Immersion type hollow fiber membrane separator and its running process

The technology of a separation device and operation method is applied in the field of membrane separation to achieve the effects of reducing investment cost, reducing energy consumption and saving land occupation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Further describe the present invention below in conjunction with embodiment and accompanying drawing thereof, but the present invention is not limited by embodiment:

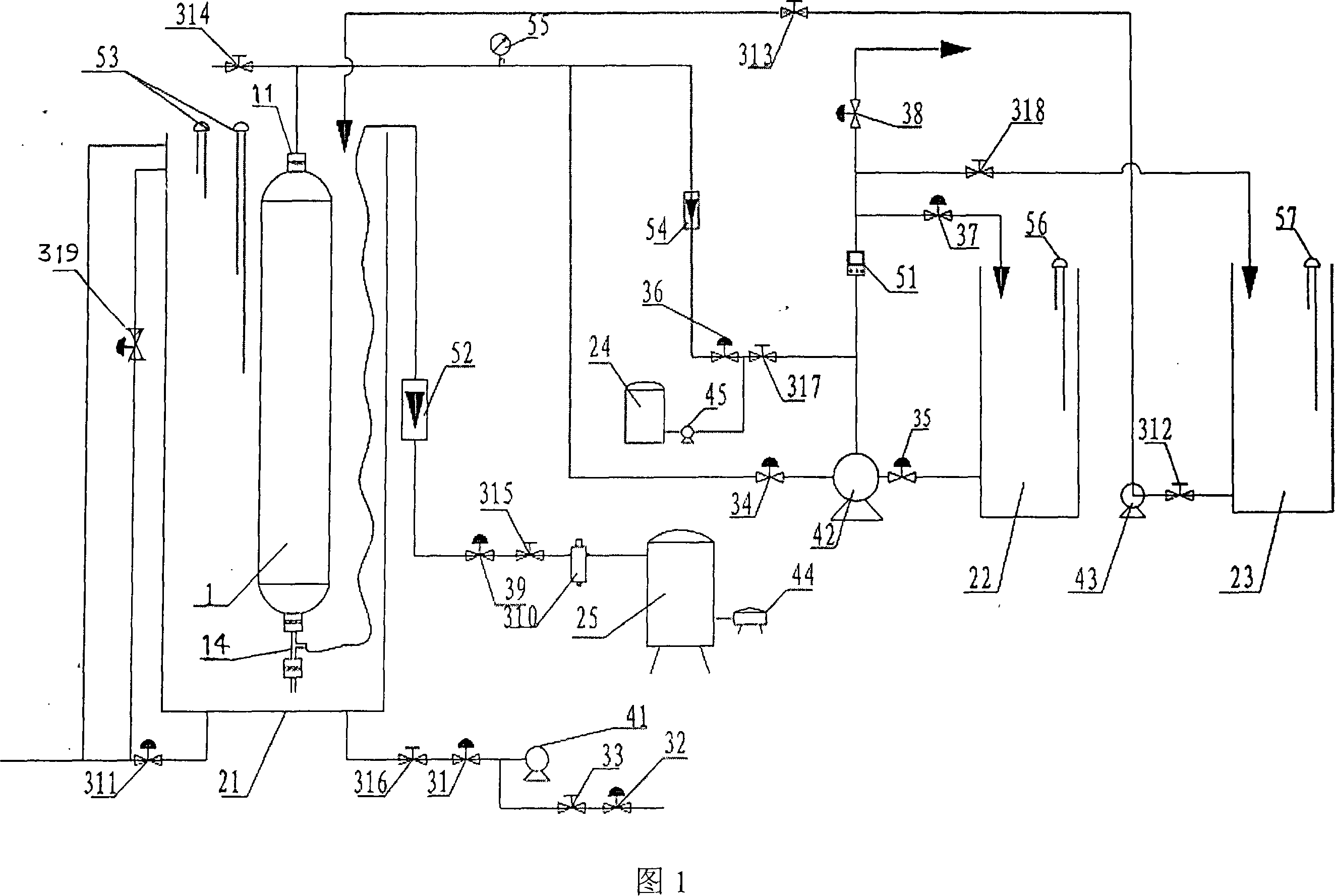

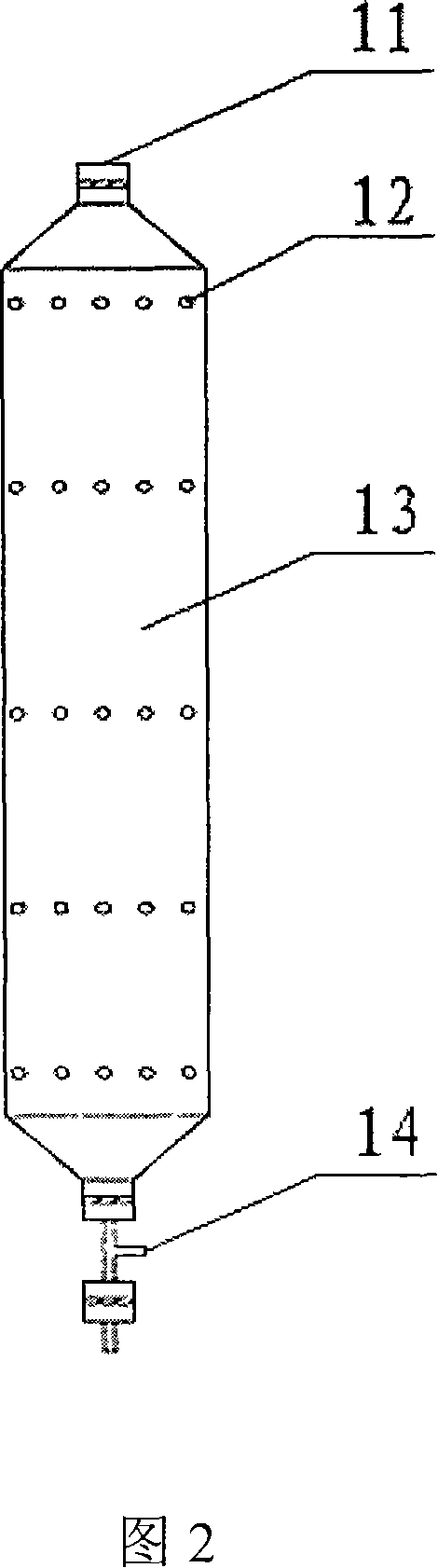

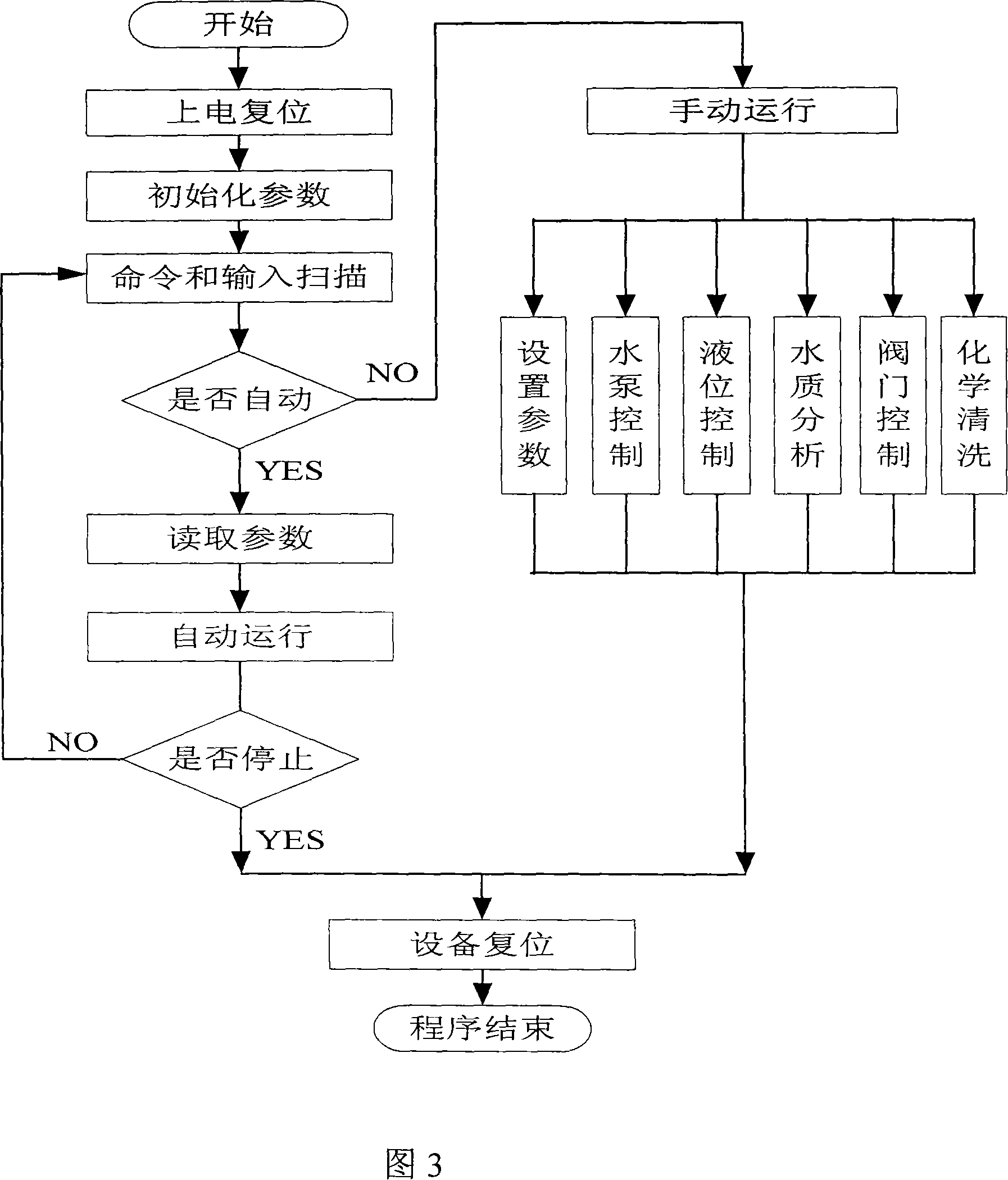

[0015] The submerged hollow fiber membrane separation device designed by the present invention (hereinafter referred to as the membrane device, referring to Fig. 1, 2), it includes a pipe-connected membrane filtration system, a water outlet system, a cleaning system and a line-connected control system, and is characterized in that the The membrane filtration system is a submerged membrane filtration system, which adopts a column type external pressure hollow fiber membrane module 1. The upper end of the membrane module has a water production port 11, and the lower end has an air washing inlet 14. There are many holes 12 on the shell 13, and the membrane In addition to the control system, the separation device is vertically installed directly in the water body to be treated; the water production system incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com