Electric-controlled pneumatic type clutch booster unit and operating method thereof

A clutch and pneumatic technology, applied in fluid-driven clutches, non-mechanical-driven clutches, clutches, etc., can solve problems such as clutch master cylinder and clutch booster failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

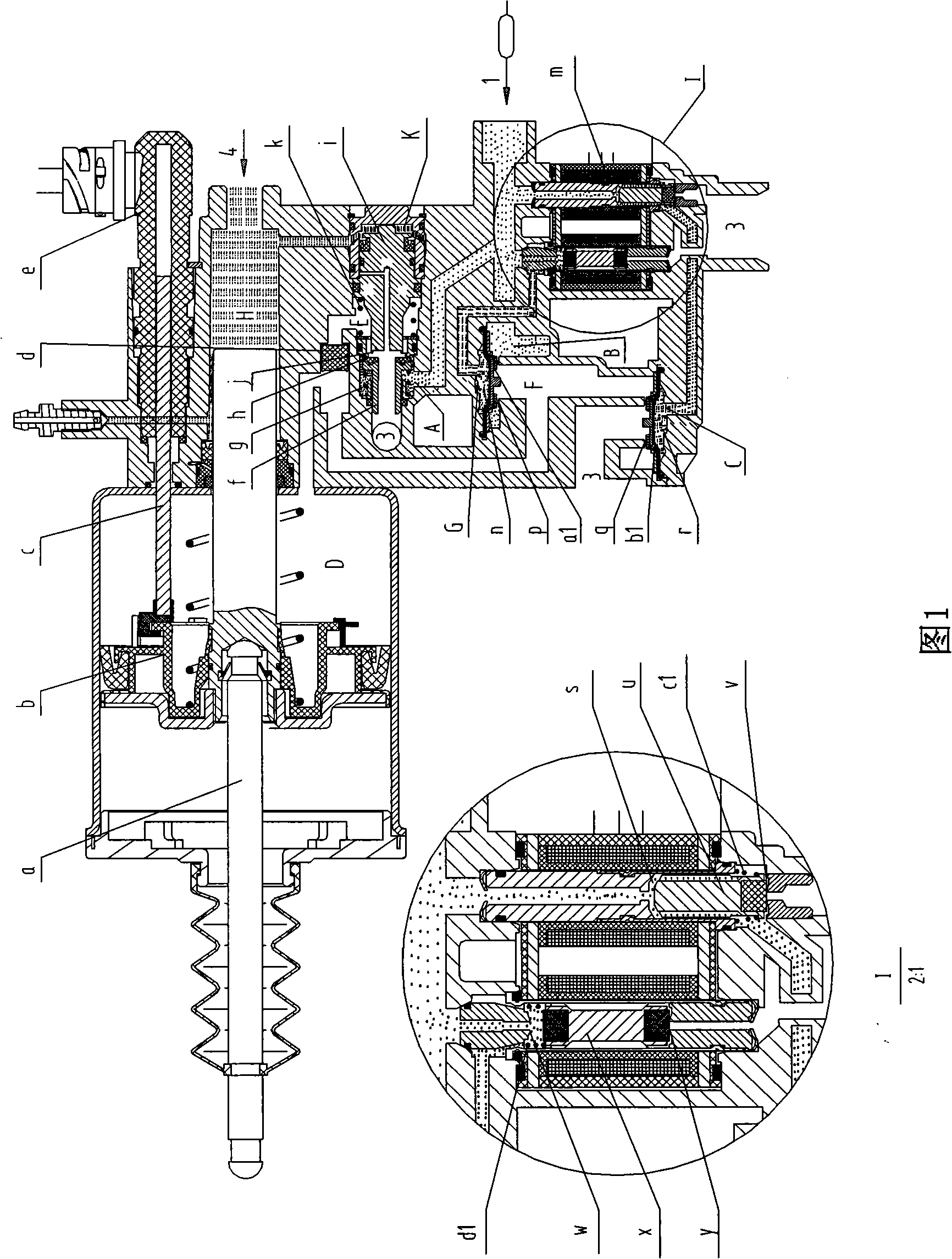

[0016] Embodiment 1: Pneumatic clutch booster device with hydraulic control mechanism and electronic control mechanism

[0017] Structural description (refer to accompanying drawing 1):

[0018] A friction clutch consists of a diaphragm spring and a release lever. The high-pressure gas is input from the air pressure input port, and the complex gas path is connected with the air pressure input port and the fourth air pressure chamber D. Multiple valves are arranged on the complex gas path, and the hydraulic control device and the electric control device control the opening and closing of these valves respectively. Control, so as to control the flow path of the high-pressure gas, when the high-pressure gas reaches the fourth air pressure chamber D, the high-pressure gas in the fourth air pressure chamber D pushes the clutch control piston b and then drives the push rod a to move to the left, the push rod a and the clutch The release lever is connected, thereby realizing the di...

