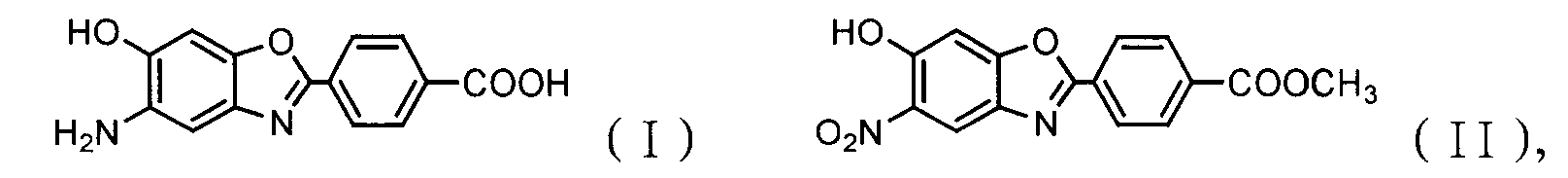

Method for synthesizing 5-amide-6-hydroxy-2-(4-carboxylphenyl)benzoxazole

A p-carboxyphenyl, synthesis method technology, applied in the field of synthesis of 5-amino-6-hydroxy-2-benzoxazole, can solve problems hindering the preparation, expansion and application of high-performance PBO materials, and achieve good industrialization Prospects and advantages, reduce production costs, and produce obvious advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

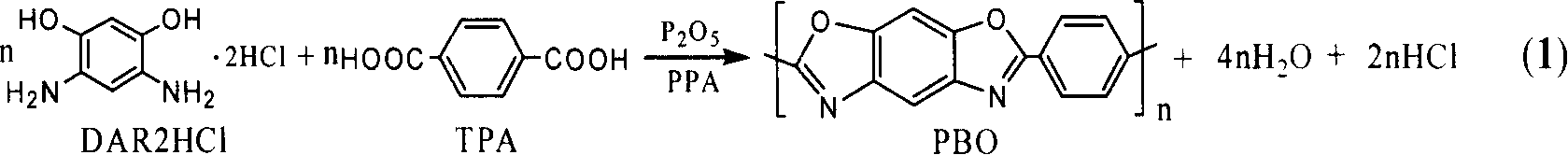

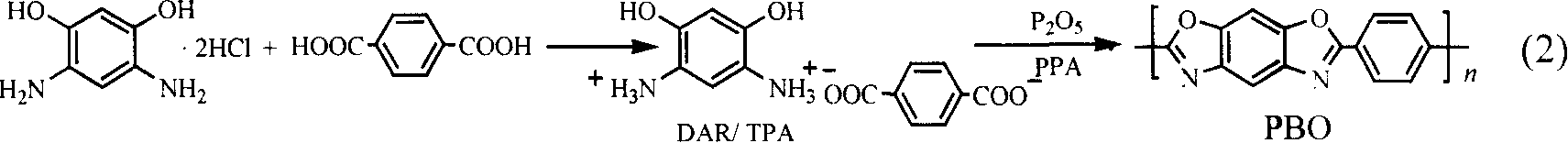

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: Preparation of 5-amino-6-hydroxyl-2-(p-carboxyphenyl) benzoxazole (ABA)

[0034] 4.0g K 2 CO 3 Dissolve in 150ml of water solvent, add 3.0g NHAB (purity 96.5%) into the dilute alkali solution, stir and heat up to 80°C, hydrolyze for 50min until the solution is clear, and slowly add 8.0 g Na 2 S 2 o 4 , control the reduction reaction at 0-5°C for 20 minutes, filter to obtain yellow crystals, wash with ice water, and vacuum-dry to obtain 2.12 g of light yellow crystalline products with a purity of 98.9%. After qualitative FT-IR, 13 C-NMR, 1 H-NMR attribute analysis and elemental analysis, determined to be a new monomer of acid type AB type PBO: 5-amino-6-hydroxyl-2-(p-carboxyphenyl)benzoxazole ABA monomer, yield 84.2% .

[0035] FT-IR (KBr, cm -1 ): 3333.4, 3269.7, 3151.1, 1676.8, 1617.0, 1579.4, 1466.6, 1409.7, 1380.8, 1294.0, 1177.3, 1129.1, 1053.9, 972.9, 879.4, 860.1, 784.9, 709.7. Elemental analysis values: C, 62.03; H, 3.75; N, 10.45. Calcula...

Embodiment 2~6

[0037] Adopt the same operation of embodiment 1, get different parameters (different temperature, raw material purity and Na 2 S 2 o 4 Consumption) reacts, and the results are shown in Table 1:

[0038] Table 1 Hydrolysis of Na by NHAB 2 S 2 o 4 Reduction "one-pot method" to prepare ABA monomer

[0039]

Embodiment 7

[0040] Embodiment 7: Alkaline hydrolysis, hydrogenation reduction in-situ synthesis method prepares ABA

[0041] 4.5g K 2 CO 3 Dissolve in 180ml of water solvent, add 3.00g of NHAB (purity 94.4%) into the dilute alkali solution, stir and heat up to 60°C, hydrolyze for 60min until the solution is clear, transfer the reaction solution to a high-pressure reactor, add 0.3g 5% Pd / C, stirred vigorously at 30°C and 0.3-0.4MPa hydrogen pressure for 3 hours, filtered to remove the catalyst, cooled the filtrate to room temperature and decolorized it with activated carbon, then used NaHSO 3 The saturated aqueous solution was adjusted to pH 6.5-7.0 to precipitate a precipitate, which was filtered and vacuum-dried to obtain 2.05 g of a khaki crystalline product with a purity of 98.2% and a yield of 82.6%. FT-IR, 13 C-NMR, 1 H-NMR attribute analysis is the same as that of Example 1 and is characterized as ABA monomer.

[0042] FT-IR (KBr, cm -1 ): 3334.3, 3269.7, 3146.3, 1675.8, 1617....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com