Patents

Literature

55 results about "Cutting tool wear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methods and systems for chip breaking in turning applications using CNC toolpaths

ActiveUS20090107308A1Reduce the temperatureEnhances ability implementProgramme controlLathesNumerical controlEngineering

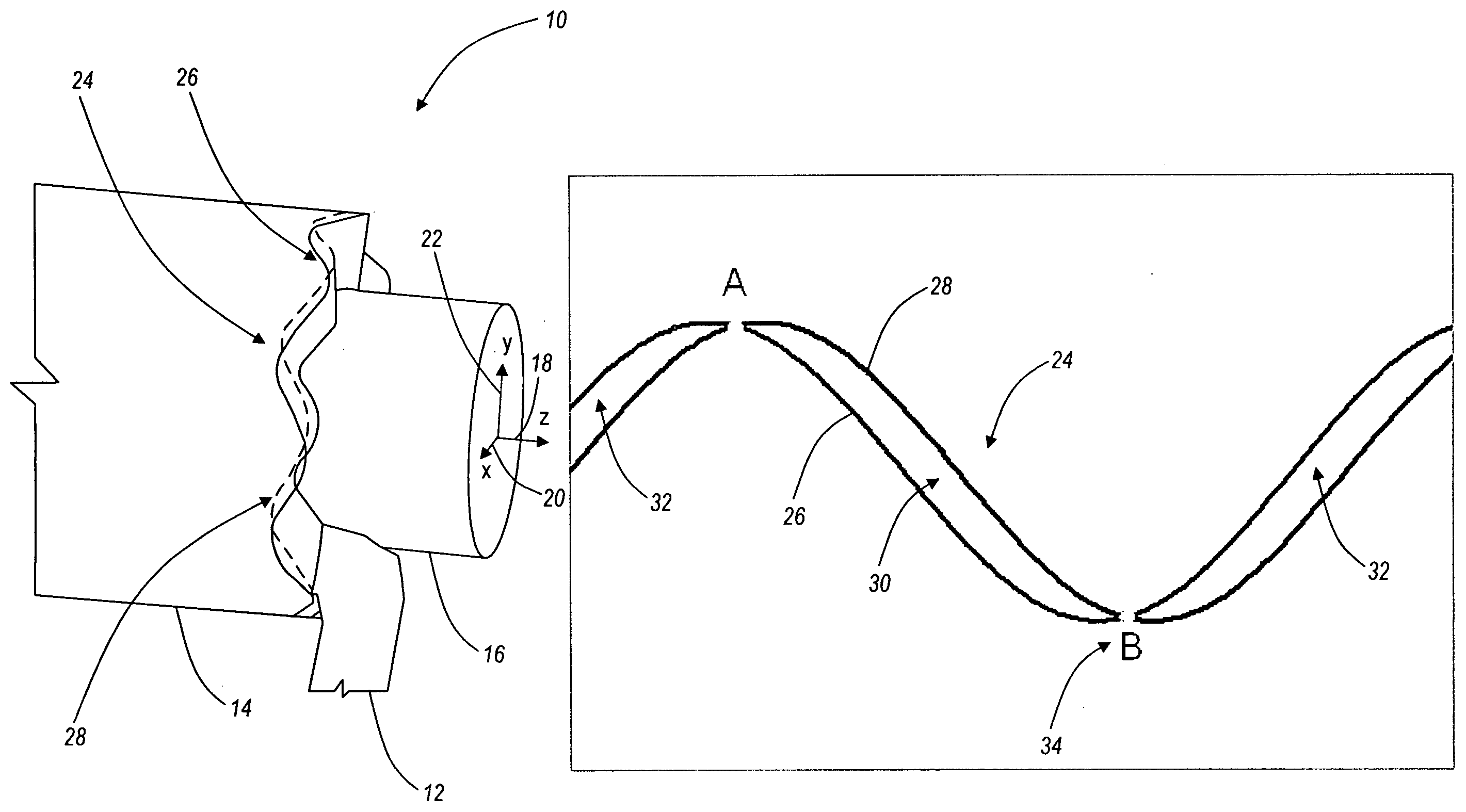

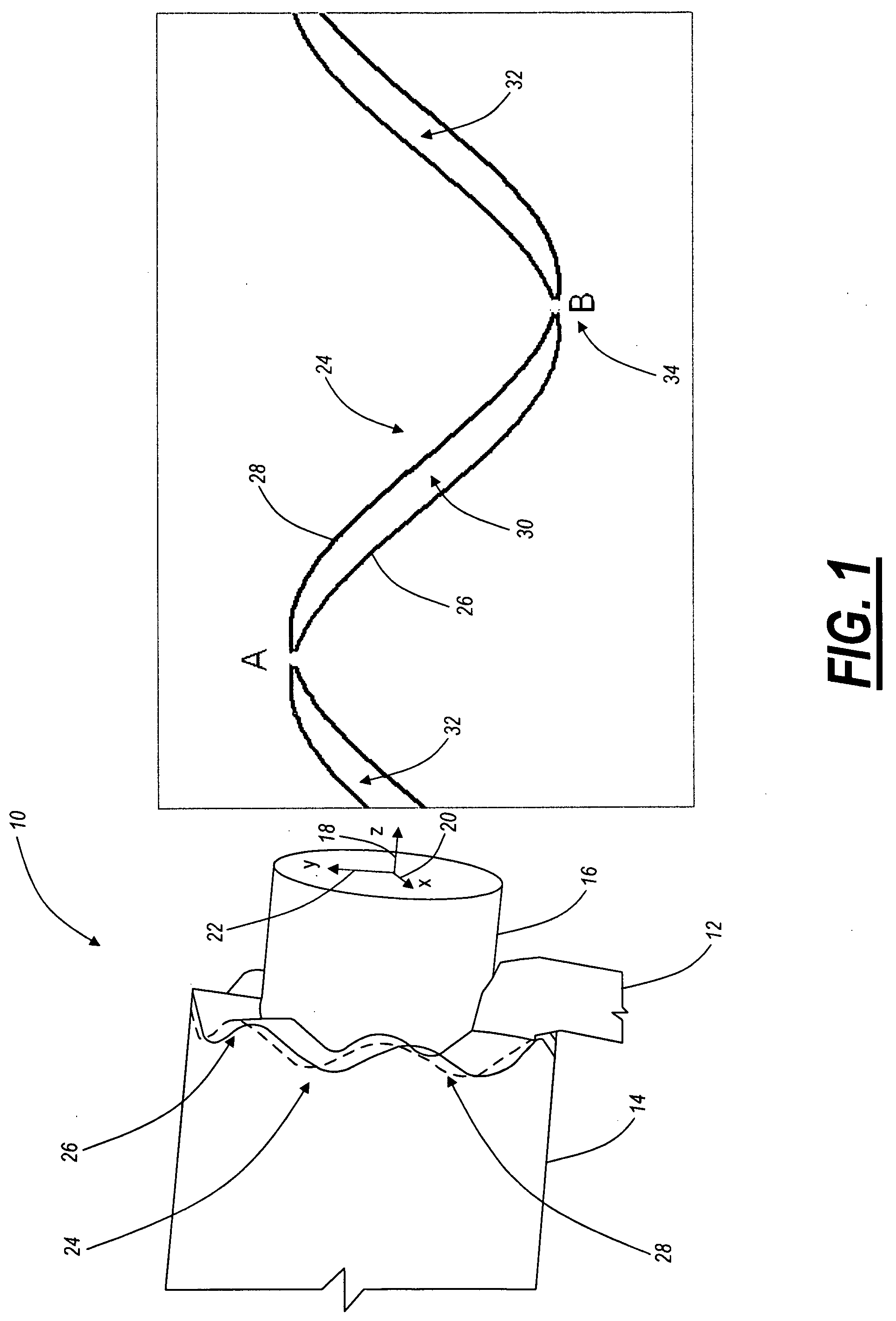

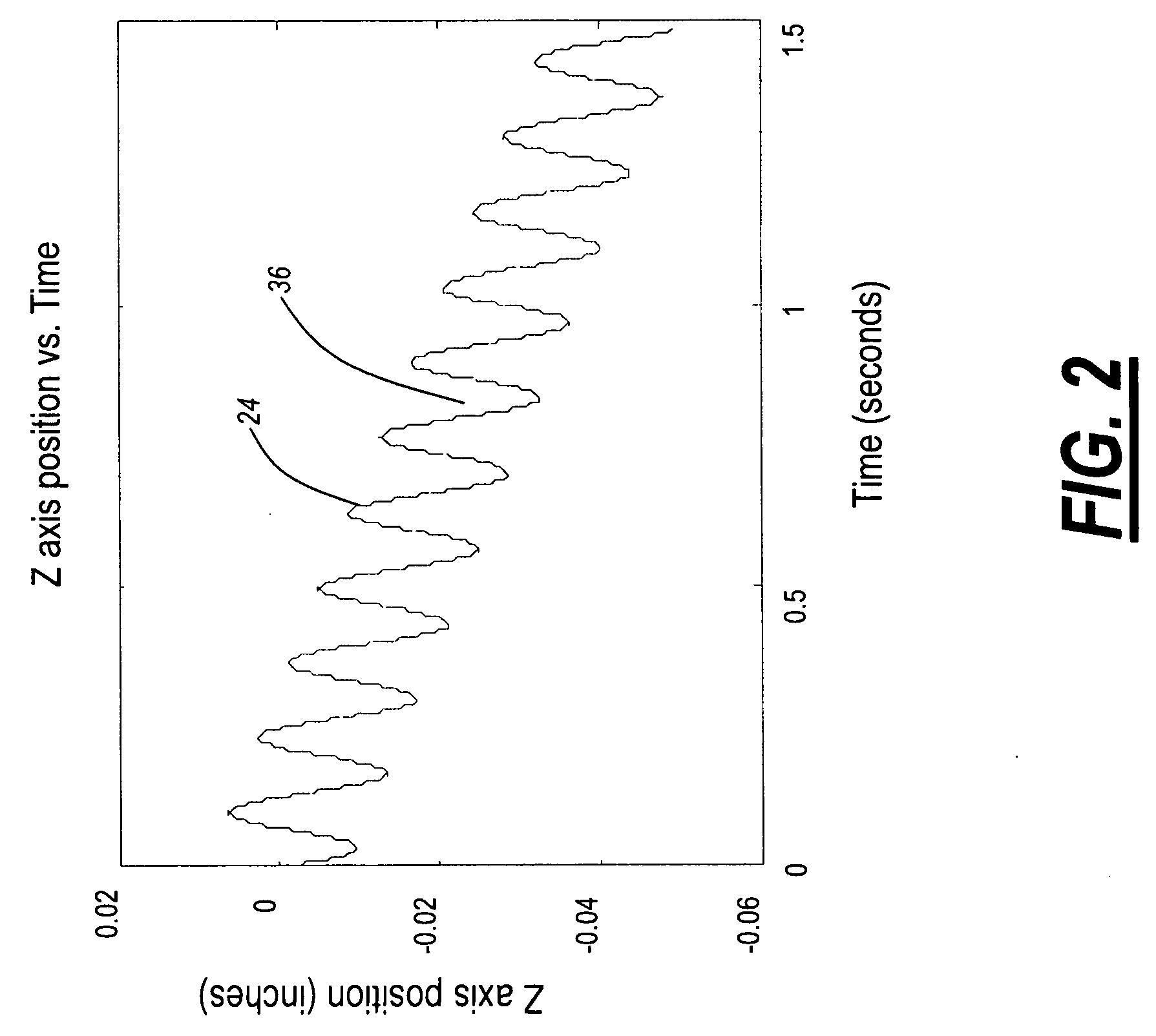

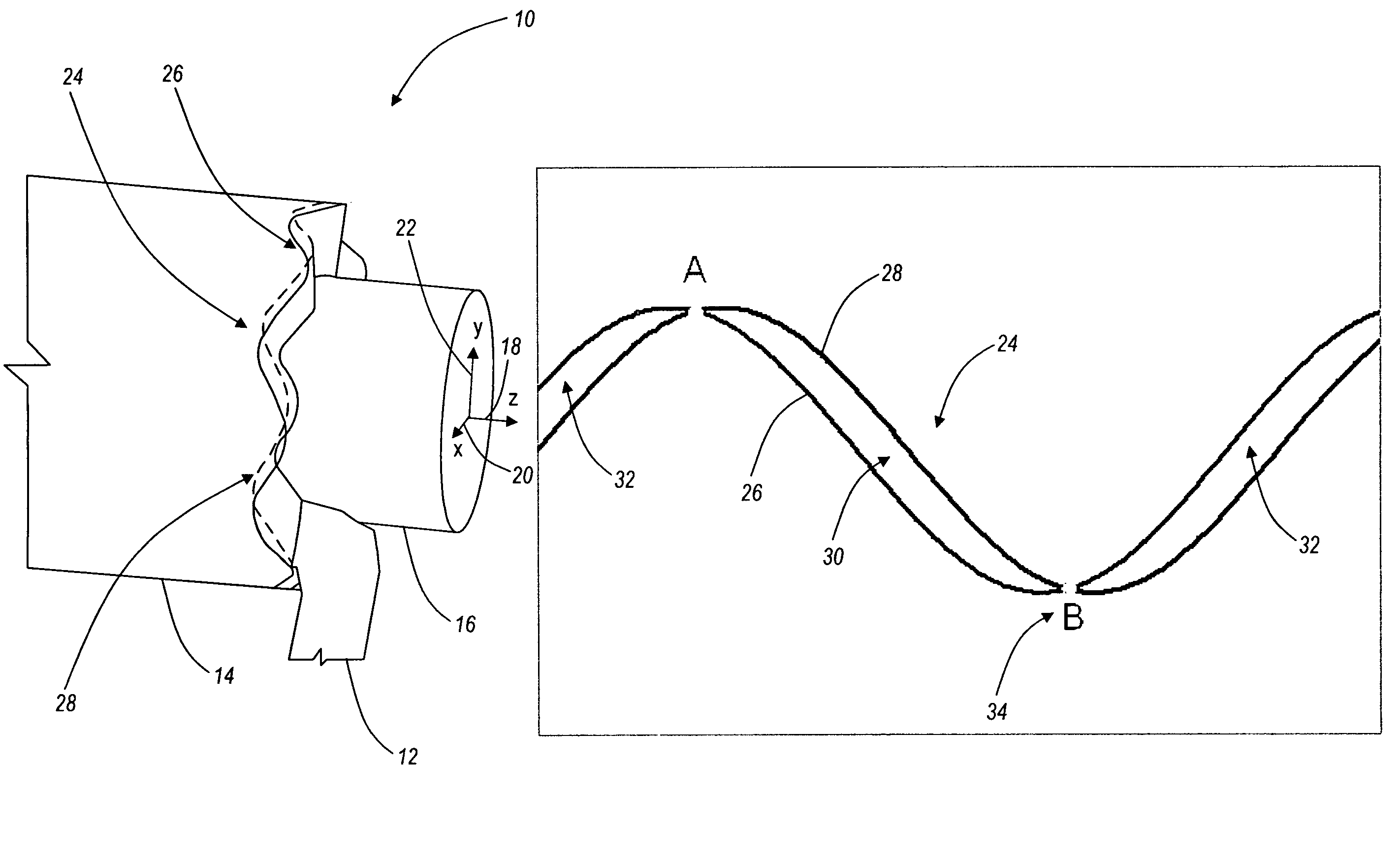

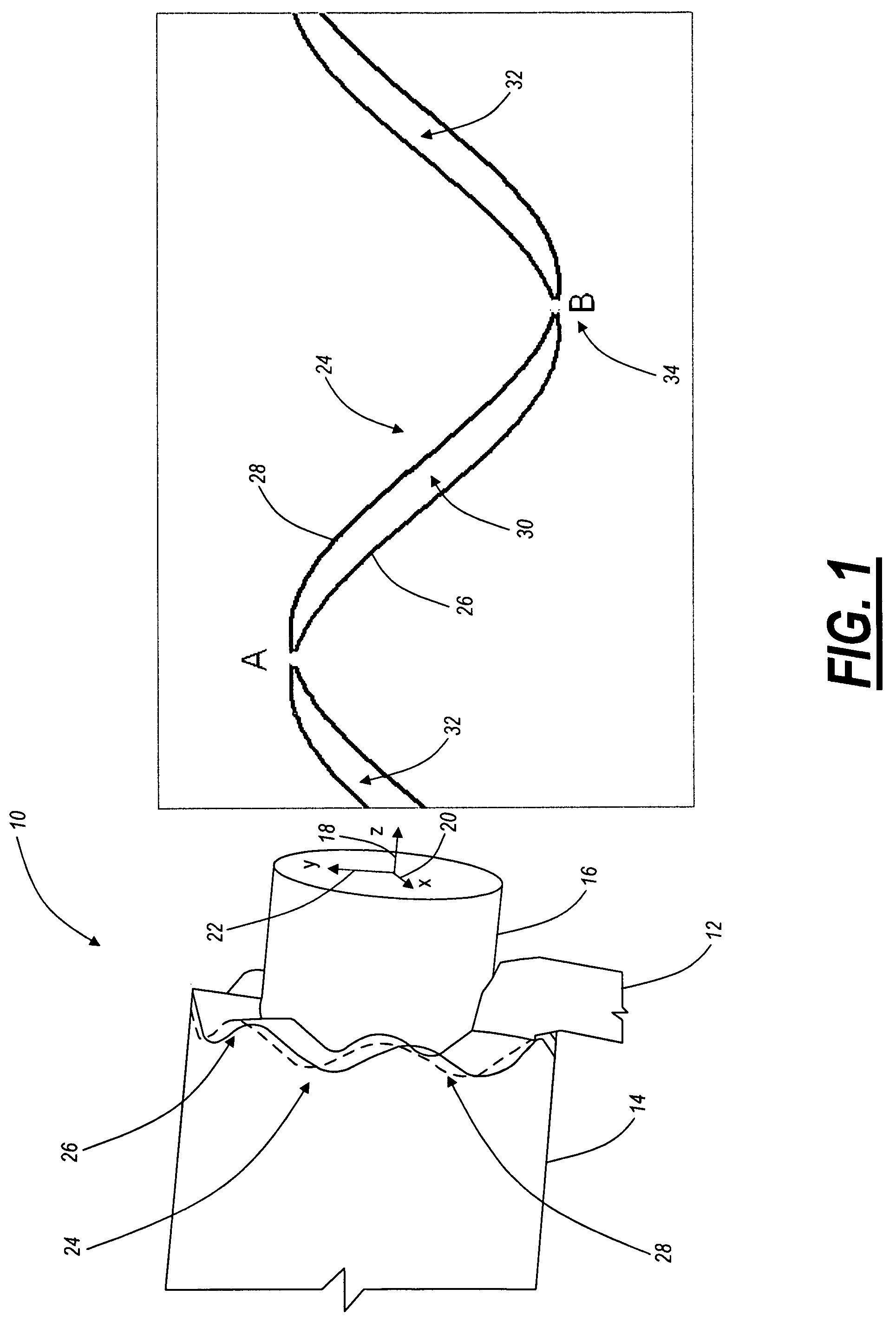

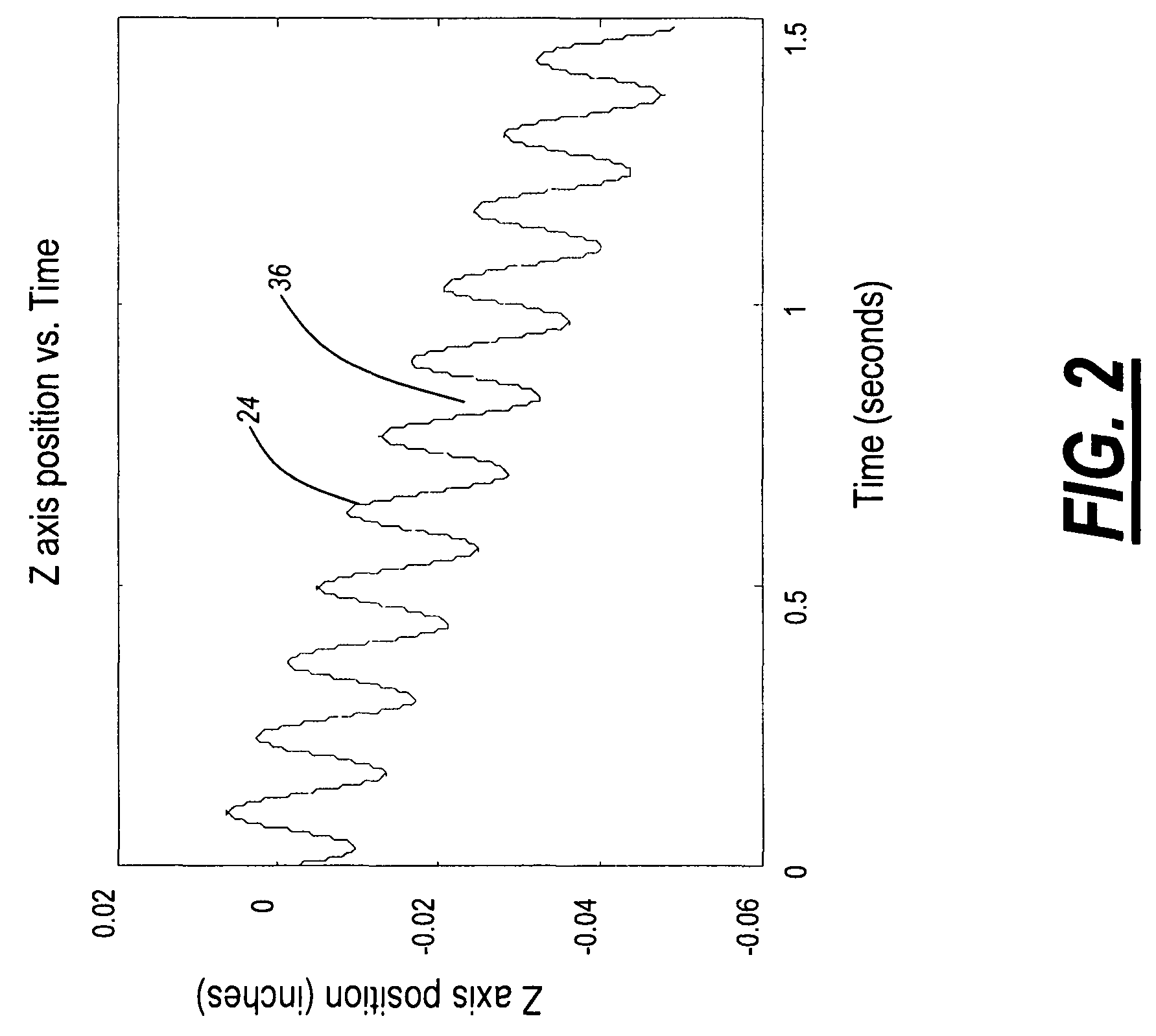

The present invention provides methods and systems for chip breaking, controlling cutting tool wear, and the like in turning, boring, and other applications, including: engaging a workpiece with a cutting tool in a feed direction along a toolpath, superimposing an oscillation in the feed direction on the toolpath, and dynamically or non-dynamically varying the oscillation superimposed in the feed direction on the toolpath such that interrupted cuts and chips of a predetermined length or less are produced. These systems take full advantage of computer numerical control (CNC) methodologies.

Owner:JUNIVERSITI OF NORT KAROLINA EHT SHARLOTT +1

Cutting tool wear sleeves and retention apparatuses

Owner:FREAR JOSEPH K

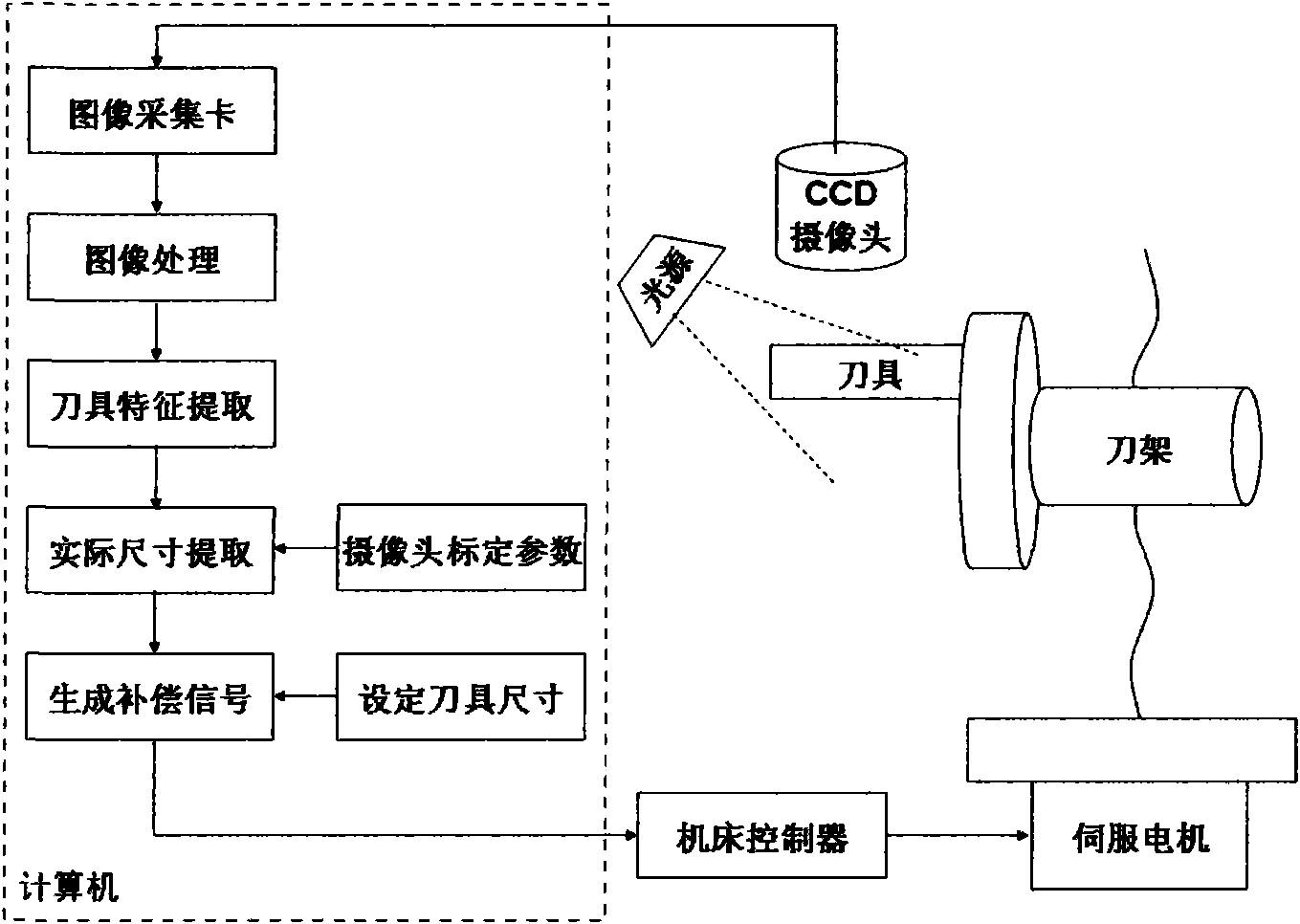

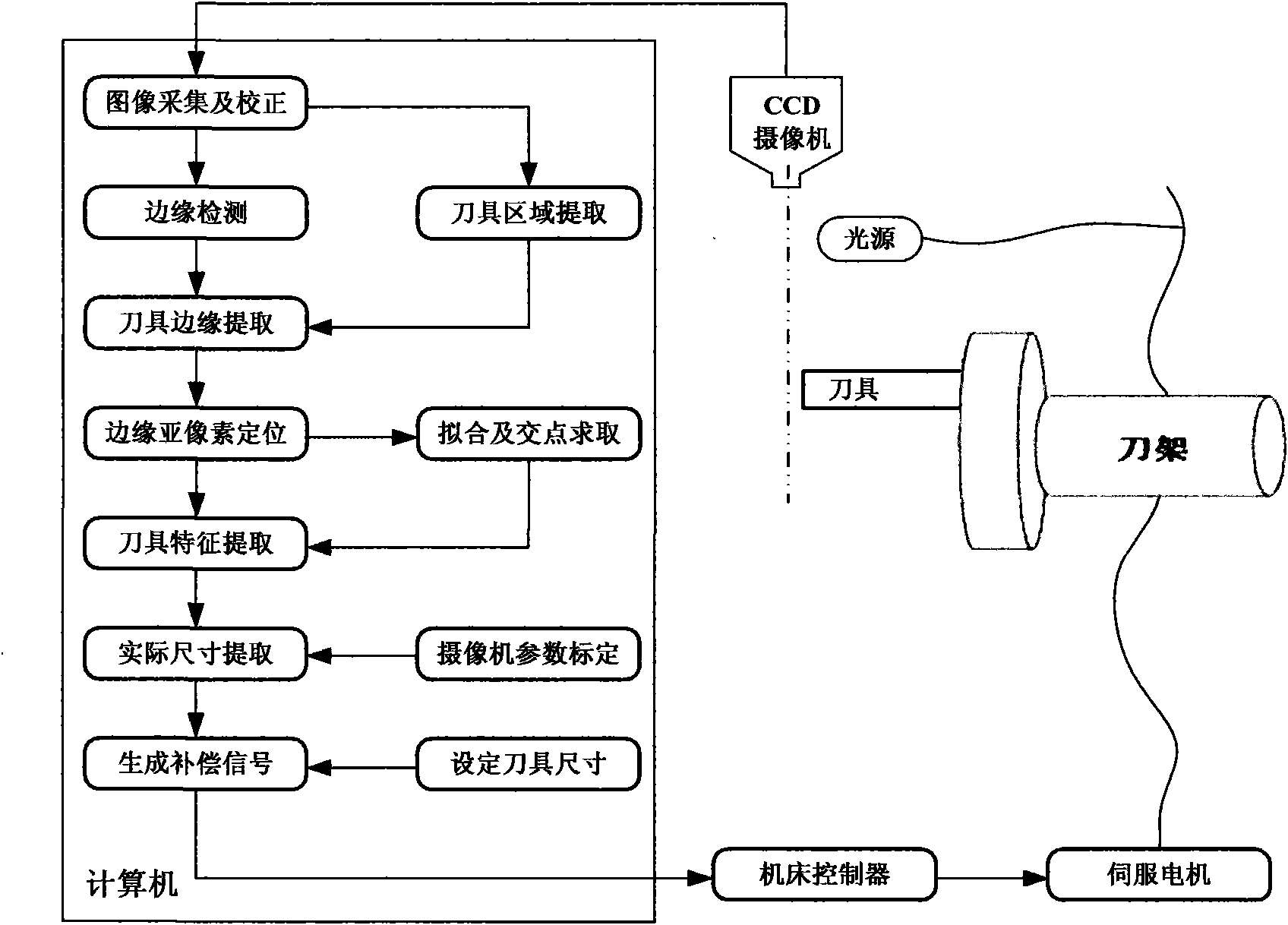

Image-based on-line detection and compensation system and method for cutting tools

