Cleaning in membrane filtration systems

a filtration system and membrane technology, applied in the direction of membranes, filtration separation, separation processes, etc., can solve the problems of large amounts of cleaning solution being used unnecessarily, additional cost and environmental impact, and achieve the effect of increasing the amount of chemical cleaning agents present during the clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

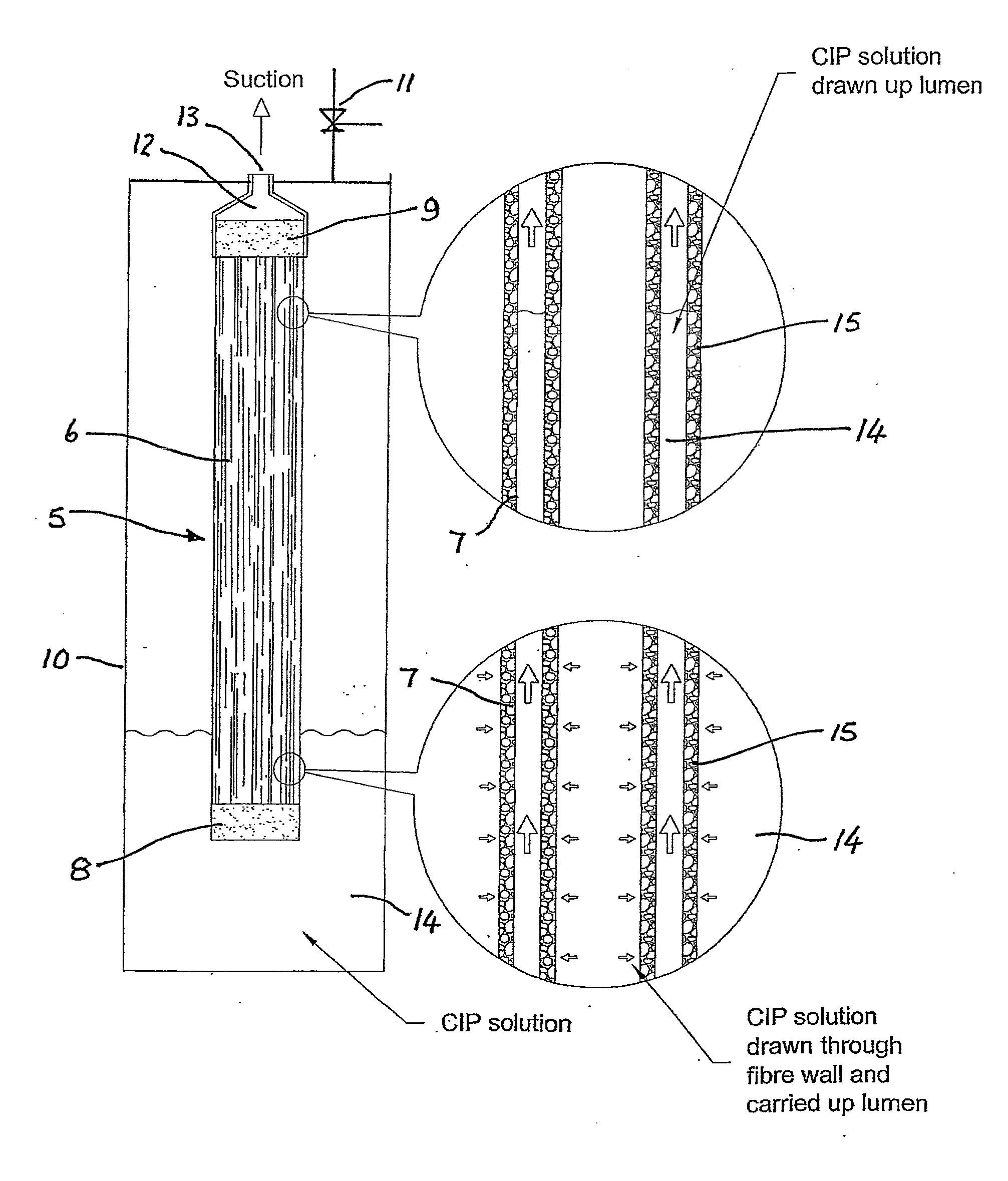

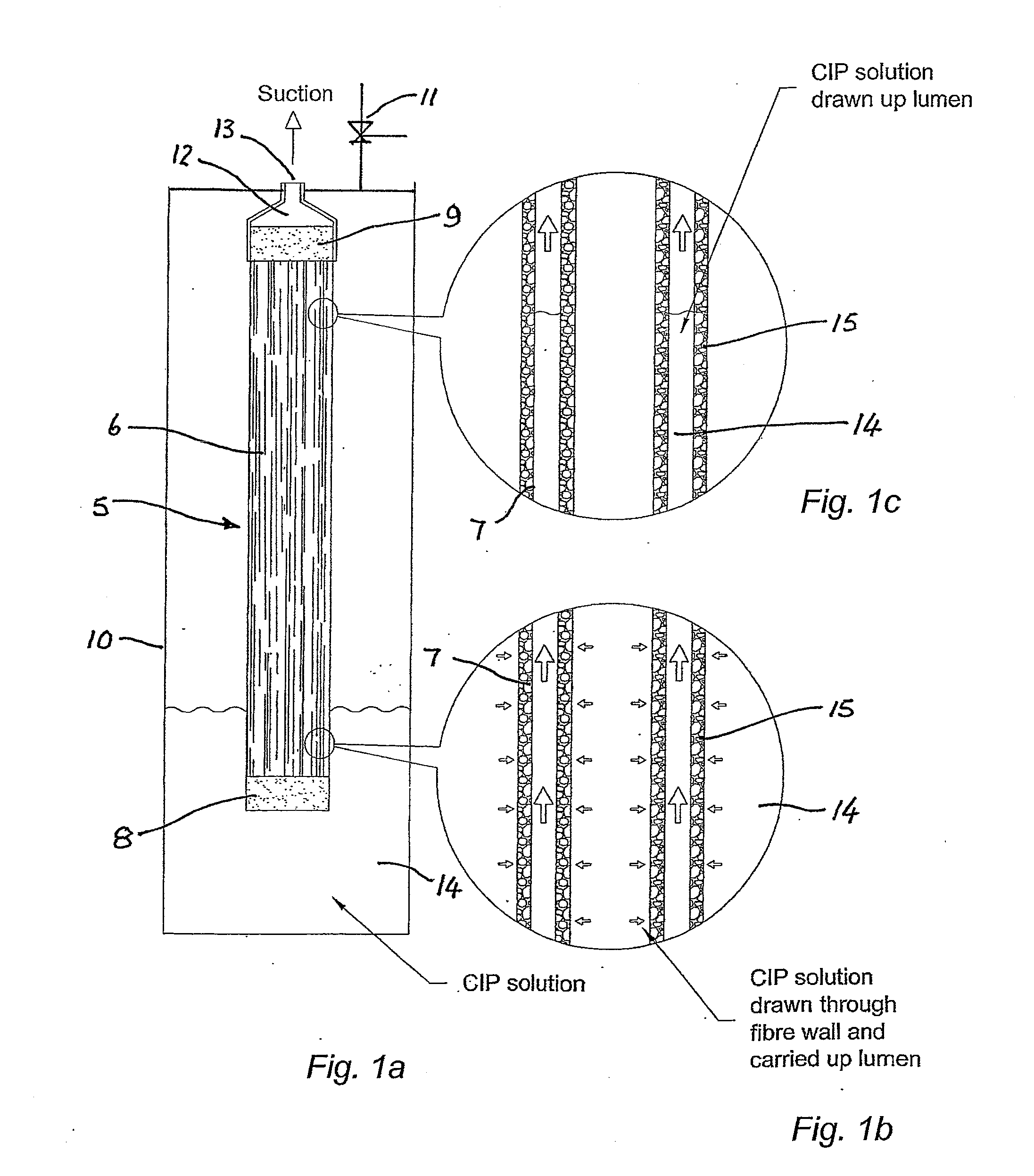

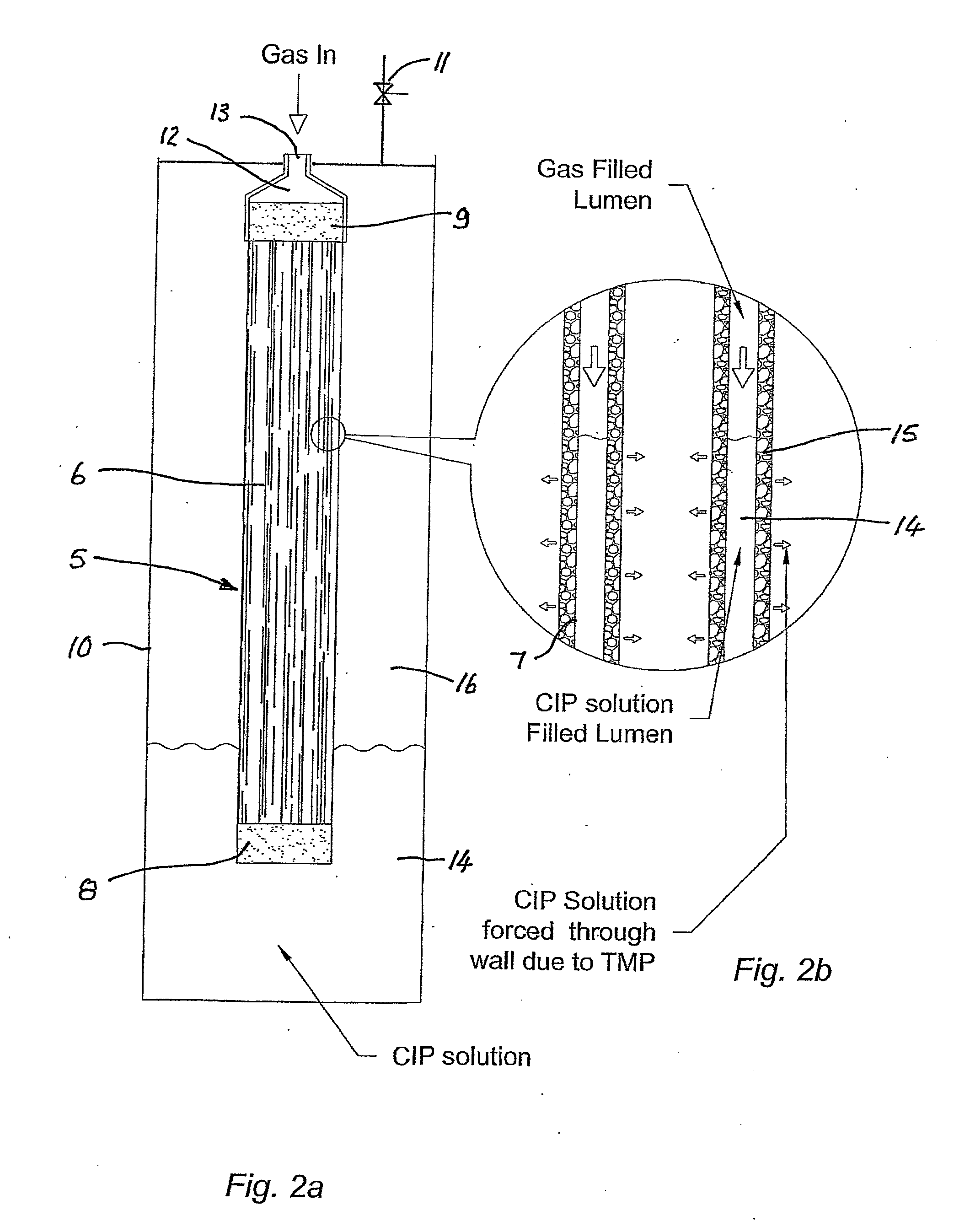

[0084] Referring to the FIGS. 1 to 7, there is shown a membrane module 5 having a plurality of hollow fibre membranes 6. The fibre membranes 6 have their lumens 7 closed at the lower end in a lower pot 8 and open at the upper end through upper pot 9. The module 5 is contained in a vessel 10 having a controllable valve 11 for opening / closing the vessel 10 to atmosphere. Upper pot 8 is connected to a filtrate collection chamber 12 having a port 13.

[0085] One embodiment of the cleaning process according to the invention will now be described with reference to FIGS. 1 to 3. As best shown in FIGS. 1a to 1c, liquid remaining in lumens 7 after filtration is drained while liquid remaining in the vessel 10 is also at least partially drained. The vessel 10 is then, at least partially, filled with cleaning solution 14 as best shown in FIG. 1a. A differential pressure is then applied across the membrane walls 15, in this embodiment by applying a vacuum to port 13, so that the cleaning solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| contact time | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com