Surface microdefect fast search and micro-milling repair device for large-diameter KDP crystal elements

A technology of crystal components and micro-defects, which is applied in the direction of fine working devices, working accessories, stone processing equipment, etc., can solve the problems of rapid search on the surface of large-diameter KDP crystal components, etc., and achieve simple structure, high magnification, and fast The effect of the knife

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

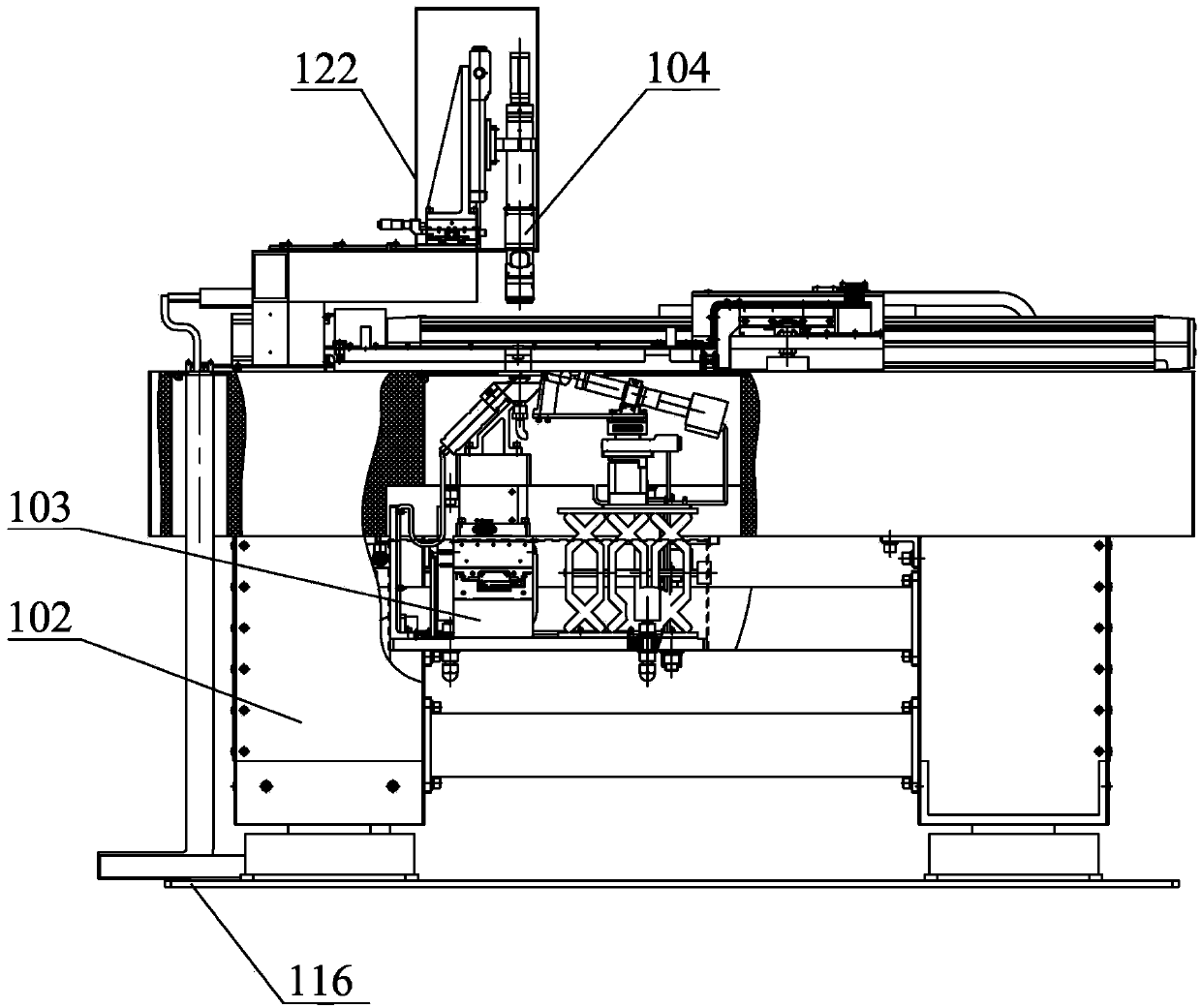

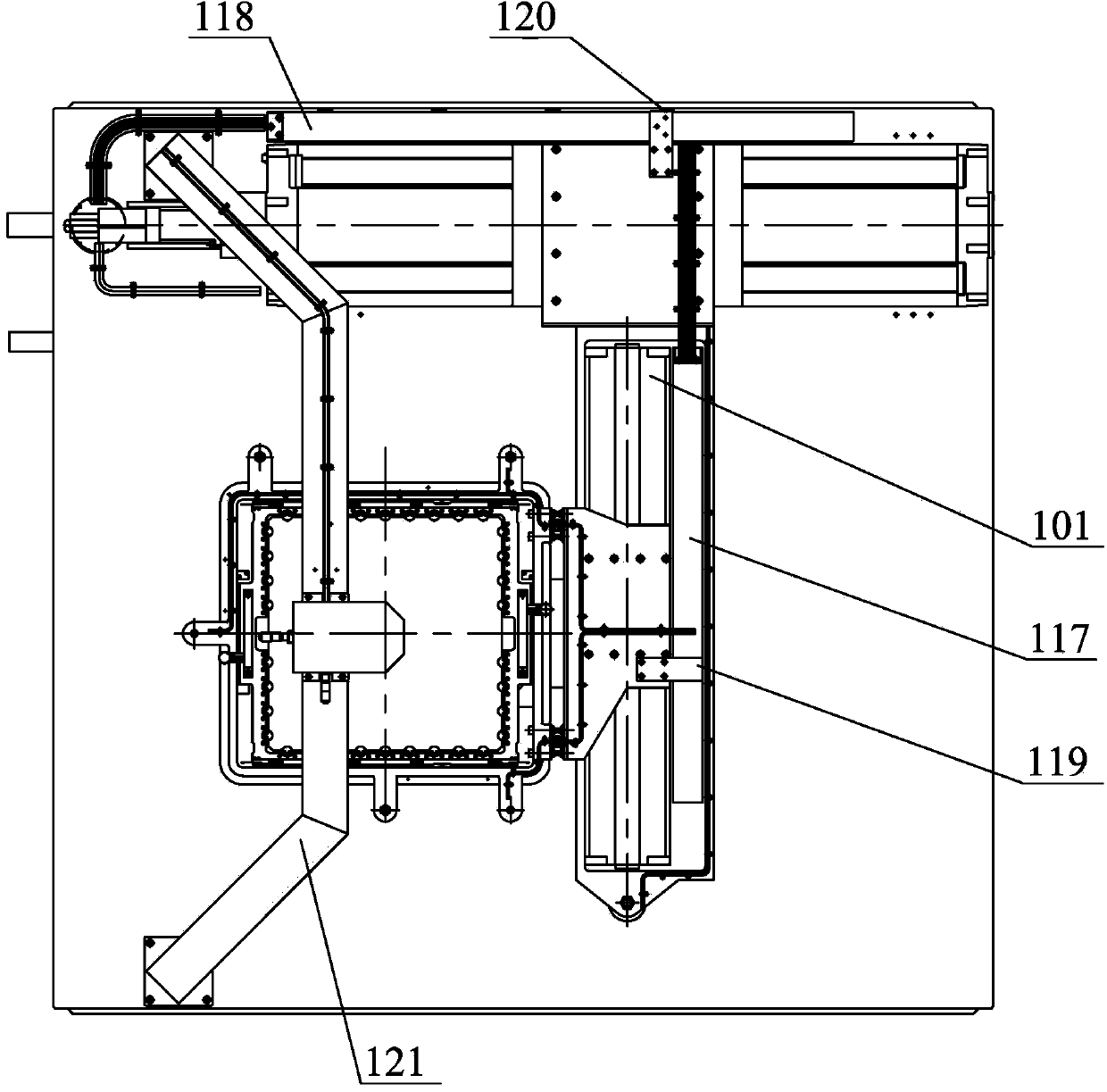

[0013] Specific implementation mode one: combine Figure 1-Figure 4 Illustrates that the large-diameter KDP crystal element surface micro-defect rapid search and micro-milling repair device of this embodiment includes a crystal mobile platform assembly 101, an overall platform assembly assembly 102, a bottom platform assembly assembly 103, and a crystal microscope mobile platform 104 , large flat plate 116 at the bottom, the first drag chain 117, the second drag chain 118, the guide rail drag chain connecting block 119, the second drag chain limit block 120 and the crystal microscope mobile platform support 121; the large flat plate 116 at the bottom (by forming It is cut from steel plates to reduce the pressure on the ground) and set horizontally, and the overall platform assembly assembly 102 is fixedly placed on the bottom large flat plate 116 (as the installation platform of the overall device, it has the functions of vibration isolation, vibration absorption, and level adj...

