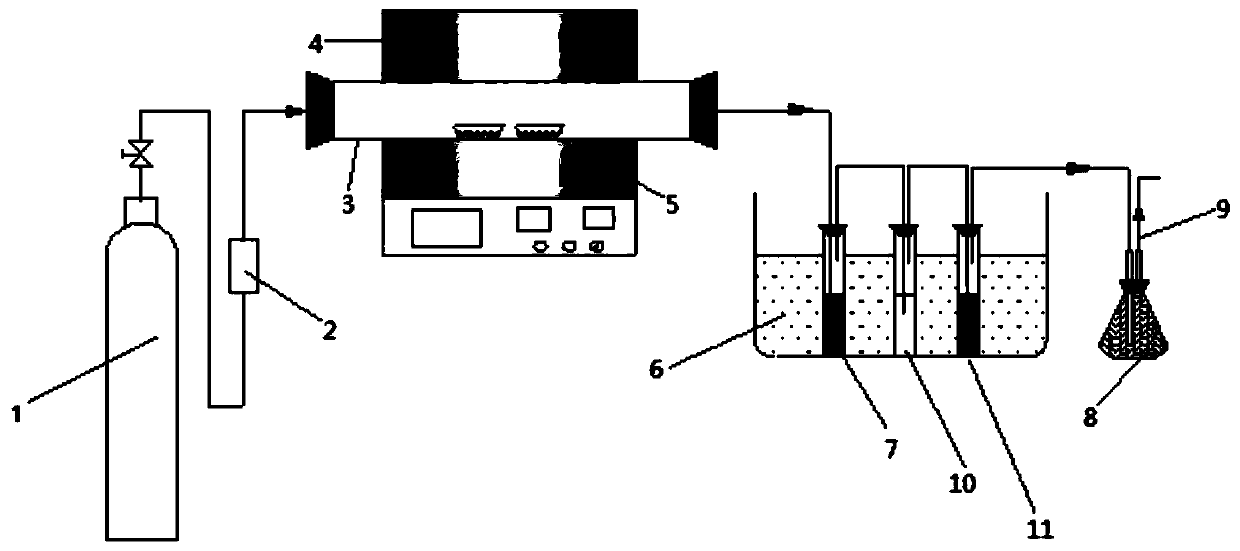

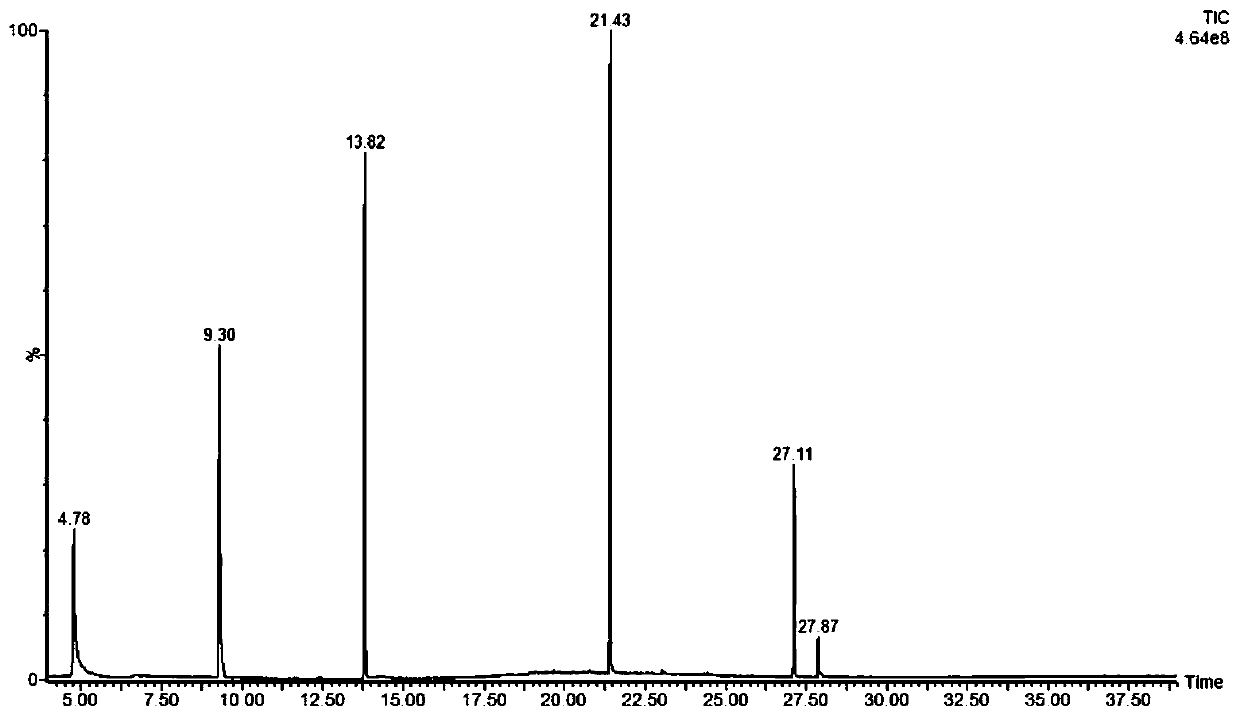

[0027] Two corundum boats were placed in the S01 tube furnace, and each corundum boat was filled with 10 g of oil-based drilling cuttings samples after natural air drying, and the catalyst addition ratio was 10%, that is, 1 g. There are 20 g of samples and 2 g of catalysts in the tube furnace. Introduce nitrogen into the pipeline, set the air flow rate to 0.1L / min, gradually increase the temperature from room temperature to 550°C, and set the holding time after reaching the final temperature to 40min;

[0028] S02 Pass the pyrolysis steam generated in the pipeline into the three-stage condensing device equipped with pyrolysis steam absorbent, and pass the part not absorbed by acetone into the tail gas receiving bottle equipped with tail gas absorption liquid, and the tail gas absorption liquid 5% HNO 3 solution and 10% H 2 o 2 The solution is fully mixed according to the volume ratio of 1:1; the tail gas not absorbed by the tail gas absorption liquid is discharged into the ...

