Patents

Literature

31results about How to "Eliminate manual feeding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

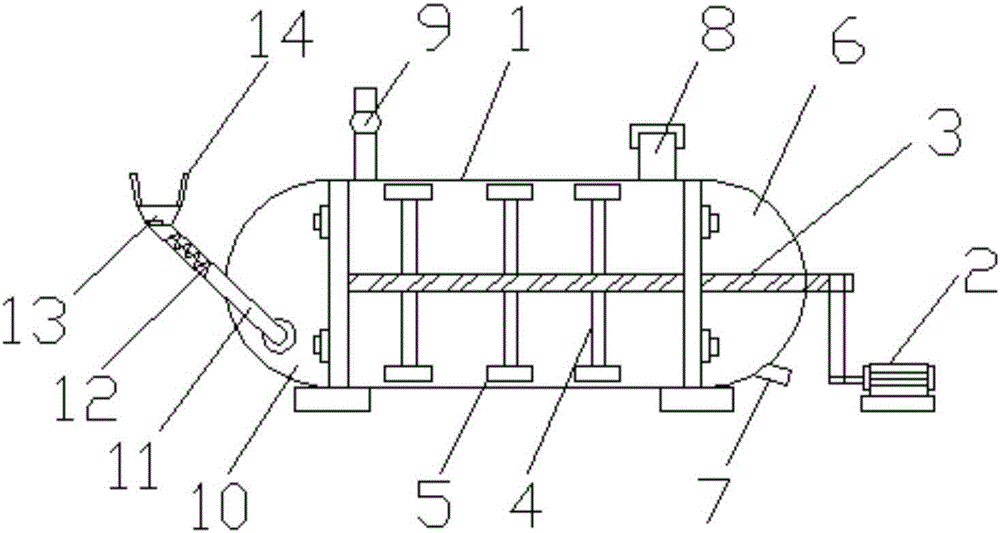

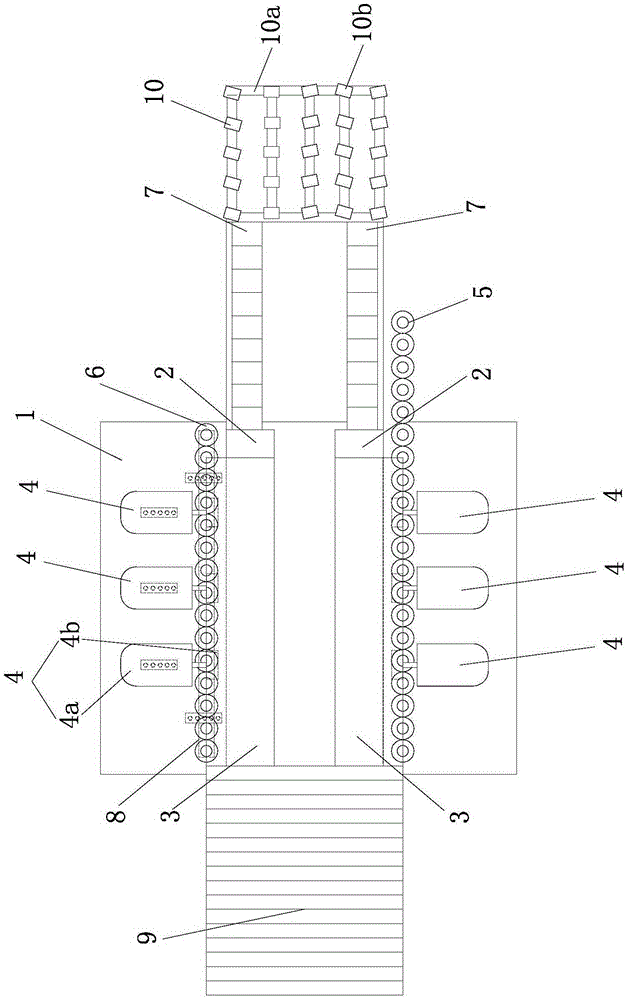

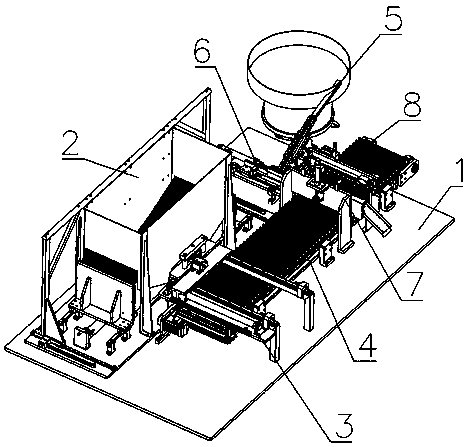

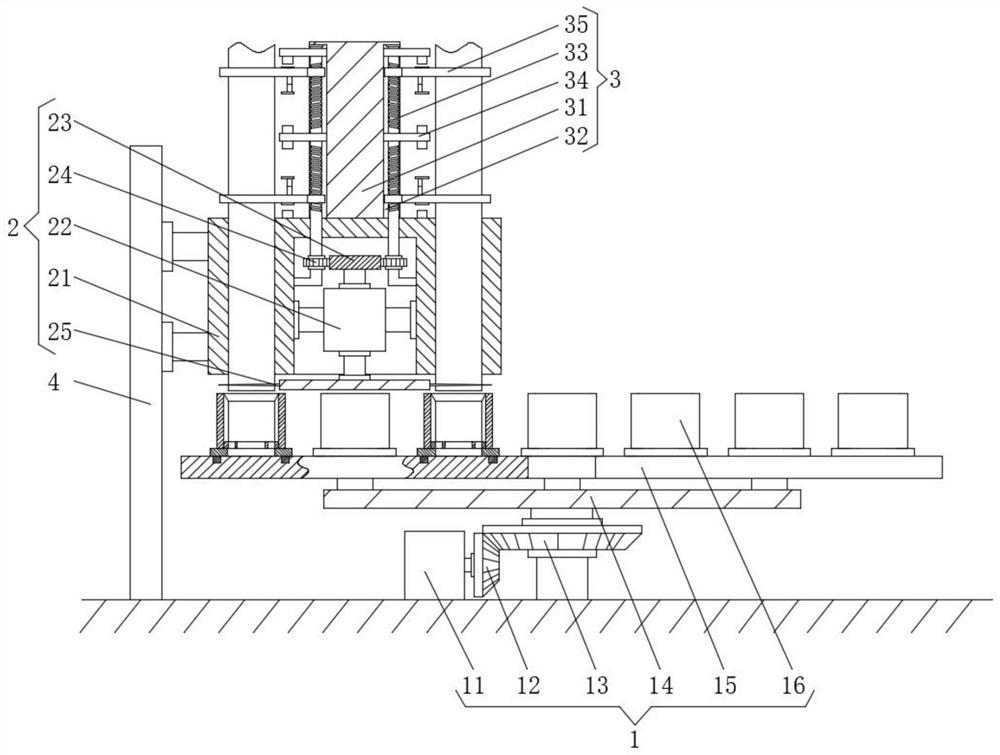

Fermented forage production system

ActiveCN106962963AExtended service lifeReduce labor intensitySievingFeeding-stuffCompression moldingAgricultural science

