Anti-static/conductive fabric and manufacture method thereof

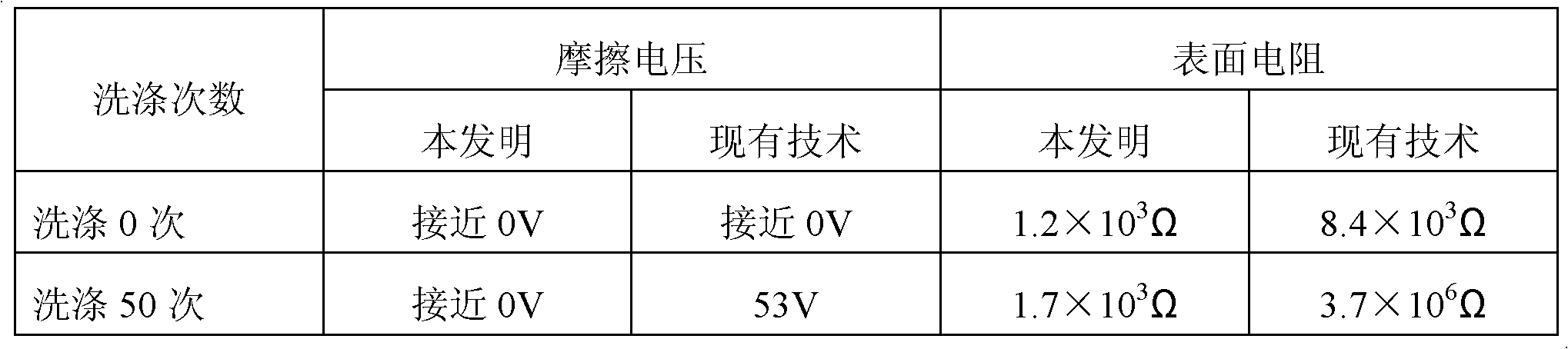

A technology of conductive fabric and production method, which is applied in the directions of plant fibers, dry cleaning fiber products, textiles and papermaking, etc., can solve the problems of poor fabric air permeability, poor durability and uniformity of anti-static properties, and high surface friction voltage of anti-static fabrics. The effect of good breathability, durability and uniformity, good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation of conductive polymer particle dispersion solution can also adopt:

[0031] Option 1. Directly select conductive polymer particles with an average particle size of 50-2000nm, such as at least one particle from polyacetylene, polyaniline, polypyrrole, polythiophene, and polypyridine, and directly add the above particles and dispersant to the water , After stirring and dispersing, it becomes a dispersion solution of conductive polymer particles.

[0032]Option 2. Mix and grind conductive polymer materials, such as at least one of polyacetylene, polyaniline, polypyrrole, polythiophene, and polypyridine, with a dispersant solid, so that the average particle size of the conductive polymer particles reaches 50-2000nm , the mixture of the above-mentioned particles and dispersant is directly added into water, and after stirring and dispersing, it becomes a dispersion solution of conductive polymer particles.

Embodiment 1

[0035] Example 1. A polyester woven fabric uniformly compounded with conductive polymer particles-conductive polypyrrole particles on the surface of fabric fibers. The average particle diameter of the conductive polypyrrole particles was 483 nm.

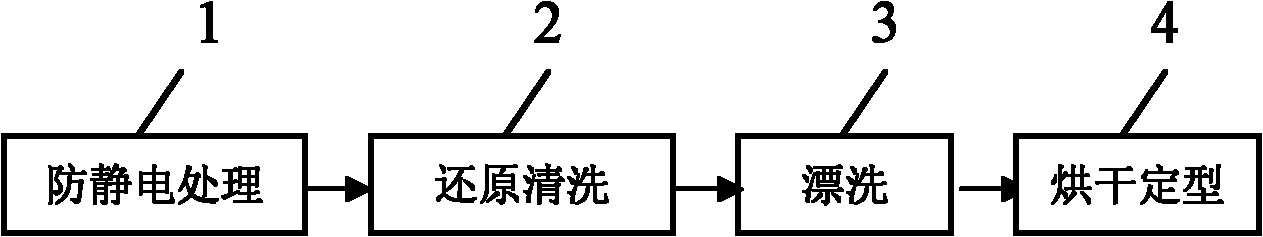

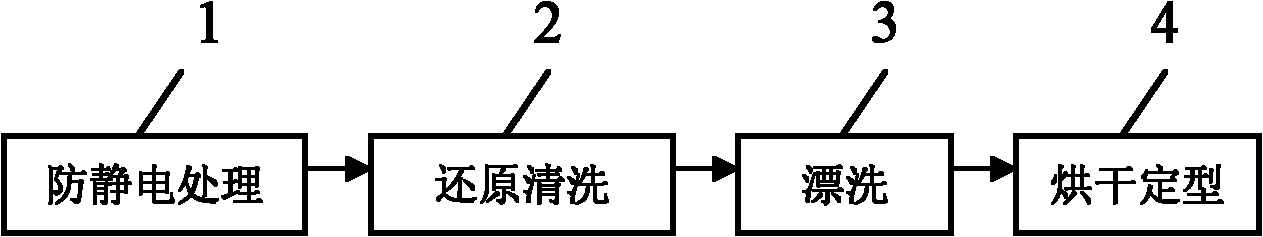

[0036] Cut the polyester woven fabric into 10cm square samples, (1) Antistatic treatment: use the conductive polypyrrole particle dispersion solution to carry out wet dip-dyeing treatment on the fabric, the concentration of the conductive polypyrrole particle is 1g / l, and the concentration of the dispersant is 0.5g / l, the water-bath ratio is 1:5, the treatment temperature is 130°C, and the treatment time is 1h; (2) Reduction cleaning: use 0.1g / l sodium dithionite and 1g / l potassium hydroxide solution to treat the modified fabric Cleaning, the cleaning temperature is 80°C, and the cleaning time is 30 minutes; (3) Rinsing: rinse the anti-static fabric after reduction cleaning with water once, the rinsing temperature is 50°C, and the r...

Embodiment 2

[0042] Example 2. Polyester knitted fabric uniformly compounded with conductive polymer particles-conductive polypyrrole particles on the surface layer of fabric fibers. The average particle diameter of the conductive polypyrrole particles was 483 nm.

[0043] Cut the polyester knitted fabric into 10cm square samples, (1) antistatic treatment: use the conductive polypyrrole particle dispersion solution to carry out wet dip-dyeing treatment on the fabric, the concentration of the conductive polypyrrole particle is 0.1g / l, and the concentration of the dispersant is 0.1 g / l, the water bath ratio is 1:50, the treatment temperature is 100°C, and the treatment time is 2h; (2) reduction cleaning: use 0.5g / l sodium disulfite and 0.1g / l sodium hydroxide solution to treat the modified The fabric was cleaned at a temperature of 90°C for 10 minutes; (3) rinsing: the anti-static fabric after reduction cleaning was rinsed once with water at a temperature of 60°C for 10 minutes; (4) Drying a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Surface resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com