Underground operation integrated shaft processing tool and method

A technology for processing tools and wellbore, which is applied in wellbore/well components, earthwork drilling and production, and cleaning equipment, etc. It can solve problems such as negligible cleaning effect, corrosion and perforation of casing, resistance and jamming of running tools, and achieve high social Benefits and economic benefits, reduce labor intensity, and reduce operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The detailed description and technical content of the present invention are described below with the drawings, but the drawings are only for reference and description, and are not used to limit the present invention.

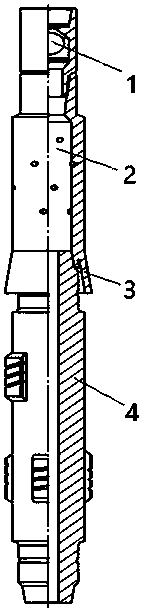

[0033] as attached figure 1 As shown, an integrated wellbore processing tool for downhole operation, including a check valve 1, a well gauge 2, opening φ3mm small holes on the well gauge body, which are evenly distributed in a spiral shape, a leather bowl seal 3, and a scraper 4 . The parts are connected by threads. During the downhole process, the scraper 4 first performs mechanical scraping and cleaning on the inner wall of the casing, and the wellbore fluid is forced to enter the inside of the tool from the lower passage of the scraper under the action of the rubber bowl seal 3. Under the action of the check valve 1, it cannot go back up to the upper tubing, and is forced to flow out from the small holes in the helical uniform distribution of the well...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com