Real-time monitoring device and operation determination method for hob status during shield construction

A technology for real-time monitoring and construction, which is applied in the direction of measuring devices, optical devices, and testing of machine/structural components. Impact wear, the effect of avoiding impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

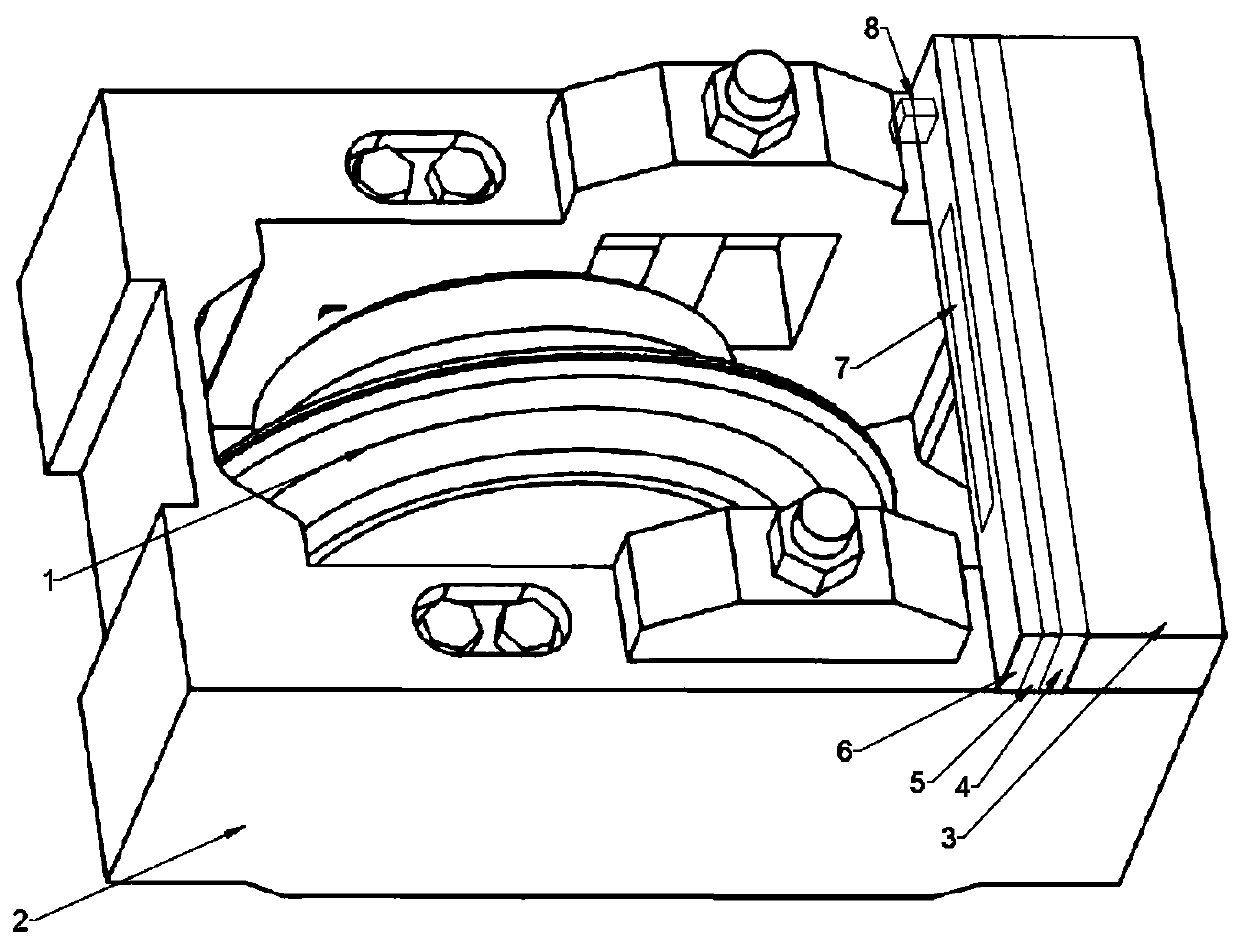

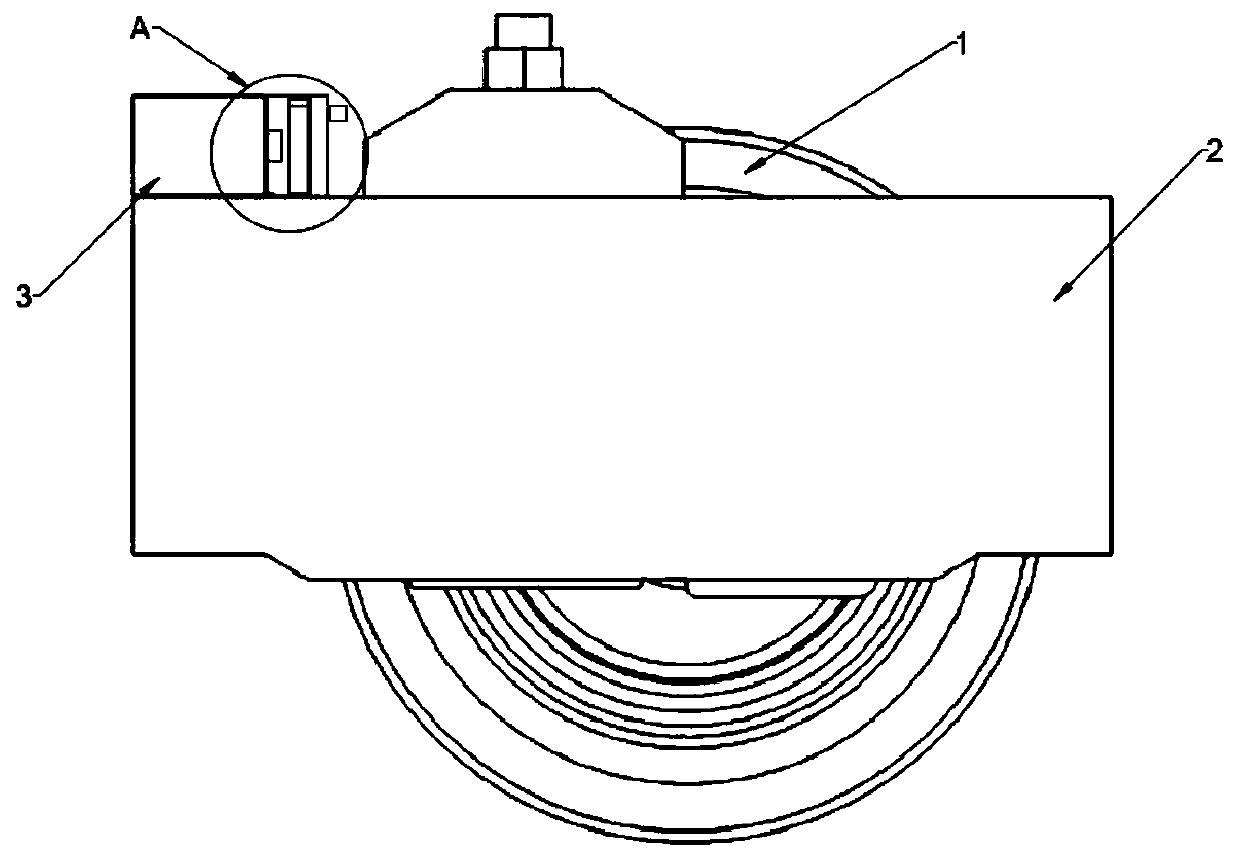

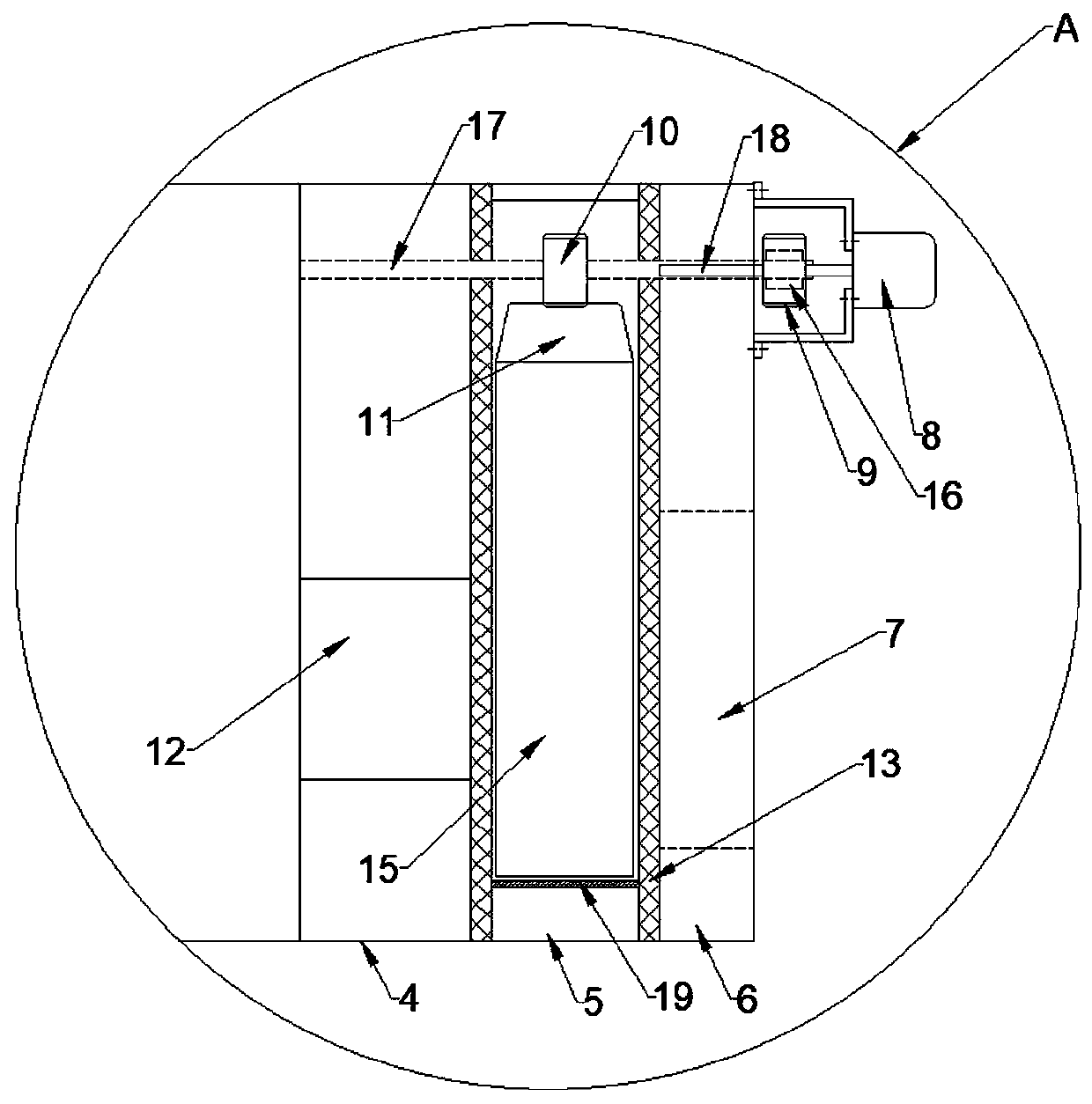

[0034] Embodiment 1: A real-time monitoring device for hob status in shield tunneling construction, see Figure 1-Figure 4, which includes a hob 1, the hob 1 is installed in the knife box 2, the upper part of the knife box 2 is fixed with a mounting bracket 3, and a laser sensor 12 is arranged on the mounting bracket 3, in order to prevent the