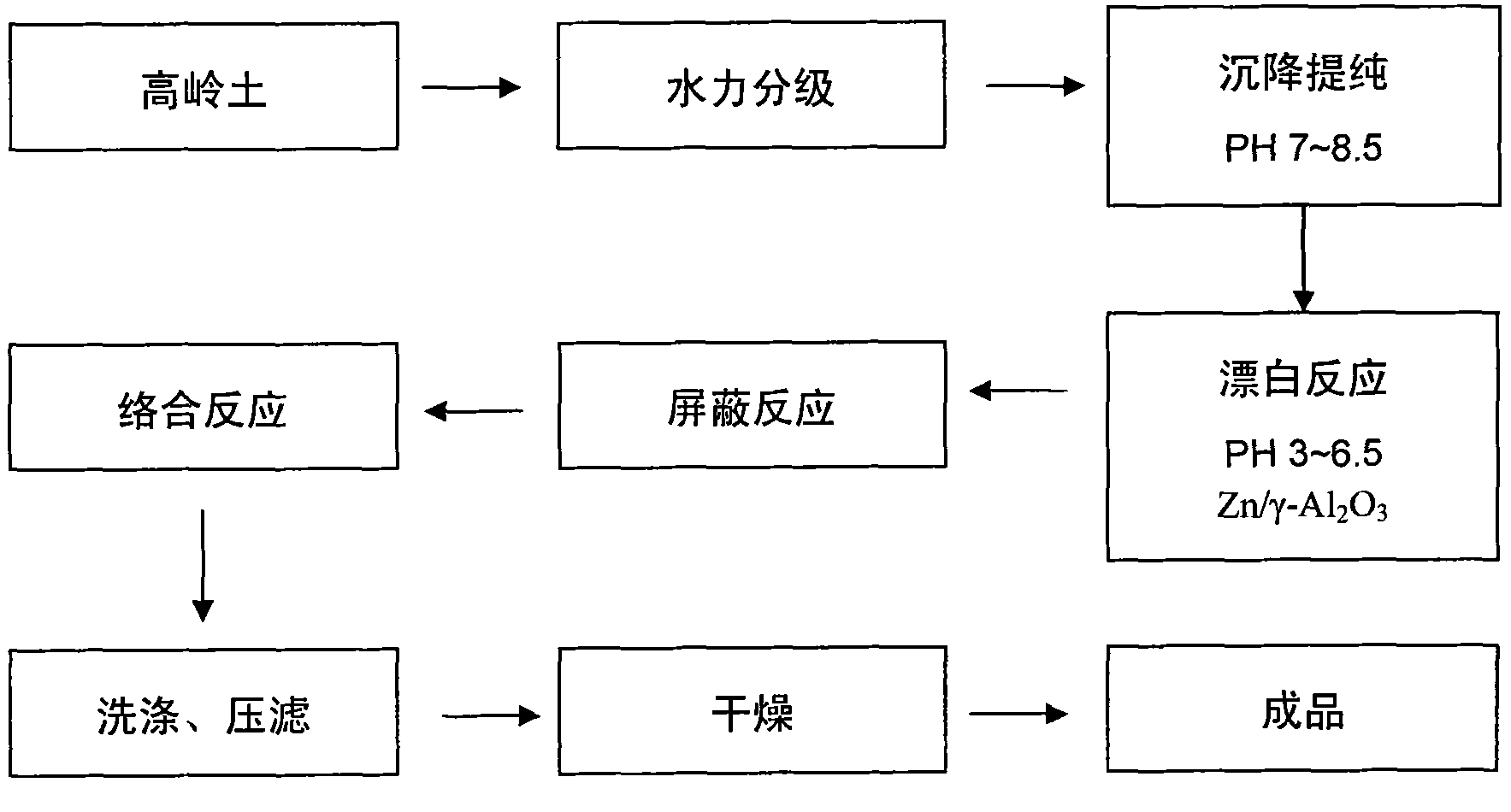

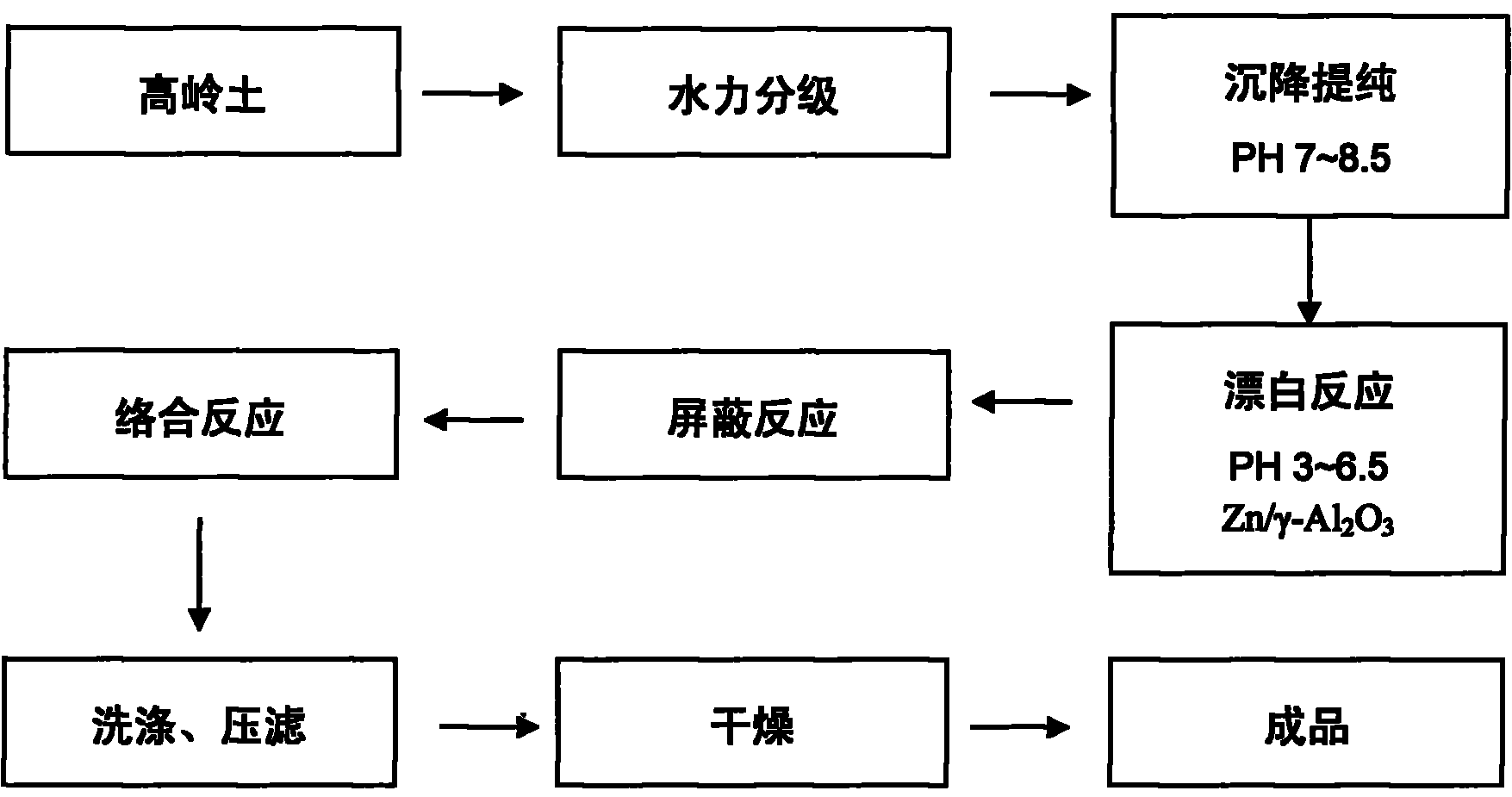

Process for enhanced reduction bleaching of kaolin by using thiocarbamide

A technology of kaolin and kaolin ore, applied in aluminum silicate, silicate and other directions, can solve problems such as equipment corrosion, environmental pollution, and difficulty in calcining whiteness to reach 90%, and achieve the effect of improving whiteness and high brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Beihai kaolin belongs to incompletely weathered granite weathering residual deposits. Impurities such as iron-bearing minerals such as iron-bearing mica and iron oxide ore in raw ore have affected the wide application of Beihai kaolin. In this embodiment, the raw material of North Sea kaolin is selected, the natural whiteness is about 77%, the calcined whiteness is about 82%, and the calcined temperature is 1200° C. (the same below). First, add 600kg of kaolin to water and stir to make slurry, add dispersant sodium hexametaphosphate and sodium hydroxide pH adjuster with 0.2% kaolin weight, the pH value of the slurry is about 7.0-8.5, and the stirring time is 30 minutes, and it is adjusted to 23-28 % mud, then carry out sedimentation purification, sedimentation to a mud volume concentration of about 20%, then adjust the pH value of the slurry to 3.0 with sulfuric acid, then add 0.6% of kaolin weight sodium dithionite and 0.2% kaolin weight of auxiliary reducing agent thio...

Embodiment 2

[0017] In the bleaching reaction, the consumption of the auxiliary reducing agent thiourea is changed to 0.5% of the kaolin weight, other conditions are the same as in Example 1, and the kaolin concentrate product with a natural whiteness of 86.2% is obtained, and its whiteness is 91.3% after calcining. %.

Embodiment 3

[0019] In the bleaching reaction, when other conditions are the same as in Example 1, without adding the auxiliary reducing agent thiourea, the obtained kaolin concentrate product has a natural whiteness of 80% and a calcined whiteness of 83.4%. It shows that the bleaching effect is not obvious.

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com