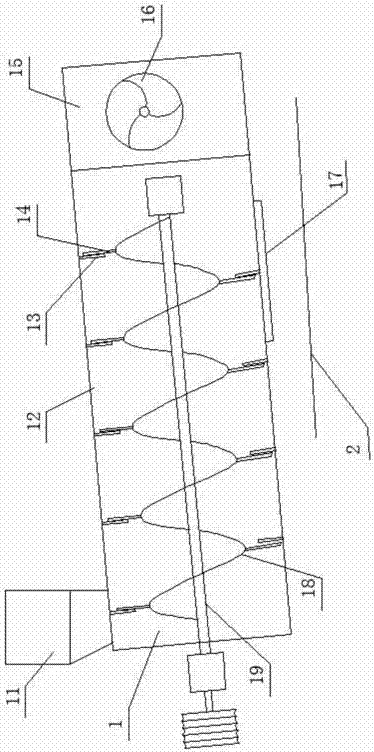

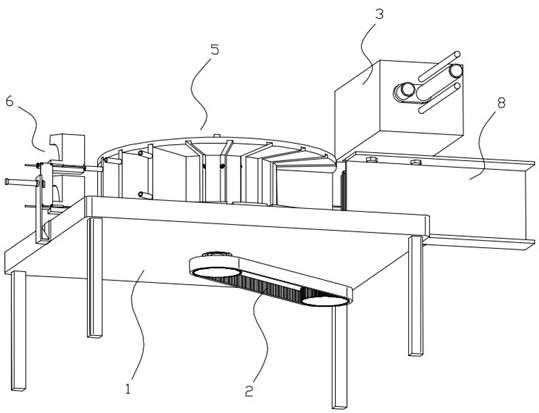

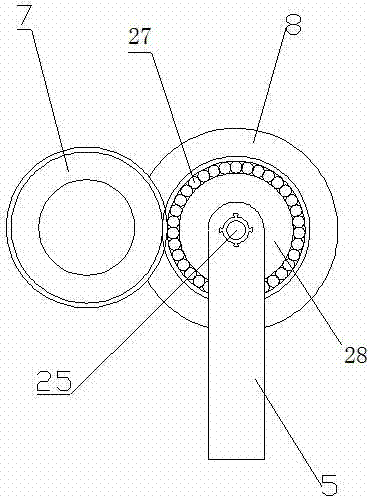

The invention provides a fermented forage production system. The production system comprises a pulverizing device, a screening device, a stirring device, a material metering mechanism, a compression molding machine and a three-dimensional film-wrapping mechanism, all are arranged sequentially along the feeding direction. The three-dimensional film-wrapping mechanism comprises an axial film-wrapping mechanism and a circumferential film-wrapping mechanism. According to the fermented forage production system, materials are pulverized through the pulverizing device; the materials are screened through the screening device and impurities are removed, then raw materials are added through the stirring device and stirred, and fermented forage obtained by processing bacterial bag waste is manufactured into a column shape through the compression molding machine so as to facilitate the sale and transportation. Thin film is wrapped around the entire outer surface of the column-shaped fermented forage by means of the arrangement of the axial wrapping mechanism and the circumferential wrapping mechanism; and the manual operation is not required in the whole process and the whole process is time-saving and labor-saving. The column-shaped fermented forage is continuously wrapped with film, thereby saving the moved time, ensuring the good effect of wrapping the film, reducing the labor strength and labor cost. The fermented forage production system has the advantages of being reasonable in design, convenient to operate, high in using efficiency and improving the process efficiency and process effect of the bacterial bag waste.

