Movable plate quick-changing structure and machining equipment

A movable plate and base plate technology, which is applied in metal processing, mechanical equipment, thin plate connection, etc., can solve the problems of time-consuming and labor-consuming, cumbersome disassembly and assembly of the movable plate, and reduce labor intensity, save labor time, and facilitate operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

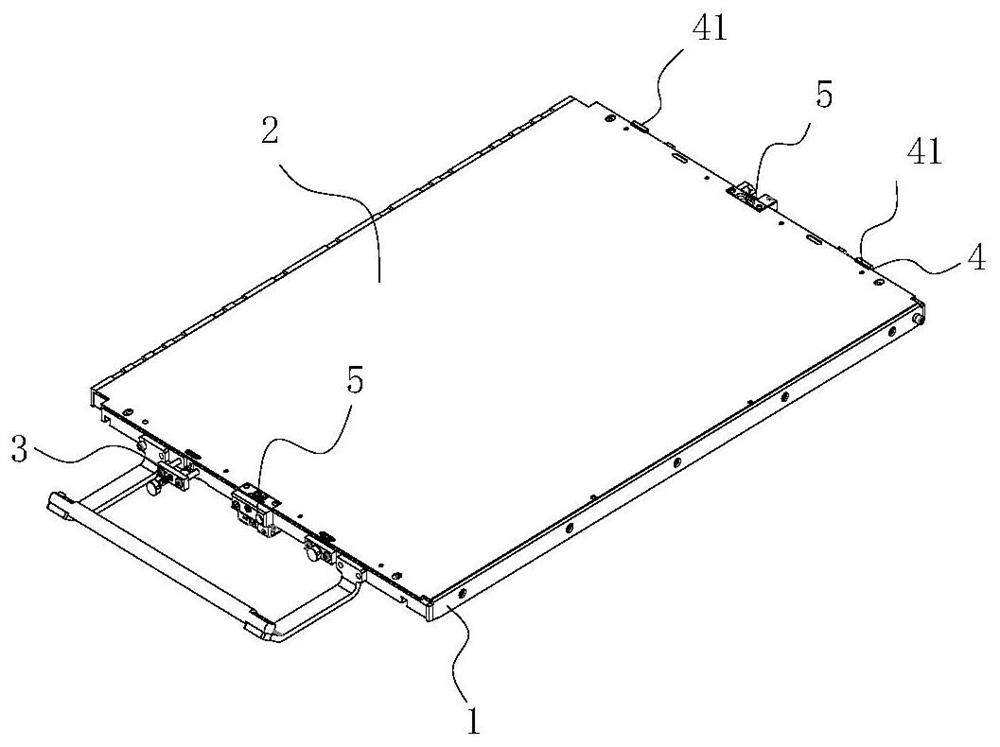

[0032] Such as figure 1 As shown, the present embodiment provides a movable plate quick-change structure for realizing quick disassembly and assembly of the movable plate 2 and the base plate 1, including:

[0033] The limit piece is arranged at one end of the movable plate 2, and is used to limit the position of the end of the movable plate 2;

[0034] The elastic locking member 3 is arranged on the other end of the movable plate 2, and includes an elastic member and a locking member, and the locking member locks the movable plate 2 under the action of the elastic member;

[0035] Both the limiting part and the elastic locking part 3 are installed on the base plate 1 .

[0036] The limiting member is arranged at the tail end of the movable plate 2;

[0037] The movable plate 2 is arranged on the upper surface of the base plate 1, the elastic locking member 3 is arranged at the head end of the movable plate 2, the limiting member is installed at the tail end of the movable p...

Embodiment 2

[0047] The elastic locking member 3 is not limited to the method described in the above-mentioned embodiments, and can also be in the form of an elastic pressing plate, for example, a guide is provided on the side of the substrate 1, the pressing plate is slidably connected to the guiding member, and the elastic member is arranged on the pressing plate in a compressed state. The upper part is used to apply downward elastic force to the pressing plate, so as to realize the pressing and fixing of the movable plate 2.