InactiveCN101549468AOvercome the amount of wearAvoid interferenceProgramme controlAutomatic control devicesEngineeringMachine tool

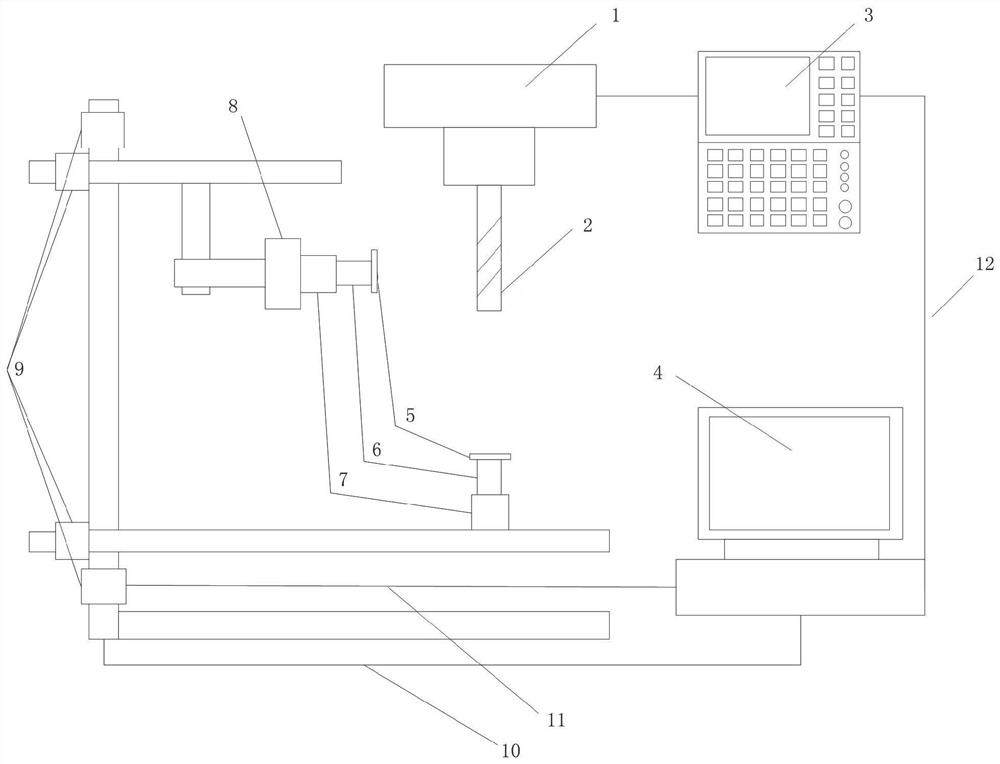

The invention discloses a kind of image-based online detection and compensation method for cutting tools which is used for online detection of the tool wear amount on the machine tool and compensation based on the wear amount, including the following steps: lay out camera equipment, and take the photo of the cutting tools installed on the machine tool through the camera; calibrate the images taken; extract the cutting tool features; convert the cutting tool features into the actual sizes through the camera parameter calibration; compare the actual sizes with the pre-set cutting tool sizes to generate compensation signals; supply the referred compensation signals to the machine tool controller and use machine tool controller to drive the servo motor to compensate for the deviation generated by cutting tool wear.

Owner:BEIJING UNIV OF POSTS & TELECOMM

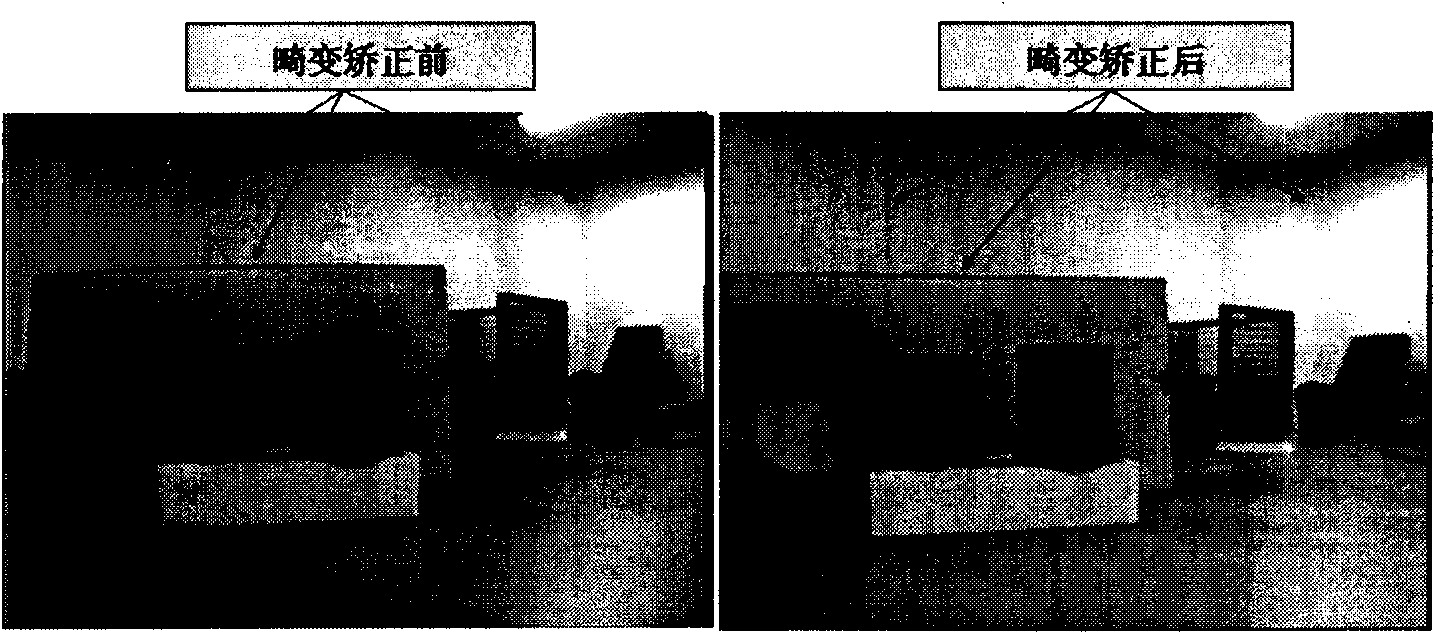

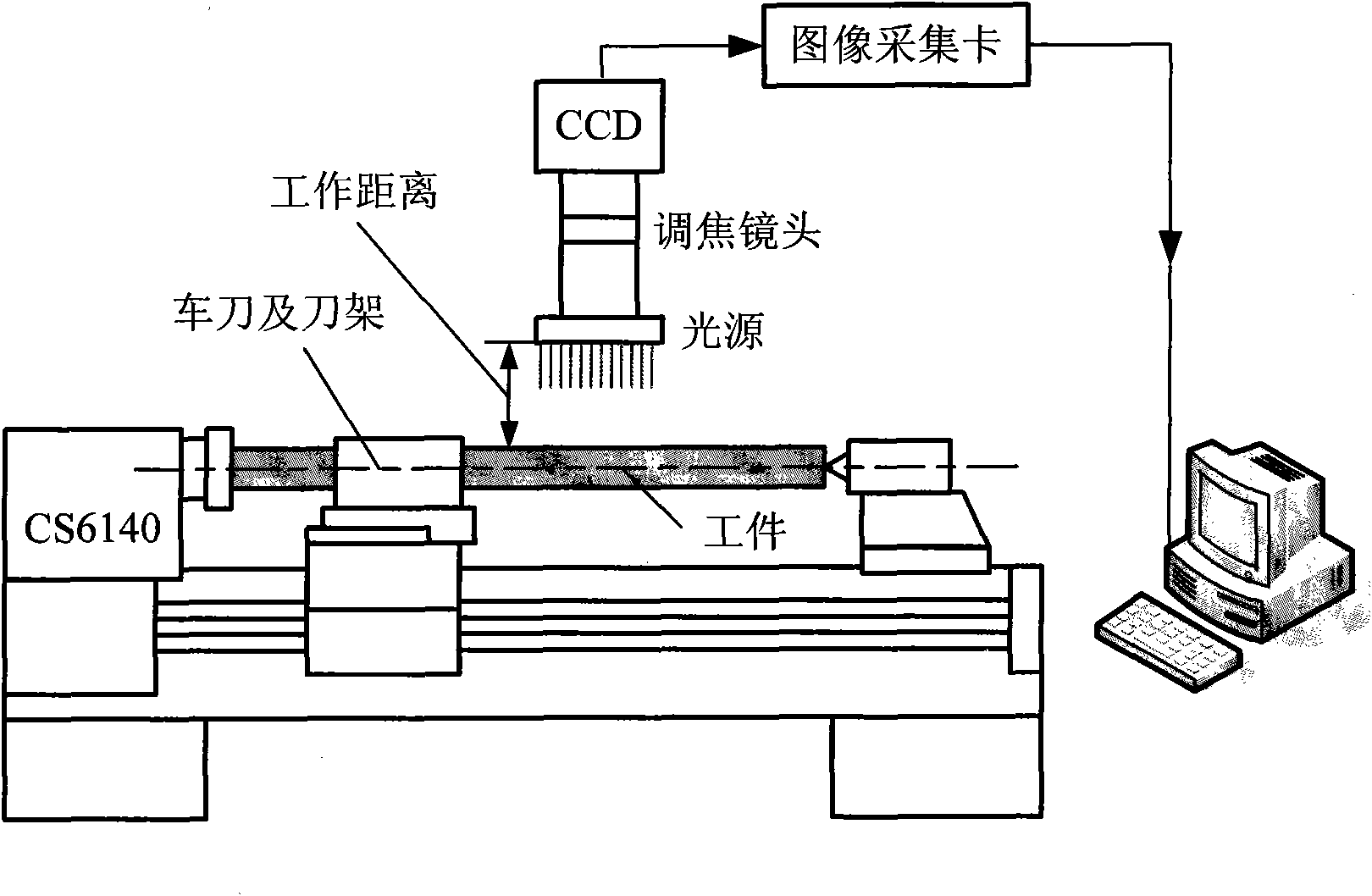

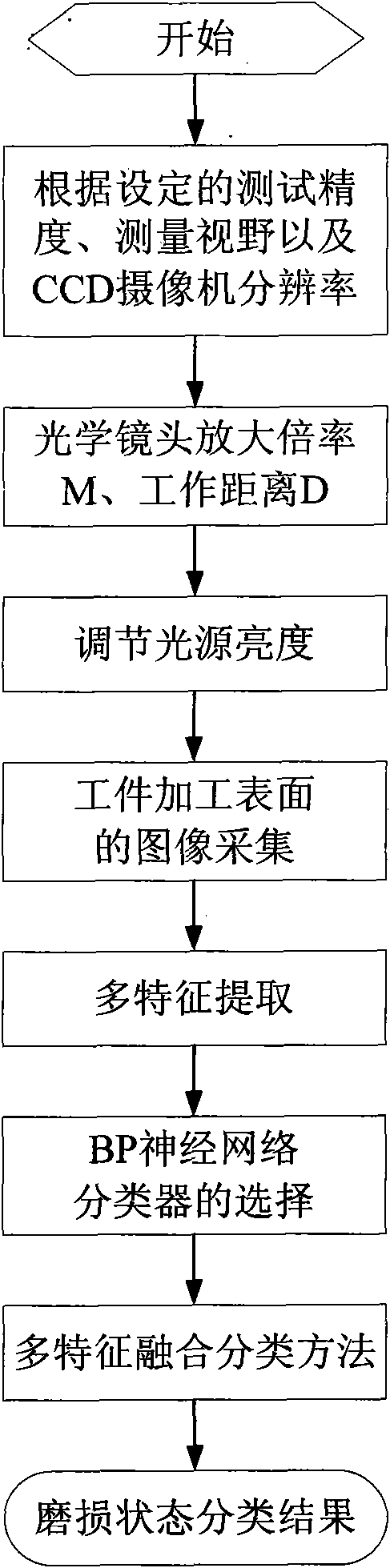

Cutting-tool wear state evaluating method based on image analysis of workpiece machining surface

InactiveCN101670533AOvercome the shortcomings of monitoringTo achieve an organic combinationMeasurement/indication equipmentsCharacter and pattern recognitionImaging analysisNeural network classifier

The invention provides a cutting-tool wear state evaluating method based on image analysis of a workpiece machining surface. The method comprises the following steps: firstly acquiring a texture imageof the workpiece machining surface by utilizing optical system imaging; then carrying out multi-feature extractions on the machining surface image and forming a BP neural network classifier facing the machining surface image according to the number of the multi-feature extractions; and adopting a fusion method based on a voting system to fuse the multi-feature classifier so as to realize the qualitative and the quantitative identification of cutting-tool wear and breakage states. The invention can better overcome the defect that the on-line image acquisition of cutting points of a cutting-tool cannot be carried out in a cutting machining process, accurately identify the wear and breakage states of the cutting-tool and can be applied to the cutting-tool on-line monitoring of numeral control machining tools.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

