A method for selectively etching silicon nano line

A silicon nanowire, selective technology, applied in nanotechnology, nanotechnology, nanostructure manufacturing and other directions, can solve the problems of high cost, complex process, incapable of mass production, etc., and achieve the effect of low cost, simple and reliable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

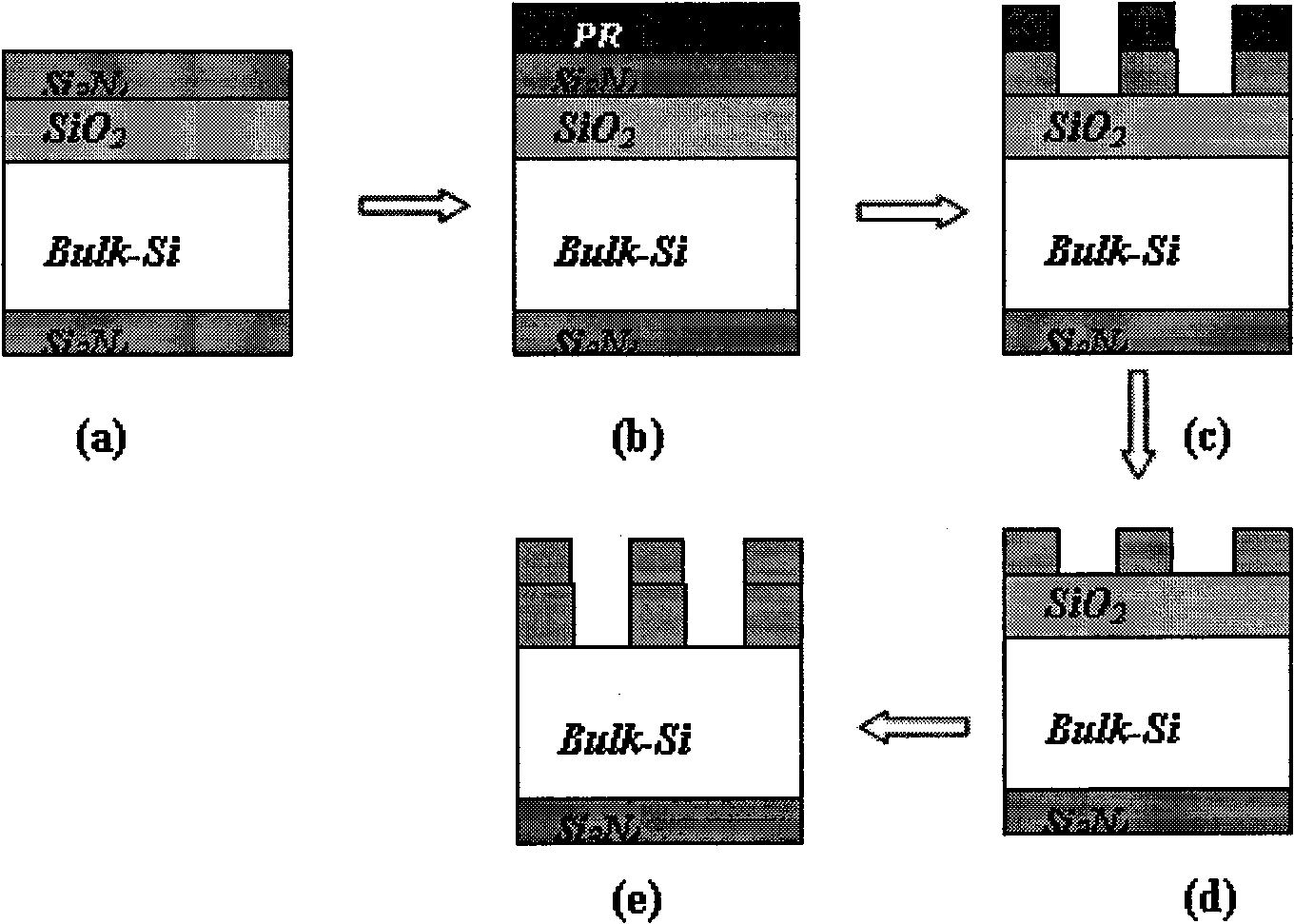

[0015] The method for selectively etching silicon nanowires of the present invention comprises the following sequential steps:

[0016] a) Using "top-down" standard microelectronics processing technology to open windows on the surface of silicon wafers

[0017] Use P(100) double-sided polished silicon wafers, according to figure 1 The process flow shown opens a window on the surface of the silicon wafer, that is, patterning:

[0018] ①Mask-First, use the method of oxidation to thermally oxidize a layer of silicon dioxide on the front and back sides of the silicon wafer, with a thickness of Secondly, use atmospheric pressure chemical vapor deposition to vapor-deposit silicon nitride on both sides of the silicon wafer, with a thickness of

[0019] ②Use photolithography to transfer the pattern on the mask to the surface of the silicon wafer;

[0020] ③Use plasma to remove silicon nitride on one side of the silicon wafer;

[0021] ④Remove silicon dioxide with silicon dioxid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com