Embodiment approach 2

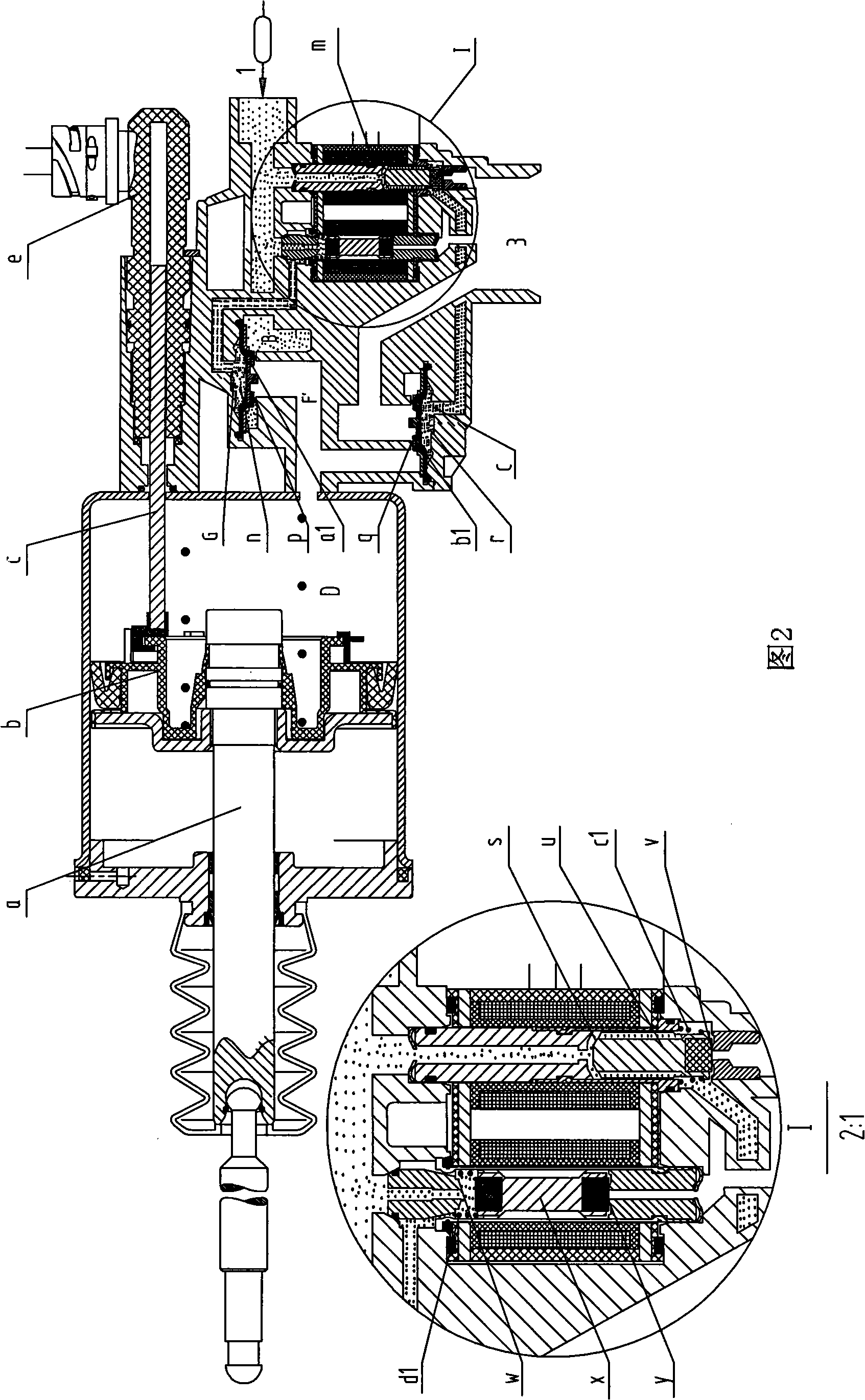

[0043] Embodiment 2: Pneumatic clutch booster device with only electronic control mechanism

[0044] Structural description (refer to accompanying drawing 2):

[0045] This embodiment omits the part of the hydraulic control mechanism and the associated high-pressure gas path and air pressure chamber in the first embodiment, and only keeps the part related to the electric control control mechanism to control the clutch.

[0046] The air pressure input port 1 directly communicates with the second air pressure chamber B, and the second air pressure chamber B communicates with the sixth air pressure chamber F' through the intake valve a1. When the intake valve a1 is opened, the high-pressure gas in the second air pressure chamber B passes through the inlet The valve p enters the sixth air pressure chamber F', and then enters the fourth air pressure chamber D. The sixth air pressure chamber F' communicates with the air pressure output port 3 through the exhaust valve b1. When th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com