Owner:连云港瑞洋牧业有限公司

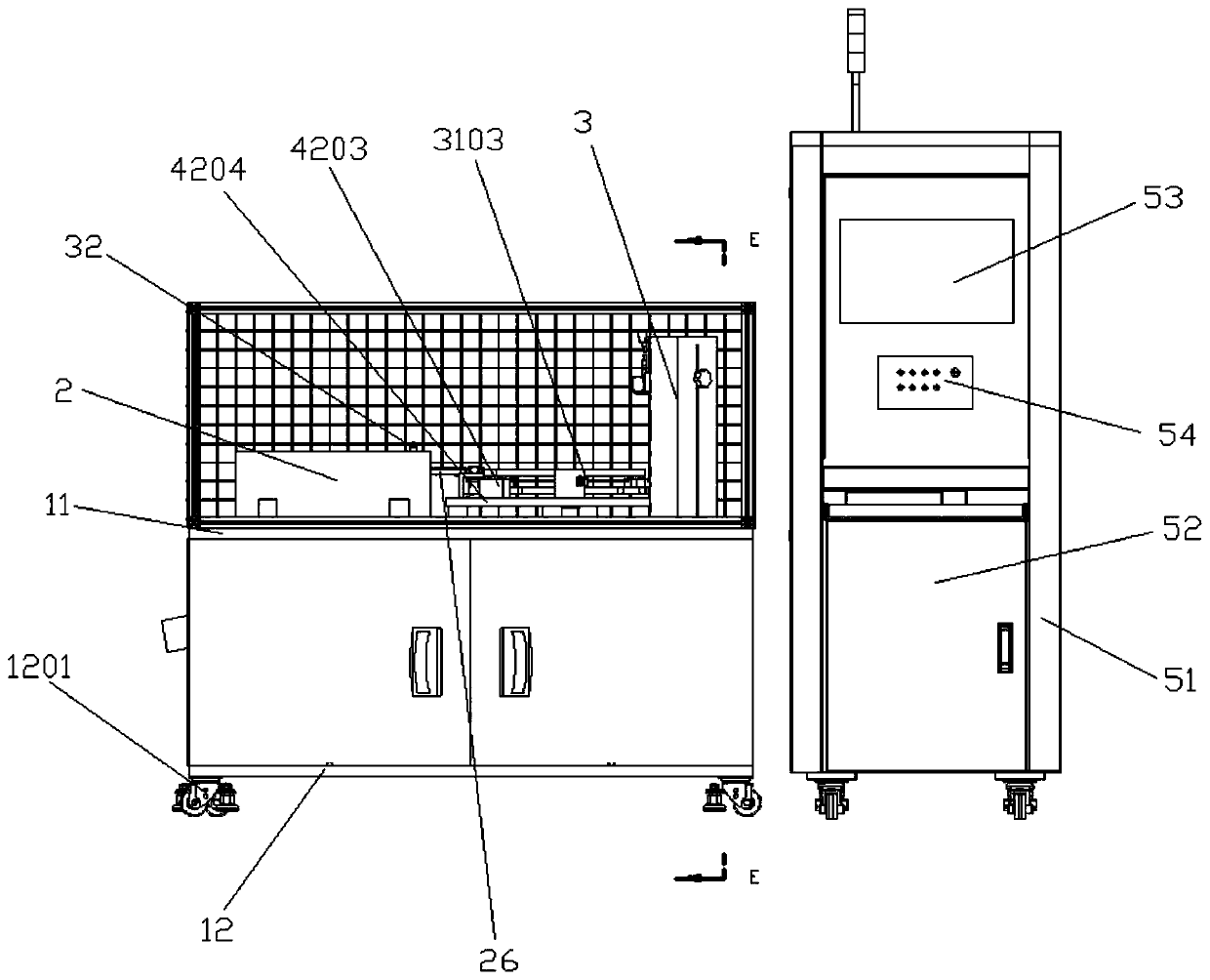

Novel carton customizing machine

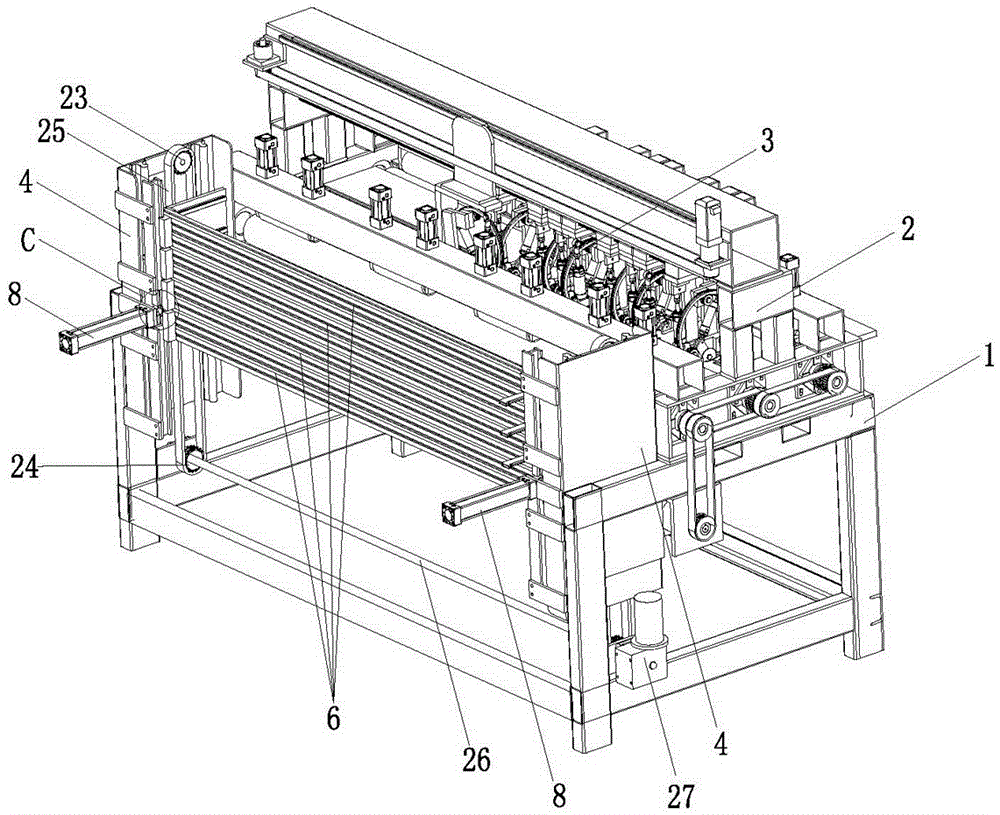

ActiveCN106827651AEasy to integrateSimple structurePaper-makingBox making operationsCartonPaperboard

The invention discloses a feeding device for a carton custom-made machine. Material rack, each clamping rack is adjusted by the lifting of two lifting slides, so that the driver will load the clamping rack holding the cardboard to the processing station along the horizontal direction, and the cutting and creasing device on the processing station will cut , the feeding device of this structure can realize fast switching of cardboards of various sizes, realizes accurate and fast automatic cardboard feeding, saves manual feeding, greatly reduces labor intensity, and is safe and efficient, reducing the time for changing cardboards , improve production efficiency, the cutting and creasing device facilitates the integration of carton cutting and creasing processes, and simplifies the structure of the carton custom machine.

Owner:佛山市顺德区迈盛达自动化机械有限公司

Wallpaper embossing and cutting device capable of automatically feeding

ActiveCN105538785APaved fastProductivityMechanical working/deformationMetal working apparatusTransmission belt

The invention discloses a wallpaper embossing and cutting device capable of automatically feeding. The wallpaper embossing and cutting device comprises a rack, wherein an embossing part and a cutting part at one side are respectively arranged on the top of the rack; the embossing part comprises a pedestal arranged on the top of the rack; a supporting plate is horizontally arranged on the pedestal; the two sides of the pedestal are in parallel provided with first rollers; the first rollers are as high as the supporting plate; the cutting part comprises a first dual-pressure roller arranged on the top of the rack; the first dual-pressure roller is parallel to the first rollers; one side of the first dual-pressure roller is in parallel provided with a second dual-pressure roller; a loading assembly is arranged at one side of the rack; the loading assembly comprises two supporting bases which are arranged correspondingly; a tripod is arranged on the upper parts of the two supporting bases; a vertical rod is perpendicularly arranged on the tripod; both upper and lower ends of the vertical rod are connected with a rotary shaft respectively; transmission belts are arranged on the upper and the lower rotary shafts; a blocking ring is arranged at the outer side of each transmission belt in an equally-spaced mode; the blocking rings on the two transmission belts are correspondingly arranged; connecting rollers are detachably arranged on the blocking rings; and wallpaper is loaded on the connecting rollers.