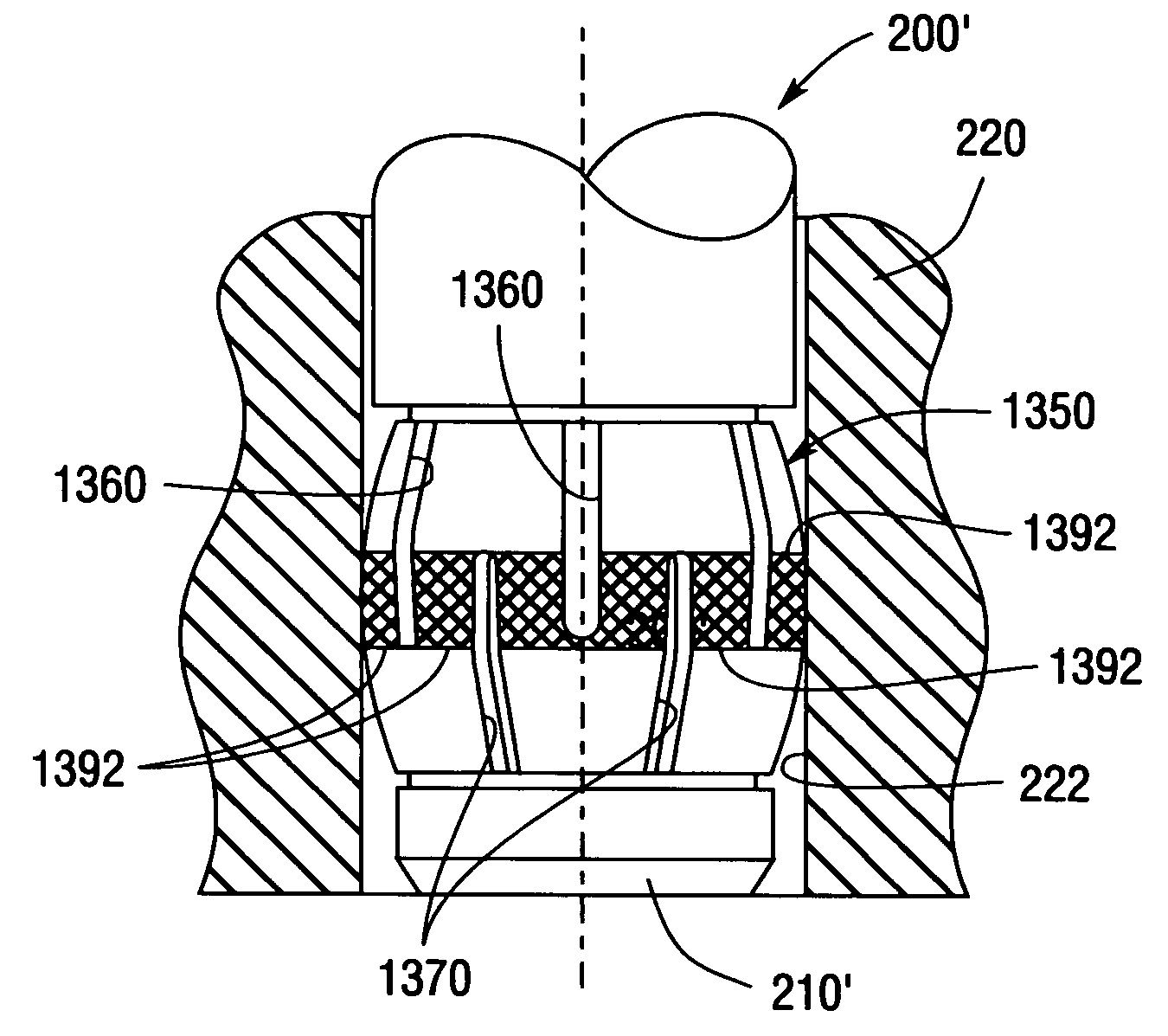

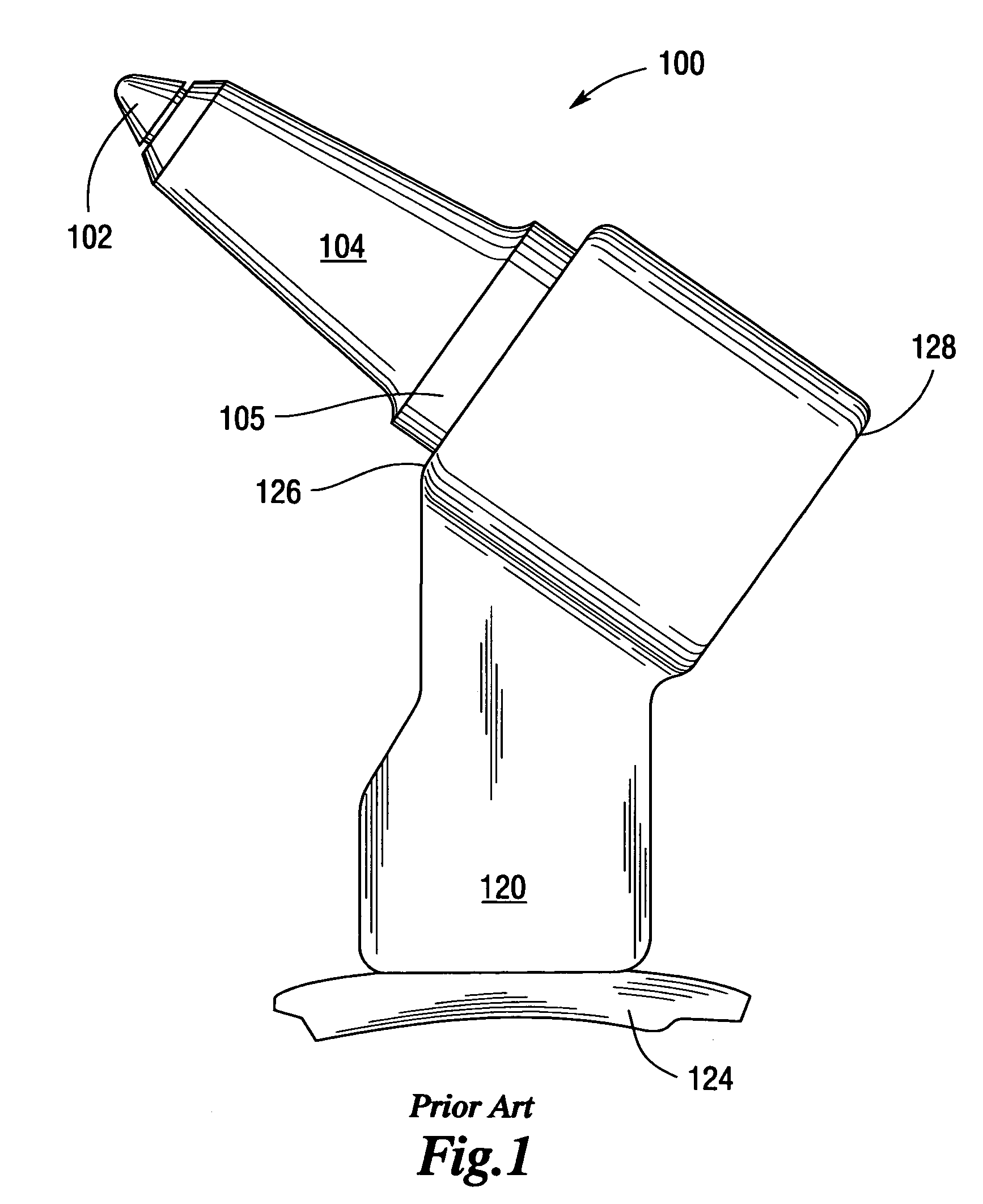

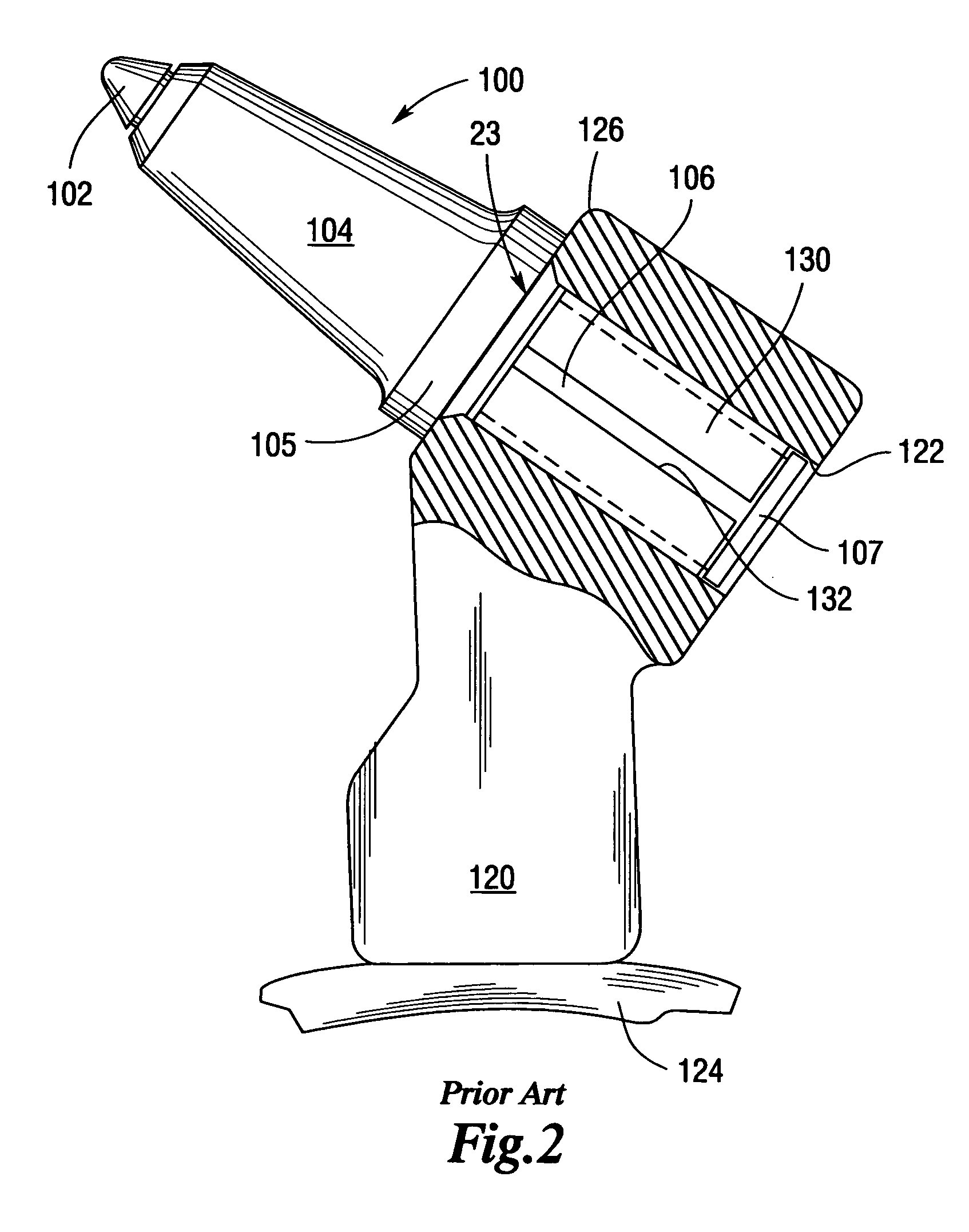

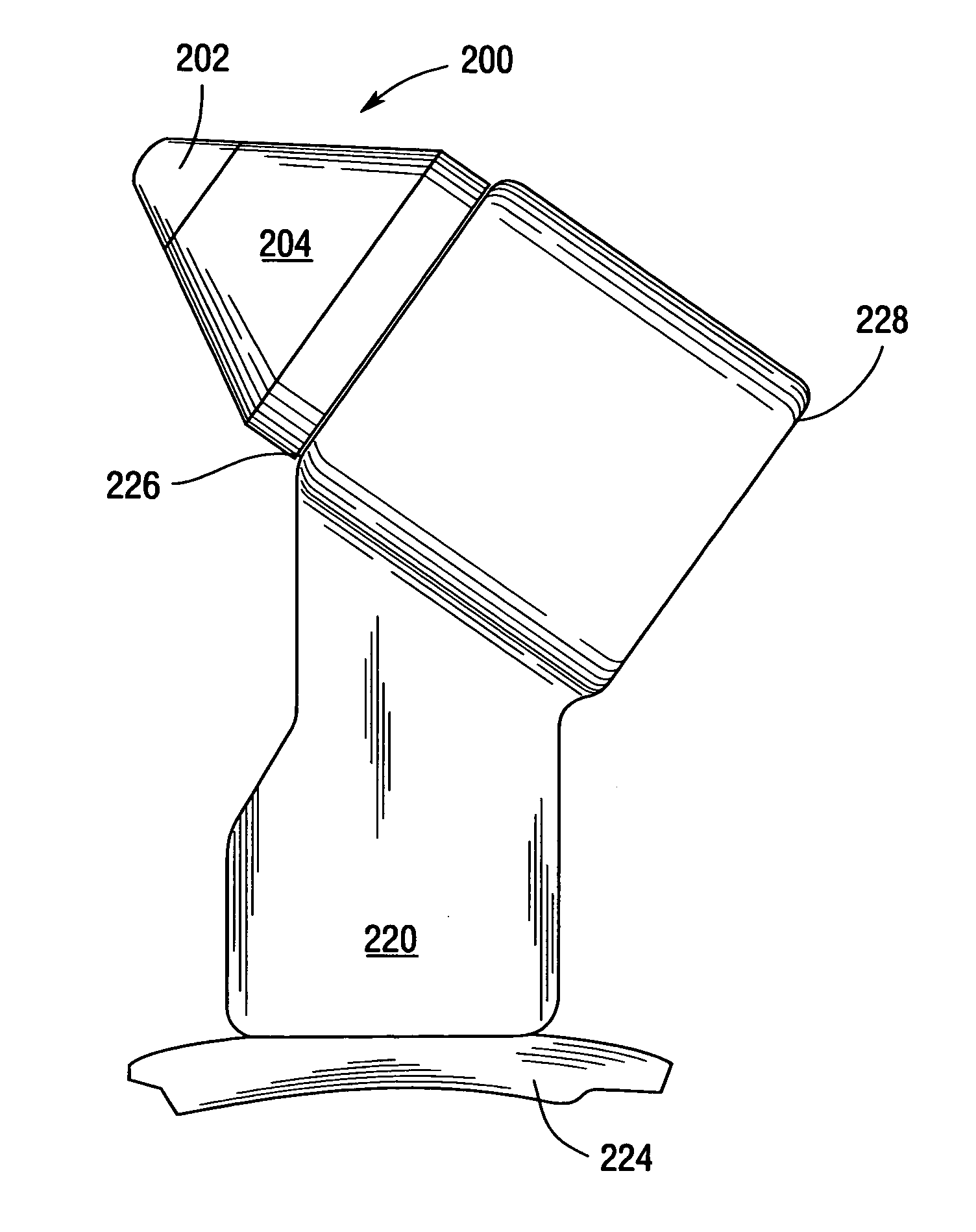

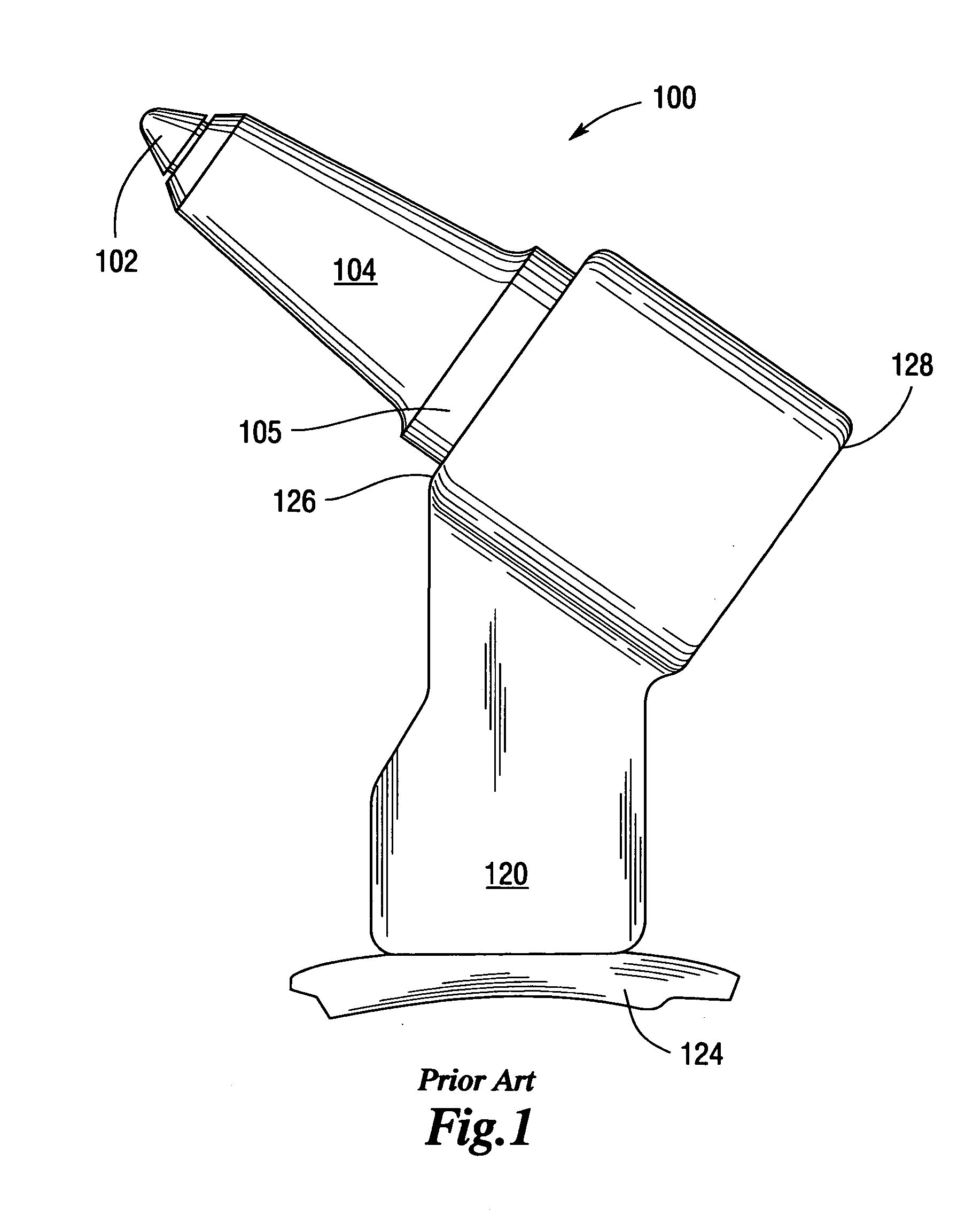

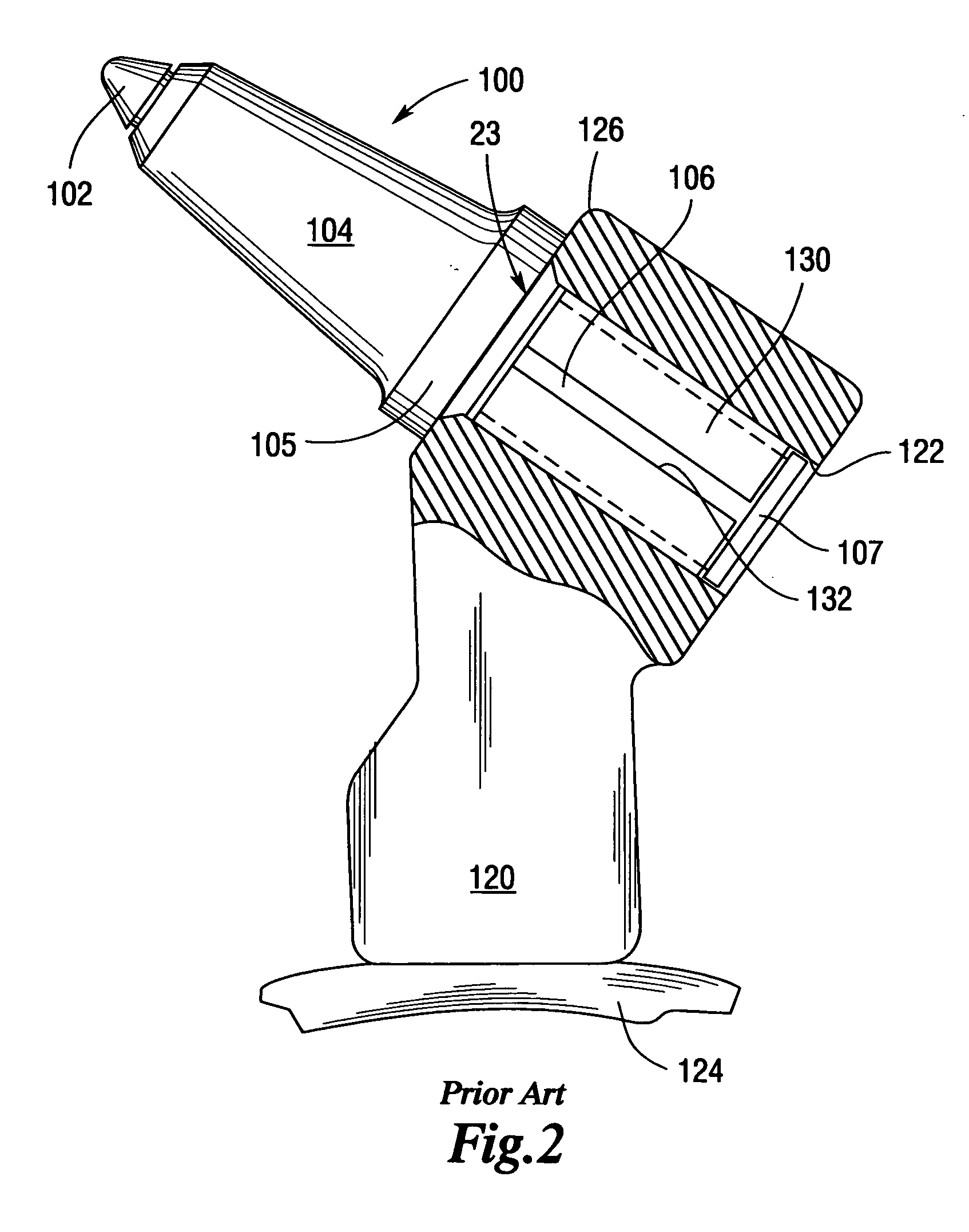

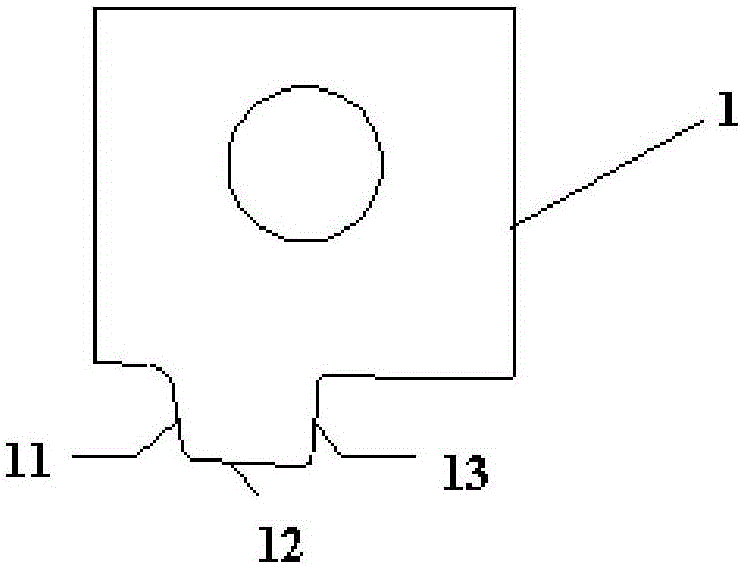

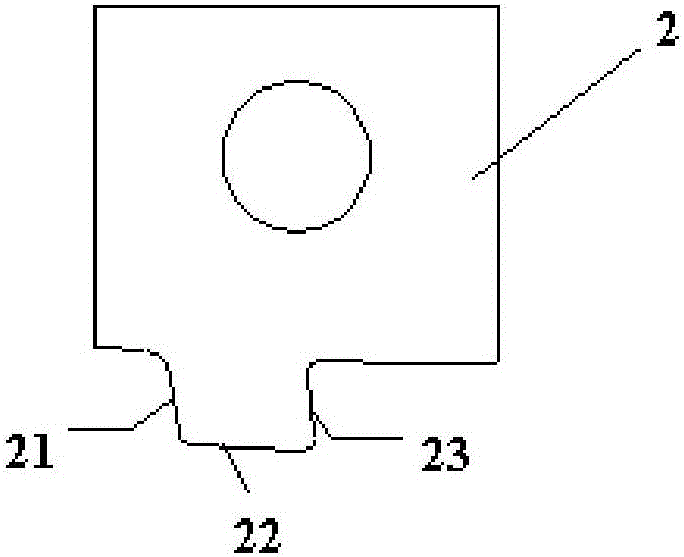

Cutting tool wear sleeves and retention apparatuses

Cutting tool assemblies and wear and retention sleeves. The assemblies may include a support block that has a sleeve-receiving hole therethrough and a cutting tool that has an elongated shank. Various configurations of sleeves are disclosed for supporting the elongated shank of the cutting bit in the support block. Such sleeve embodiments may be provided with a plurality of axially extending overlapping notches to establish segments of various degrees of interference fit between the sleeve and the support block when seated in the sleeve-receiving hole of the support block. Some sleeve embodiments are configured to permit the shank of a cutting bit to freely rotate therein. Other sleeve embodiments are configured to prevent rotation of the cutting bit shank when inserted therein.

