Cutting path planning method applied to folded waveguide slow wave structure

A slow-wave structure, folded waveguide technology, applied in automatic control devices, feeding devices, milling machine equipment, etc., can solve the problems of easy inclination of side walls of deep grooves, easy bending and collapse of island structures, and difficult removal of burrs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

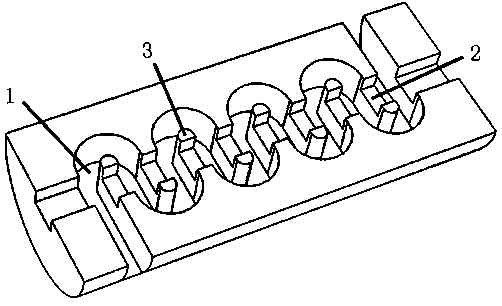

[0058] The invention relates to a method for planning the trajectory of a knife applied to a folded waveguide slow wave structure, which is used for processing such as figure 1 The folded waveguide slow-wave structure shown. The slow wave structure is a semi-cylindrical body cut in the axial direction, and S-shaped grooves 1, straight grooves 2, and islands 3 formed by the intersection of the two are distributed on the axial section. The S-shaped grooves have a total of 75 periods, and the S-shaped grooves The aspect ratio is 255μm / 100μm, and the straight groove channel width is 140μm. The material of the slow wave structure is Al 2 o 3 For dispersed oxygen-free copper with a particle volume fraction of 1.1% and a particle size of 50-100nm, it is required that the dimensional accuracy after processing should be better than ±2μm, and the surface roughn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com