Owner:WUJIANG WALLMATE DECORATION MATERIALS

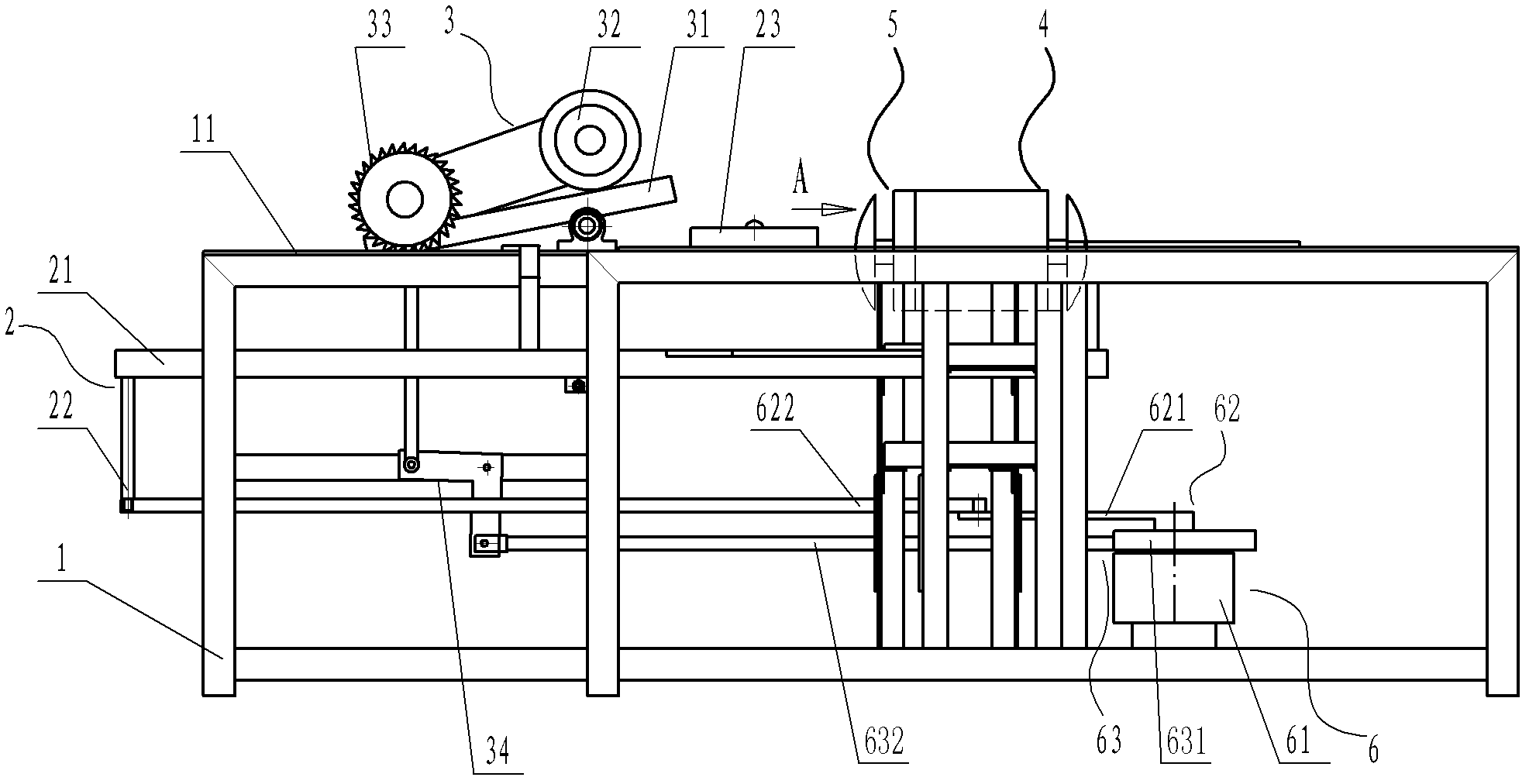

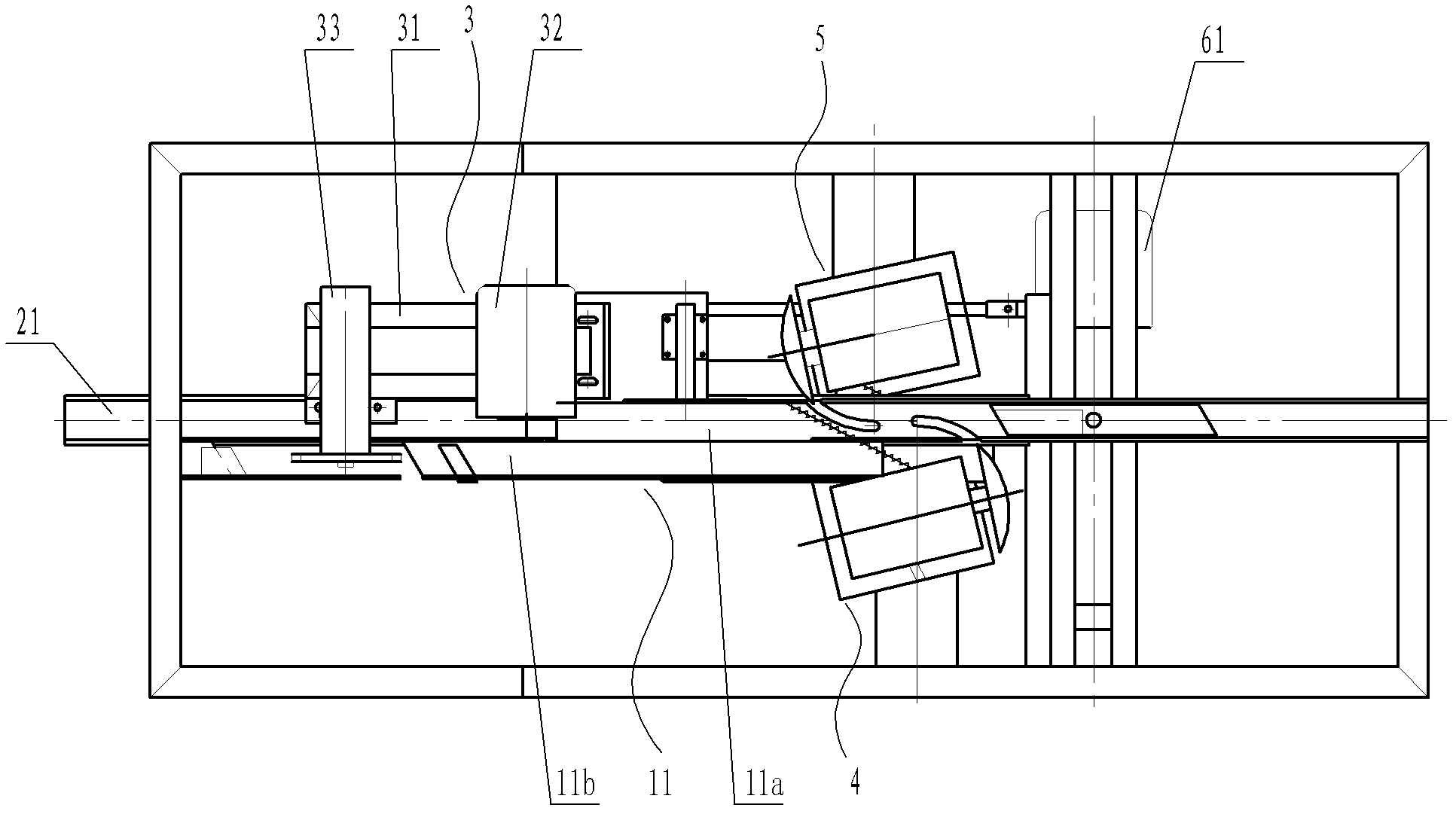

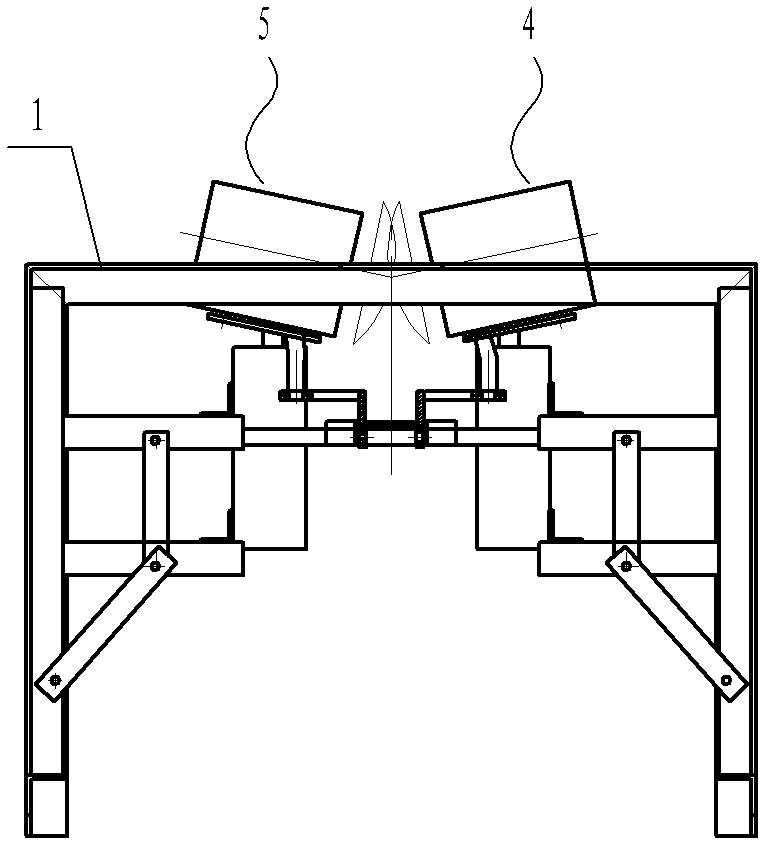

