Method for cleaning ultrafiltration membrane

A technology of ultrafiltration membrane and cleaning solution, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as microbial pollution, achieve the effect of eliminating pollution and restoring performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

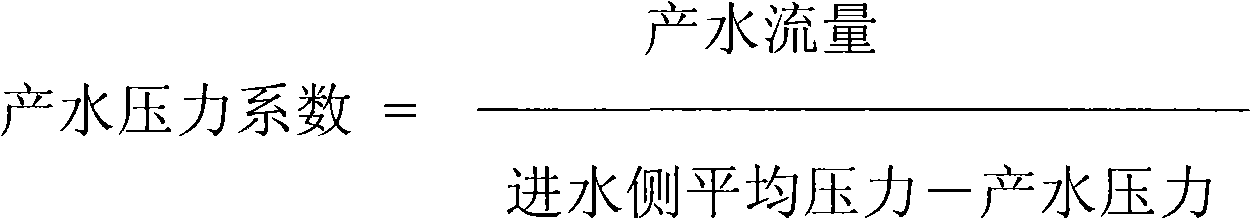

[0040] Example 1: By monitoring the product water flow rate and the corresponding pressure drop, the product water pressure coefficient of the ultrafiltration membrane module can be calculated:

[0041]

[0042] Average pressure on the inlet side = (inlet pressure + concentrated water outlet pressure) ÷ 2 (cross-flow filtration)

[0043] Average pressure of water inlet side = inlet pressure (full flow filtration)

[0044] Draw a graph with the time as the abscissa and the pressure coefficient of the product water as the ordinate every day, which can judge the pollution degree of the ultrafiltration membrane module. If it is found that the curve drops by 20% compared with the beginning of operation, it means that the ultrafiltration membrane module has been polluted, and the ultrafiltration membrane module must be cleaned.