Owner:FREAR JOSEPH K

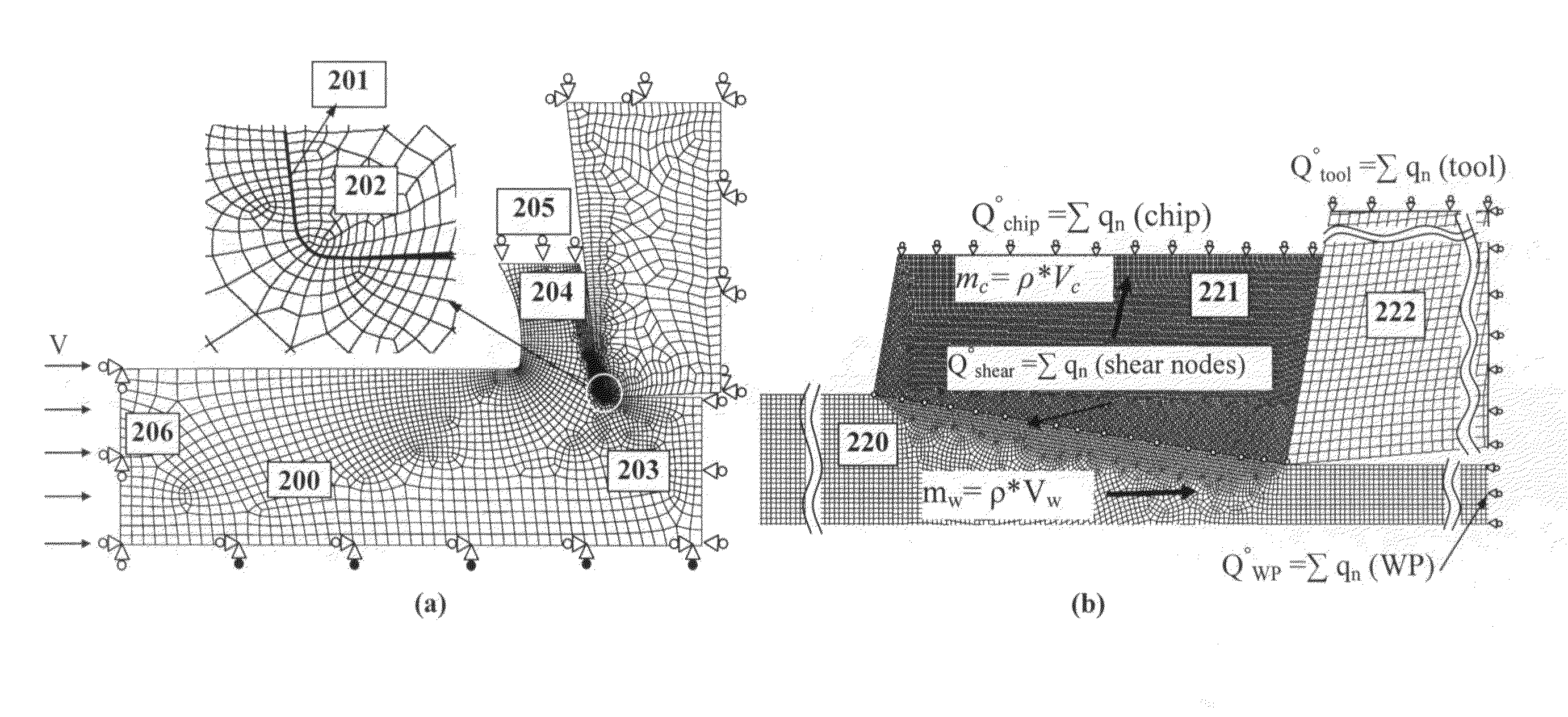

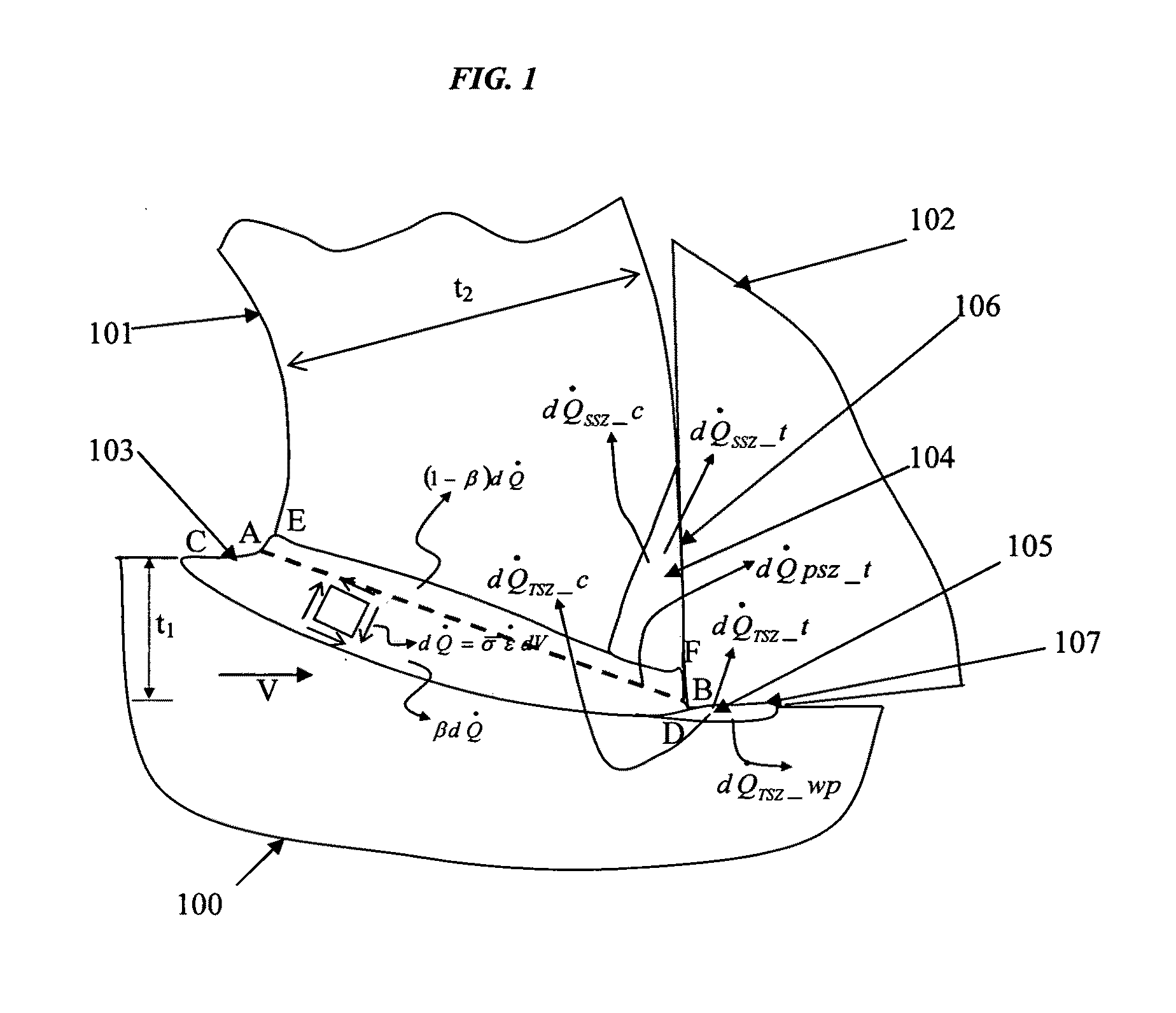

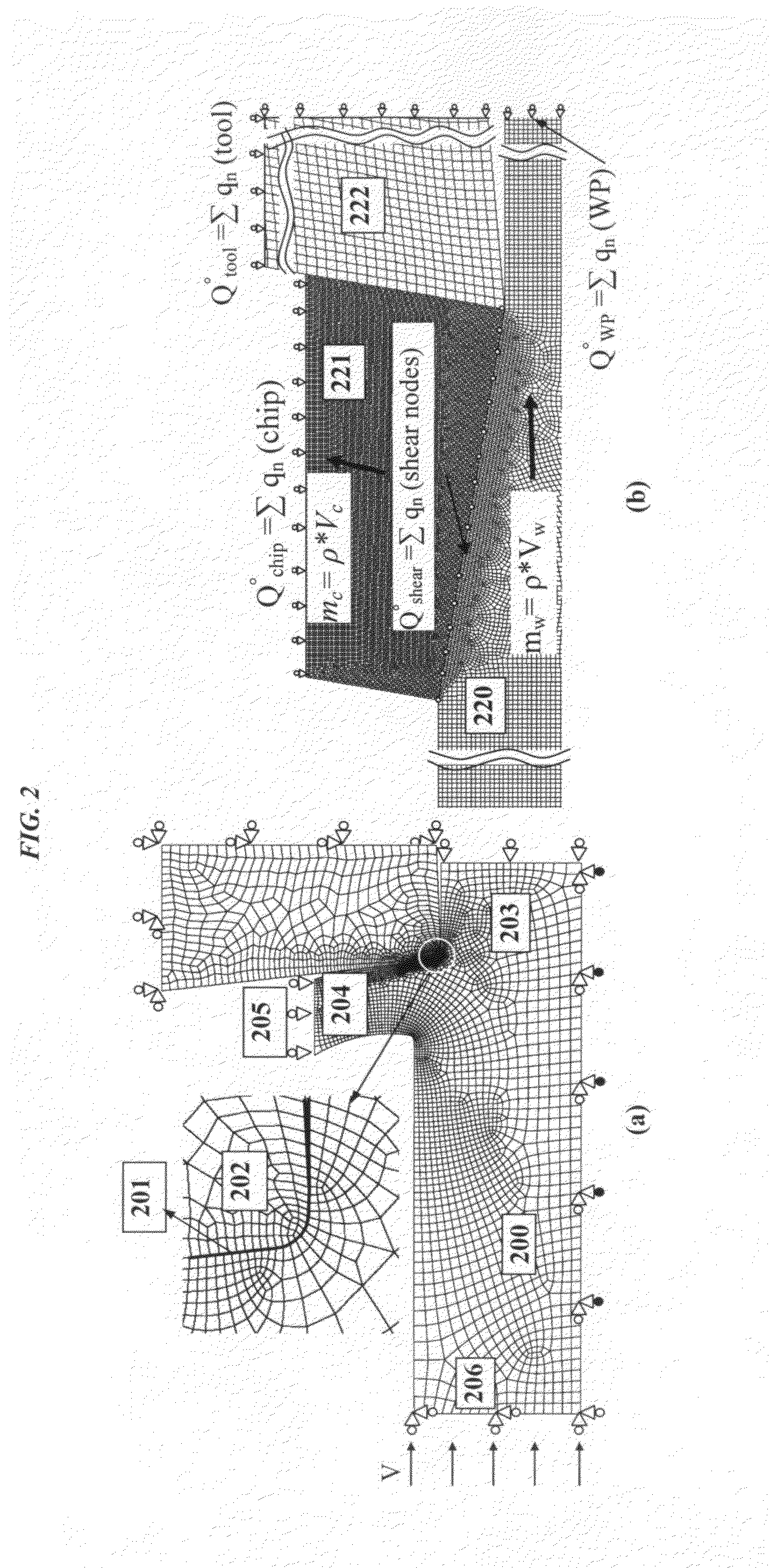

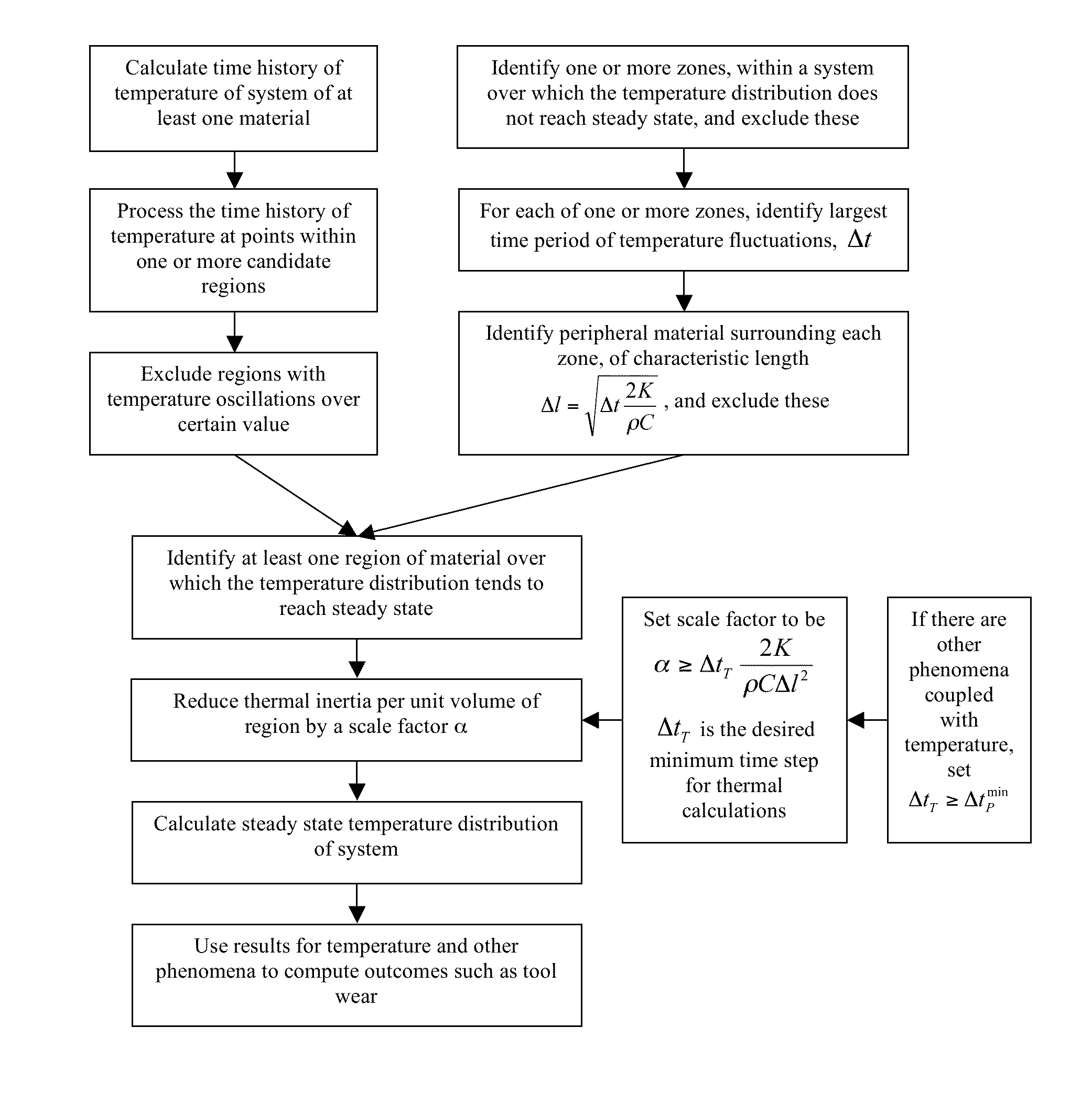

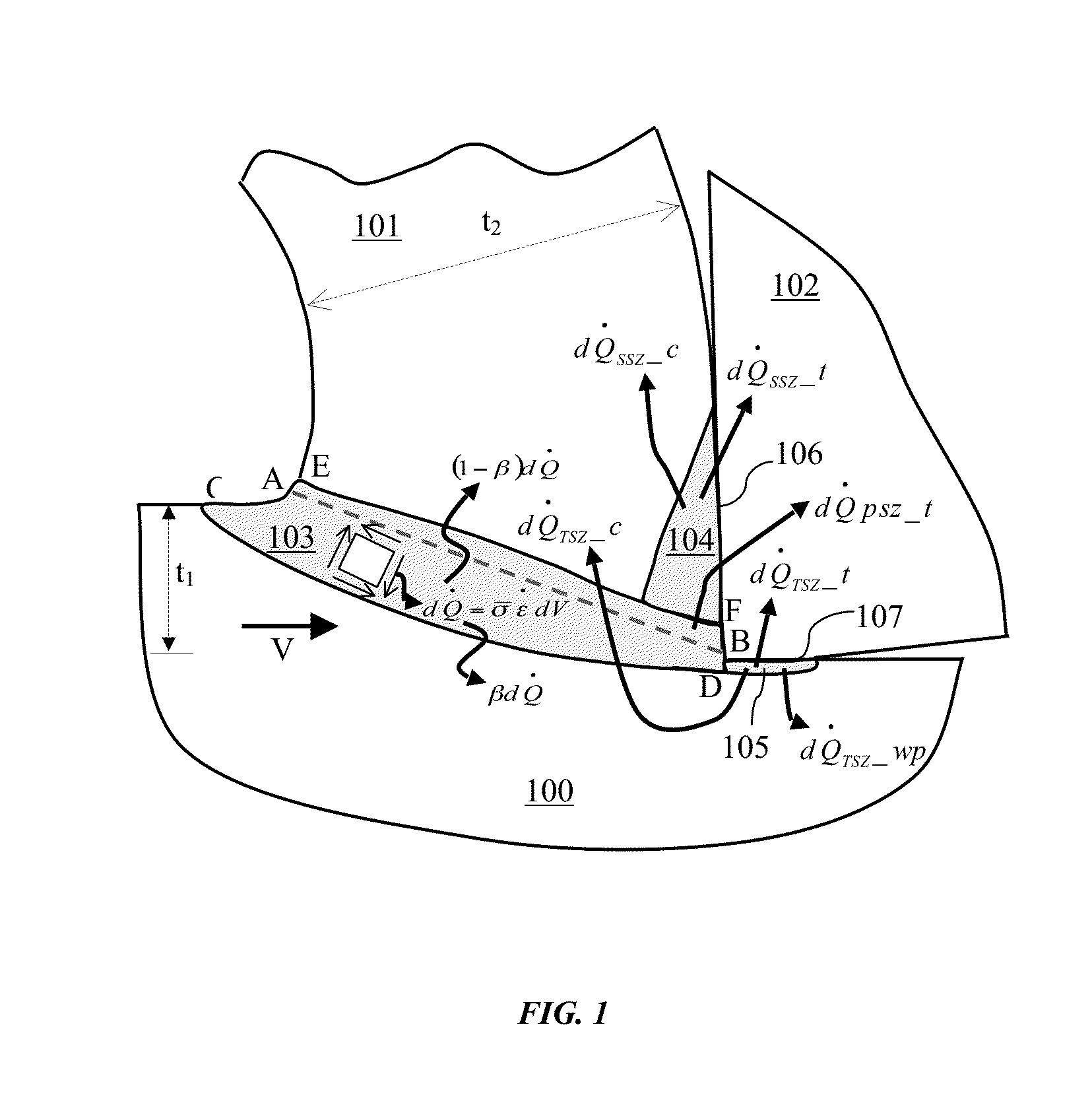

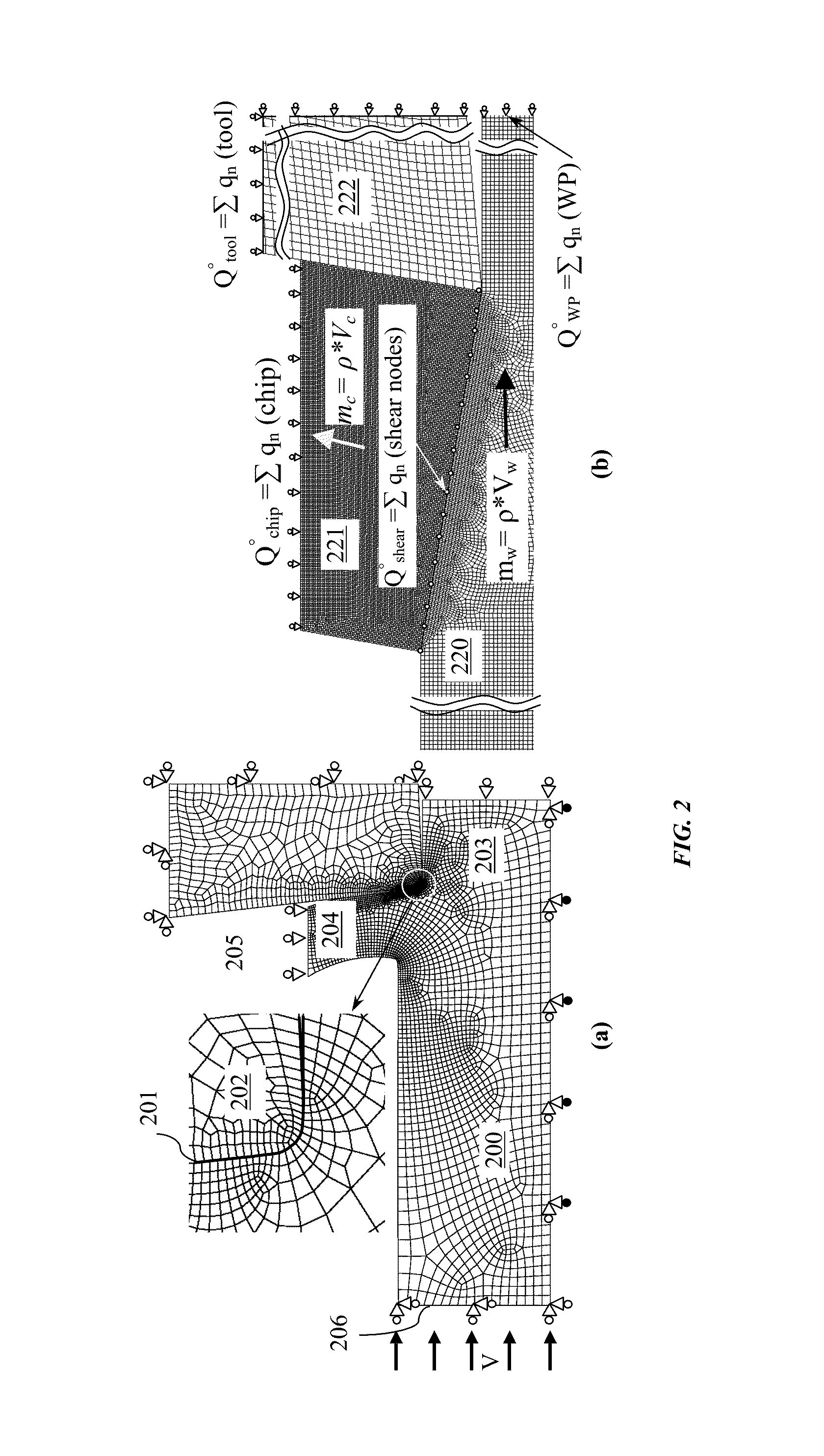

Thermal modeling of an orthogonal machining process

ActiveUS20100174515A1Lower the volumeNo loss of accuracyComputation using non-denominational number representationDesign optimisation/simulationSteady state temperatureElement analysis

A novel procedure is disclosed, that can be incorporated into Finite Element Analysis (FEA) or other similar analysis techniques, to obtain the steady state temperature distribution in a coupled transient heat transfer analysis rapidly as well as accurately. A scale factor is used to reduce the thermal inertia per unit volume (specific heat capacity) in regions of steady state temperature distribution, thereby hastening the achievement of steady state. An application of this procedure to estimate steady state temperature distributions within cutting tools, and the estimation of cutting tool wear based on the obtained steady state temperature distributions is shown as an example.

Owner:MADHAVAN VISWANATHAN +1

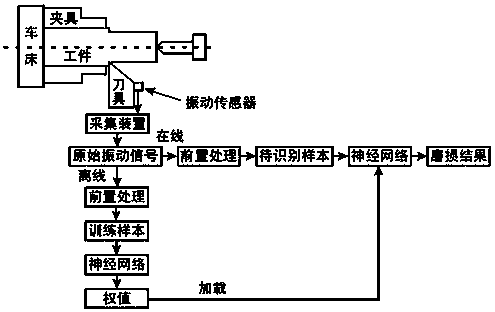

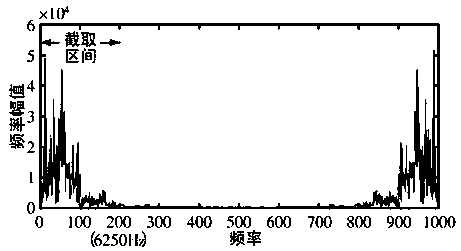

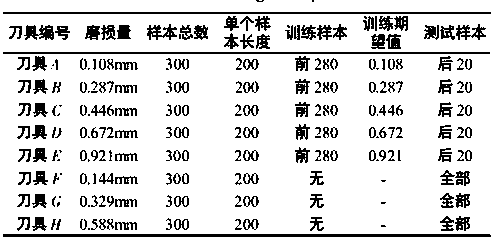

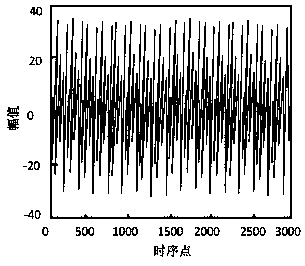

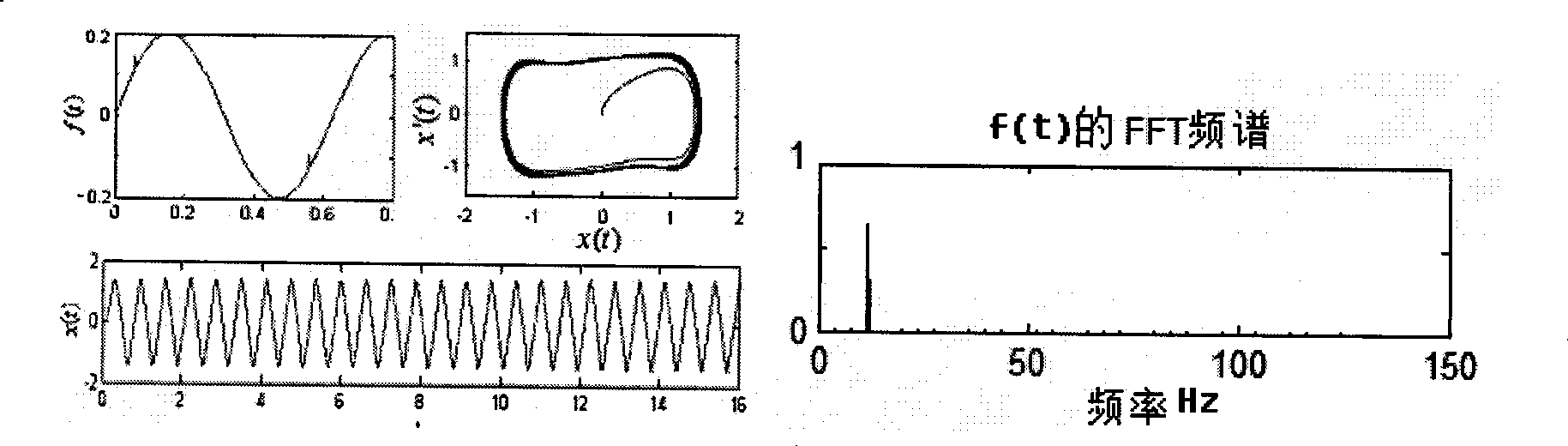

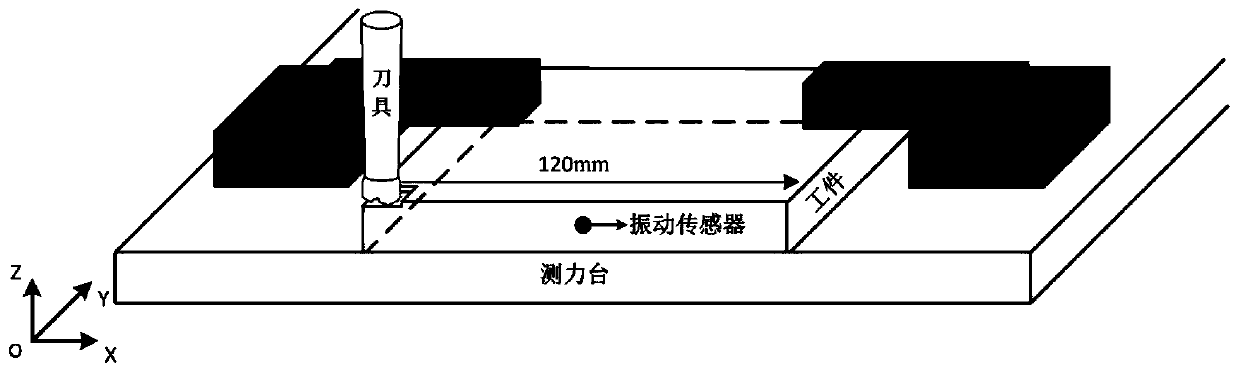

Cutting tool wear measurement method based on vibration spectrum and neural network

InactiveCN108747590AFast and efficient wear detectionEfficient detectionMeasurement/indication equipmentsVibration amplitudeFrequency spectrum

The invention provides a method for estimating cutting tool wear by vibration spectrum. The method comprises the steps: collecting a vibration signal in the cutting process by using a vibration sensor, and conducting Fourier transform for the vibration signal; inputting a vibration amplitude value of a spectrum concentration area into a neural network for training; establishing a mapping relationship between the vibration spectrum and cutting tool wear extent, and thus forecasting cutting tool wear.

Owner:HARBIN UNIV OF SCI & TECH

Method for quickly selecting cutting tool materials

InactiveCN101625298AImprove measurement efficiencyInvestigating abrasion/wear resistanceStatistical analysisEngineering

The invention relates to a method for quickly selecting cutting tool materials, which comprises the following five steps: step 1: selecting various cutting tool materials which are suitable for processing certain workpiece materials in the prior market; step 2: arranging single-factor cutting tool wear tests by using cutting tool materials as contrast factors; step 3: only carrying out primary wear tests for each group of wear tests; step 4: calculating and comparing primary wear rate values of each cutting tool; and step 5: quickly and preferably selecting proper cutting tool materials according to the evaluation standard of the invention. The method for quickly selecting cutting tool materials can avoid standard cutting tool wear tests during selecting the cutting tool materials by using the research results of statistical analysis of cutting tool wear, thereby quickly and effectively selecting one or more kinds of preferable cutting tool materials. The invention has wide utility value and application prospects in the metal cutting field.

Owner:BEIHANG UNIV

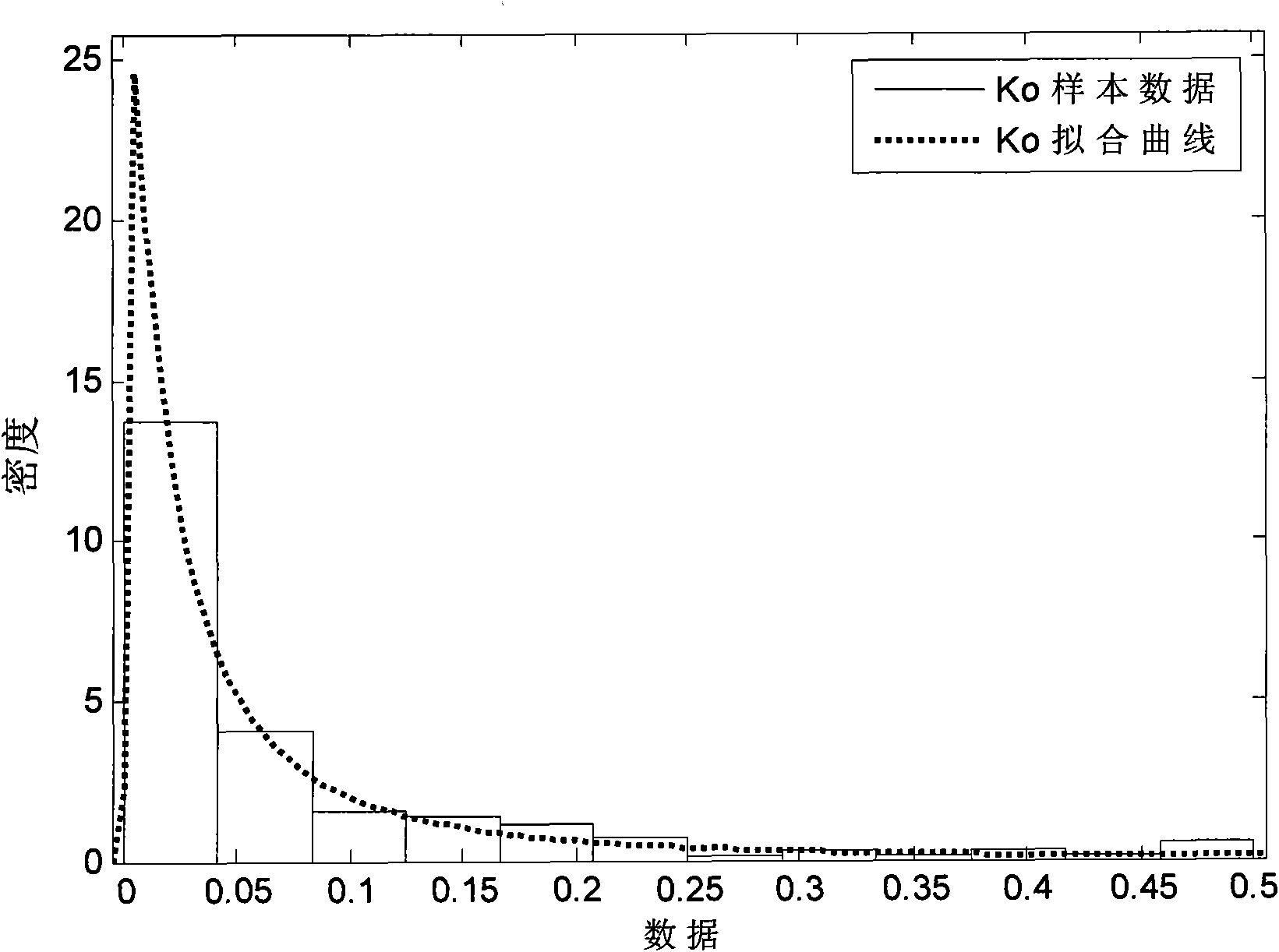

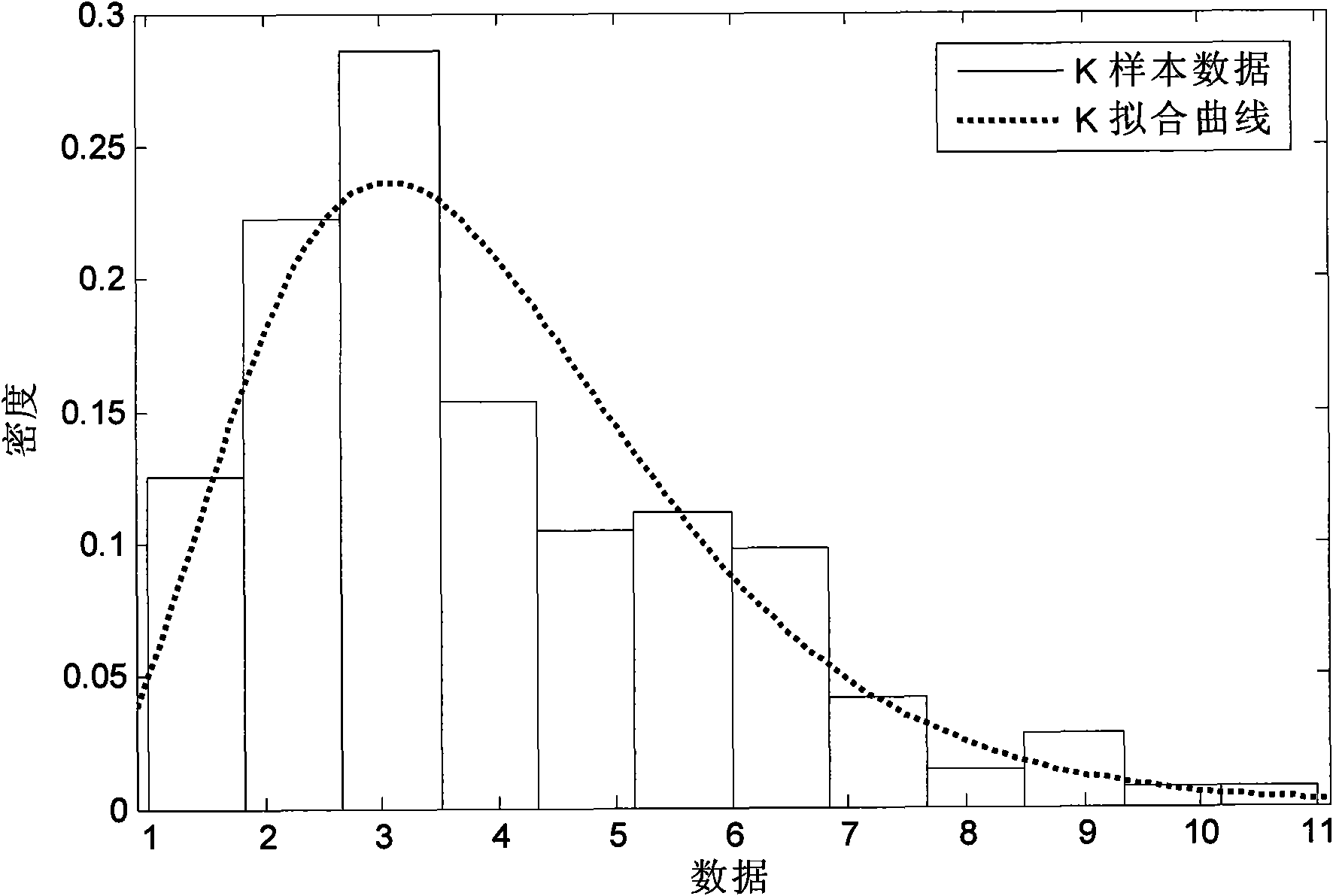

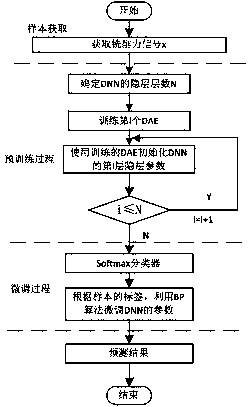

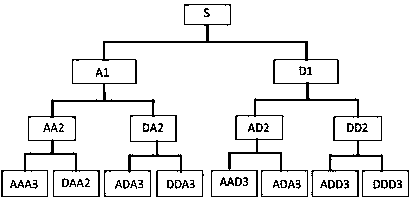

Milling cutter wear states monitoring method based on deep neural network

InactiveCN109434564AAvoid dependenceReduce the impactMeasurement/indication equipmentsHidden layerMilling cutter

The invention relates to a milling cutter wear states monitoring method based on a deep neural network. The milling cutter wear states monitoring method based on the deep neural network comprises thefollowing steps of 1, collecting cutting force signals in machining process; 2, carrying out wavelet packet decomposition on collected cutting force signals by using 6-layer db 8 wavelet; and 3, using64 sub-energy bands as inputs of DNN network. Multiple DAEs are stacked layer by layer to form a DNN hidden layer structure, and fault information is extracted layer by layer through unsupervised learning layer by layer. After pre-training is completed, an output layer with a classification function is added, parameters of the DNN are finely adjusted by using a BP algorithm, and finally cutting tool wear states can be predicted. The milling cutter wear states monitoring method based on the deep neural network can be adopted without dependence on experience of signal processing experts, wear states of the milling cutter under different machining conditions can be rapidly and accurately recognized; and the milling cutter wear states monitoring method based on the deep neural network has thecharacteristics of being high in monitoring precision, adaptability and the like.