Embodiment 2

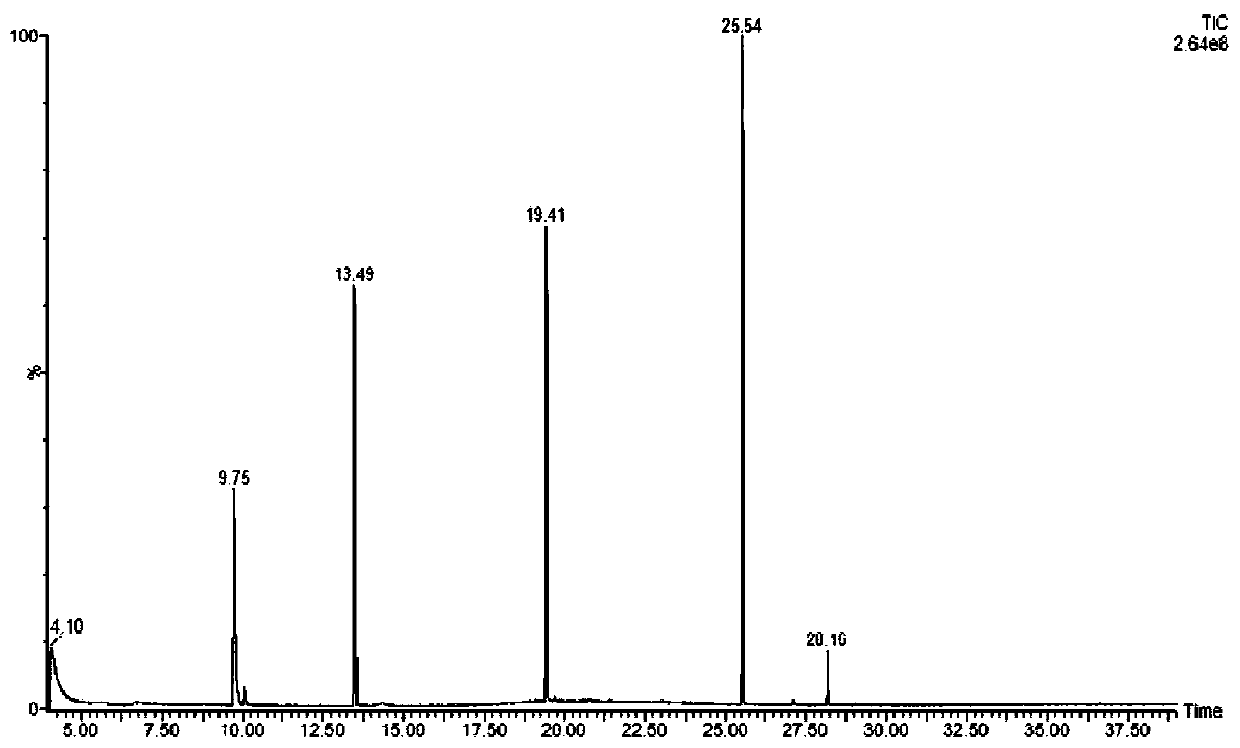

[0032] Two corundum boats were placed in the S01 tube furnace, and each corundum boat was filled with 10 g of oil-based drilling cuttings samples after natural air drying, and the catalyst addition ratio was 5%, ie 0.5 g. There are 20 g of samples and 1 g of catalyst in the tube furnace. Introduce nitrogen into the pipeline, set the air flow rate to 0.2L / min, gradually increase the temperature from room temperature to ℃, and set the holding time after reaching the final temperature to 60min;

[0033] S02 Pass the pyrolysis steam generated in the pipeline into the three-stage condensing device equipped with pyrolysis steam absorbent, and pass the part not absorbed by acetone into the tail gas receiving bottle equipped with tail gas absorption liquid, and the tail gas absorption liquid 4% HNO 3 solution and 12% H 2 o 2 The solution is fully mixed according to the volume ratio of 1:3; the exhaust gas not absorbed by the exhaust gas absorption liquid is discharged into the air....

Embodiment 3

[0035] Two corundum boats were placed in the S01 tube furnace, and each corundum boat was filled with 10 g of oil-based drilling cuttings samples after natural air drying, and the catalyst addition ratio was 15%, that is, 1.5 g. There are 20 g of samples and 3 g of catalyst in the tube furnace. Introduce nitrogen into the pipeline, set the flow rate of nitrogen to 0.08L / min, gradually increase the temperature from room temperature to ℃, and set the holding time after reaching the final temperature to 60min;

[0036] S02 Pass the pyrolysis steam generated in the pipeline into the three-stage condensing device equipped with pyrolysis steam absorbent, and pass the part not absorbed by acetone into the tail gas receiving bottle equipped with tail gas absorption liquid, and the tail gas absorption liquid 6% HNO 3 solution and 9% H 2 o 2 The solution is fully mixed according to the volume ratio of 1:5; the tail gas not absorbed by the tail gas absorption liquid is discharged into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com