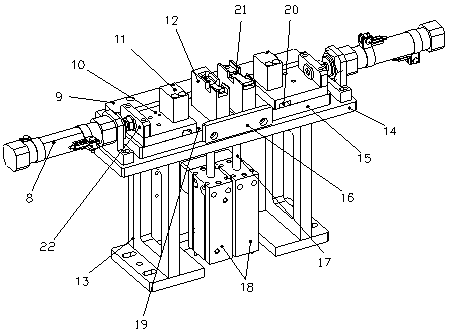

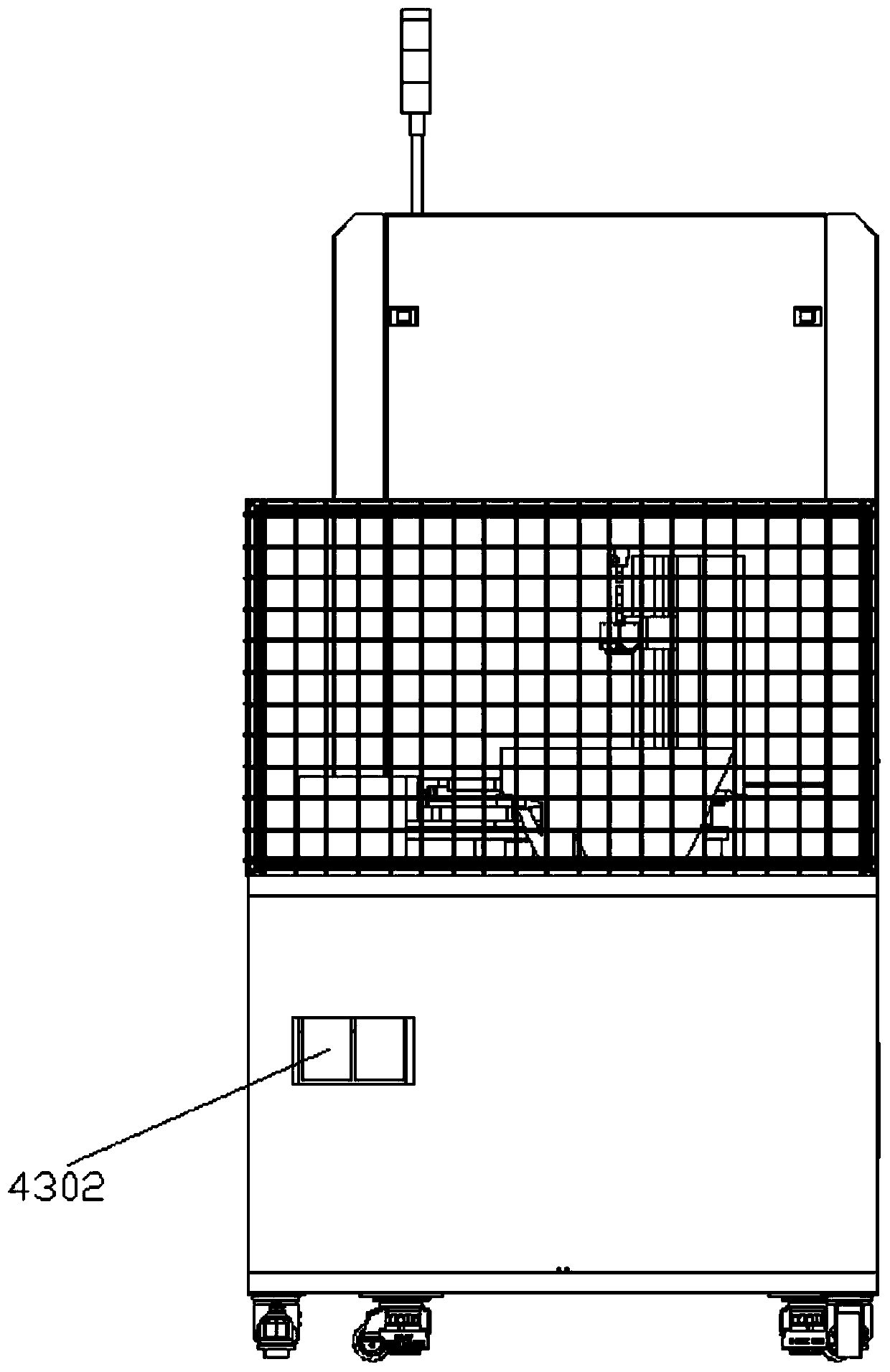

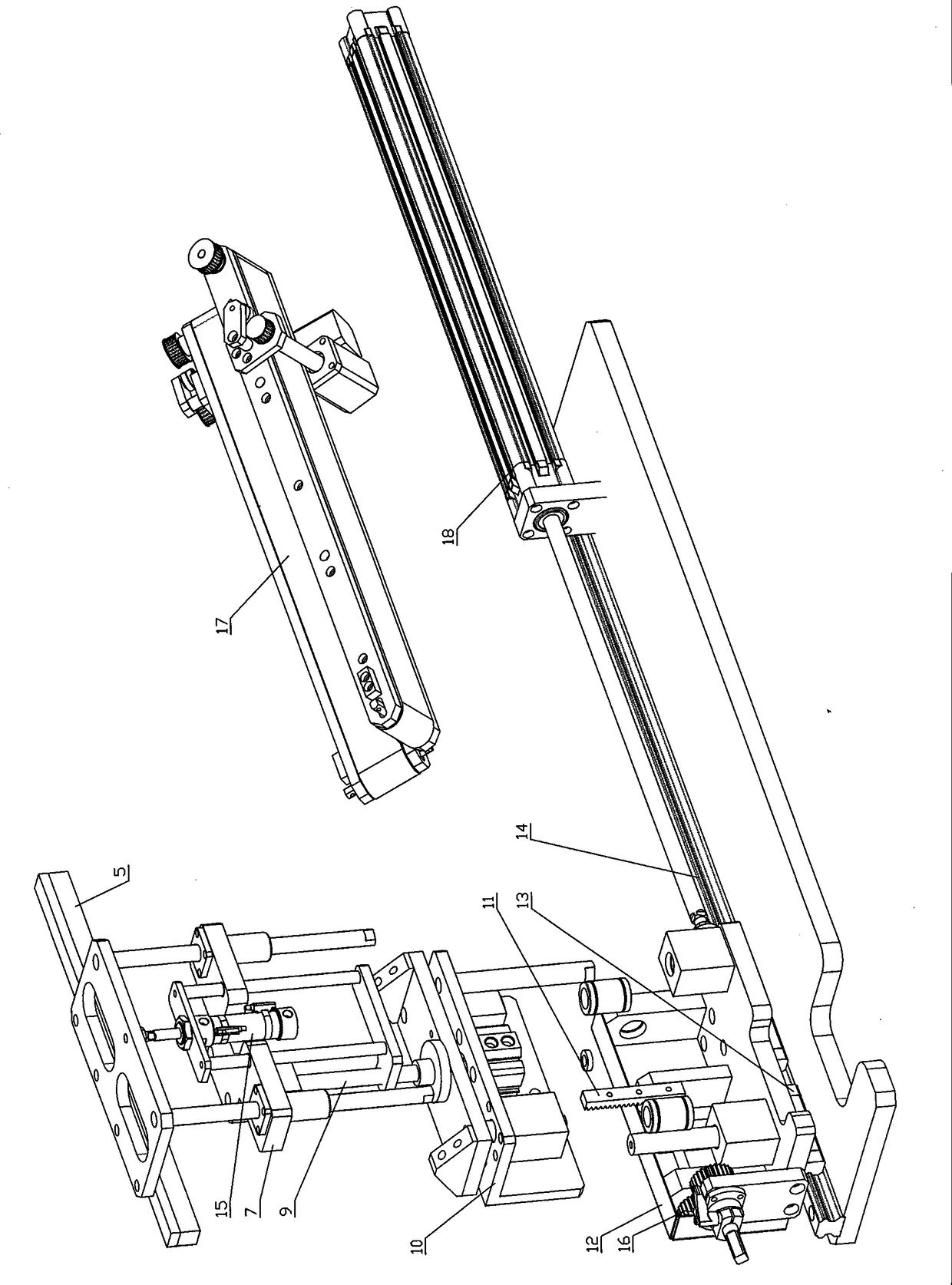

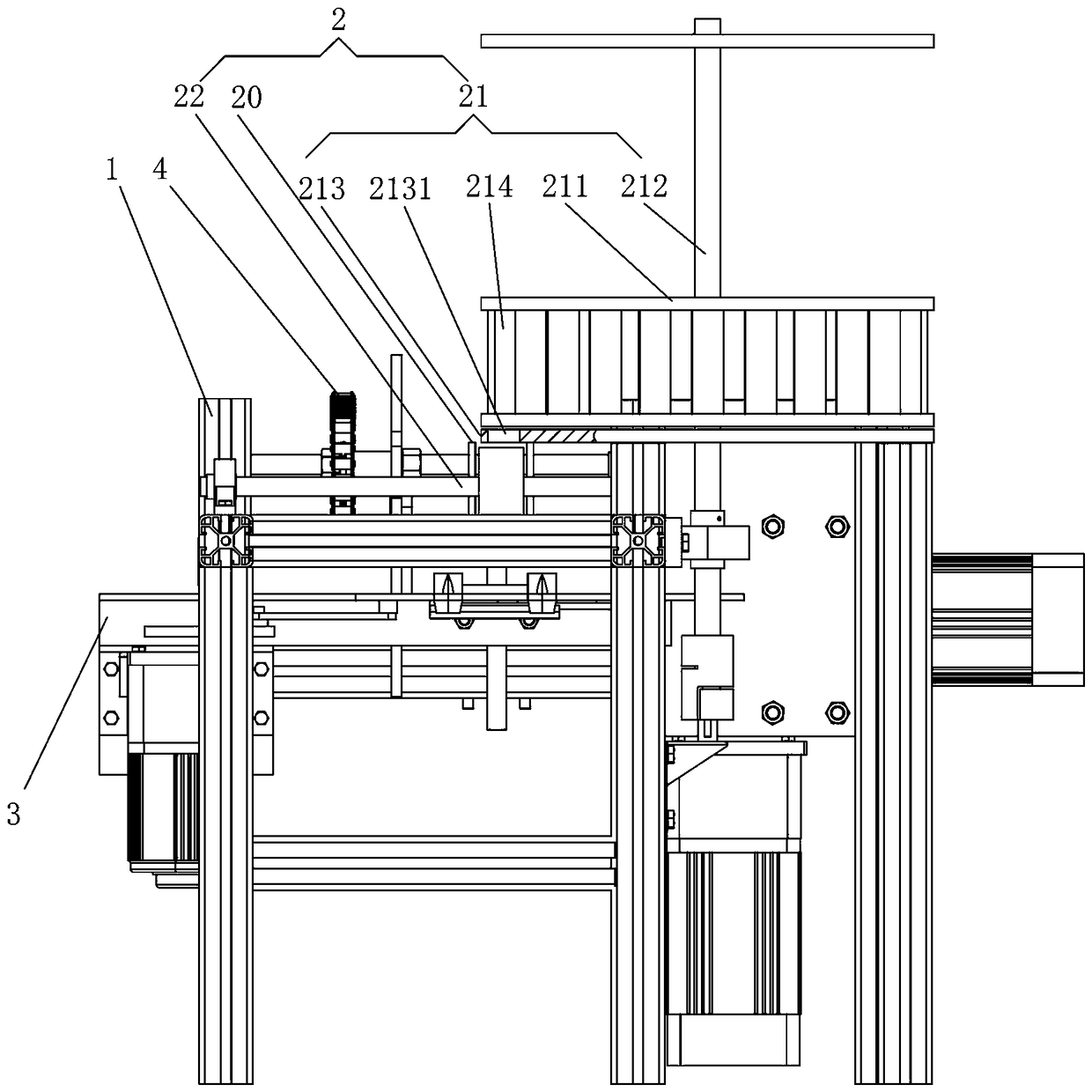