Owner:HARBIN UNIV OF SCI & TECH

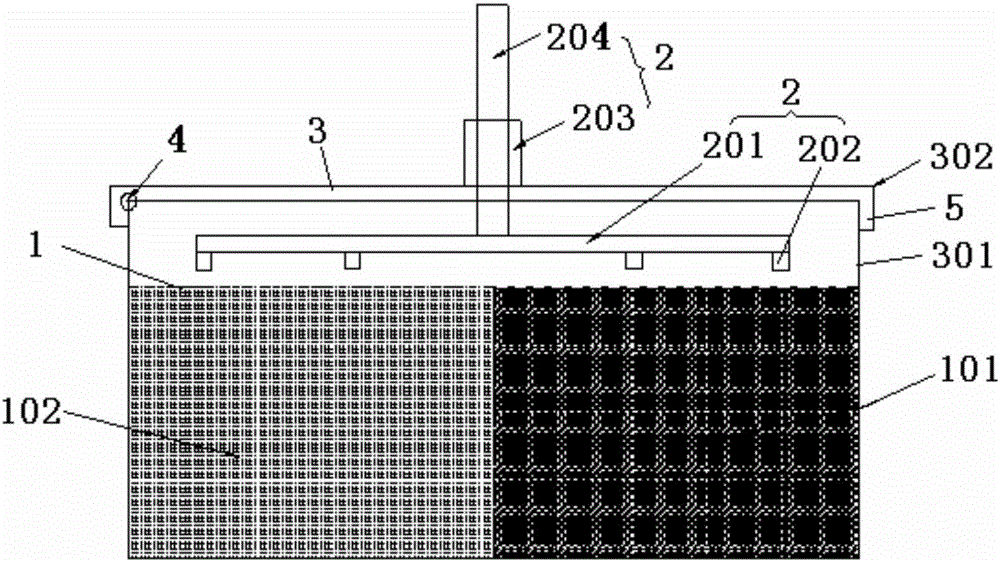

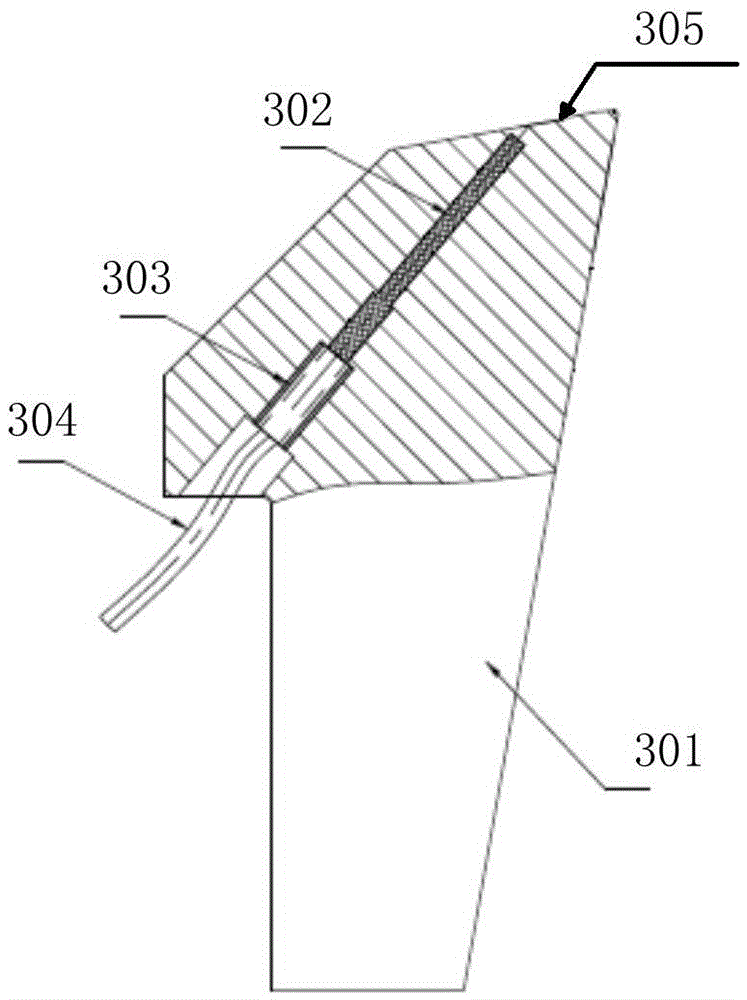

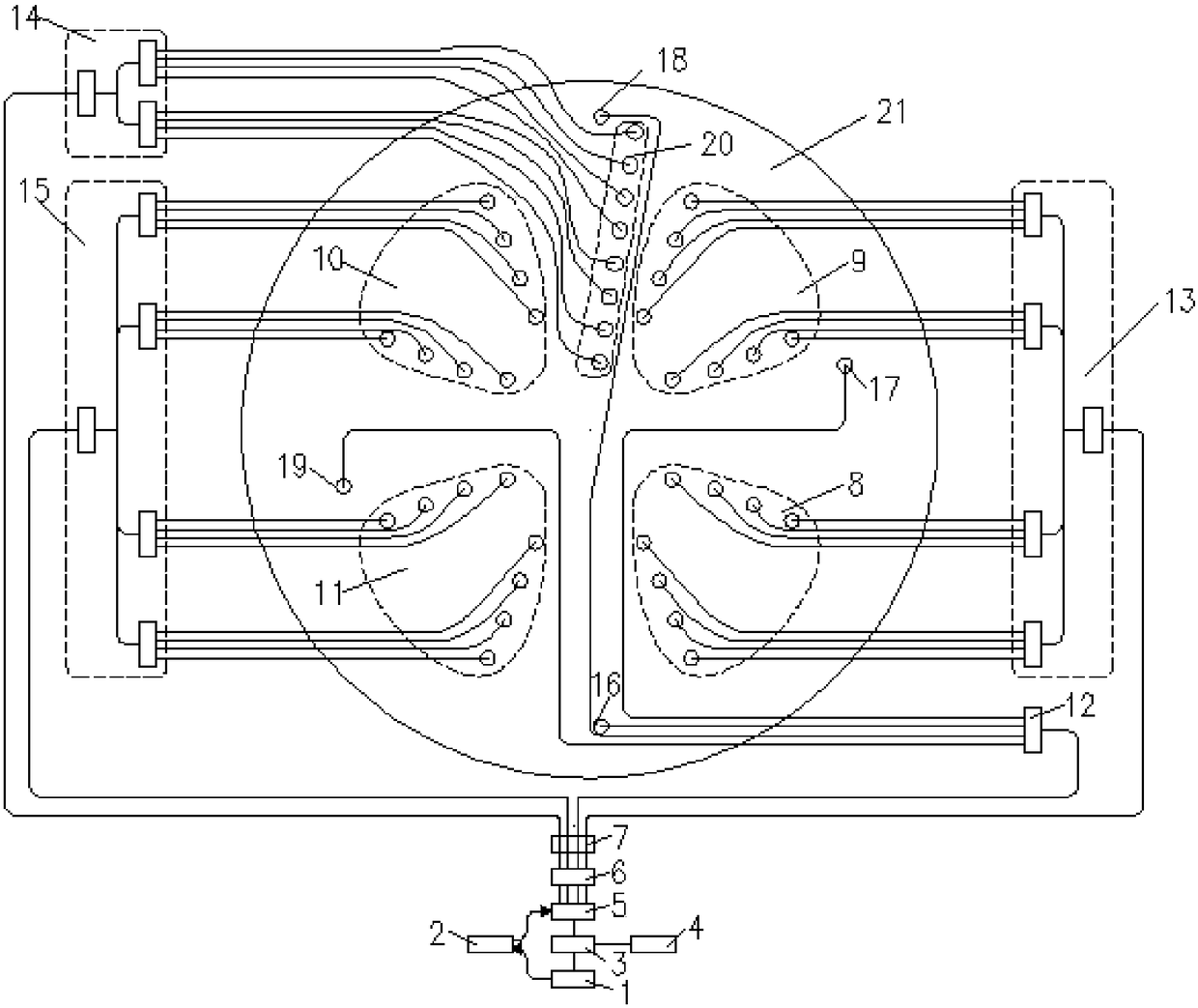

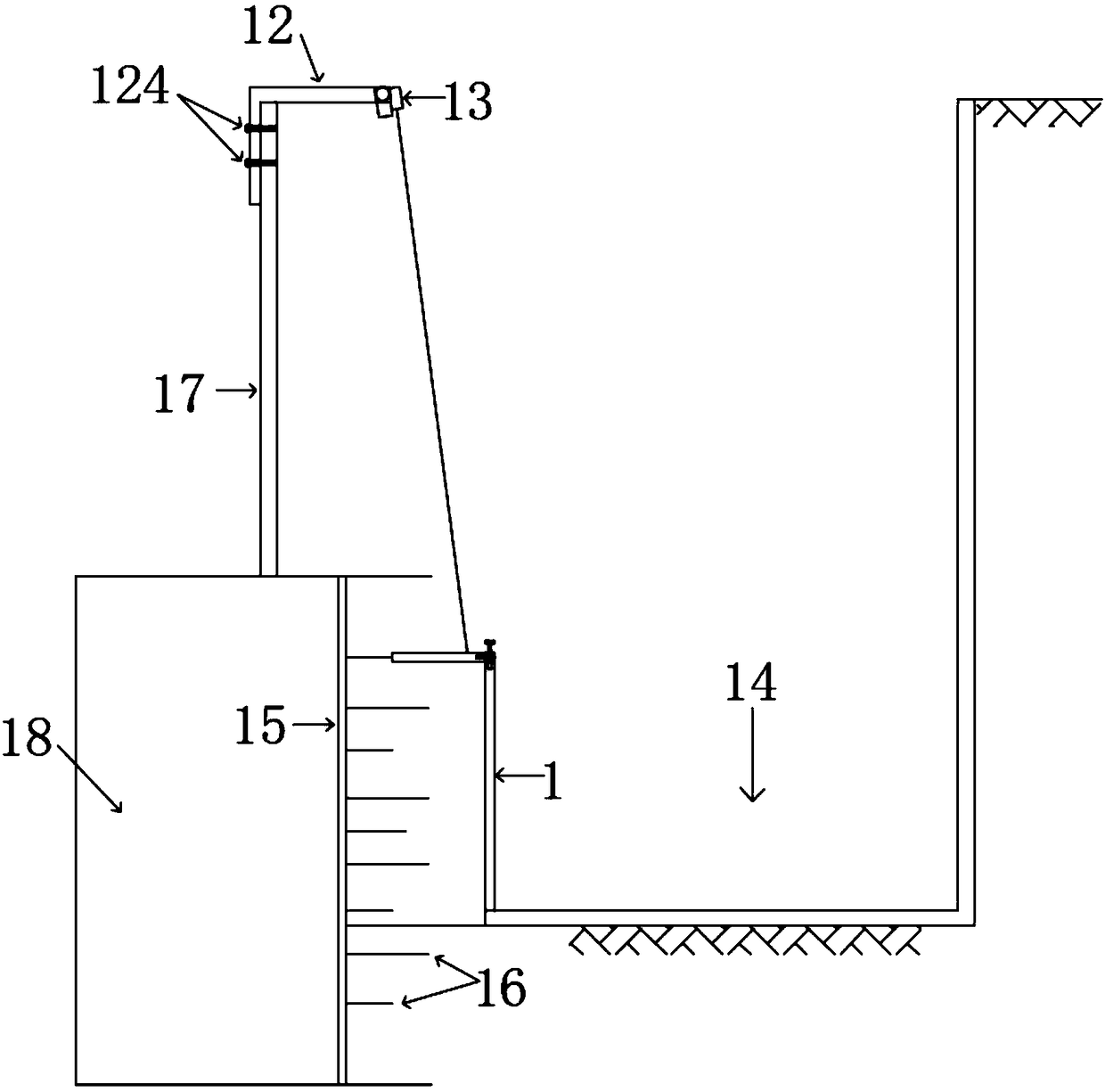

Shield machine cutter wear simulation testing device and method for upper-soft lower-hard stratum

InactiveCN106441751AImprove construction progressImprove construction efficiencyElasticity measurementEngineeringModel test

The invention provides a shield machine cutter wear simulation testing device and a shield machine cutting tool wear simulation testing method for an upper-soft lower-hard stratum. The shield machine cutter wear simulation testing device for the upper-soft lower-hard stratum comprises a simulate soil body used for simulating a site survey soil state of the upper-soft lower-hard stratum and a shield cutter head simulation device used for simulating rotation and tunneling of a cutter portion of a shield machine, wherein the simulate soil body is filled in a model test box, a simulate cutter head and a simulate cutter, obtained by simulating a real cutter head and a real cutter according to a scaled down rule, are arranged at an output end of the shield cutter head simulation device, and the simulate cutter head and the simulate cutter are stretched into the model test box, and laid towards the direction of the simulate soil body. By filling two types of soil bodies different in intensity in the test box according to work conditions in actual tunneling on site, the upper-soft lower-hard stratum is really simulated, and therefore effective test data is collected in aspects of thrust force, rotation speed, torque, tunneling length, cutter wear degrees and the like, and data support is provided to cutter improvement in actual construction.

Owner:CENT SOUTH UNIV +3

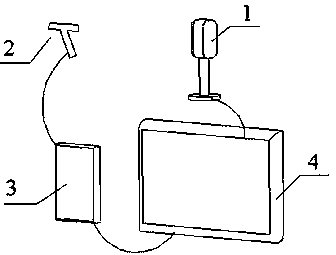

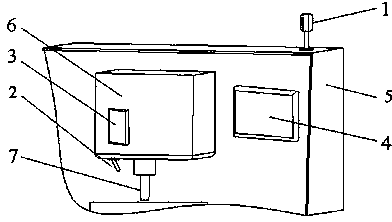

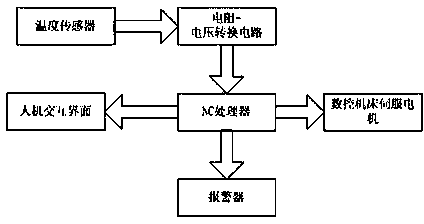

Automatic warning device for numerical control cutting tool wear

InactiveCN103878643ARealize automatic alarmAvoid burnsMeasurement/indication equipmentsMaintainance and safety accessoriesElectrical resistance and conductanceNumerical control

The invention discloses an automatic warning device for numerical control cutting tool wear. The automatic warning device comprises a temperature sensor (2), a resistance-voltage conversion circuit (3), an NC processor (4) and a warner (1). The temperature sensor (2) is used for collecting a temperature value of a cutting area, the temperature value is compared with a warning temperature threshold value set for the NC processor (4) in advance and a machining stopping temperature threshold value so that automatic warning of tool wear can be achieved, when operating personnel do not stop the device in time to replace a tool after automatic warning and the temperature value of the cutting area exceeds the machining stopping temperature threshold value, a numerically-controlled machine tool is required to be shut down by the NC processor (4), an alarm is continuously given to notify the operating personnel of subsequent processing, and thus the situation that due to labor misjudgments, production efficiency is reduced or surfaces of machined materials are burnt or strained is avoided and even the scrap problem is avoided; the automatic warning device can also be shut down automatically when the operating personnel do not stop the device in time to replace the tool, and the tool is to be replaced by the operating personnel.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

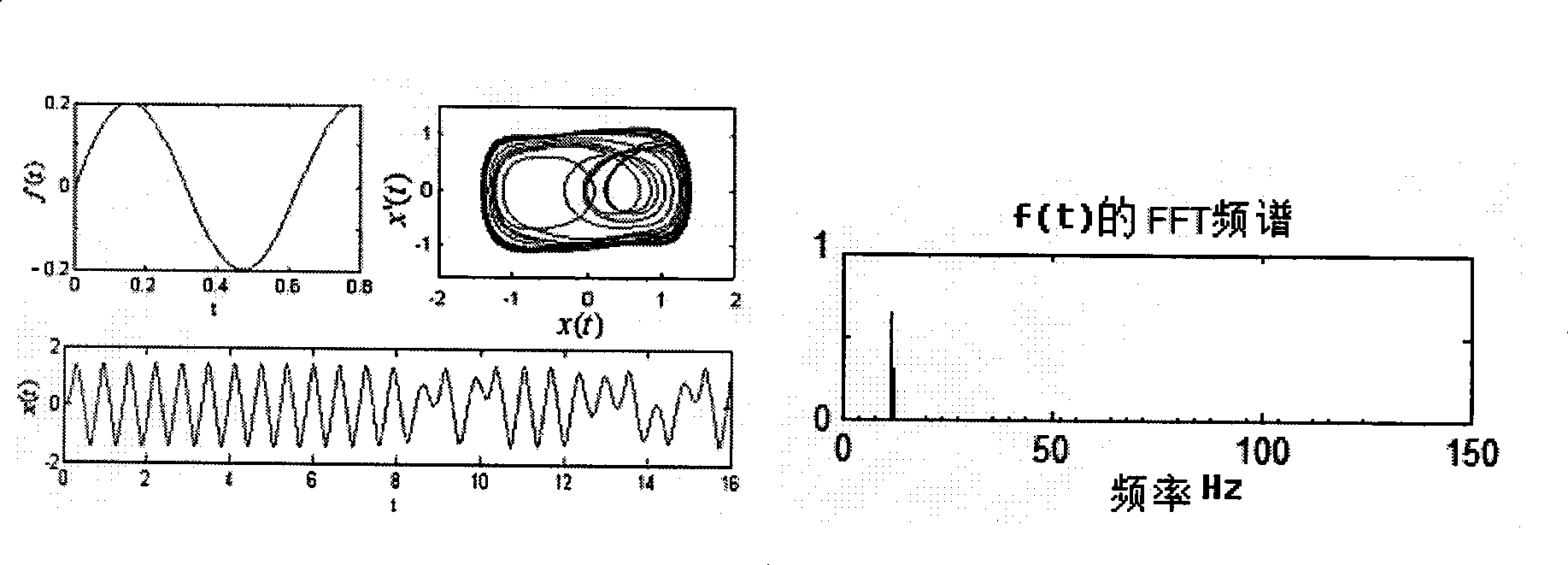

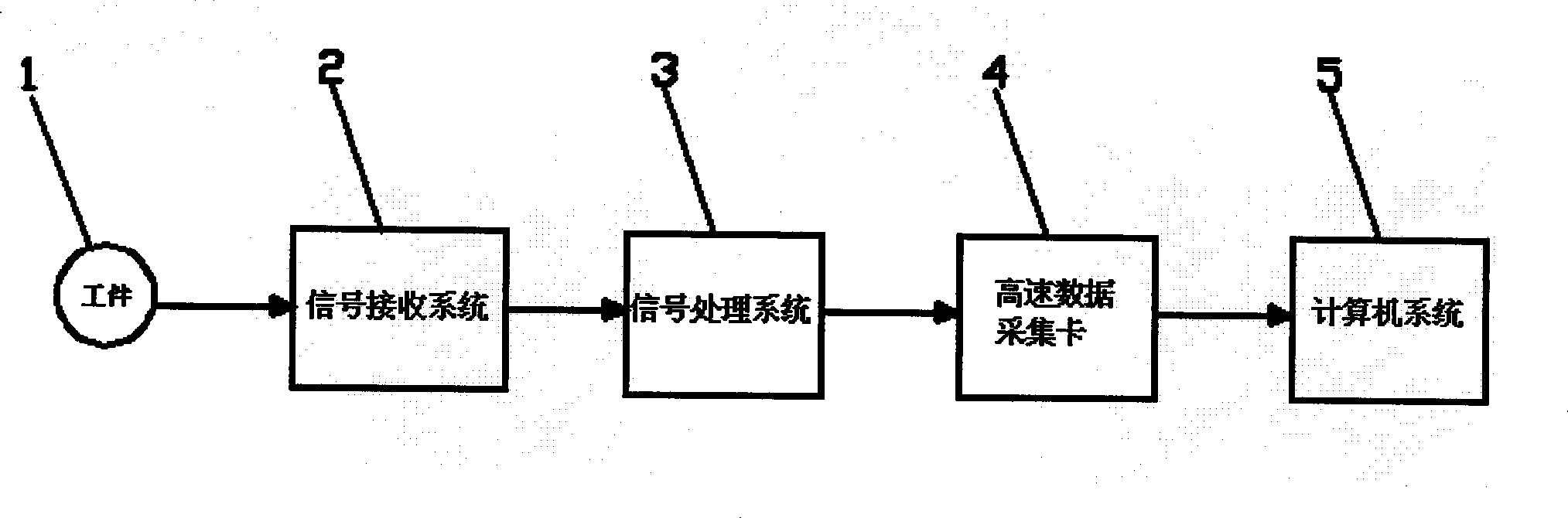

Cutting tool wearing-state detection device based on chaos vibrator and detection method thereof

InactiveCN101362301AEasy extractionReduce testing costsMeasurement/indication equipmentsComputerized systemData collecting

The invention discloses a wear condition detection device for a cutter and a detection method thereof. The invention is characterized in that the device comprises the following parts: a signal receiving system for receiving the original signal from a work piece and transmitting the signal to a signal processing system, the signal processing system for processing the signal from the signal receiving system, a high speed data collecting card for collecting the processed signal from the signal processing system and transmitting the signal to a computer system for analysis, and the computer system for analyzing the signal. The collection capability of weak signals is improved, simultaneously, complex instrumented detection equipment is not required, the detection cost is reduced, so that the technology has stronger practicability and wider application prospect, therefore, the aim of the invention can be realized.

