Revolving electric device, and its manufacturing method

A technology for rotating electrical machines and manufacturing methods, applied in the direction of manufacturing motor generators, electromechanical devices, electrical components, etc., to achieve the effects of firm fixation, increased rated output, and stable contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

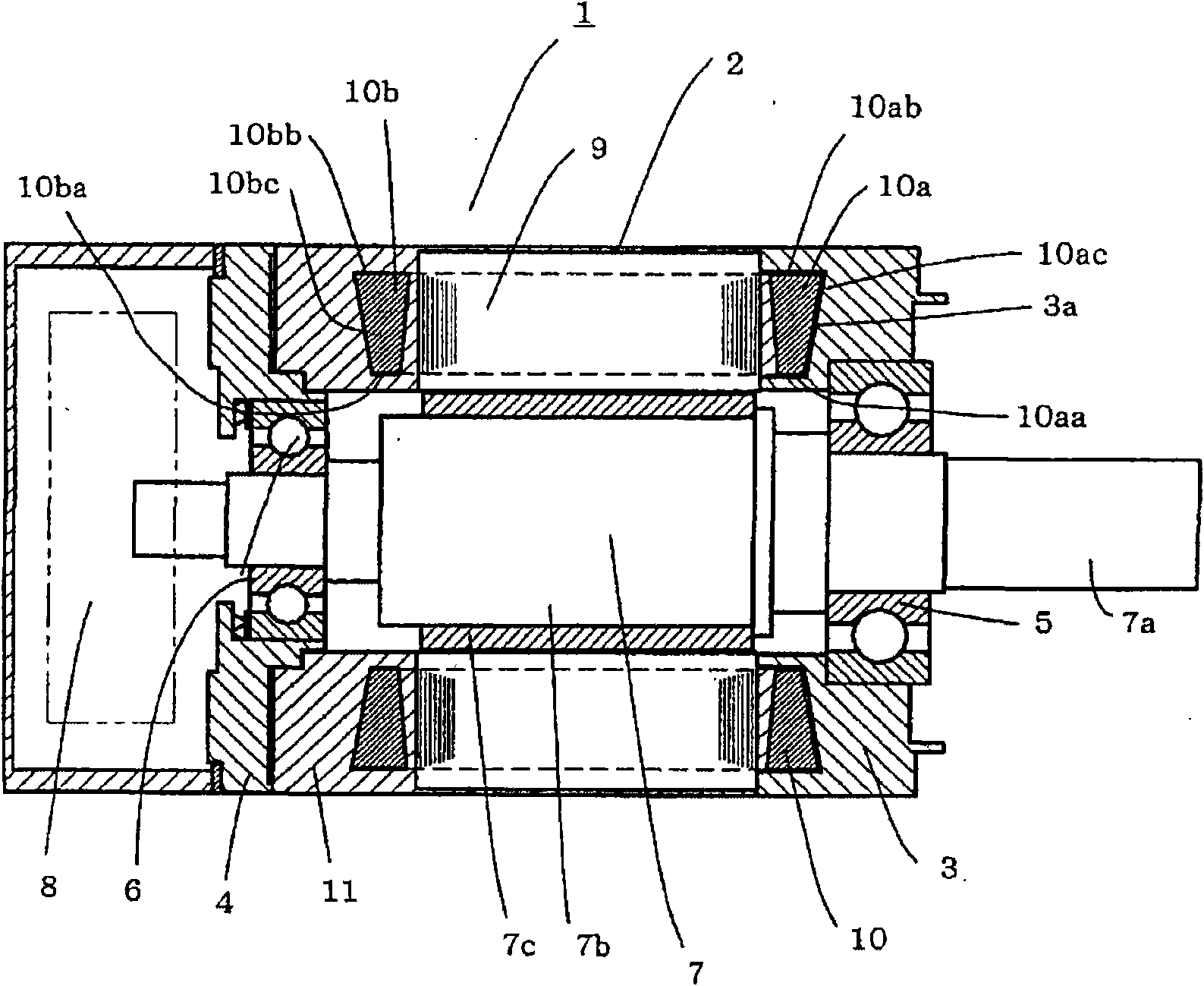

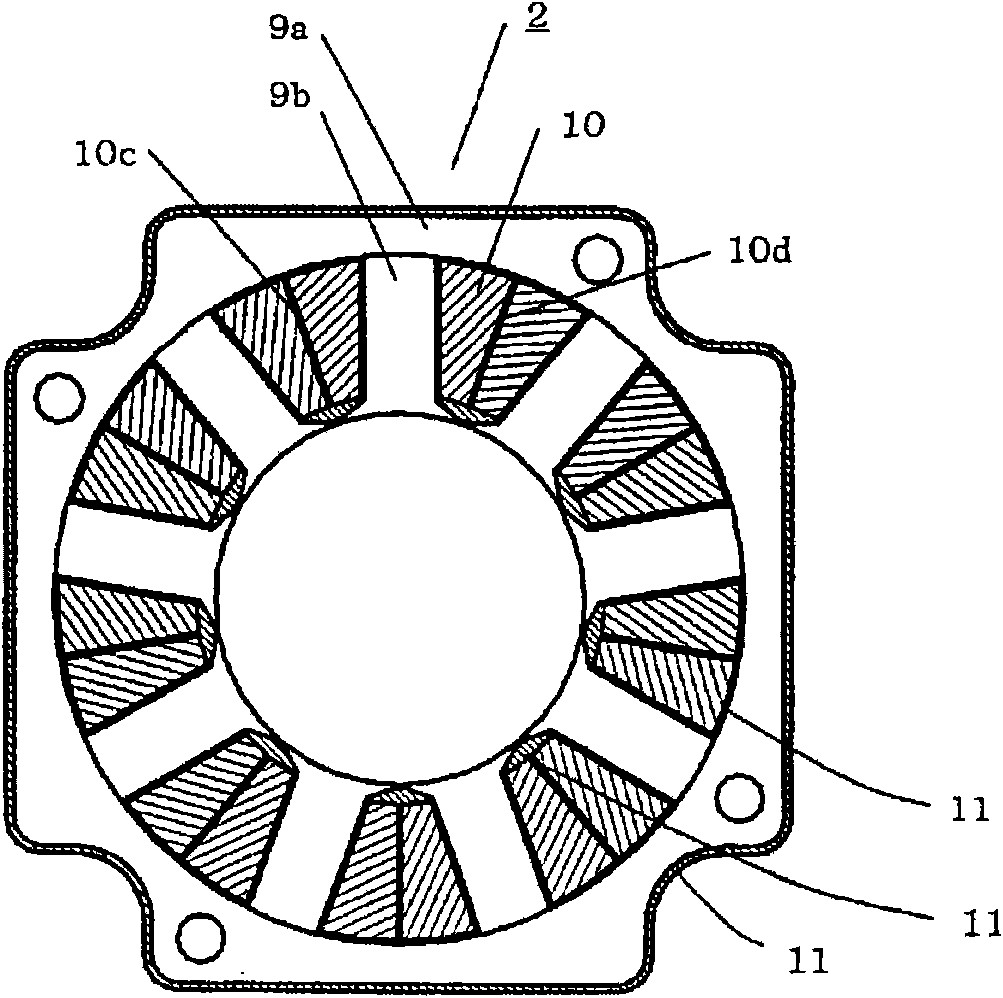

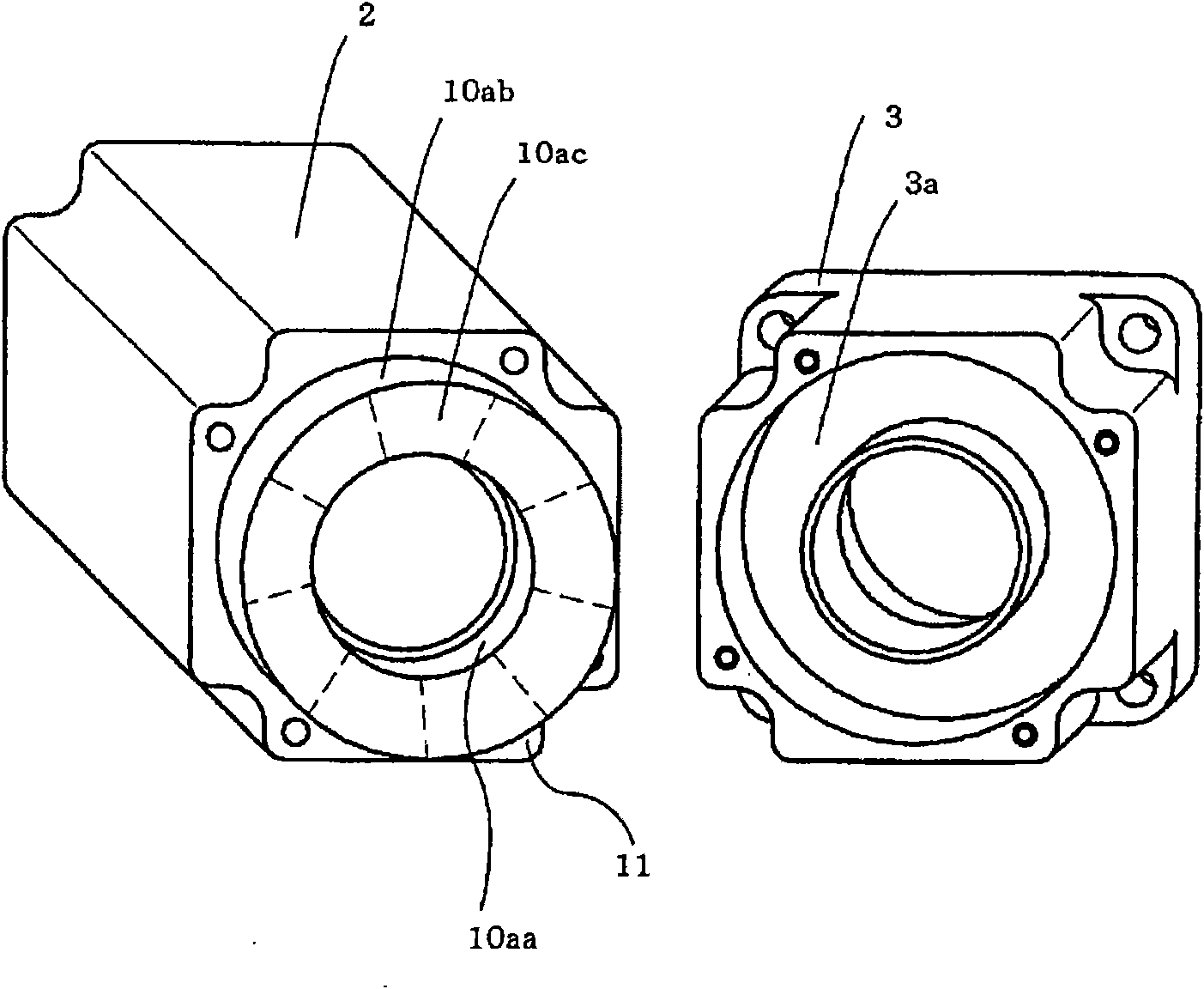

[0082] figure 1 It is a side test sectional view showing a rotating electrical machine such as a permanent magnet motor in the first embodiment of the present invention. figure 2 Yes figure 1 The front sectional view of the rotating electrical machine in , the rotor is omitted.

[0083] exist figure 1 and figure 2 Among them, 1 is a rotating electrical machine such as a permanent magnet motor, and includes: a stator 2; ; the opposite load side bracket 4 arranged on the opposite load side; the cylindrical shape having the rotating shaft 7a rotatably supported by the load side bracket 3 and the load opposite side bracket 4 through the bearings 5 and 6 The rotor 7, and the rotation detector 8, such as an encoder, etc. which are arrange|positioned to the opposite load side than the said load opposite side bracket 4, etc. are comprised. 7b is a rotor core fitted to the said rotating shaft 40a, 7c is a permanent magnet attached to the outer peripheral surface of the said...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com