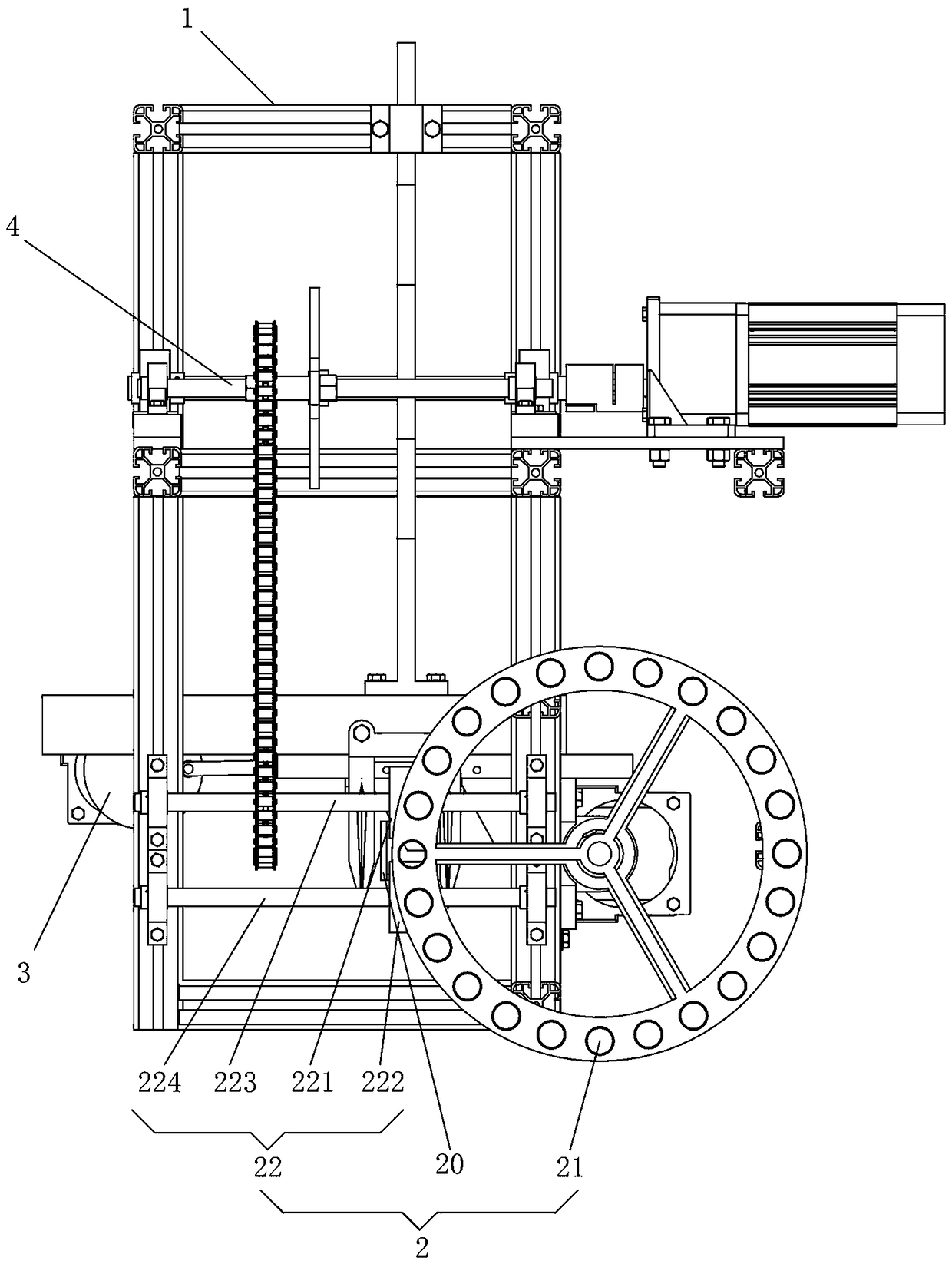

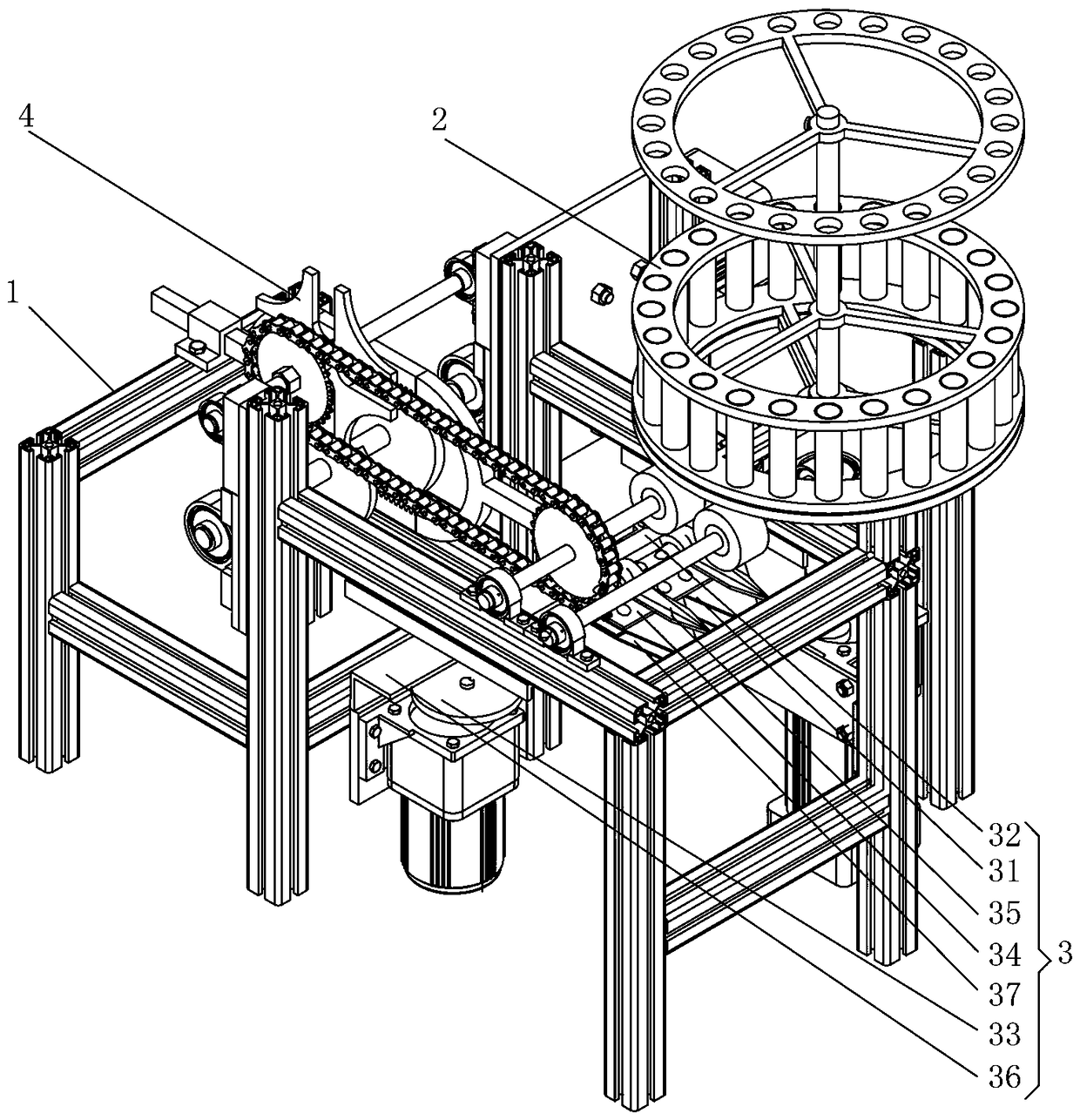

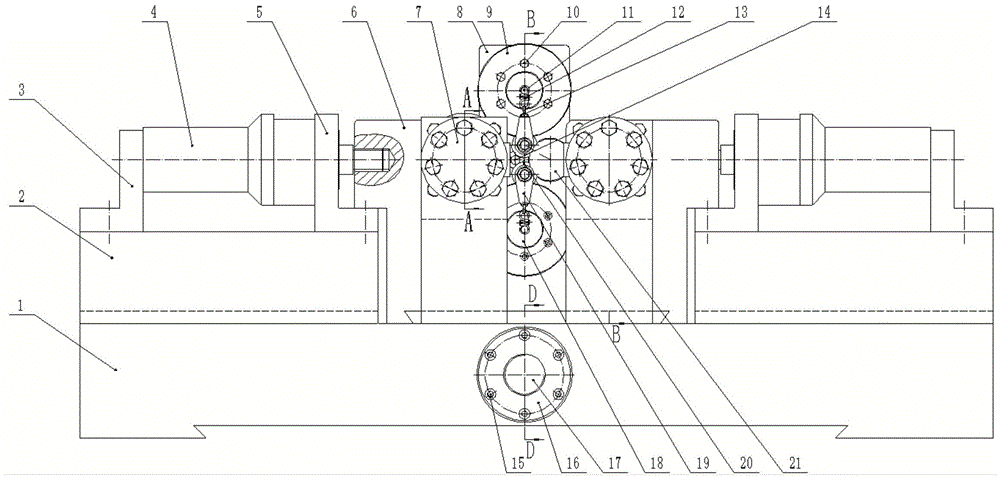

