Wear-resistant lubricating cleaning solution for cotton picker picking ingot and preparation method thereof

A cleaning liquid and cotton picker technology, applied in lubricating compositions, chemical instruments and methods, detergent compositions, etc., can solve the comprehensive effects of self-emulsification instability, spindle picking anti-wear and lubrication, cleaning, cooling, etc. Unsatisfactory problems, to achieve excellent and stable self-emulsifying performance, excellent self-emulsifying performance, and improve the effect of anti-wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~ Embodiment 4

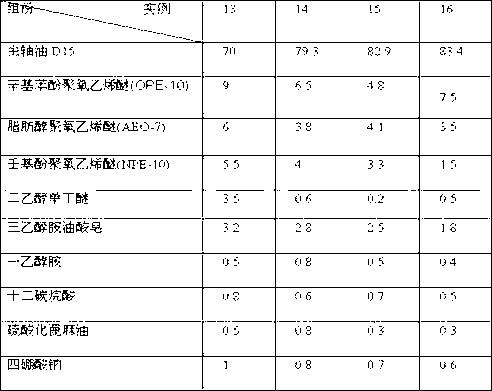

[0048] Embodiment 1~embodiment 4: see the following table for the anti-wear lubricating and cleaning liquid of cotton picker picking spindles of the present invention:

[0049] Table 1 (unit: weight percent %)

[0050]

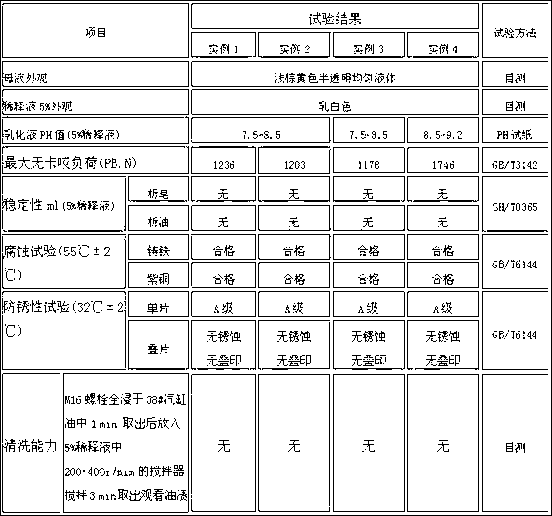

Embodiment 5~ Embodiment 8

[0052] The formula of each embodiment of the anti-wear lubricating cleaning liquid for picking the spindle of the cotton picker of the present invention is shown in the following table:

[0053] Table 2 (unit: weight percent %)

[0054]

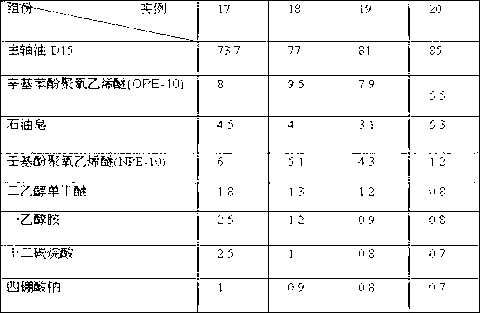

Embodiment 9~ Embodiment 12

[0056]The formula of each embodiment of the anti-wear lubricating cleaning liquid for picking the spindle of the cotton picker of the present invention is shown in the following table:

[0057] Table 3 (unit: weight percent %)

[0058]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com