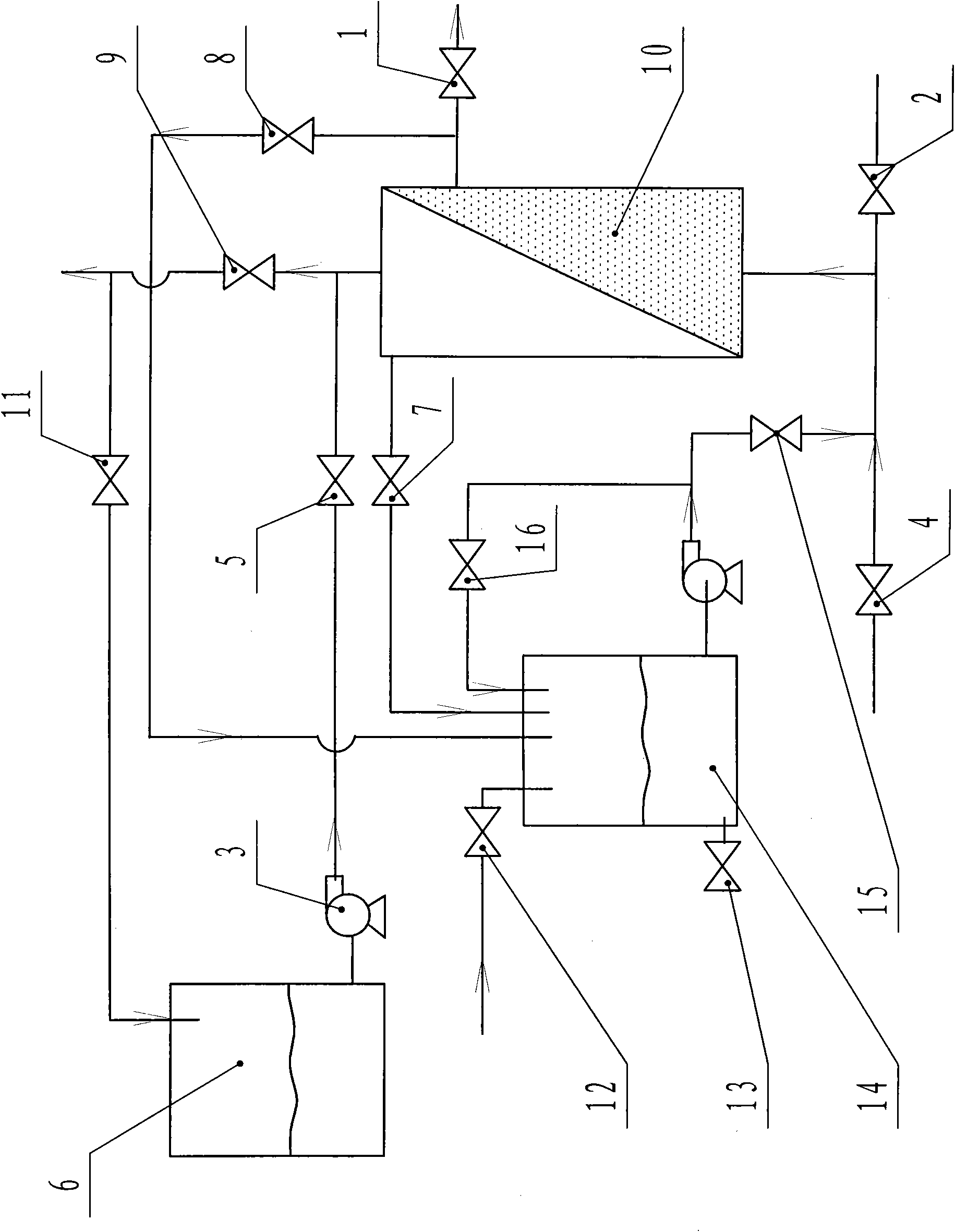

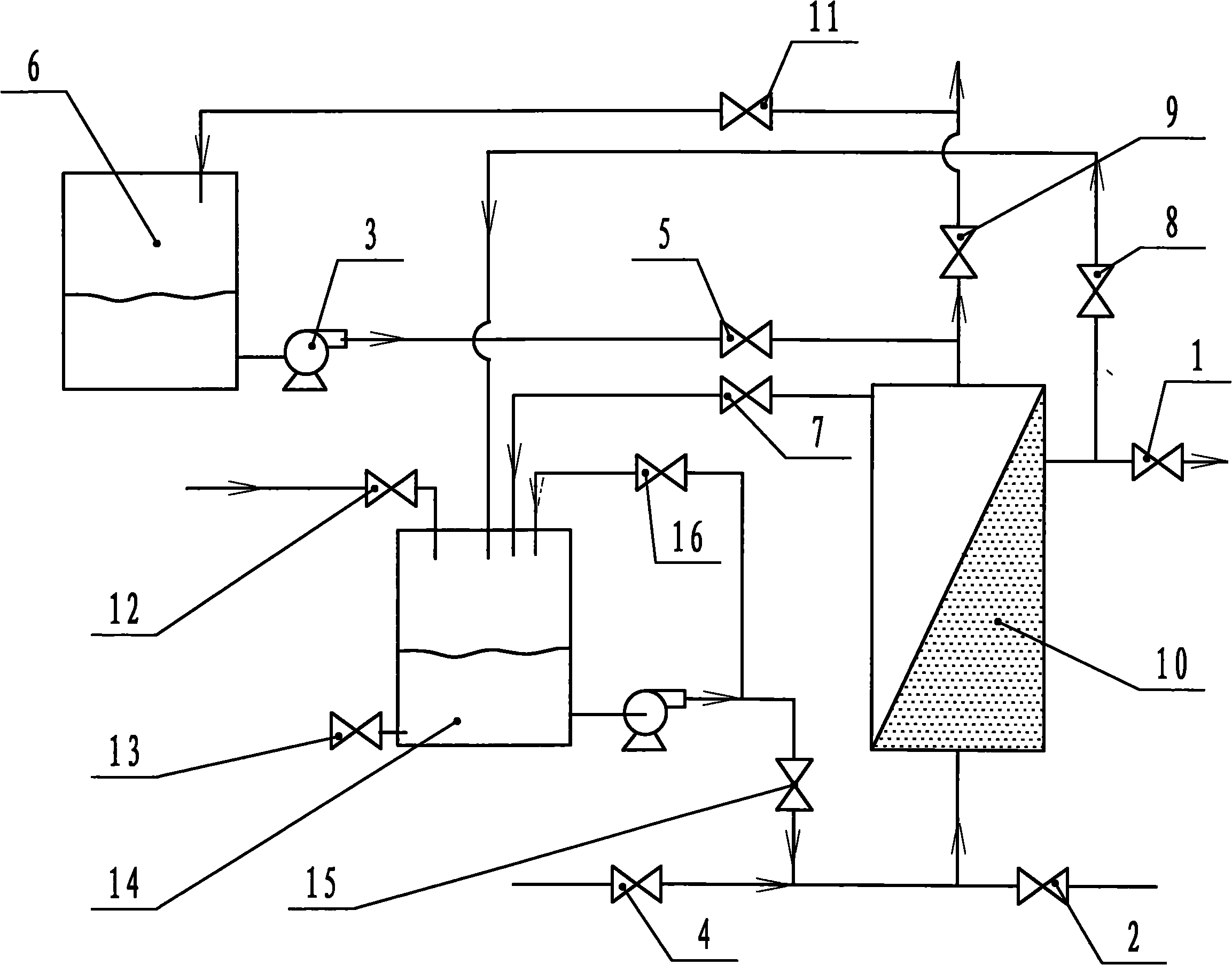

[0045] figure 1 As shown, the specific steps for cleaning the ultrafiltration membrane module are:

[0046] 1. Stop feeding sewage into the ultrafilt...

Embodiment 2

[0057] Embodiment 2: The acid cleaning solution of this embodiment adopts a citric acid solution with a concentration of 2%, and no alkaline cleaning solution is used for cleaning, and the rest of the cleaning steps are the same as in Example 1.

Embodiment 3

[0058] Embodiment three: the acid cleaning liquid of this embodiment adopts the hydrochloric acid solution that concentration is 0.4%, and other steps are identical with embodiment two.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com