Cutting-tool wear state evaluating method based on image analysis of workpiece machining surface

A technology for machining surfaces and tool wear, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., and can solve the problems of tool wear and damage state evaluation methods that have not been found yet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of the present invention will be further described in detail below with examples in conjunction with the accompanying drawings.

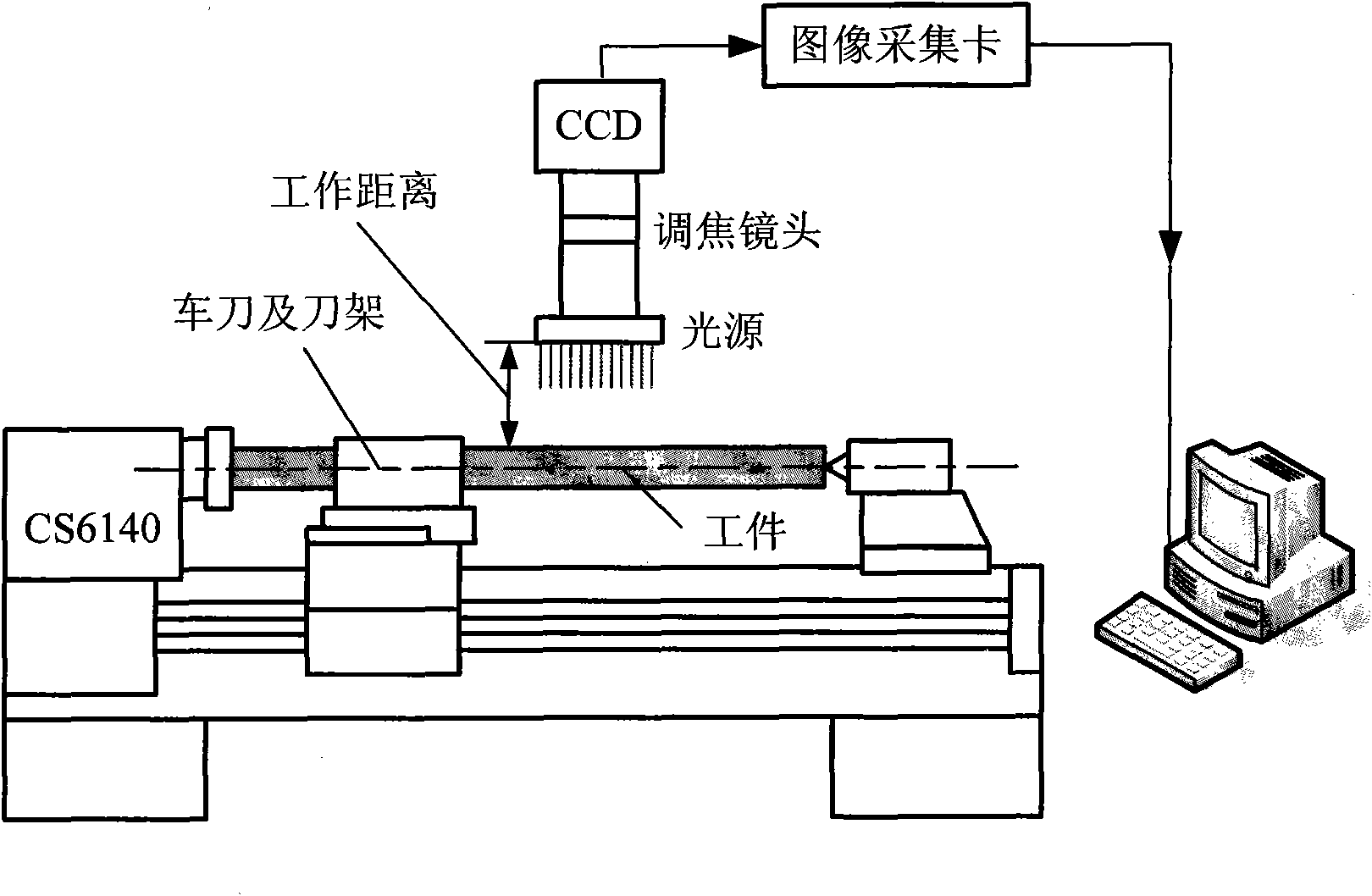

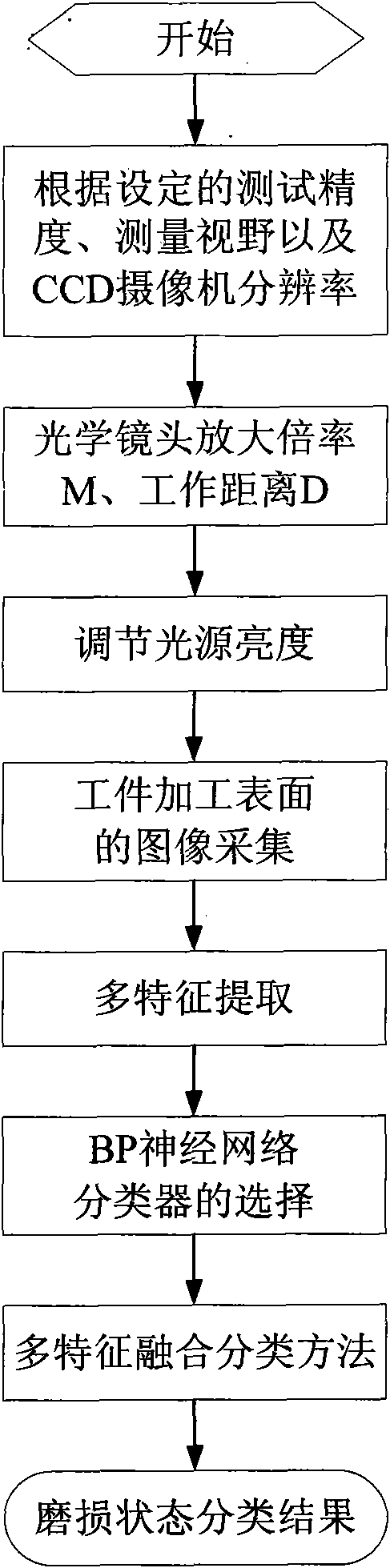

[0025] Such as figure 1 As shown, this embodiment is carried out on a common lathe CS6140, the workpiece to be processed is a shaft with a diameter of Φ180mm, the relevant parameters are 45 steel, quenched and tempered, and the hardness is 225HBW; the cutting tool is a carbide turning tool; round turning. The hardware configuration of the image measurement system is shown in Table 1, and the basic structure diagram is shown in figure 1 As shown, it mainly includes: CS6140 lathe, CCD camera, light source, focusing microscope lens, image acquisition card and computer, etc.

[0026] video camera

COSTAR C400, 1 / 2"Color CCD, pixels 752×582

focus lens

AFT-M0025

Imagenation PCX200Frame Grabber Card

Ose RIN-70-3R-0R

power supply

12V

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com