Embodiment 3

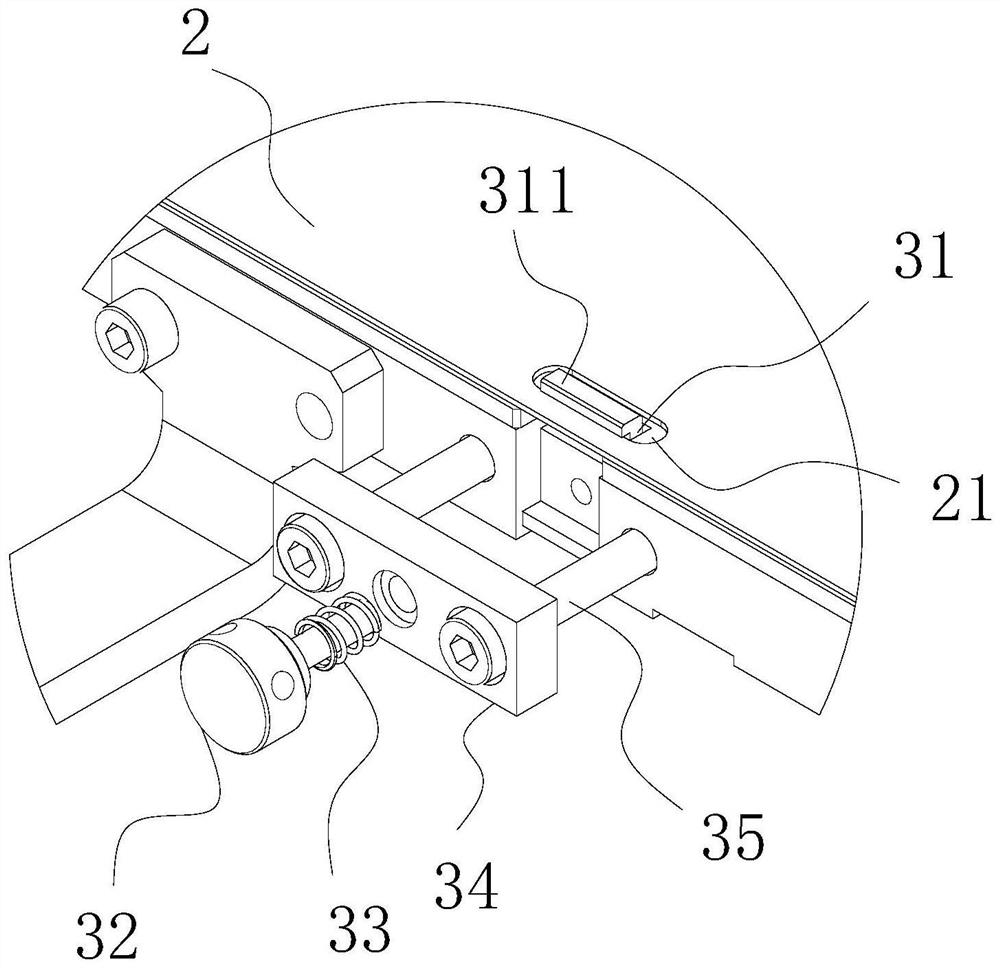

[0049] In addition to the above two methods, the elastic locking member 3 can also adopt the following methods:

[0050] The locking plate 31 is arranged in the slot in a hinged form, one end of the spring 33 abuts against the inner surface of the fixing plate 34, and the other end abuts against the middle and lower side of the locking plate 31, and the spring 33 locks towards the locking plate in a compressed state. The middle and lower sides of the plate 31 apply elastic force, and the bottom of the locking plate 31 moves inwardly and upwardly (because the locking plate 31 is hinged in the slot, the bottom moves in the opposite direction to the upper direction), and the stop hook at the top Two 311 move to the outside to realize the locking of movable plate 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com