Owner:SHANGHAI UNIV OF ENG SCI

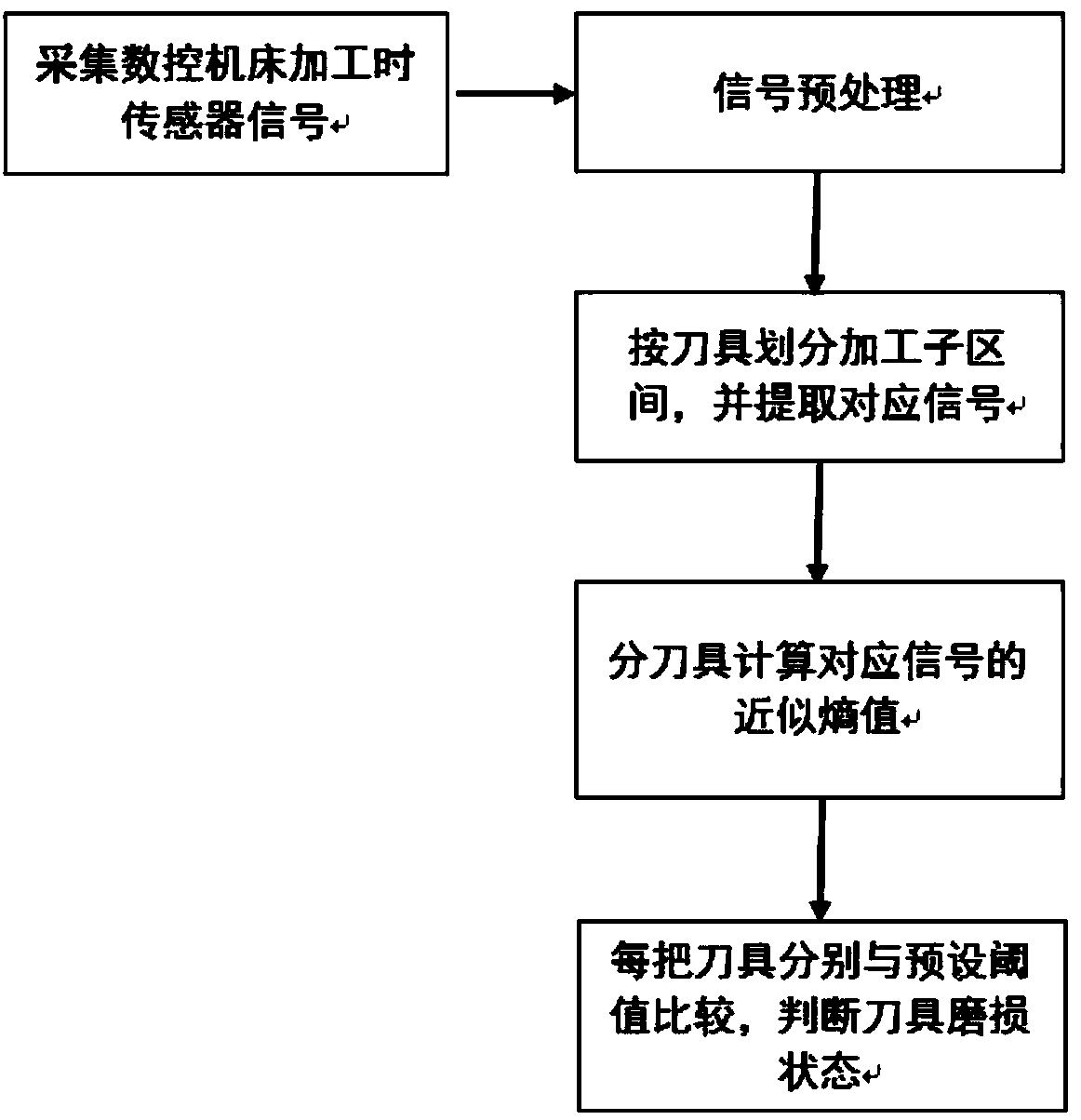

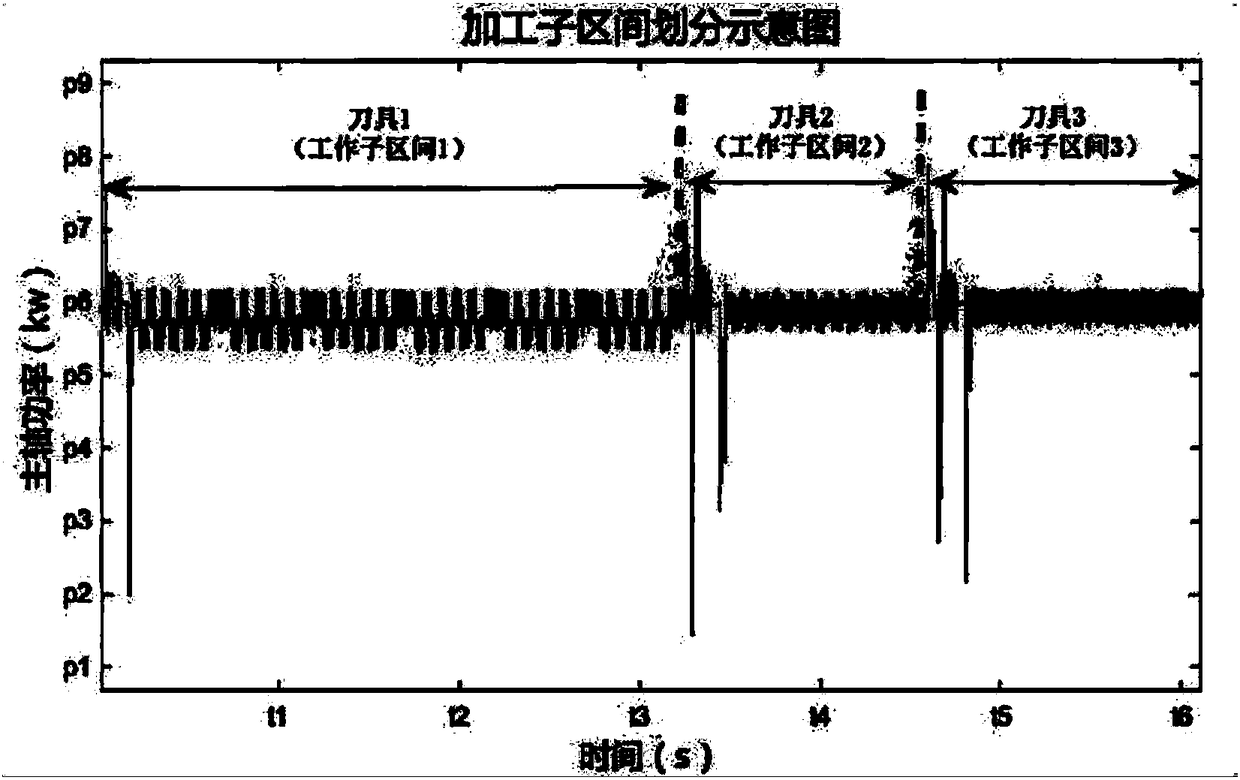

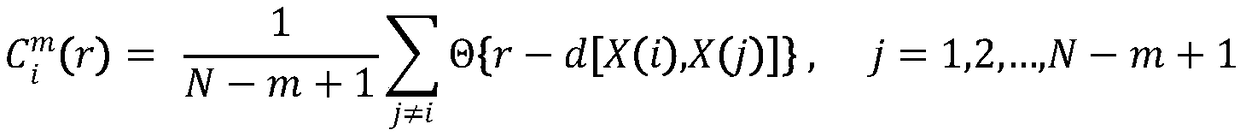

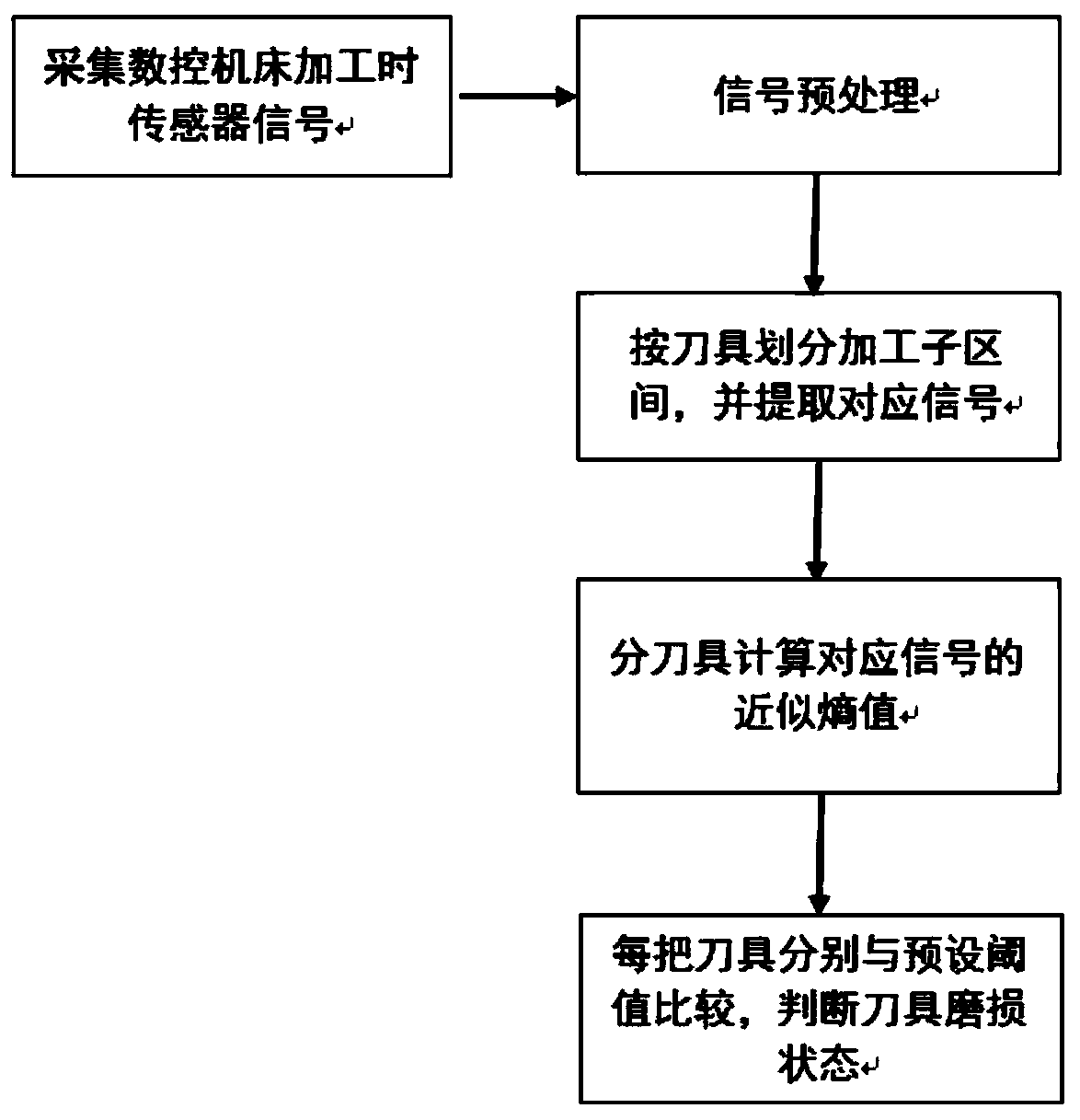

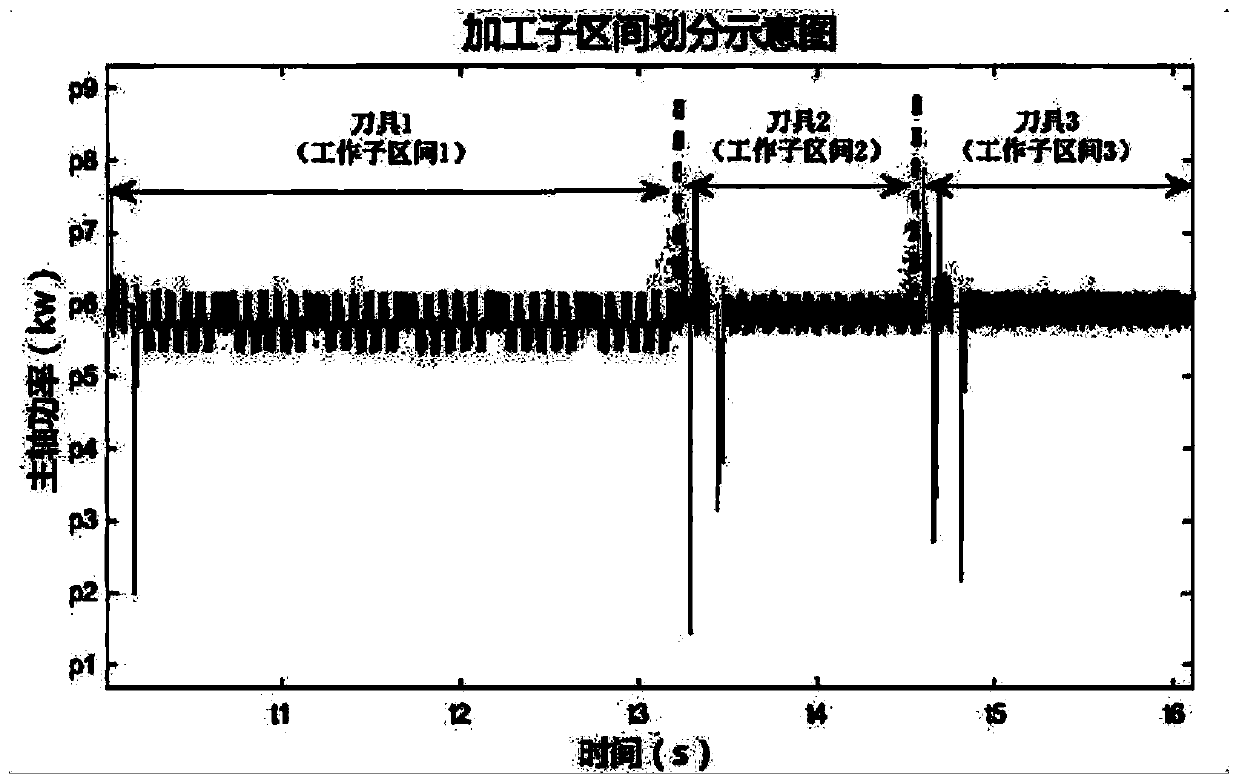

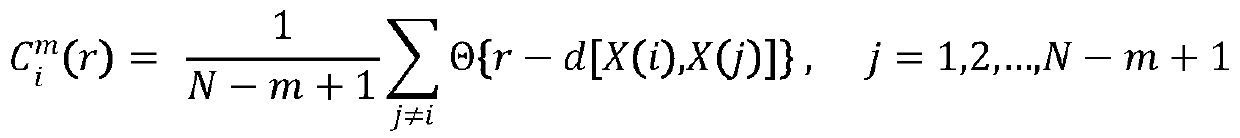

Numerical control machine tool cutting tool wear state real-time monitoring method

ActiveCN108490880ANo change in structureDoes not affect dynamic characteristicsProgramme controlComputer controlNumerical controlMeasurement device

The invention discloses a numerical control machine tool cutting tool wear state real-time monitoring method, which comprises the following steps: collecting sensor signals during machining of a numerical control machine tool in real time, and carrying out signal preprocessing; dividing the machining process into a plurality of working subintervals according to different machining tools, and extracting signal data during machining of each tool of the numerical control machine tool; calculating approximate entropy of the signal obtained during machining of each tool of the numerical control machine tool; and comparing the calculated approximate entropy of each tool and a preset threshold, and judging the tool wear state. The method has the advantages of needing no measuring equipment and needing no construction of an experiment platform, and is fast in prediction speed and high in accuracy; and meanwhile, the tool does not need to be assembled or disassembled, normal machining of the numerical control machine tool is not affected, and real-time monitoring of the wear state of the numerical control machine tool cutting tool can be realized.

Owner:谷城万利铸造有限公司

Cutting parameter determining method for combined machining of cutting tool and high-temperature alloy

Provided is a cutting parameter determining method for combined machining of a cutting tool and high-temperature alloy. The cutting parameter determining method is used for solving the problems that in the high-temperature alloy cutting process, due to the fact that reasonable cutting parameters cannot be easily selected, a tool is seriously worn, and efficiency of cutting machining is low. The cutting parameter determining method is based on an Archard model in an adhesive wear theory tool model built by F.T.Bowden and D.Tabor, the cutting temperature adopted when the adhesive wear between a workpiece material and a wear surface of the cutting tool is minimum in the cutting process of the high-temperature alloy is determined by building a wear model of a rear tool face in the combined machining process of the cutting tool and the high-temperature alloy and according to cutting test data, the correspondence between different cutting speeds and different cutting feed rates is built according to the cutting temperature obtained through the wear model, and the cutting speed and the cutting feed rate are determined; the purpose of improving cutting machining efficiency and the purpose of reducing tool wear are achieved.

Owner:HEILONGJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

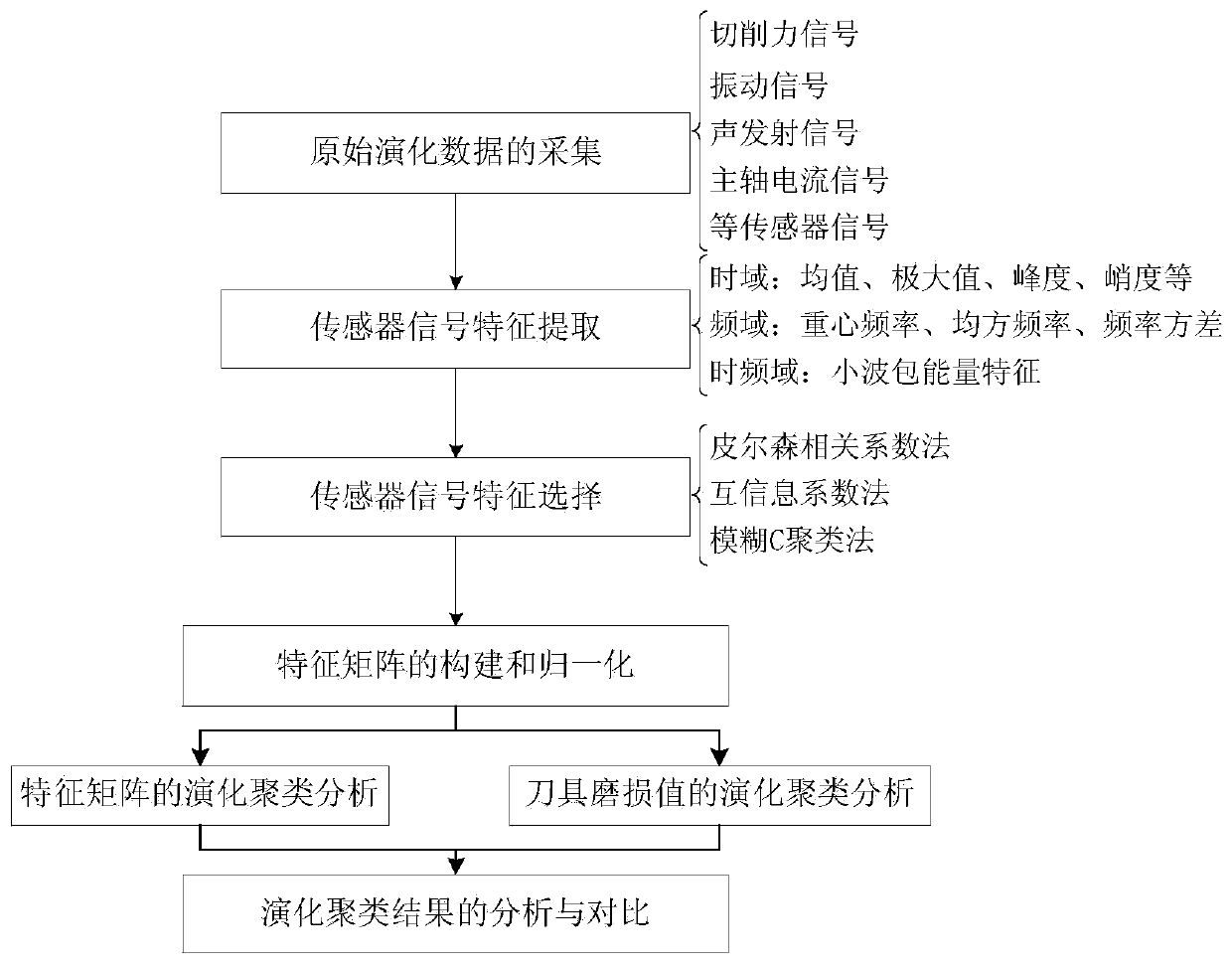

Cutting tool wear monitoring method based on evolutionary data clustering analysis

ActiveCN110647943AHigh coincidence rateImprove practicalityMeasurement/indication equipmentsCharacter and pattern recognitionCorrelation coefficientSilhouette coefficient

The invention discloses a cutting tool wear monitoring method based on evolutionary data clustering analysis. The method is used for solving the technical problem that an existing cutting tool wear monitoring method is poor in practicability. The technical scheme comprises the following steps of collecting sensor signals; extracting feature values, selecting a correlation coefficient calculation method to screen features sensitive to evolution of the tool wear value; constructing a feature matrix in a normalized manner; the method comprises the following steps of: determining an optimal clustering number by using a Cannski-Harabasz index, a Davies-Boulin index and a Silhouette coefficient; and finally, carrying out clustering analysis on two kinds of evolution data of the cutter wear valueand the feature matrix by utilizing an agglomeration hierarchical clustering method; comparing whether the clustering cluster where each element in the feature matrix evolution clustering result is located is the same as the clustering cluster where each element in the tool wear value evolution clustering result is located, to acquire the high coincidence rate of the feature matrix and the element corresponding to the tool wear value in the whole tool wear period so that the practicability is good.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

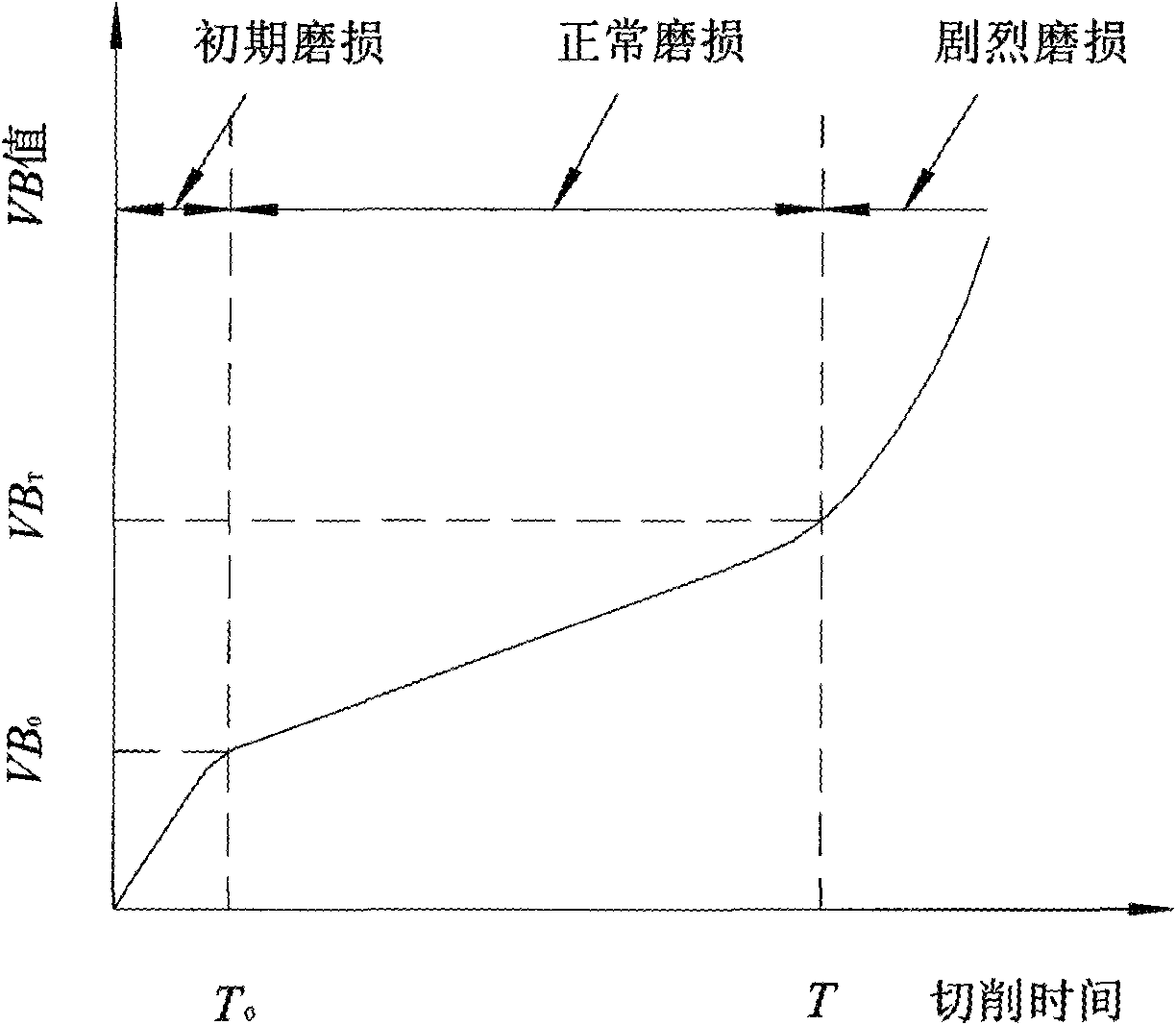

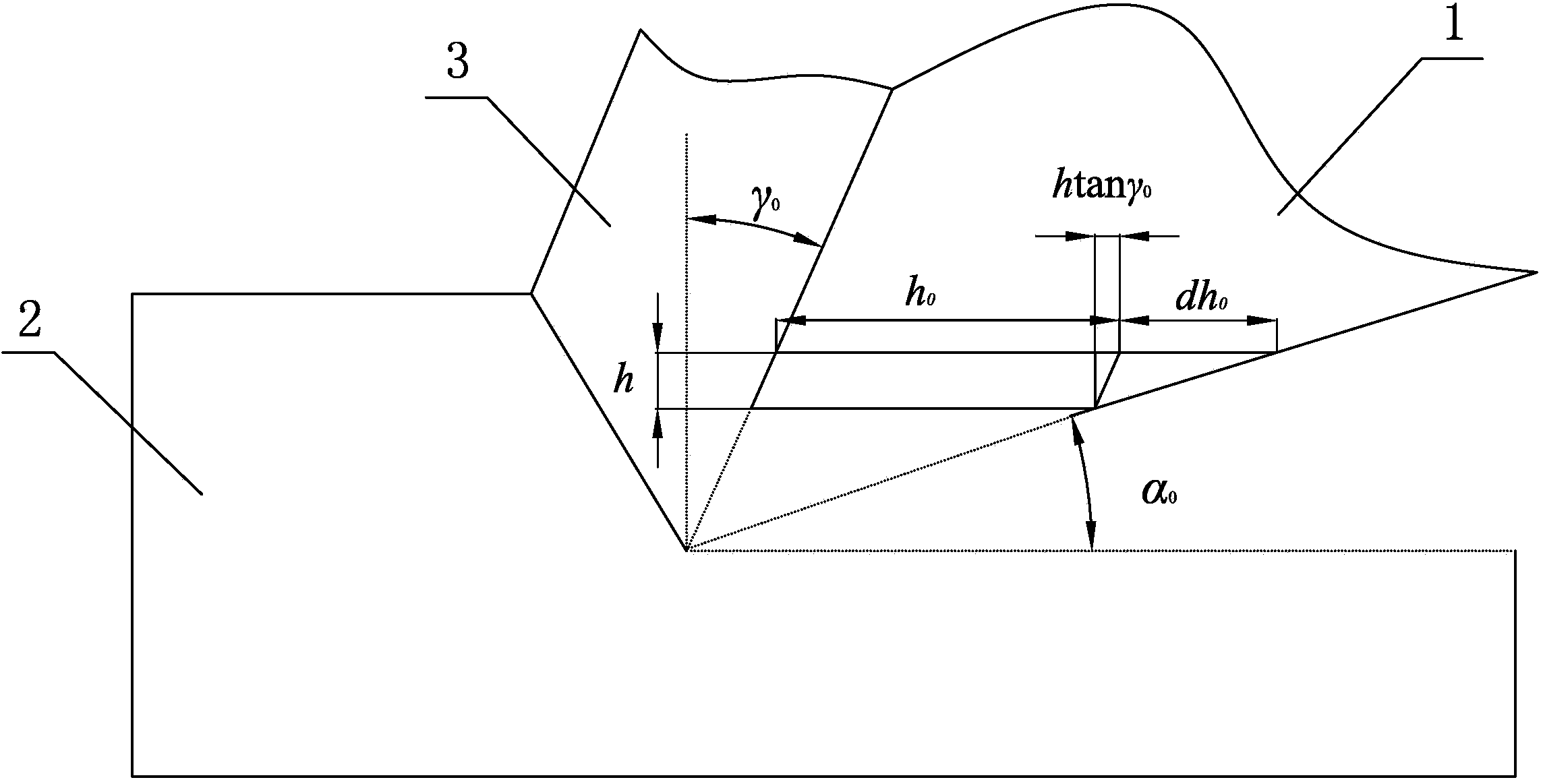

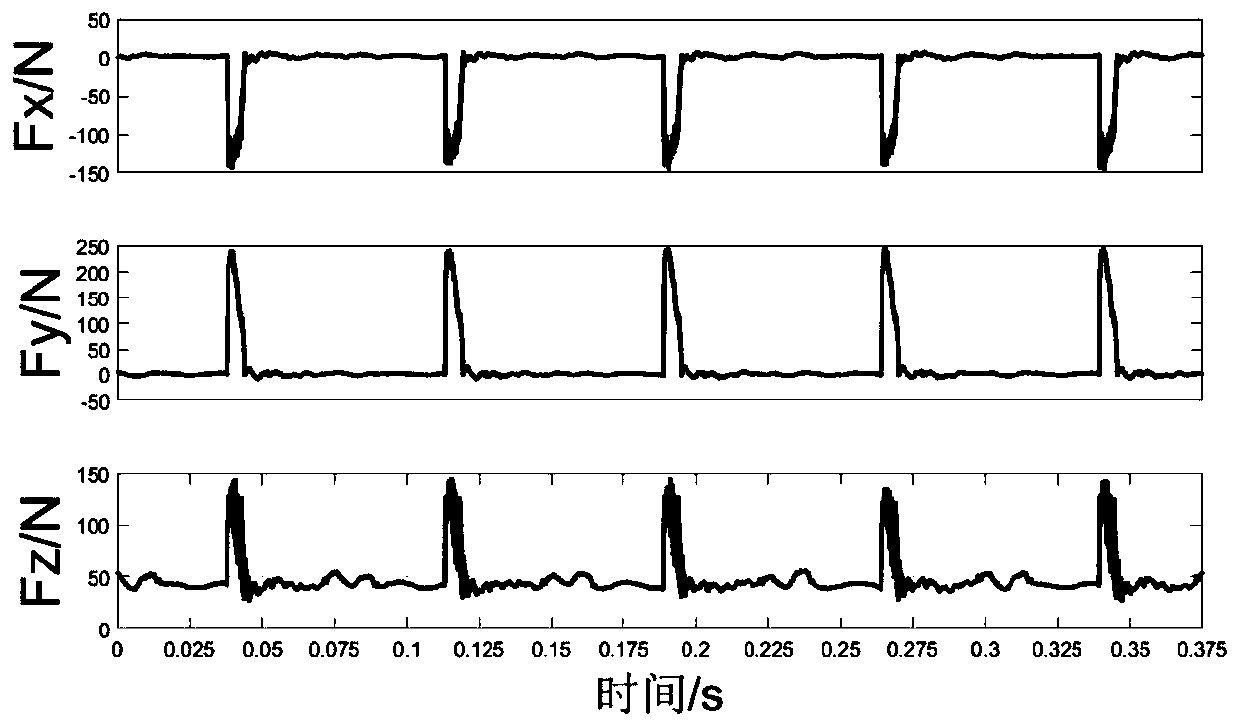

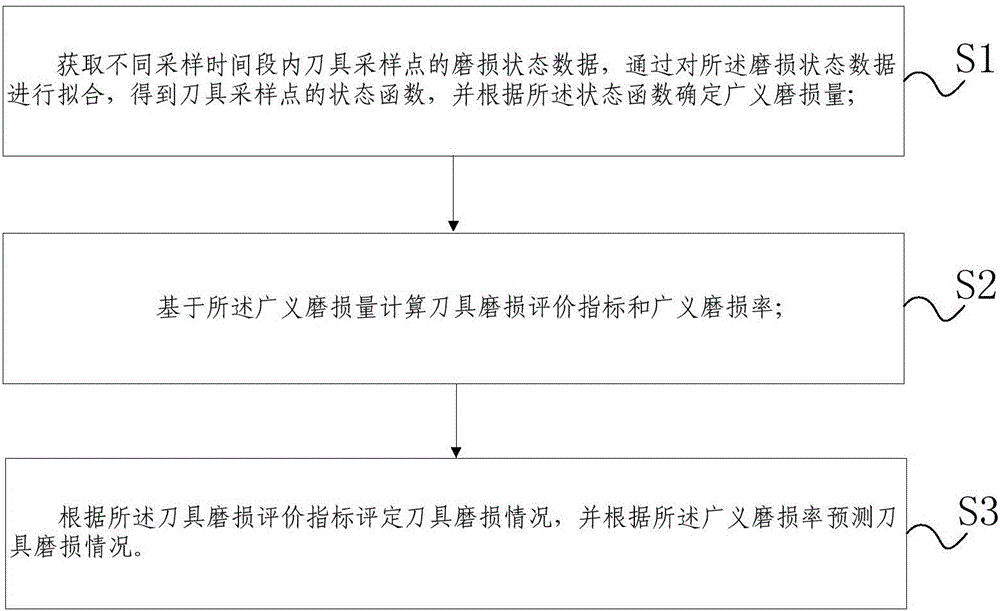

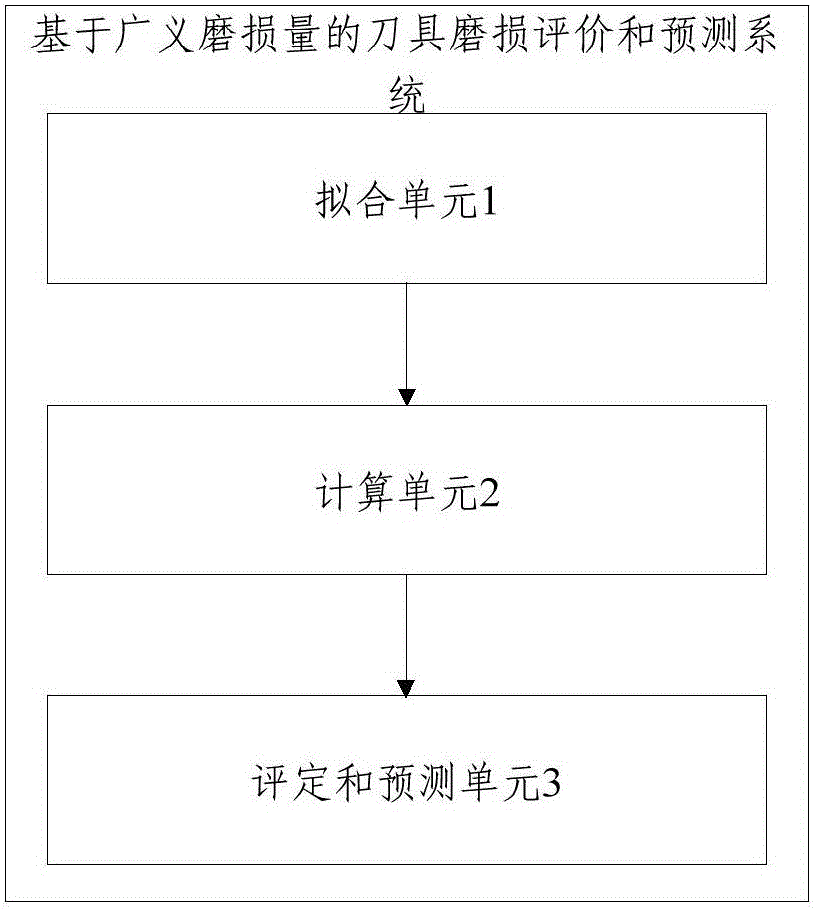

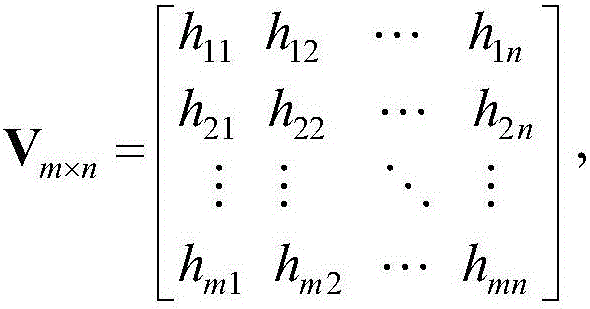

Cutting-tool wear evaluation and prediction method and system based on generalized wear extent

ActiveCN105893760AOptimizing the Wear Measurement Study ProcessGuide designInformaticsComplex mathematical operationsComputer scienceResearch process

The invention discloses a cutting-tool wear evaluation and prediction method and system based on generalized wear extent. The method and the system can be used for supplementing shortages of the existing one-dimensional and two-dimensional measurement and evaluation methods and are beneficial to the optimization of a cutting-tool wear measurement and research process and the deep understanding of a cutting-tool wear pattern and an evolutionary process thereof, and thereby better instructing the design and use of cutting tools. The method comprises the following steps: (S1) acquiring wear state data of sampling points of a cutting tool in different sampling time periods, fitting the wear state data so as to obtain a state function of the sampling points of the cutting tool, and determining the generalized wear extent according to the state function; (S2) calculating cutting-tool wear evaluating indicators and a generalized wear rate based on the generalized wear extent; (S3) evaluating cutting-tool wear conditions according to the cutting-tool wear evaluating indicators, and predicting the cutting-tool wear conditions according to the generalized wear rate.