laser sensor 12 from being damaged during the hob working process, The laser sensor 12 is provided with a protection device outside, and the protection device includes a first protection board 4, a second protection board 5, a third protection board 6, a vertical sealing strip 13, a transverse sealing strip 14, a protective lens 15, a light-transmitting Window 7, the middle part of the first protective plate 4 is provided with a through hole, the laser sensor 12 is fixedly arranged in the through hole of the first protective plate 4, the second protective plate 5 is arranged on the first protective plate 4, the third protective plate 6, ...

Embodiment 2

[0039] Embodiment 2: A method for judging the state of the hob in shield construction, characterized in that it uses the real-time monitoring device for the state of the hob in shield construction described in claim 1 to monitor, and during the construction of the shield, The cutter head rotates, the hob data is collected in real time through the laser sensor, and the operating status of the hob is judged by the data monitored by the laser sensor:

[0040] ① When the wear value of the hob fluctuates steadily and gradually increases, it means that the hob is operating normally to break rocks; if Figure 5 as shown in (a);

[0041] ②When the wear value of the hob jumps suddenly and then fluctuates steadily, it means that the hob has string grinding; if Figure 5 as shown in (b);

[0042] ③When the wear value of the hob is stable, it means that the hob is stuck and does not roll to break the rock; if Figure 5 as shown in (c);

[0043] When the two situations of ② and ③ occur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com