specific Embodiment approach 2

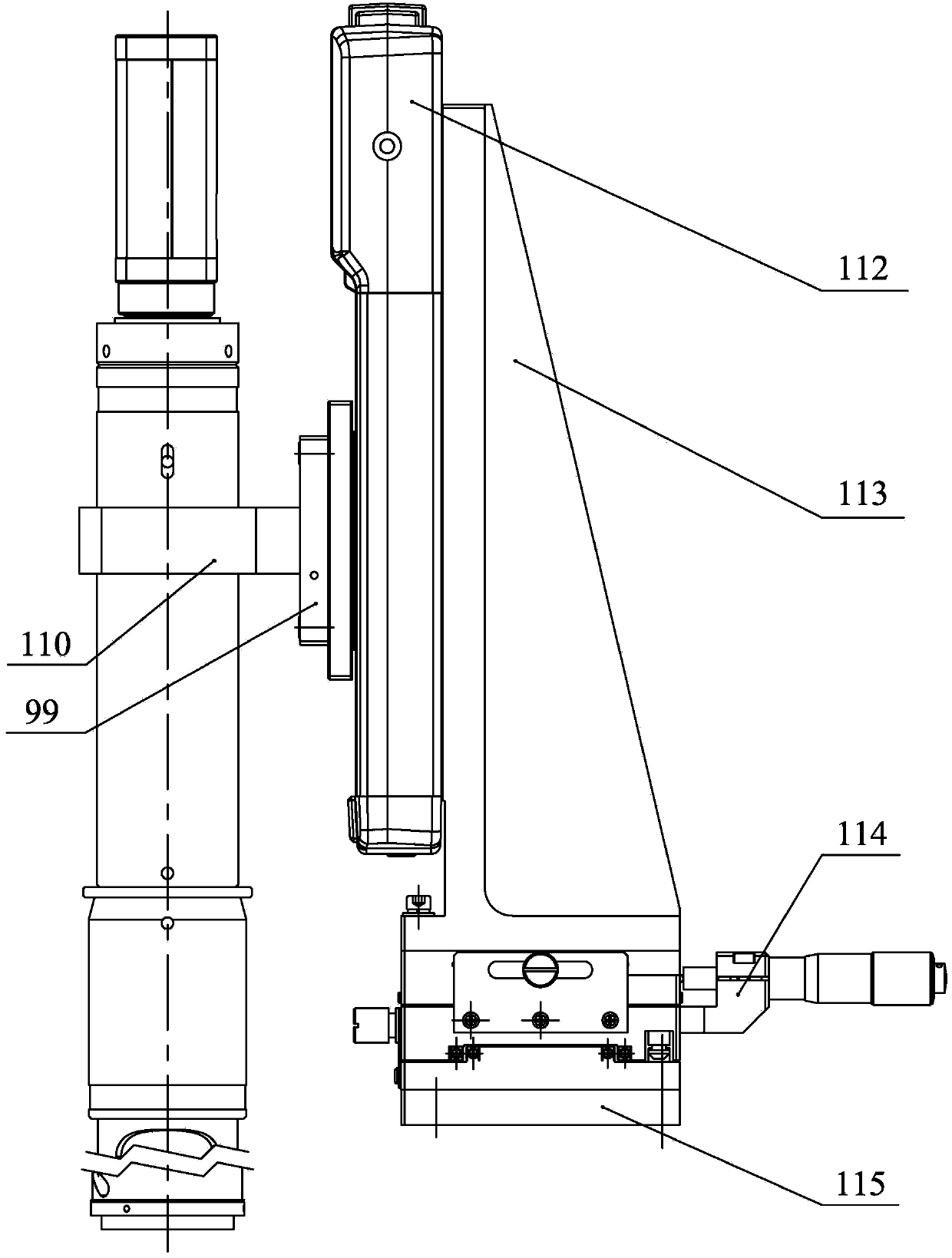

[0014] Specific implementation mode two: combination Figure 2 to Figure 13Explain that the crystal mobile platform assembly 101 in this embodiment includes an air float frame 30, an X-axis linear unit 31, a stepper motor 32, an X-axis guide rail connecting plate 10, a Y-axis guide rail tray 33, a Y-axis linear unit 12, and a Y-axis linear unit 12. Axis guide rail connecting plate 14 and two sets of flexible hinges 3; the X-axis linear unit 31 is fixed on the upper surface of the precision platform, and the X-axis guide rail connecting plate 10 is fixed on the moving parts of the X-axis linear unit 31; stepping motor 32 Drive the moving parts of the X-axis linear unit 31 to do linear motion, the Y-axis guide rail connecting plate 14 is fixed on the moving parts of the Y-axis linear unit 12; the Y-axis linear unit 12 is fixed in the Y-axis guide rail tray 33, and the Y-axis guide rail One end surface of the tray 33 is positioned and connected to one side of the X-axis guide rai...

specific Embodiment approach 3

[0015] Specific implementation mode three: combination Figure 5 , Figure 7 and Figure 8 Explain that the air float frame 30 includes a crystal frame 1, two pressing blocks 6, two locking blocks 9, two positioning blocks 15, five connecting ears 20, three spherical hinge studs 13 and three Air floating pad-11; the crystal frame 1 is a rectangular frame arranged horizontally, two groups of flexible hinges 3 are fixedly connected to the same arbitrary outer surface of the crystal frame 1, and five connecting points are fixed on the remaining three outer surfaces of the crystal frame 1 Ear 20, one positioning block 15 is respectively fixed on the two opposite inner surfaces of the crystal frame 1, and a positioning surface 15-1 is respectively arranged on the two positioning blocks 15, and the two positioning surfaces 15-1 are arranged in the same vertical plane , the large-aperture optical element 40 is placed inside the crystal frame 1 as a whole, and is positioned by the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com