Method for cleaning copper tubes of condenser

A technology for condensers and copper tubes is applied in the field of cleaning heat transfer pipes, which can solve the problems of a large amount of funds for robots and high cleaning costs, and achieve the effects of low cost, good cleaning effect and less time-consuming cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

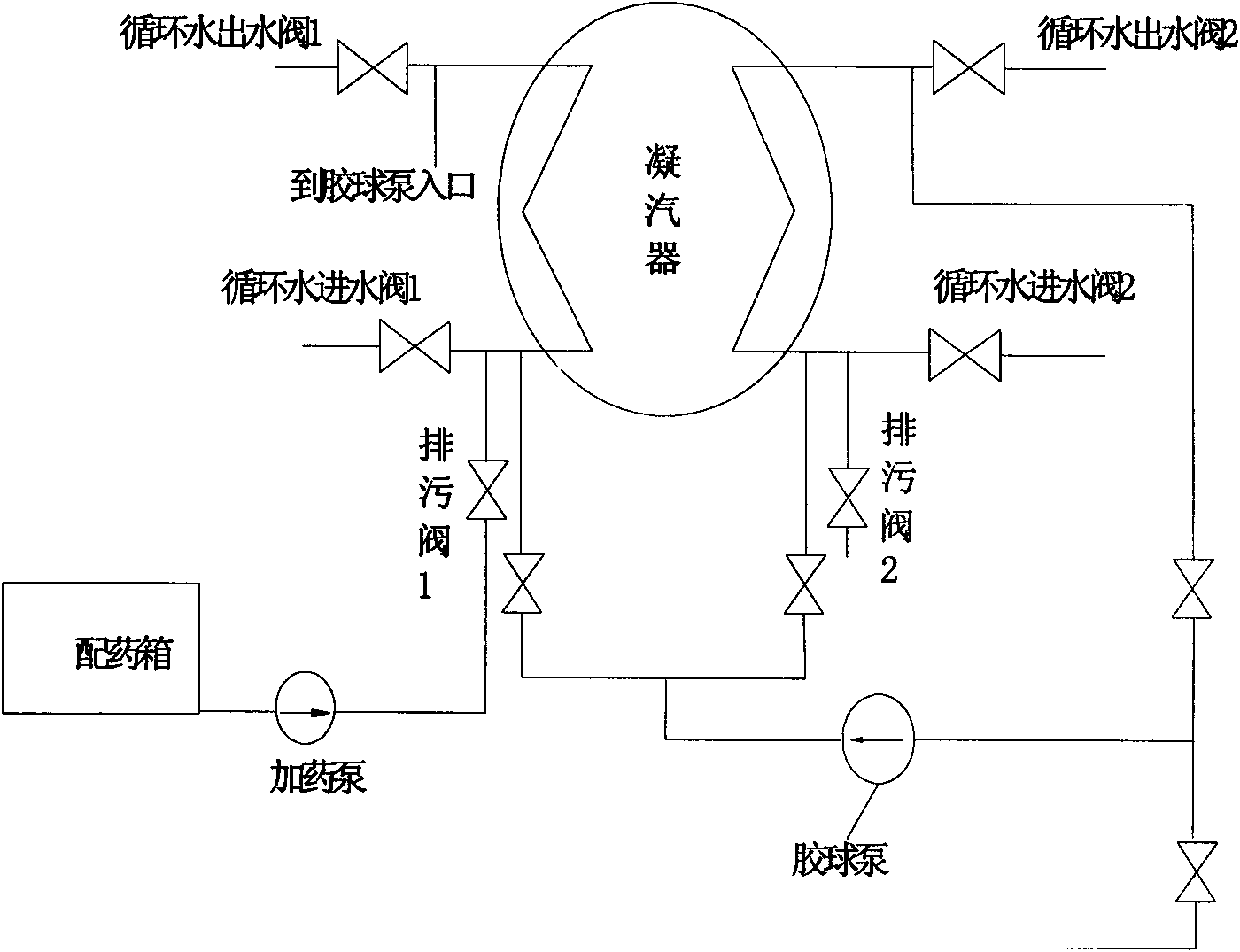

[0022] Embodiment This method is applied in the power plant of Wengfu (Group) Co., Ltd. to clean the copper pipe of the steam turbine condenser of the plant.

[0023] First, after the steam turbine condenser is shut down, the circulating water inlet valve 2 and outlet valve 3 of a single condenser 1 are closed;

[0024] The second step is to rinse the condenser 1 copper tube with clean water for 1 hour;

[0025] The third step is to inject an acidic chemical cleaning solution into the water side of condenser 1. The formula is 0.3% of pickling corrosion inhibitor Lan-826, 0.1% of copper corrosion inhibitor tolyltriazole, 100mg / L of penetrant JFC, chemical Cleaning agent sulfamic acid 6.0%, dispersant polyacrylic acid PAA 200mg / L, soak and clean for 6 hours;

[0026] The fourth step is to neutralize the soaking solution with caustic soda solution until the pH value reaches 6.0-7.0;

[0027] The fifth step is to rinse the copper pipe of the condenser 1 with clean water for 1 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com