Owner:ZHENGZHOU DIAMOND PRECISION MFG

Methods and systems for chip breaking in turning applications using CNC toolpaths

ActiveUS8240234B2Reduce the temperatureEnhances ability implementLathesProgramme controlNumerical controlEngineering

The present invention provides methods and systems for chip breaking, controlling cutting tool wear, and the like in turning, boring, and other applications, including: engaging a workpiece with a cutting tool in a feed direction along a toolpath, superimposing an oscillation in the feed direction on the toolpath, and dynamically or non-dynamically varying the oscillation superimposed in the feed direction on the toolpath such that interrupted cuts and chips of a predetermined length or less are produced. These systems take full advantage of computer numerical control (CNC) methodologies.

Owner:JUNIVERSITI OF NORT KAROLINA EHT SHARLOTT +1

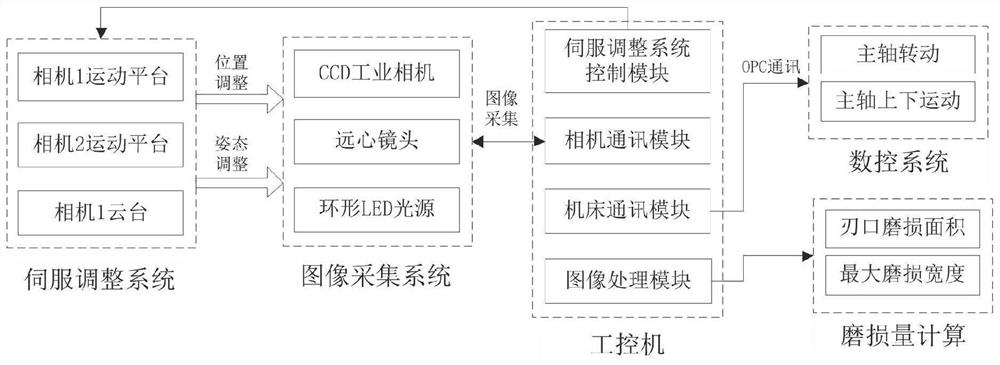

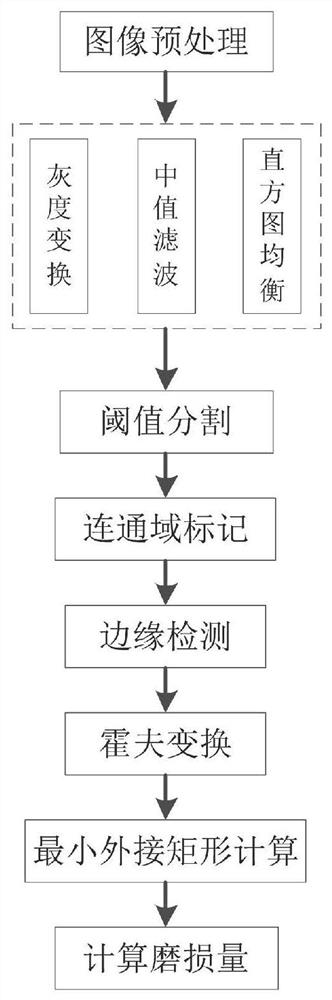

Cutting tool wear in-situ measurement device and method for manufacturing Internet of Things

PendingCN112264839ARealization of in-situ measurement of wearRealization of in-situ measurementMeasurement/indication equipmentsNumerical controlImaging processing

The invention provides a cutting tool wear in-situ measurement device and method for the manufacturing Internet of Things, which achieve in-situ measurement of cutting tool wear in the manufacturing Internet of Things, and thus improve the efficiency and the accuracy of tool wear measurement. The measurement device comprises a numerical control machine tool spindle, a cutter, telecentric lenses, CCD industrial cameras, and an industrial personal computer, wherein the cutter is a to-be-detected object and is installed on the numerical control machine tool spindle, the cutter is provided with aside edge and a bottom edge, the numerical control machine tool spindle drives the cutter to rotate or reciprocate linearly in the Z-axis direction, the two groups of telecentric lenses and CCD industrial cameras face the side edge and the bottom edge of the cutter correspondingly and are used for photographing the cutter, the telecentric lenses and the CCD industrial cameras can also reciprocatelinearly in the X-axis direction and the Z-axis direction, the industrial personal computer comprises a camera communication module, a machine tool communication module and an image processing and abrasion loss calculation module, and the industrial personal computer is used for controlling actions of the CCD industrial cameras and the numerical control machine tool spindle and can process pictures shot by the CCD industrial cameras.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

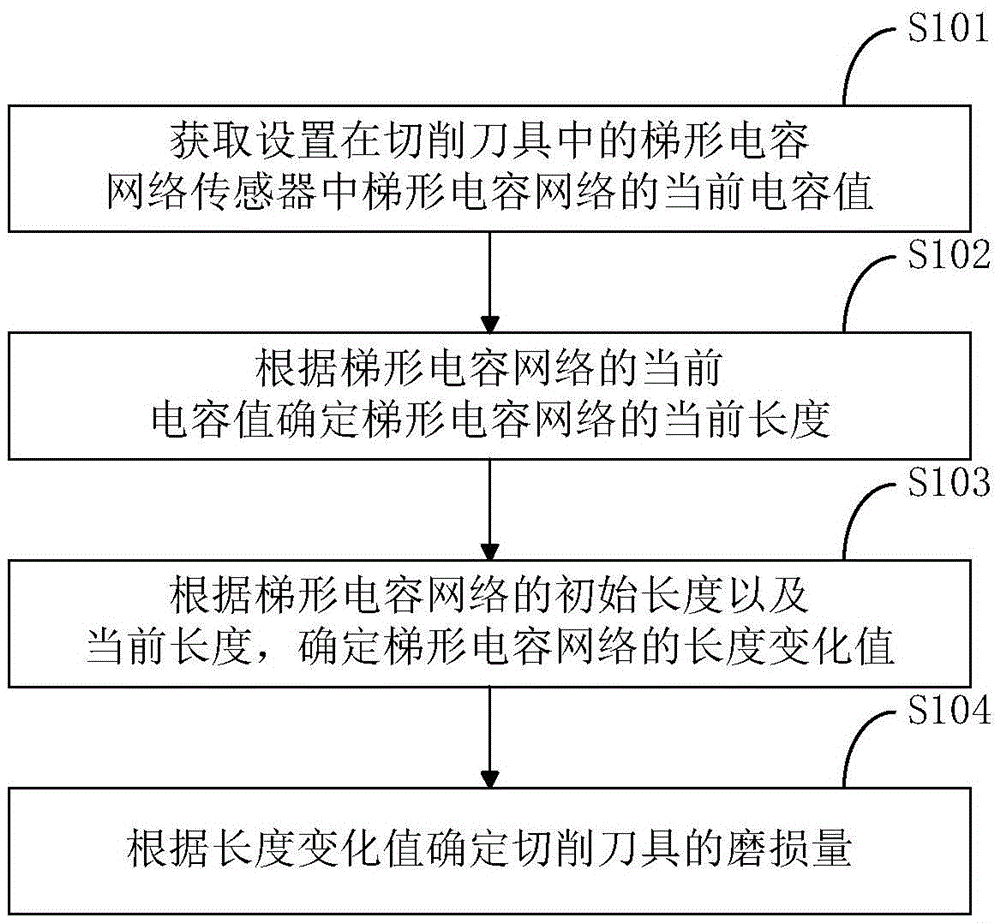

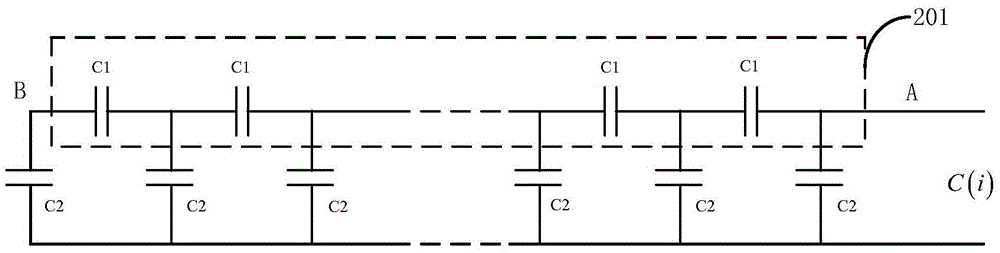

Cutting tool wear detection method

ActiveCN105466321ADetect wearSimple structureUsing electrical meansElectrical/magnetic thickness measurementsCapacitanceMultiple sensor

The invention discloses a cutting tool wear detection method. The method comprises a step of determining a capacitance value in which the current capacitance value of a ladder-shaped capacitor network in a ladder-shaped capacitor network sensor arranged in the cutting tool is acquired, a step of determining the current length of the capacitor network in which the current length of the ladder-shaped capacitor network is determined according to the current capacitance value of the ladder-shaped capacitor network, and a step of determining the wear amount in which the length change value of the ladder-shaped capacitor network is determined according to the initial length and the current length of the ladder-shaped capacitor network and the wear amount of the cutting tool is determined according to the length change value. The method of the invention can determine the wear amount of the cutting tool more accurately, and in the case of need, the wear shape of the cutting tool can be determined through configuring multiple sensors.

Owner:CHINA RAILWAY CONSTR HEAVY IND

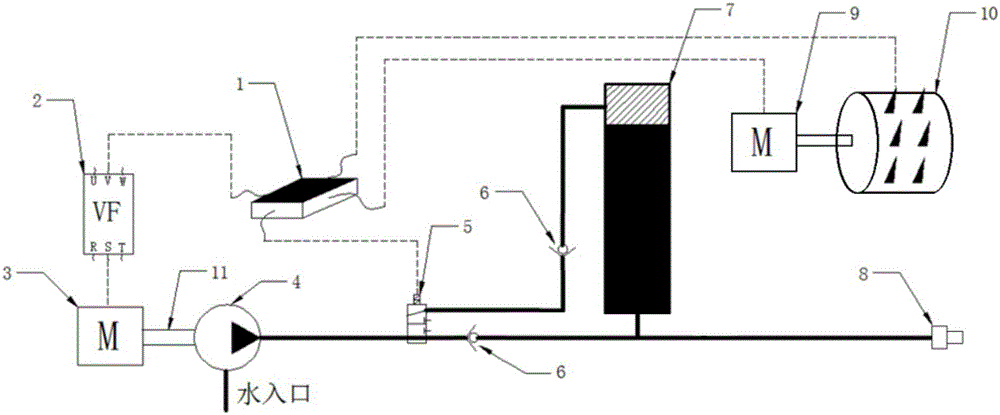

Adaptive abrasive slurry jet mining system and method

InactiveCN105952456AImprove mining efficiencyReduce wearSlitting machinesHydraulic miningSystem pressureEngineering

The invention discloses an adaptive abrasive slurry jet mining system. The system employs a single chip microcomputer, an electromagnetic valve, a frequency converter and other elements to control close cooperation of a roller coal cutter and an abrasive slurry jet system, and realizes efficient mining of thin coal seam with a complex geological structure. The adaptive abrasive slurry jet mining system provided by the invention employs the single chip microcomputer to receive a cutting force signal on the roller, automatically adjusts the frequency converter and the electromagnetic valve, controls the rise and fall of the abrasive slurry jet system pressure and switch of the abrasive slurry, thus realizing joint-cutting of the high pressure abrasive slurry jet before roller crushing paring and dust fall automation of low pressure pure water jet during roller mining of a coal seam, also the contradictions of ''small body and big power'' in a narrow space during thin coal seam mining can be effectively solved, the thin coal seam mining efficiency is improved, and the cutting tool wear is reduced.

Owner:CHINA UNIV OF MINING & TECH

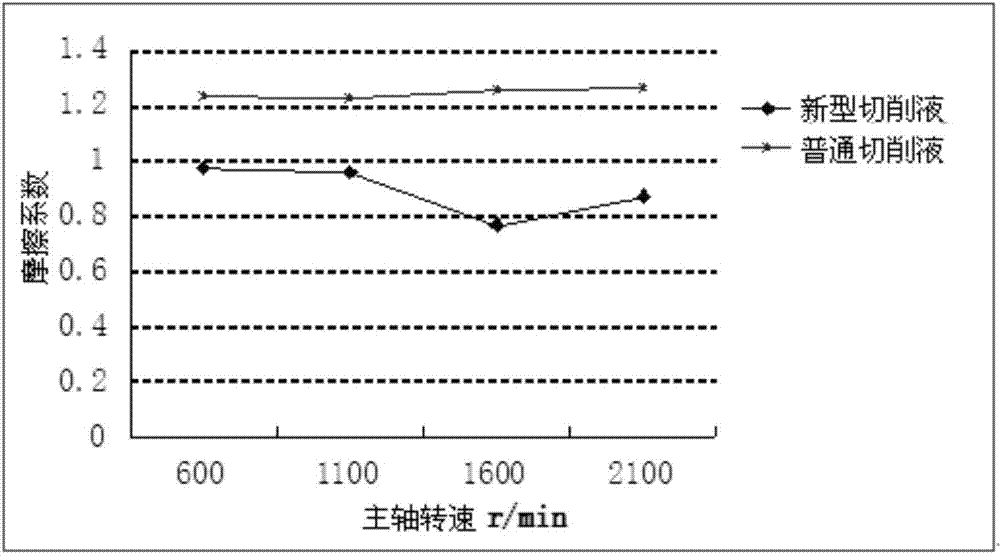

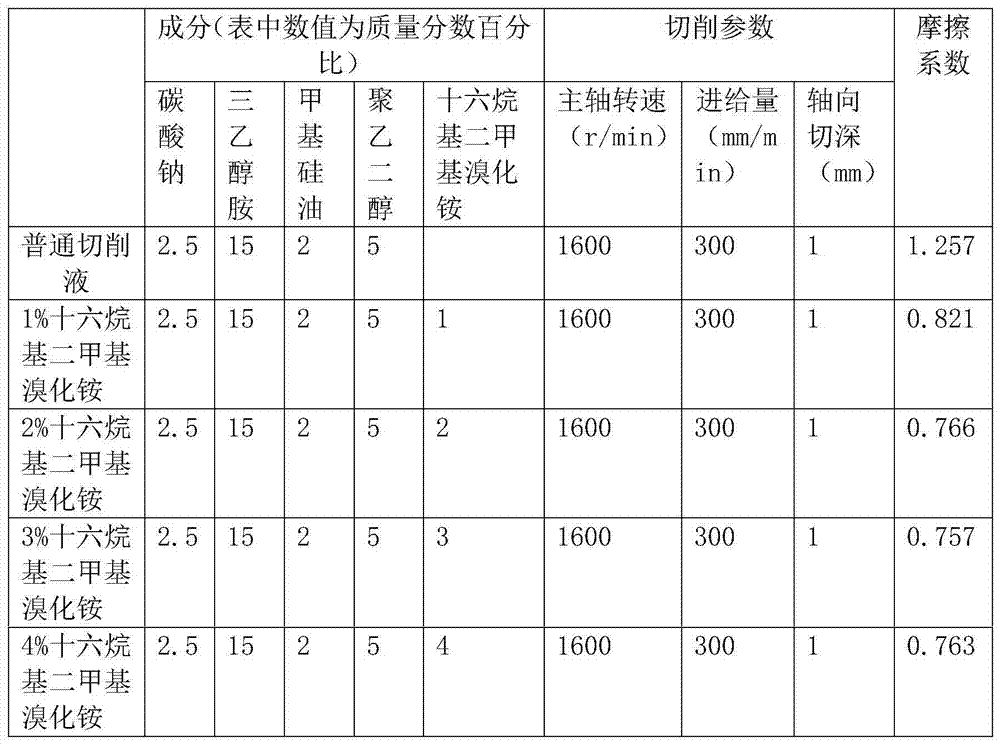

Novel cutting fluid capable of effectively reducing wear of titanium-alloy high-speed cutting tool

InactiveCN104711106AImprove anti-friction performanceReduce wearLubricant compositionEnvironmental resistanceHazardous substance

The invention provides a novel cutting fluid capable of effectively reducing wear of a titanium-alloy high-speed cutting tool. The fluid is prepared from the following raw materials by mass: 2.5% of sodium carbonate, 15% of triethanolamine, 2% of methyl silicone oil, 5% of polyethylene glycol, 1% to 5% of cetyltrimethylammonium bromide, with the balance being deionized water. According to the invention, due to the addition of cetyltrimethylammonium bromide, the novel cutting fluid exerts good wear reducing effect on the cutting tool; harmful substances like nitrite are not contained, so the fluid is healthy and environmentally friendly; and a preparation method for the fluid is simple and has low cost.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

A real-time monitoring method for cutting tool wear status of CNC machine tools

ActiveCN108490880BNo change in structureDoes not affect dynamic characteristicsProgramme controlComputer controlNumerical controlMachine

The invention discloses a numerical control machine tool cutting tool wear state real-time monitoring method, which comprises the following steps: collecting sensor signals during machining of a numerical control machine tool in real time, and carrying out signal preprocessing; dividing the machining process into a plurality of working subintervals according to different machining tools, and extracting signal data during machining of each tool of the numerical control machine tool; calculating approximate entropy of the signal obtained during machining of each tool of the numerical control machine tool; and comparing the calculated approximate entropy of each tool and a preset threshold, and judging the tool wear state. The method has the advantages of needing no measuring equipment and needing no construction of an experiment platform, and is fast in prediction speed and high in accuracy; and meanwhile, the tool does not need to be assembled or disassembled, normal machining of the numerical control machine tool is not affected, and real-time monitoring of the wear state of the numerical control machine tool cutting tool can be realized.

Owner:谷城万利铸造有限公司

Process capable of improving machining quality of numerical control mold

InactiveCN107755765AImprove processing efficiencyGuarantee processing qualityMilling equipment detailsNumerical controlSurface finish

The invention discloses a process capable of improving the quality of mold numerical control machining, which obtains a constant cutting layer area and material removal rate through calculation, so that the cutting load and the tool wear rate are kept in balance; the inclined lower knife with an inclination angle of 20° to 30° is adopted Method; provide root cleaning to remove corners with large remaining machining allowance after rough machining to ensure uniform machining allowance in subsequent processes, and the contact point between the tool and the workpiece changes with the surface slope of the machined surface and the effective radius of the tool. , while defining the amount of side engagement, define the height of the remaining area of the machining surface. The radius of curvature of the finishing surface should be greater than 1.5 times the tool radius. In the finishing machining of the mold, when cutting in and out of the workpiece, the The change of direction should adopt arc or curve transfer as far as possible. This process can not only improve the efficiency of mold processing, but also ensure the processing quality, and the molding quality is higher when the subsequent mold is used.

Owner:韩海威

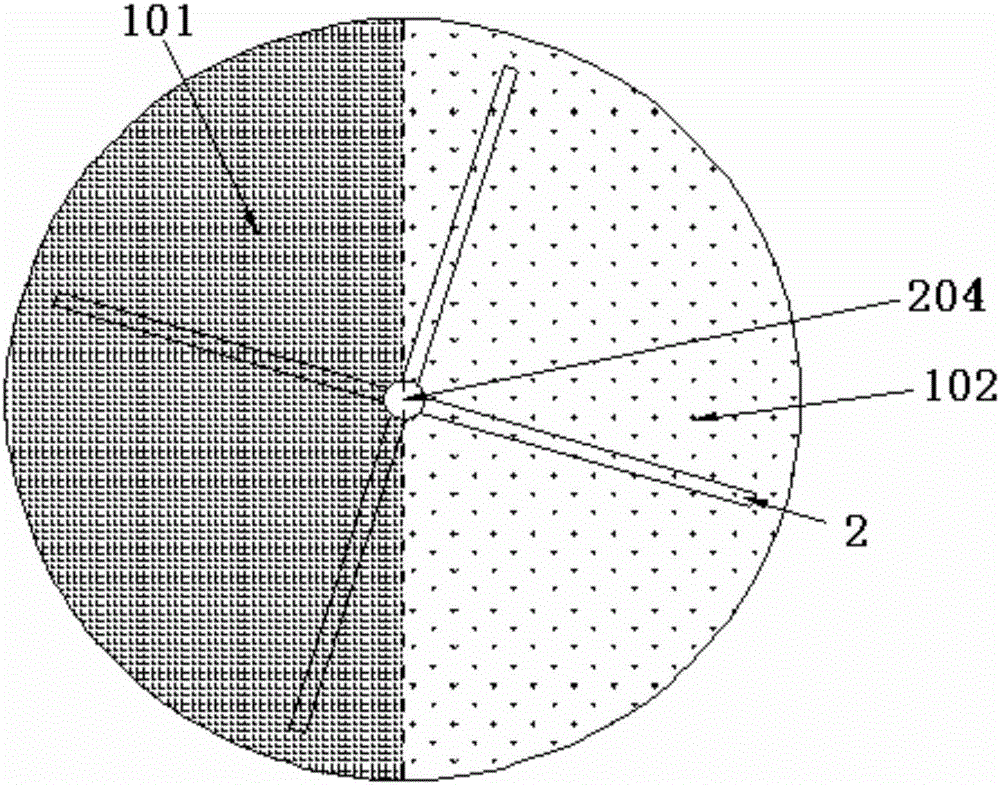

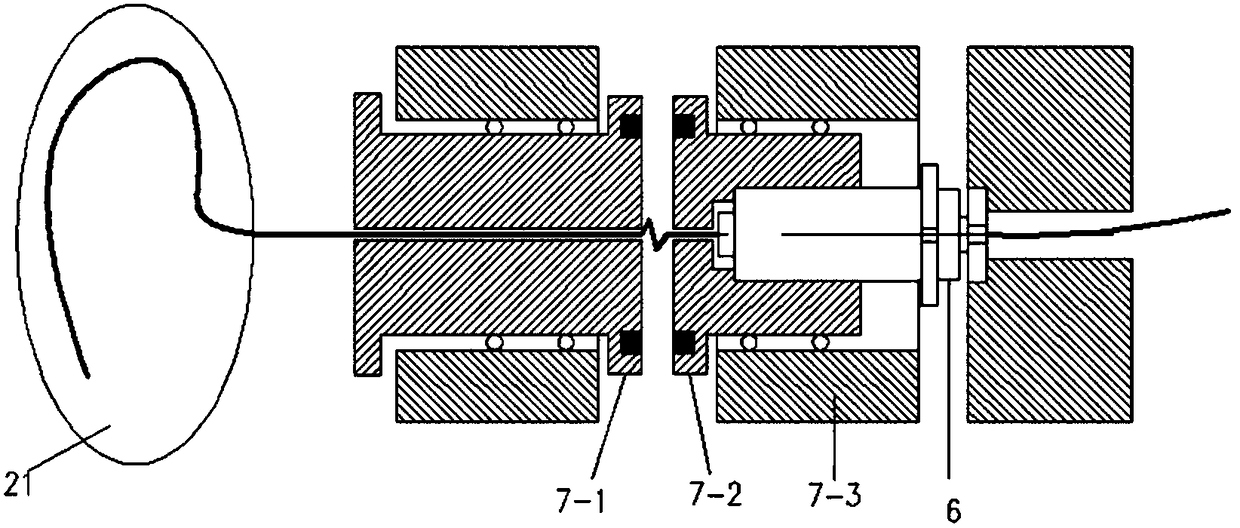

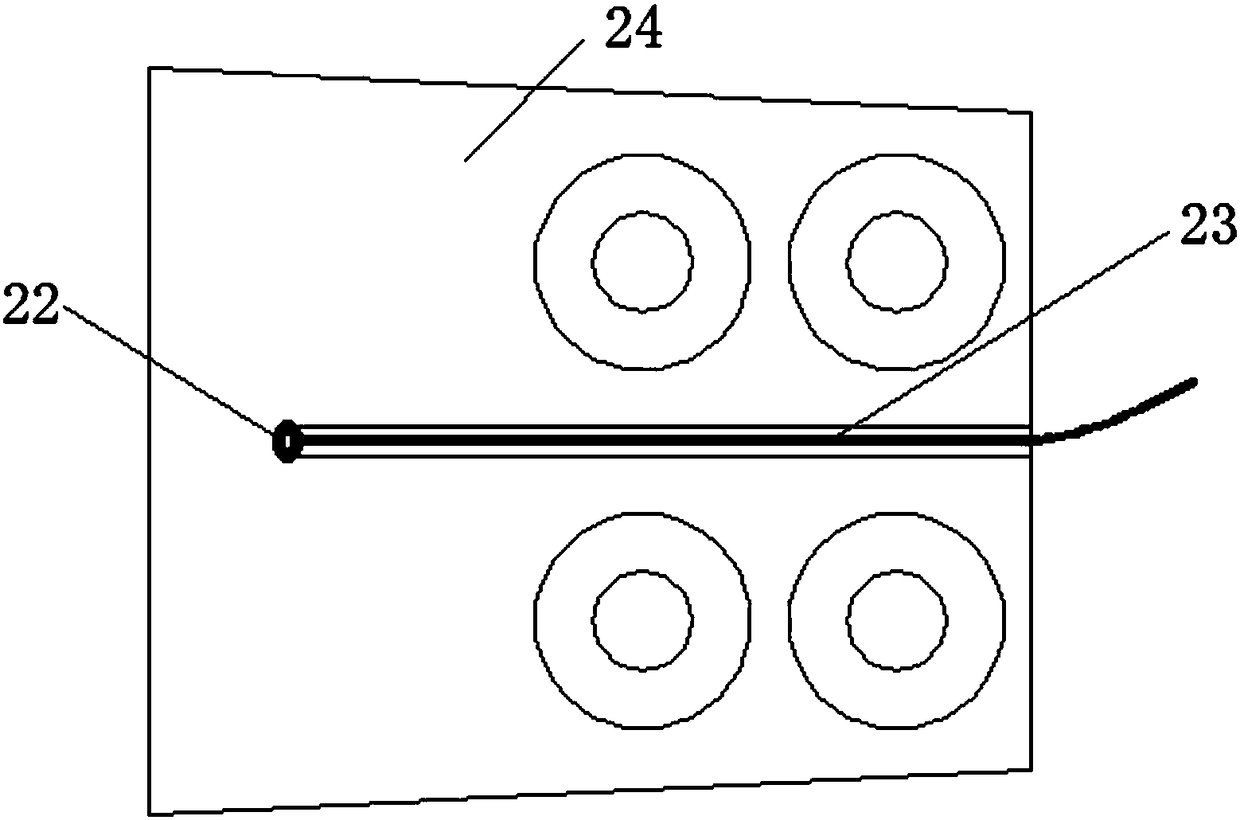

On-line detection device and method for shield machine tool and cutterhead wear based on optical fiber sensing

ActiveCN105973896BReduce volumeAvoid EMI designOptically investigating flaws/contaminationTunnelsGratingBeam splitting

The invention provides a shield tunneling machine cutter and cutter head wearing online detection device based on optical fiber sensing. The device comprises a fiber bragg grating position sensor group installed in a deep hole of a device to be detected, a beam splitting system used for transmitting light to each fiber bragg grating position sensor, a demodulating system used for demodulating light returned from each fiber bragg grating position sensor into electric signals, and a control system used for controlling on and off of the beam splitting system, analyzing the electric signals demodulated by the demodulating system, and judging whether any one or more of a cutter, a wearing detection cutter and a cutter head are worn and wearing positions, and the optical fiber end of each fiber bragg grating position sensor is located at the wearing limit position of the device to be detected. By the adoption of the device, the anti-electromagnetic interference design of the sensors is avoided, and no negative affect is caused to the normal working state of the shield tunneling machine cutter and cutter head.