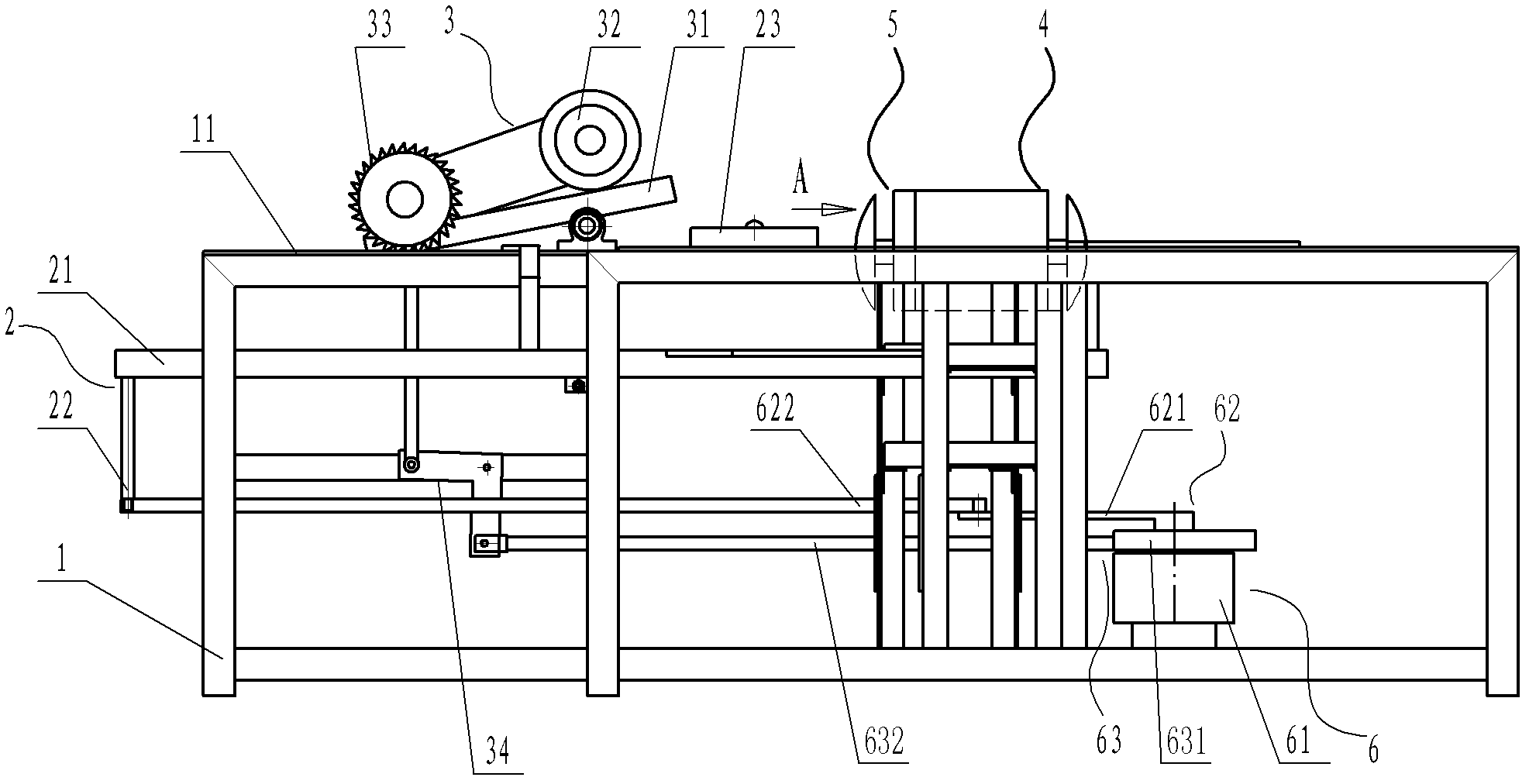

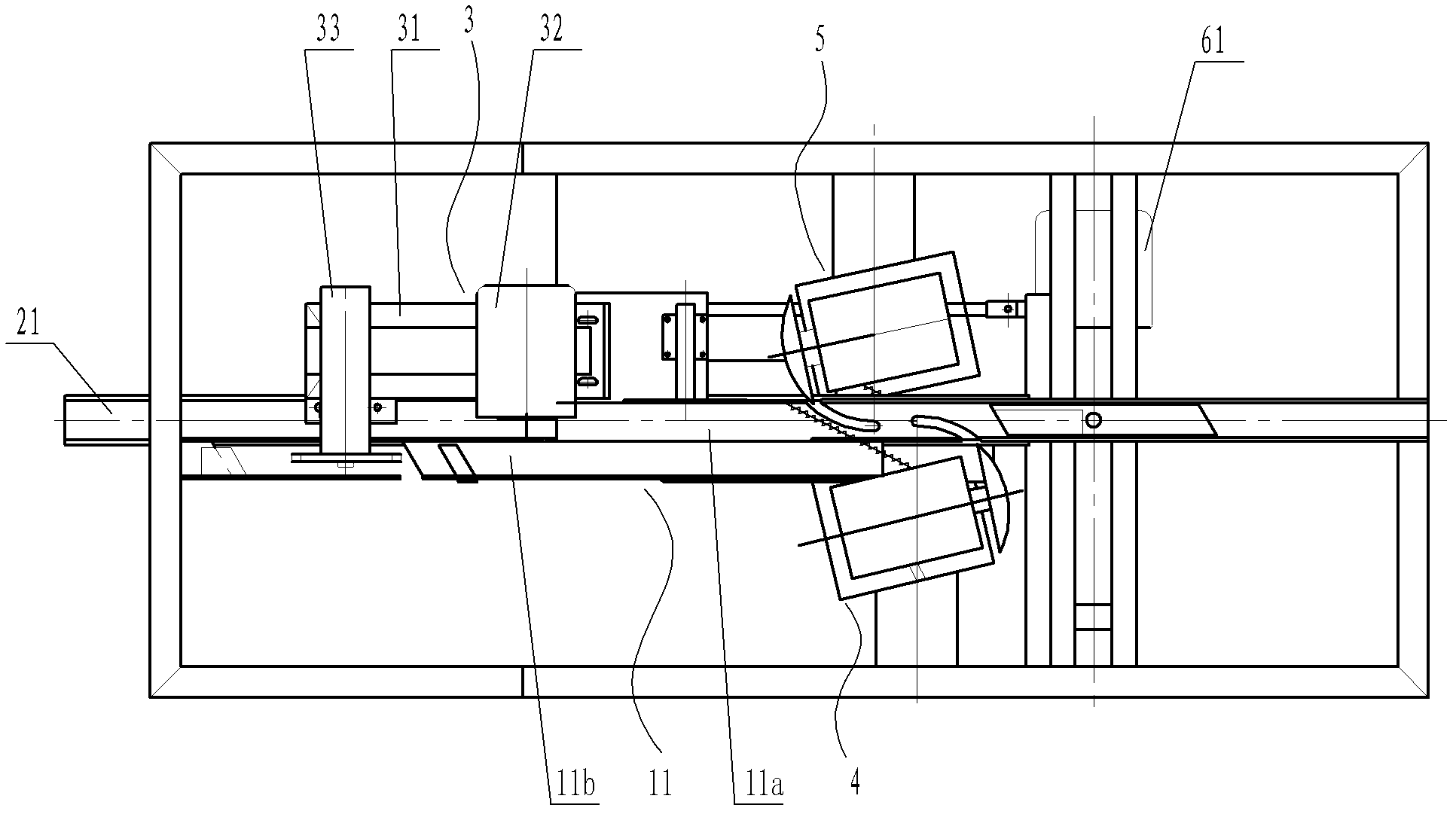

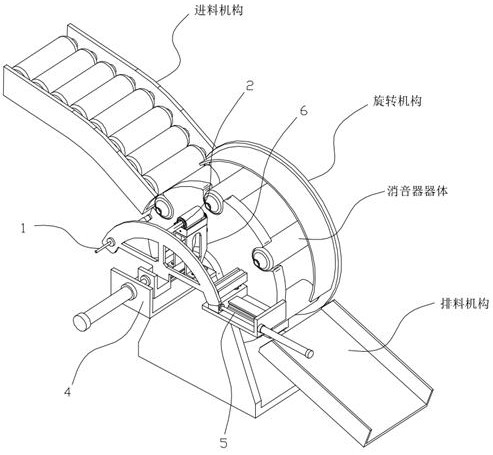

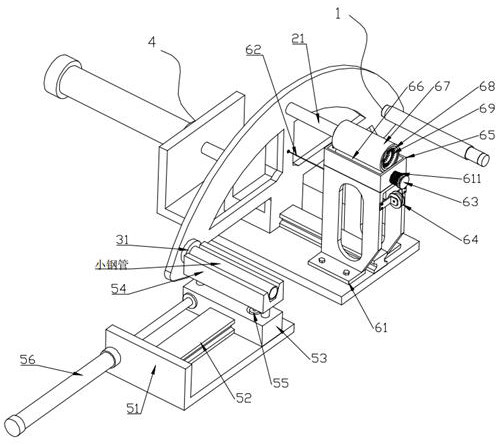

