Efficient water treatment device and water treatment method

A water treatment device and high-efficiency technology, which is applied in the directions of water/sewage multi-stage treatment, water/sludge/sewage treatment, osmosis/dialysis water/sewage treatment, etc., to save the cost of chemicals, reduce disinfection by-products, and relieve panic Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

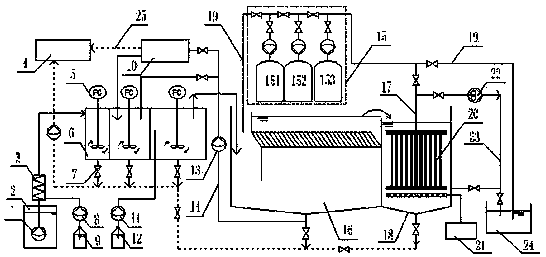

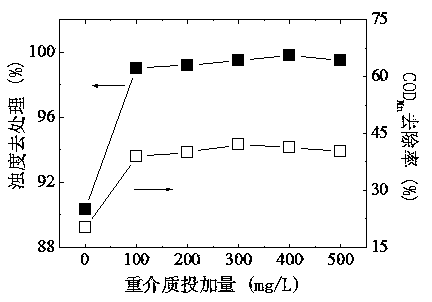

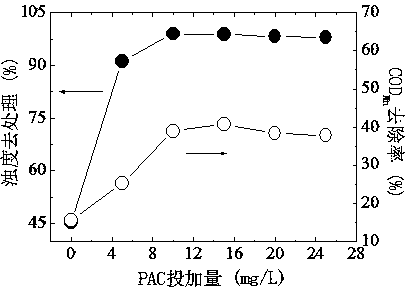

[0054] In the operation of the water treatment process, if excessive magnetic powder, PAC and PAM are added in the dense medium coagulation and sedimentation stage, it will not only increase the operating cost, but also aggravate the membrane fouling. The dosing amount of magnetic powder, PAC and PAM is also different due to the different water quality of the water source. Here, water is taken from the lower reaches of the Yangtze River (raw water turbidity: 50-100 NTU, COD Mn : 2-4 mg / L) as an example, such as figure 2 , image 3 and Figure 4 As shown, the dosages of magnetic powder, PAC and PAM in the dense medium coagulation and sedimentation stage (process residence time 10min) were 100 mg / L and 10 mg / L (in the form of liquid polymerized AlCl 3 ρ=1.24g / ml) and 0.1 mg / L are more suitable. At this time, the turbidity removal rate of dense medium coagulation sedimentation water is about 99% (can be lower than 1 NTU), and the COD Mn The removal rate is about 40% (about 1...

Embodiment 2

[0056] In order to investigate the impact of the type and dosage of polymer coagulants used in the water treatment process on membrane fouling, three common polymer flocculants were selected here: cationic polyacrylamide (CPAM), nonionic polyacrylamide (PAM) and anionic polyacrylamide (APAM). The dosages of heavy medium and flocculant polyaluminum (PAC) adopt the preferred dosages in Example 1, which are 100mg / L and 10mg / L respectively. Membrane Flux Operating Flux of 20 Lm -2 h -1 , the running time is 24h. Dimensionless transmembrane pressure difference (NTMP=△P / △P 0 ) change as Figure 5 and Figure 6 Shown: Compared with only adding PAC, the addition of CPAM helps to reduce the membrane fouling, while the addition of APAM will increase the membrane fouling. For PAM, when the dosage is 0.1mg / L, the membrane fouling will be reduced, but when the dosage is 1mg / L, the membrane fouling will increase significantly. Preferably, CPAM should be selected as the polymer floccu...

Embodiment 3

[0059] Table 1: Key effluent quality indicators of dense media coagulation sedimentation / ultrafiltration water treatment process

[0060]

[0061] In order to investigate the effluent water quality of the water treatment process, the following operating conditions were adopted: the dosages of CPAM, PAC and heavy medium were 0.1mg / L, 10mg / L and 100mg / L respectively. Membrane operating flux is 20 Lm -2 h -1 , the running time is 40min. The backwashing method is air-water backwashing, and the washing intensity is 50Lm -2 h -1 , the air washing intensity is 50m 3 / (m 2 membrane pool h), each 60s. As shown in Table 1, the impact of dense media coagulation sedimentation / ultrafiltration treatment on NTU and COD Mn Removal rates of over 99% and 45% respectively; due to the good quality of raw water, the removal effect of total phosphorus and ammonia nitrogen is not obvious here; the removal rate of total coliforms and total bacterial colonies can reach 100%, and no Detecte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com