On-line chemical cleaning method for membrane bioreactor

A bioreactor, chemical cleaning technology, applied in chemical instruments and methods, biological water/sewage treatment, membrane technology, etc., can solve the problems of no more detailed and clear operational parameters, no online chemical cleaning, etc., to achieve long-term Stable operation, ensuring long-term operation stability, and extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

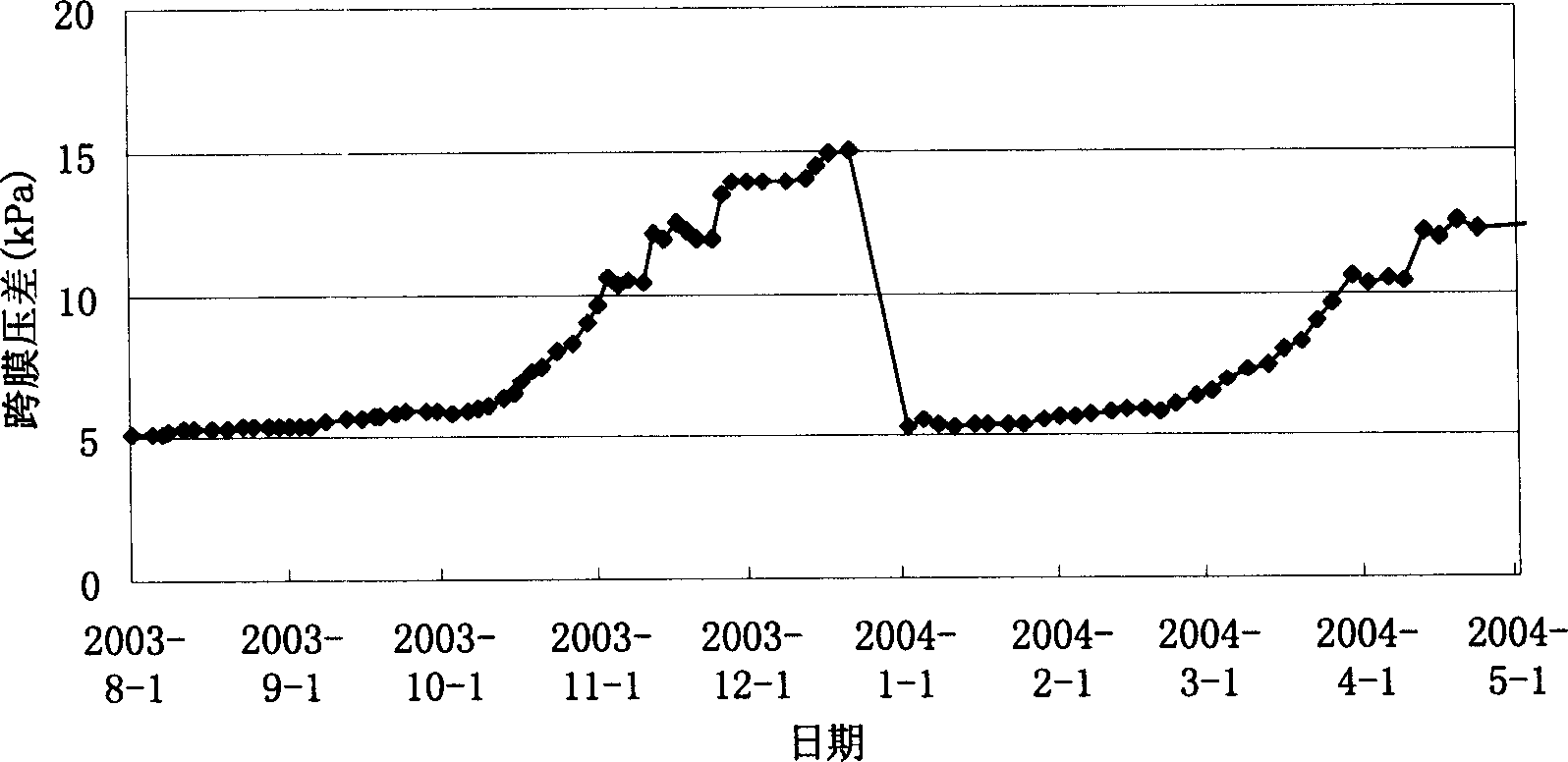

[0031] The invention is an online chemical cleaning method for controlling membrane fouling in a membrane-bioreactor. The online chemical cleaning method is to use cleaning agents to clean and install corresponding devices.