Owner:WUHAN UNIV OF TECH

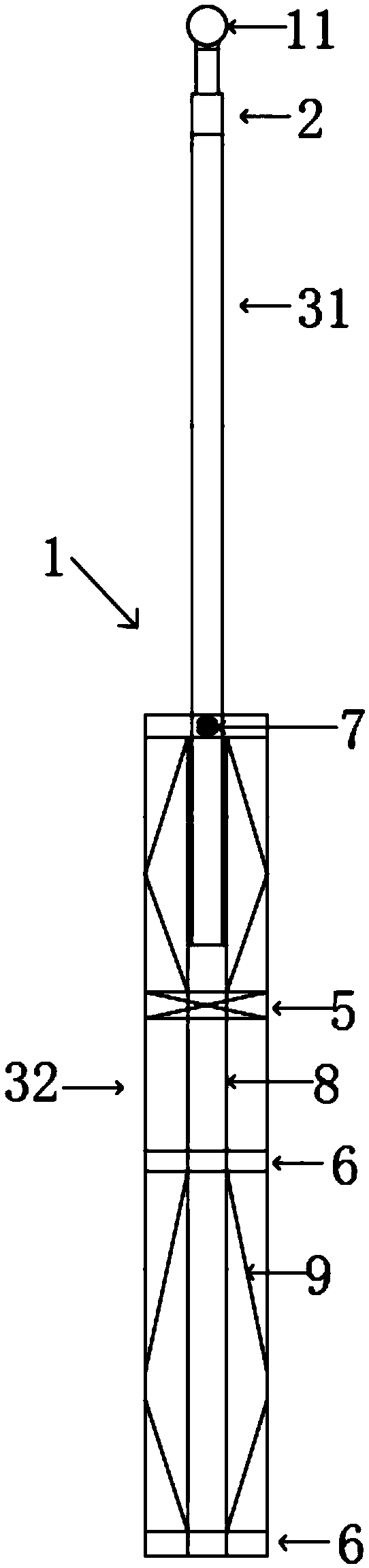

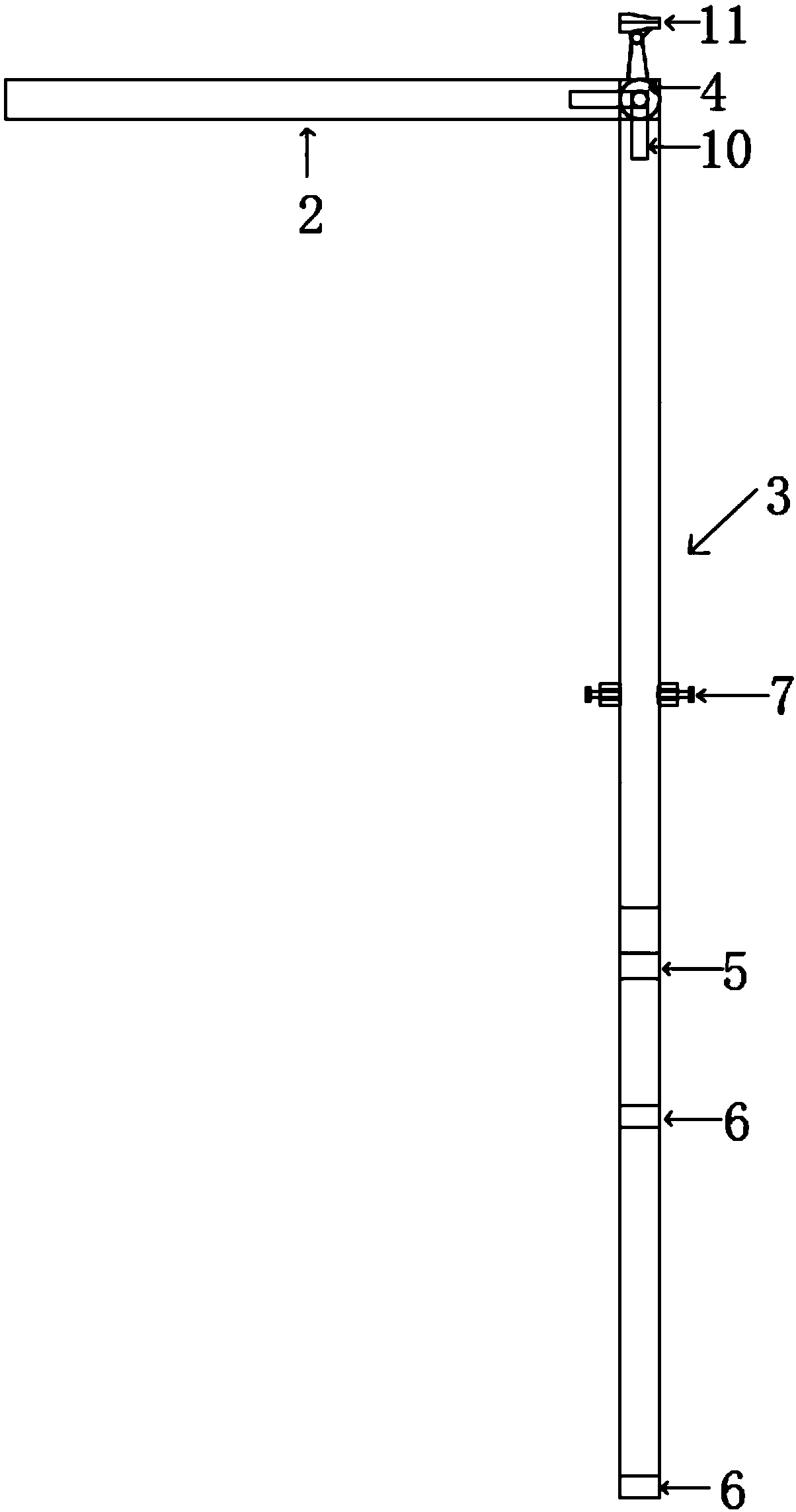

Shield machine cutter head and cutting tool wear measurement rotation ruler, measurement system and measurement method

PendingCN109405708AThe principle is simplePlay a guiding roleTunnelsMechanical measuring arrangementsHeight differenceMechanical engineering

The invention provides a shield machine cutter head and cutting tool wear measurement rotation ruler and a measurement system based on a level. The rotation ruler is composed of a measurement cross ruler for reading and a telescopic vertical rod for adjusting a height, the relative height difference between different positions on the shield machine cutter head can be realized, the wear amount of the cutting tool and the wear amount of the cutter head can be measured, the structure is simple, the measurement is accurate, the operation is easy, the measurement efficiency is high, tool exchange for the shield can be guided, the overall tool height of the cutter head after tool exchange can be rechecked, and the tunneling efficiency of the shield machine can be accurately evaluated and mastered by engineers and technicians.

Owner:CHINA UNIV OF MINING & TECH (BEIJING) +1

Thermal modeling of an orthogonal machining process

ActiveUS9418185B2Lower the volumeNo loss of accuracyComputation using non-denominational number representationDesign optimisation/simulationSteady state temperatureElement analysis

A novel procedure is disclosed, that can be incorporated into Finite Element Analysis (FEA) or other similar analysis techniques, to obtain the steady state temperature distribution in a coupled transient heat transfer analysis rapidly as well as accurately. A scale factor is used to reduce the thermal inertia per unit volume (specific heat capacity) in regions of steady state temperature distribution, thereby hastening the achievement of steady state. An application of this procedure to estimate steady state temperature distributions within cutting tools, and the estimation of cutting tool wear based on the obtained steady state temperature distributions is shown as an example.

Owner:MADHAVAN VISWANATHAN +1

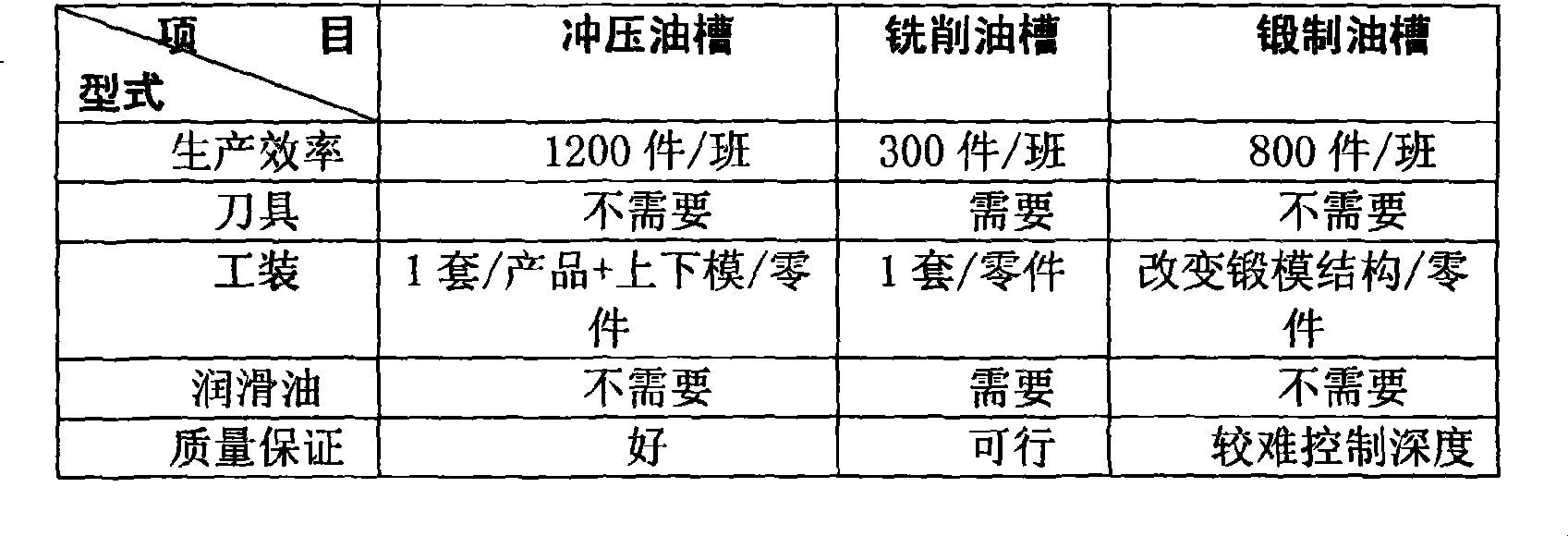

Cold punching processing method for gear face oil groove

The invention relates to a cold punching processing method for a gear-face oil groove. The processing procedure of the cold punching processing method for the gear-face oil groove comprises the following steps: a rough turning gear face, a fine turning of a gear inner hole and the gear face, wherein after the rough turning of the gear face, the gear-face oil groove is directly punched coldly by a die, and the gear inner hole and the gear face are finely turned, namely cold punching processing of the gear-face oil groove is completed. By adoption of the processing method to process the gear-face oil groove, the frock processing labor hour and the cutting-tool wear can be reduced. Moreover, as for an AQ015 five-gear driving gear inner concave station oil groove which can not be processed by the milling technology, the problem that the oil groove is difficult to process can be completely solved by the cold punching technology. The cold punching processing method for the gear-face oil groove not only guarantees the quality but also improves the efficiency.

Owner:曾能君

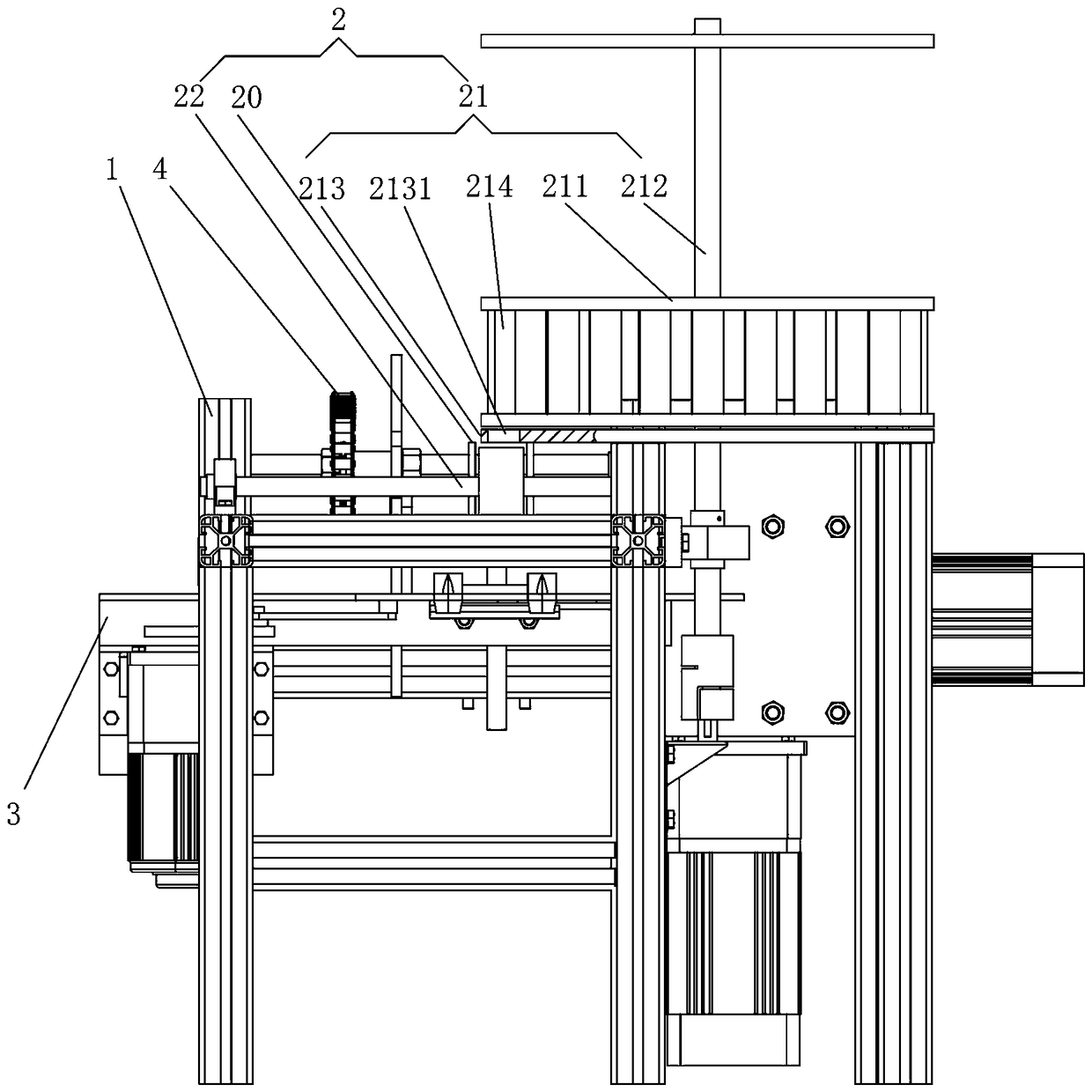

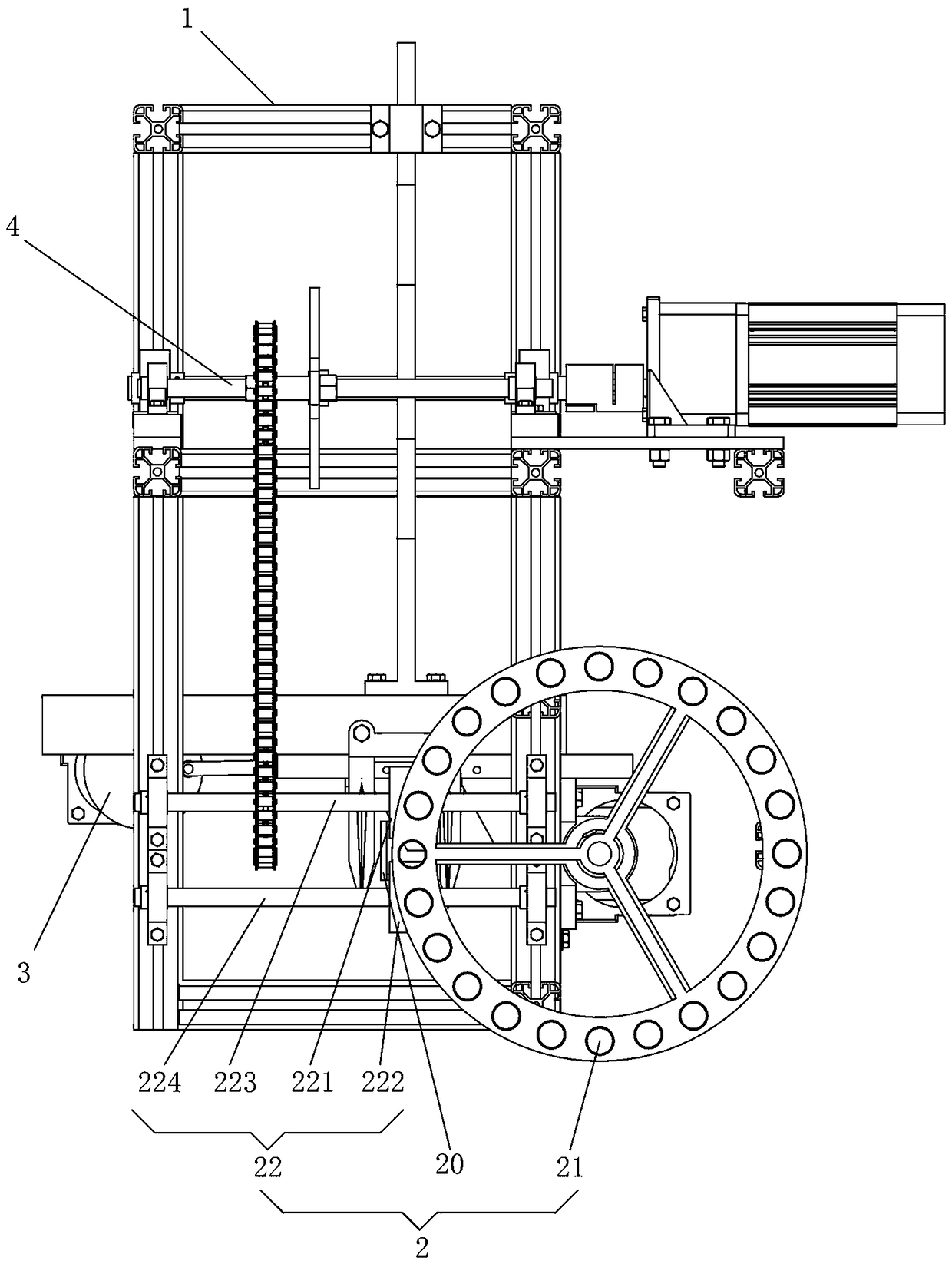

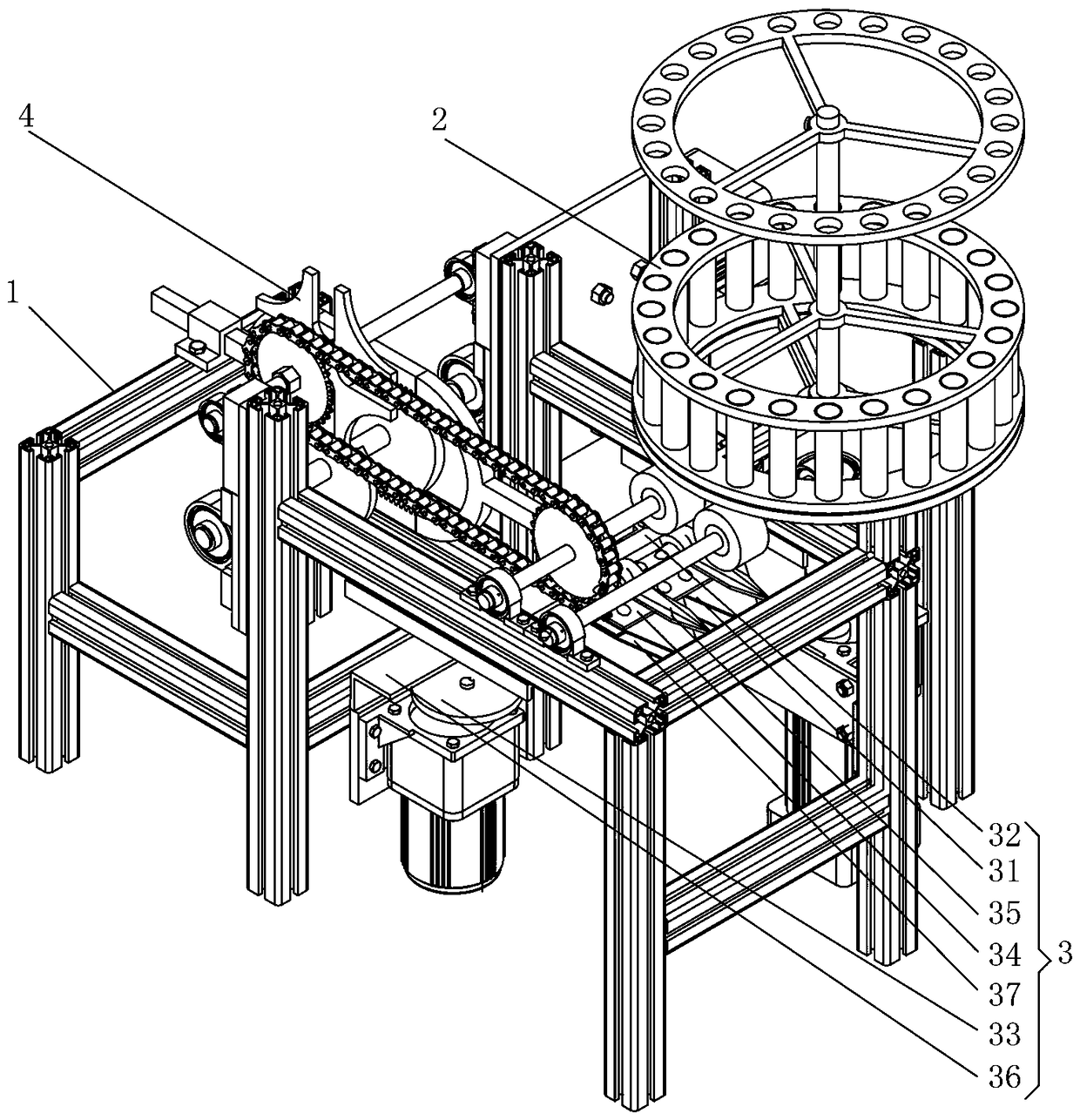

Ramie stem cutting tool wear test bed with changeable supporting state

PendingCN108132195AAvoid damageEliminate manual feedingInvestigating abrasion/wear resistanceEngineeringSingle cycle

The invention discloses a ramie stem cutting tool wear test bed with a changeable supporting state. The ramie stem cutting tool wear test bed comprises a rack, and further comprises a material feedingdevice, a cutting device and an intermittent transmission device which are arranged on the rack, wherein the material feeding device is connected with the cutting device through the intermittent transmission device; under the synergistic effect of the intermittent transmission device, material feeding and cutting are continuously and cyclically performed; in a single cycle process, the intermittent transmission device drives the material feeding device to downwards convey ramie stems, and the cutting device is driven and conveyed to a cutting station at the same time; after the ramie stems are conveyed to the cutting station, the cutting device arrives at the cutting station to execute cutting action; after the cutting action is completed, the intermittent transmission device drives and conveys the cutting device to an avoiding station for staying; a detachable cutting and supporting plate is arranged below the material feeding device. The ramie stem cutting tool wear test bed with the changeable supporting state has the advantages that labor and time are saved, cutting tool wear test data is accurate, and the cutting supporting state is adjustable.

Owner:HUNAN AGRICULTURAL UNIV

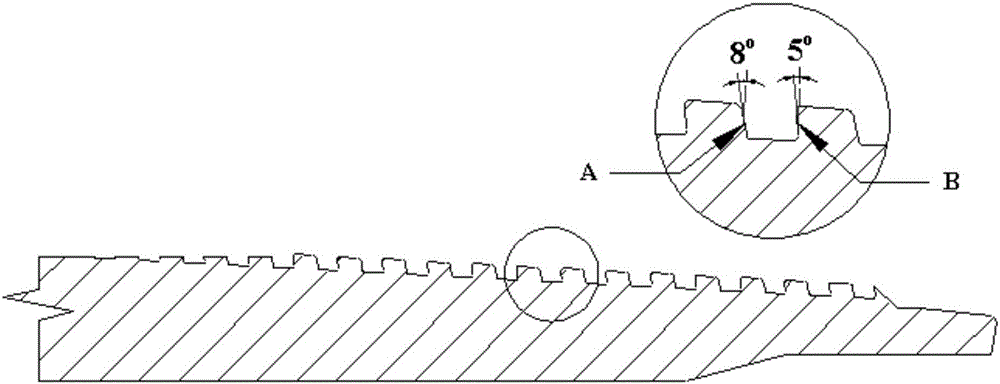

Blade and method for processing special screw thread of oil sleeve pipe

ActiveCN105935819AReduce usageGuaranteed wearThread cutting toolsThread cutting machinesManufacturing technologyScrew thread

The invention discloses a blade and a method for processing a special screw thread of an oil sleeve pipe. The blade and the method for processing the special screw thread of the oil sleeve pipe relate to the technical field of processing and manufacturing. The blade comprises a screw thread body turning tool and a screw thread outline turning tool; outline shapes of cutting edges of the screw thread body turning tool and outline shapes of cutting edges of the screw thread outline turning tool are the same; the outline shapes of the cutting edges of the screw thread outline turning tool are matched with a thread form outline line of the target special screw thread. The method comprises the steps of using the screw thread body turning tool to turn a thread form main body part of the target special screw thread; using the screw thread outline turning tool to turn a thread form outline of the target special screw thread at a time. The blade and the method for processing the special screw thread of the oil sleeve pipe provided by the invention solve the problems of quick cutting-tool wearing, low processing efficiency and poor turned screw thread precision during the existing processing of the special screw thread of the oil sleeve pipe.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Production method of low-carbon sulfur series free-cutting steel continuous casting billet

The invention relates to a production method of a low-carbon sulfur series free-cutting steel continuous casting billet. The method comprises the steps of: first placing scrap steel into a converter, then loading liquid iron into the converter; conducting top-bottom combined blowing; carrying out tapping; performing deoxygenation and alloying; implementing argon blowing treatment; conducting soft argon blowing after alloy fine adjustment; adding carbonized rice hulls into a steel ladle when the argon blowing is over; starting continuous casting when the molten steel temperature reaches 1530-1570DEG C; and employing a continuous casting process of tundish treatment, crystallizer control, secondary cooling, straightening and cutting. The invention has the characteristics that: the smelting is free of desulfurization, LF refining treatment and other processes, no steel breakout phenomenon exists in casting, the composition control is stable, the yields of S and Mn elements are both above 90%, the cutting-tool wear can be reduced during processing so as to improve the service life, the tundish has a high utilization rate, the continuous casting billet has no subcutaneous bubble, heart crack, surface crack and other defects, and is free of composition segregation, and the inclusions in the casting billet are thick, big and in a spherical shape, thus being in favor of shape control of the rolled inclusions and improvement of the steel cutting performance.

Owner:武汉钢铁有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com