Nanofiltration reproduction method of waste reverse osmosis membrane element

A technology of reverse osmosis membrane and reverse osmosis composite membrane, which is applied in the field of reuse of waste reverse osmosis membrane elements, can solve the problems of high cost and single variety, and achieve the effect of simple regeneration process and resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

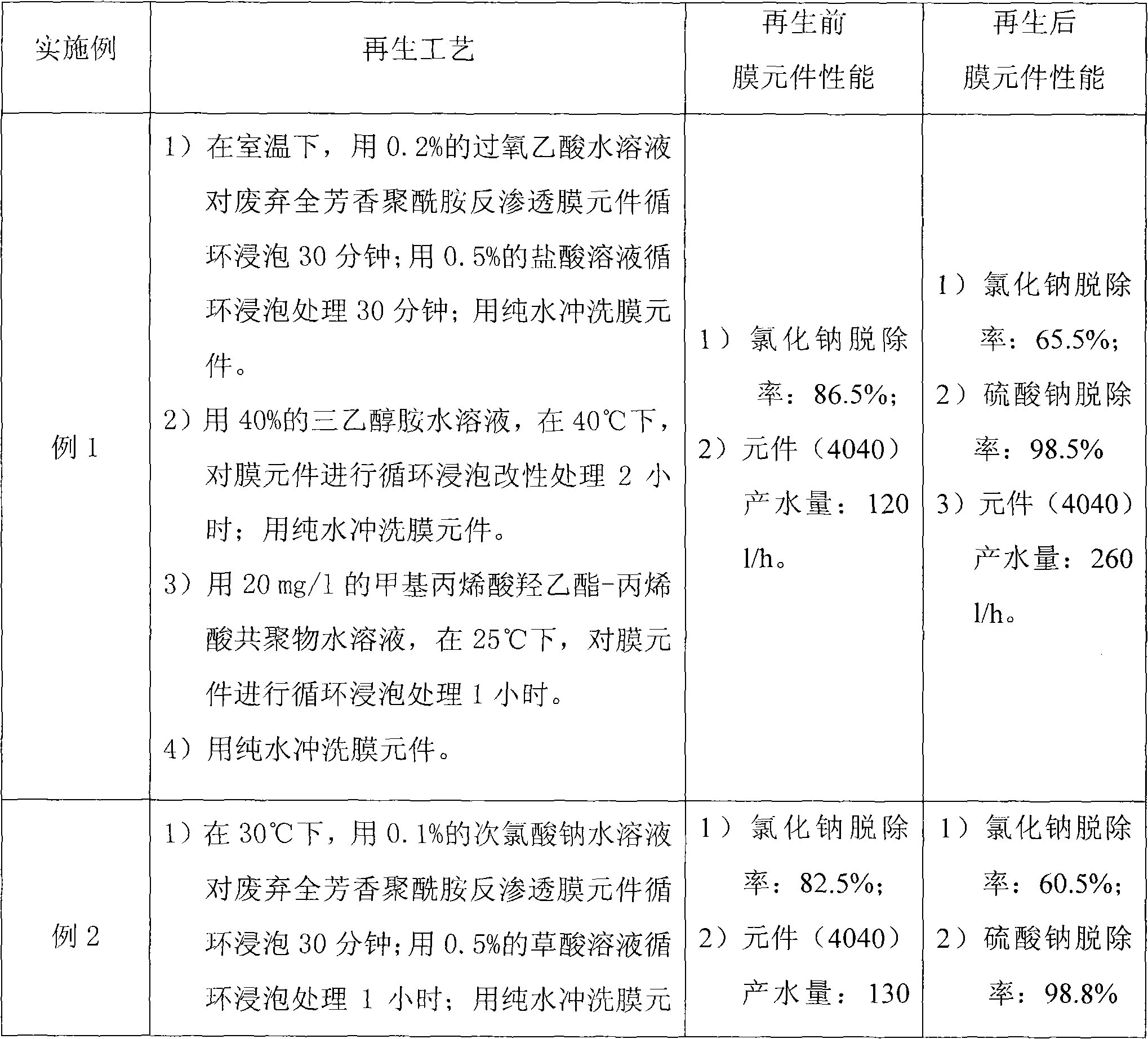

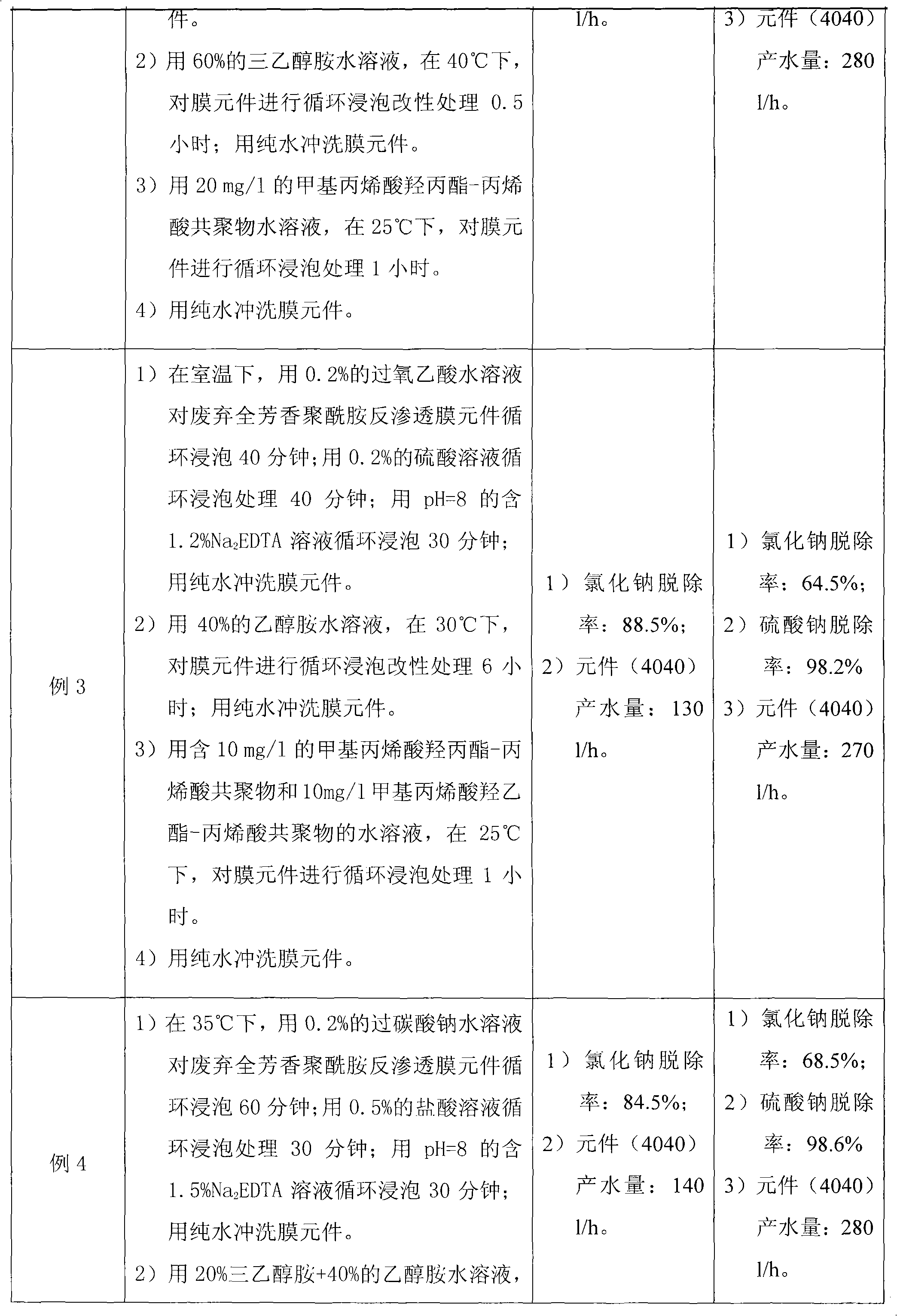

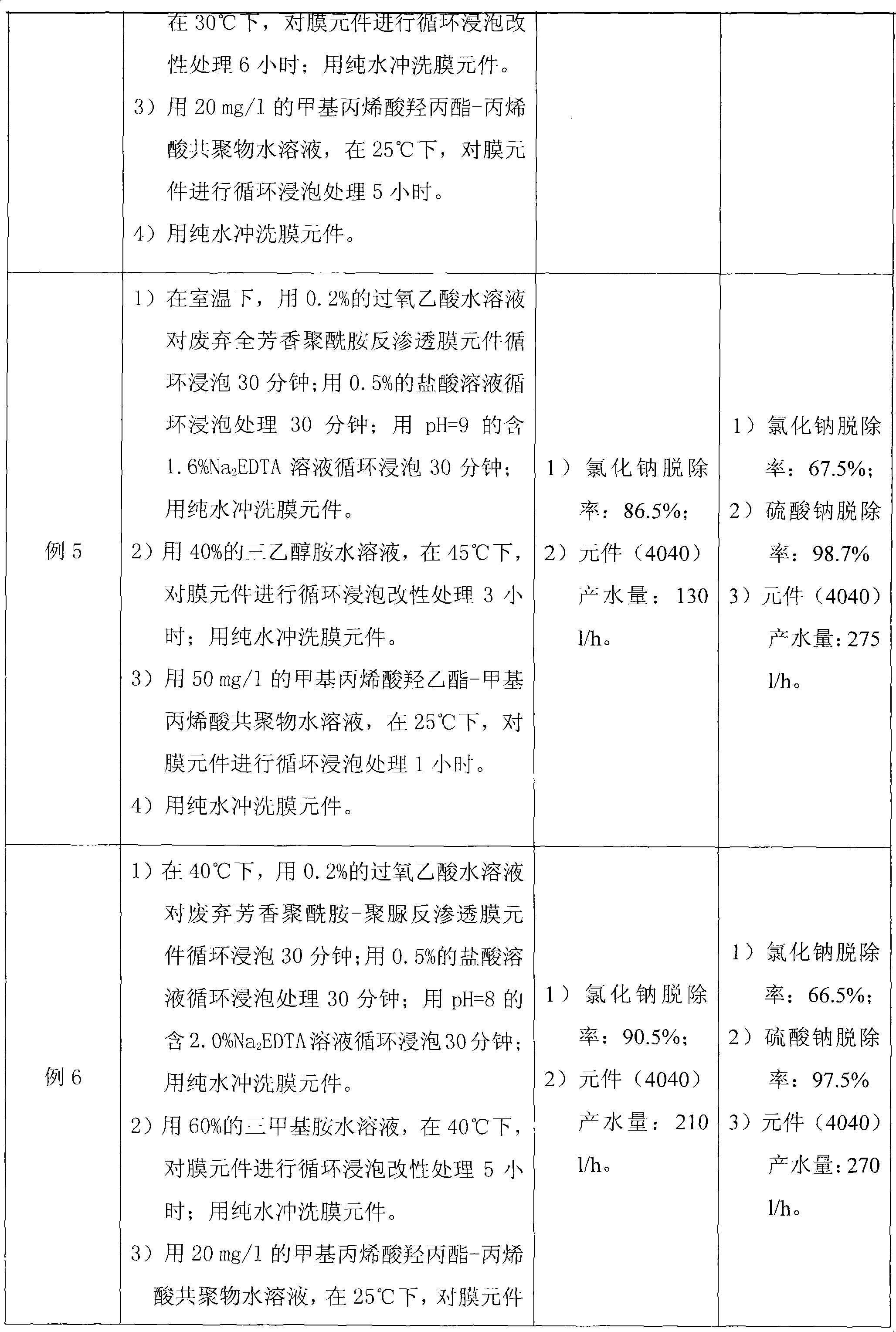

Examples

Embodiment Construction

[0045] The implementation of the present invention is described in detail below:

[0046] Conventional reverse osmosis membrane cleaning solution circulation immersion cleaning treatment of discarded reverse osmosis membrane elements: inject a clear solution containing cleaning agent into the polluted membrane system. , surfactant, chelating agent, enzyme, etc. The cycle soaking treatment time is 30-600 minutes, and the temperature is 20-40°C. After cleaning, rinse the membrane elements with pure water.

[0047] Circular immersion modification treatment of waste reverse osmosis membrane elements with amine-containing solution: pass a certain concentration of amine-containing solution into the above-mentioned waste reverse osmosis membrane elements that have been conventionally cleaned, and perform cyclic immersion treatment on the membrane elements at a certain temperature. The amine in the amine-containing solution is usually ammonia, or dimethylamine, or ethylenediamine, o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com