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

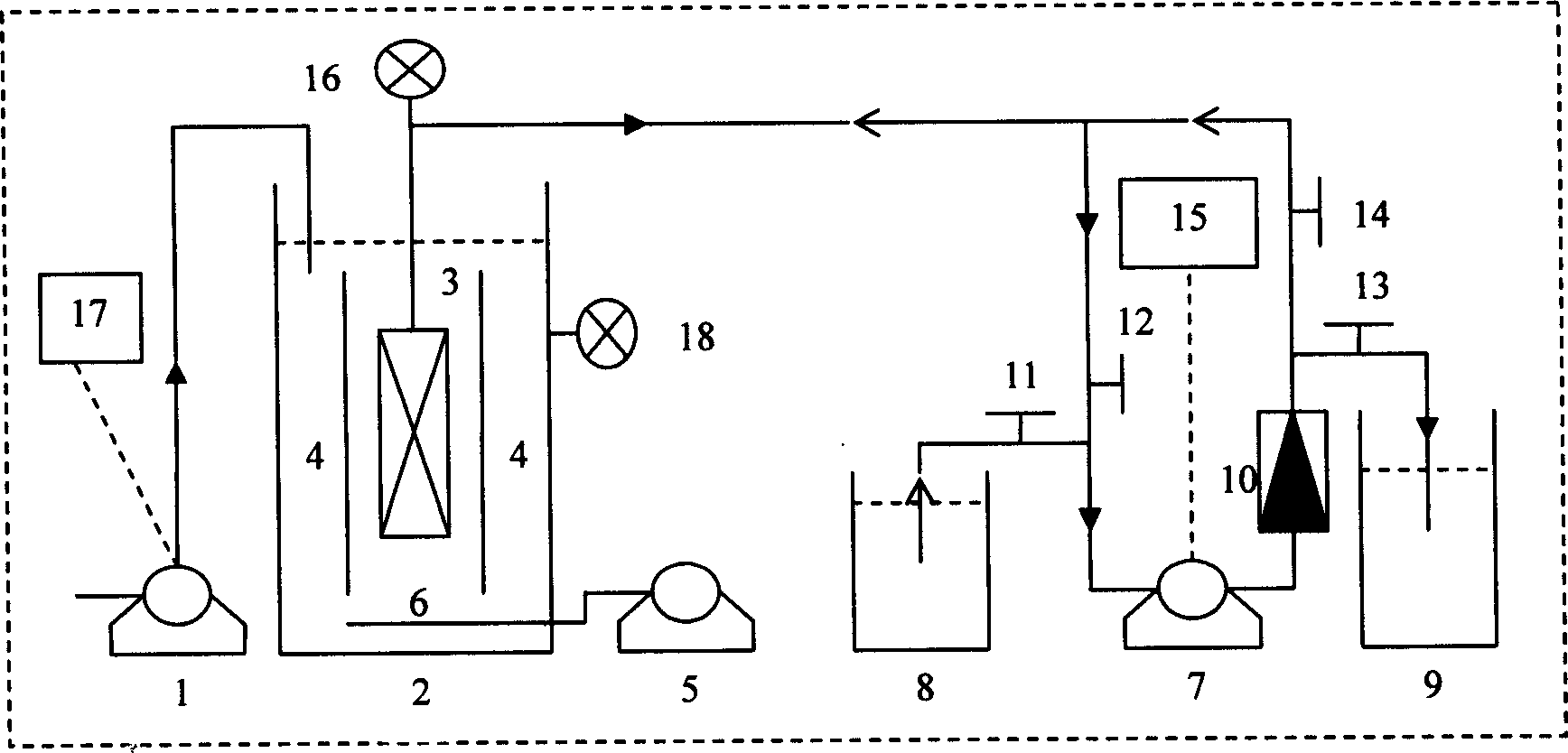

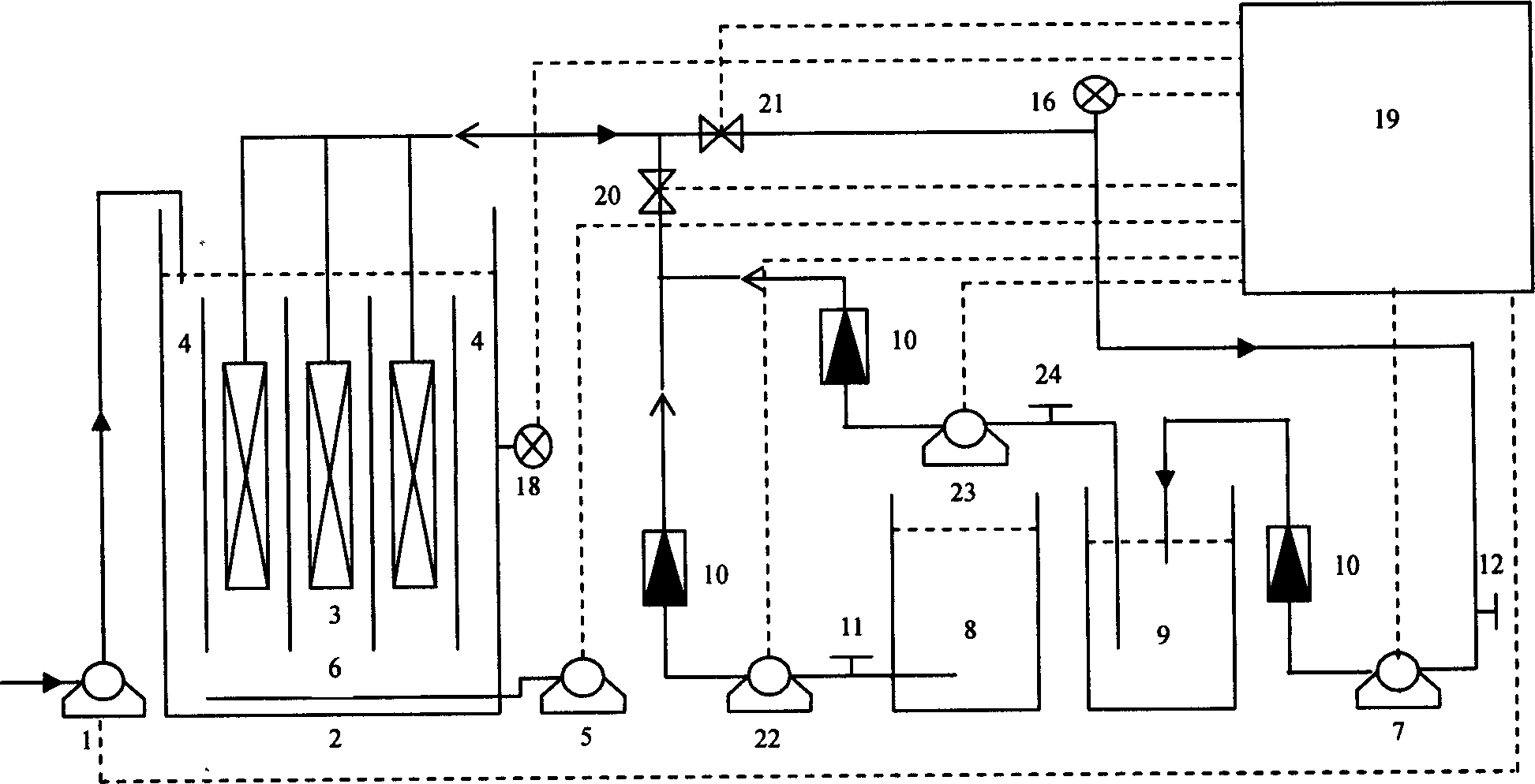

[0033] figure 1 Shown is a schematic diagram of a small-scale integrated membrane-bioreactor using TMP development rate-controlled online chemical cleaning mode. The system consists of water inlet pump 1 and water inlet pipeline, bioreactor 2, membrane module 3, blower 5 and aeration pipeline 6, suction / dosing pump 7 and water outlet pipeline, flow meter 10, clear water tank 9, pumping Suction / dosing 7, medicine washing pipeline, medicine liquid pool 8 and corresponding valves 11, 12, 13, 14, controller 15 and liquid level gauge 17 are composed. The water inlet pump 1 is automatically controlled by the liquid level gauge 17 to ensure that the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com