Deinking, bleaching and treating process of waste paper

A treatment process, waste paper deinking technology, applied in the field of waste paper deinking and bleaching treatment process, can solve the problems of impure color, affecting pulp production, poor whiteness, etc., and achieve the reduction and increase of the content of pigment and total organic matter The effect of pulping material output and shortening the time occupied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

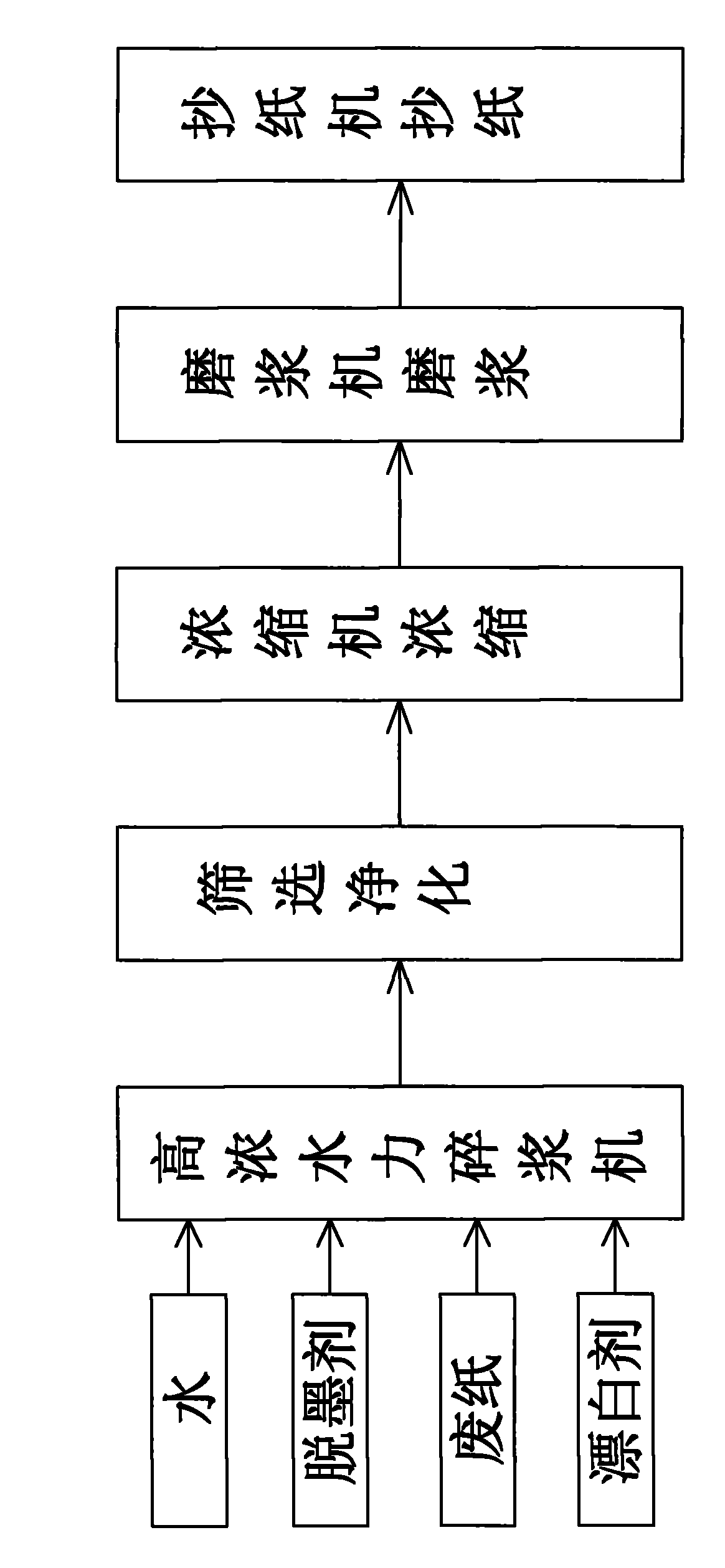

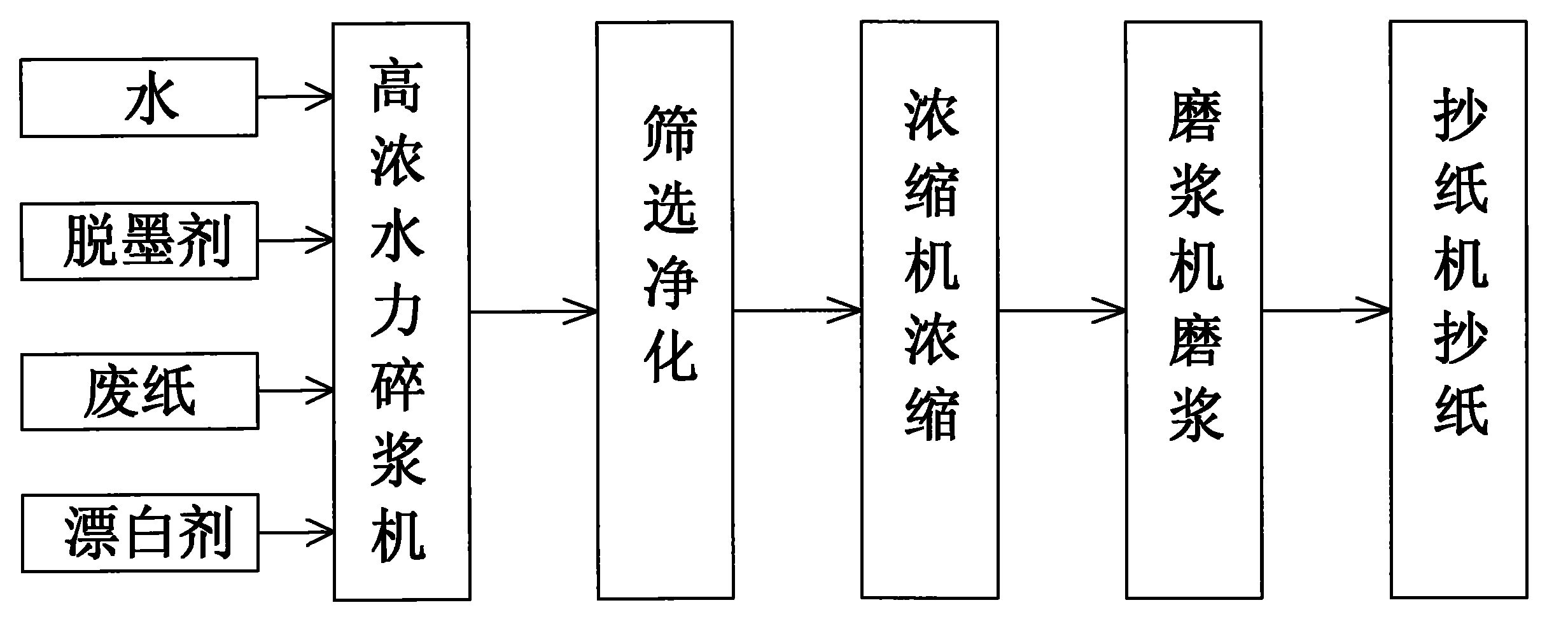

[0023] As shown in the figure, the waste paper deinking and bleaching process includes the following steps:

[0024] 1. Use a high-consistency hydraulic pulper, calculate the water consumption and waste paper input according to the pulp concentration of 16%, first add water to the pulper according to the calculated water consumption, and heat the water to keep the water temperature at 70-90 between ℃.

[0025] 2. When the water reaches the temperature requirement, start to add the deinking agent. Based on the weight of 100 parts of waste paper, the deinking agent is composed of the following substances: 2 parts of sodium hydroxide, 3 parts of sodium silicate, polyoxyethylene alkyl 0.5 parts of phenylene ether, 0.5 parts of polyoxyethylene sorbitan monooleate, and 3 parts of sodium dodecylbenzenesulfonate; then quickly put waste paper in according to the calculated amount of waste paper.

[0026] 3. Start timing after putting in waste paper, and carry out the first stage of bl...

Embodiment 2

[0030] As shown in the figure, the waste paper deinking and bleaching process includes the following steps:

[0031] 1. Use a high-concentration hydraulic pulper, calculate the water consumption and waste paper input according to the pulp concentration of 12%, first add water to the pulper according to the calculated water consumption, and heat the water to keep the water temperature at 70-90 between ℃.

[0032] 2. When the water reaches the temperature range requirement, start to add the deinking agent. Calculated by the weight of 100 parts of waste paper, the deinking agent is composed of the following substances uniformly mixed: 1 part of sodium hydroxide, 1.5 parts of sodium silicate, polyoxyethylene alkanes 0.1 part of phenylene ether, 0.1 part of polyoxyethylene sorbitan monooleate, and 0.5 part of sodium dodecylbenzene sulfonate; then quickly throw waste paper in accordance with the calculated amount of waste paper.

[0033] 3. Start timing after putting in the waste p...

Embodiment 3

[0037] As shown in the figure, the waste paper deinking and bleaching process includes the following steps:

[0038] 1. Use a high-concentration hydraulic pulper, calculate the water consumption and waste paper input according to the pulp concentration of 20%, first add water to the pulper according to the calculated water consumption, and heat the water to keep the water temperature at 70-90 between ℃.

[0039] 2. When the water reaches the temperature requirement, start to add the deinking agent. Based on the weight of 100 parts of waste paper, the deinking agent is composed of the following substances: 3.5 parts of sodium hydroxide, 4 parts of sodium silicate, polyoxyethylene alkyl 2 parts of phenyl ether, 2 parts of polyoxyethylene sorbitan monooleate, 8 parts of sodium dodecylbenzenesulfonate. Then quickly throw in the waste paper according to the calculated amount of waste paper.

[0040] 3. Start timing after putting in the waste paper, and carry out the first stage o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com