Chemical cleaning method of ultrafiltration membrane

A technology for chemical cleaning and ultrafiltration membranes, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

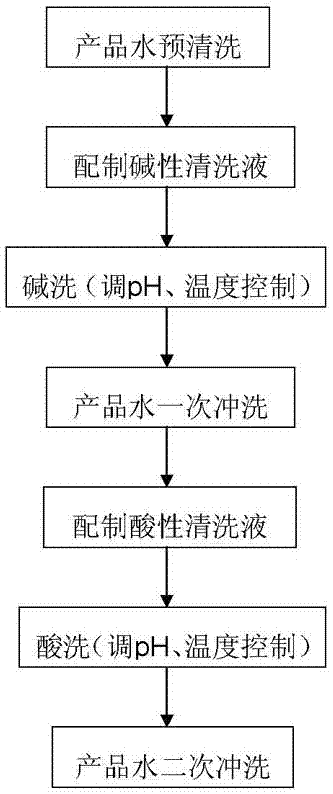

Method used

Image

Examples

Embodiment 1

[0048] In this example, the landfill leachate wastewater enters the ultrafiltration system after being biochemically treated by MBR to realize the separation of mud and water. The ultrafiltration unit is a tubular ultrafiltration membrane module made of PVDF, with a membrane pore diameter of 8 mm and a molecular weight cut-off of 1,000 to 100,000 Dal. Dayton, the area of a single membrane is 27m 2 , The operation method adopts cross-flow filtration.

[0049] In this embodiment, the fouling form of the ultrafiltration membrane is mainly organic dirt enclosing inorganic dirt. The pollution form is related to the specific components of the landfill leachate. When the total amount of dissolved solids in the landfill leachate is high; when the concentration of calcium and magnesium ions and suspended solids are quite high, the pollution form of the ultrafiltration membrane is mainly inorganic scale wrapped with organic scale; when When the concentration of calcium and magnesium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com