A debugging-free multifunctional clutch booster

A technology for clutches and boosters, applied in clutches, fluid-driven clutches, non-mechanical-driven clutches, etc., can solve the problems of increasing the difficulty and process of manufacturing friction plates, expensive prices, and increased manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

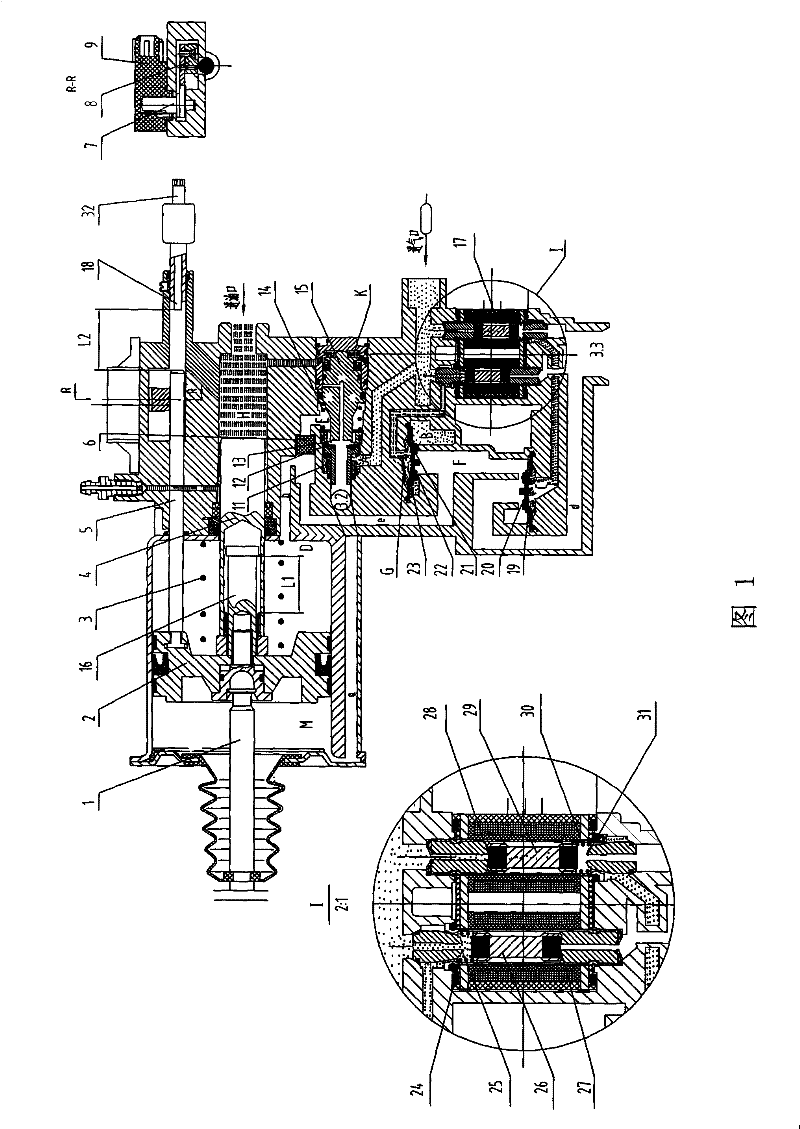

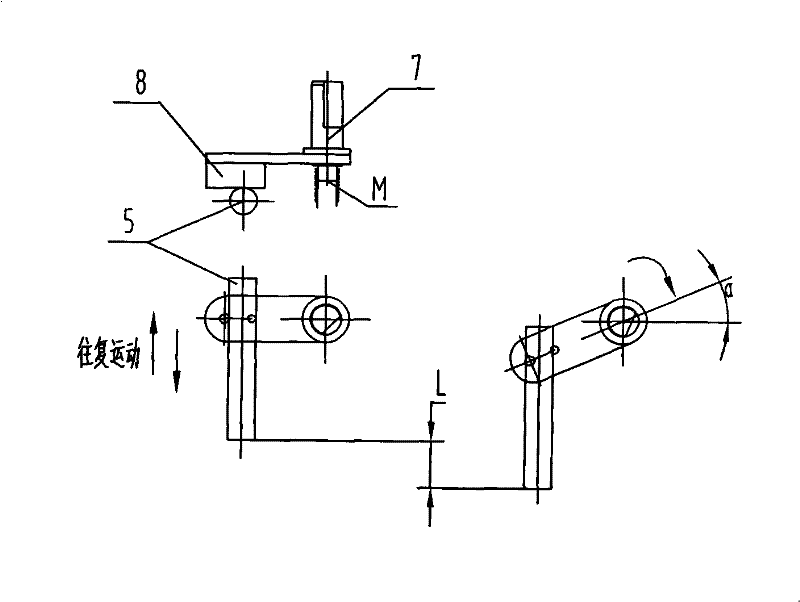

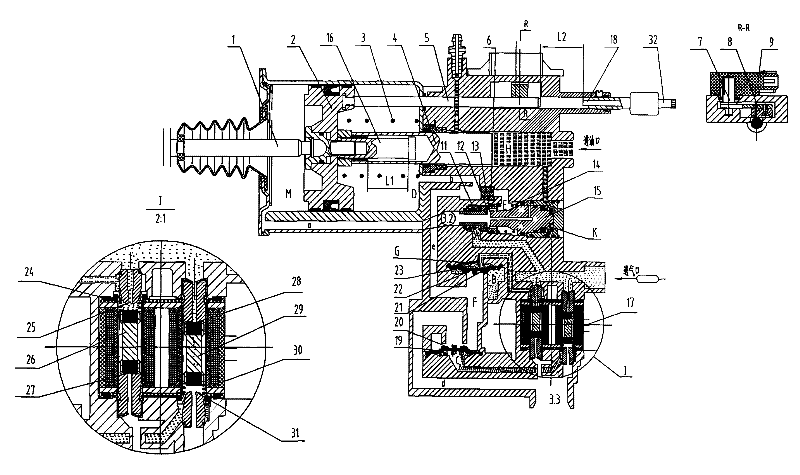

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings. The words "upper", "lower", "left", "right" etc. used in this article to describe the orientation are based on the orientation shown in the drawings for the convenience of explanation. In the actual device, these Orientation may vary due to how the unit is placed. In this paper, "clutch disengagement process" refers to the process of the clutch from the engaged state to the disengaged state; "clutch engagement process" refers to the process of the clutch from the disengaged state to the engaged state; Stay engaged.

[0030] Structure description:

[0031] Such as figure 1 As shown in , the high-pressure gas in the pneumatic clutch booster is input from the air inlet connected to the air source, and the complex gas path communicates with the air inlet and the fourth air chamber D, and multiple Valves, hydraulic control devices and electric control devices respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com