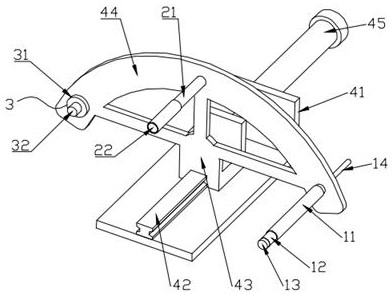

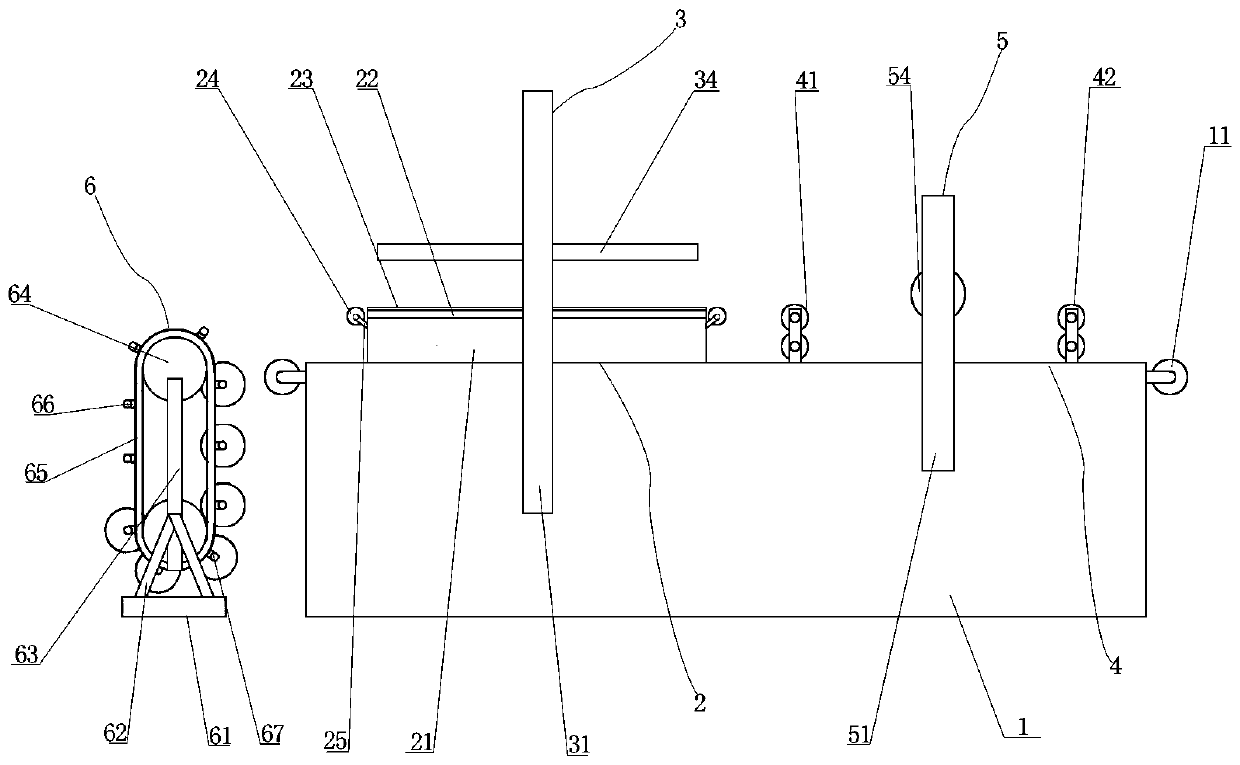

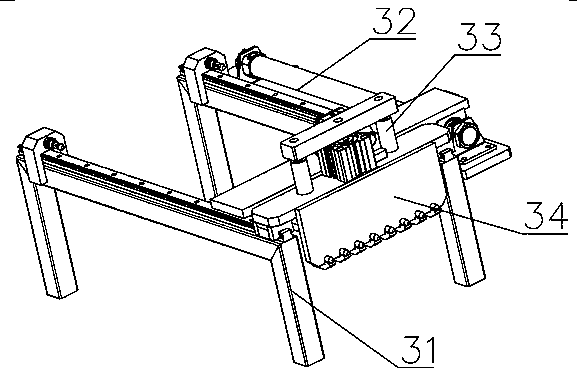

Automatic sawing and bending machine

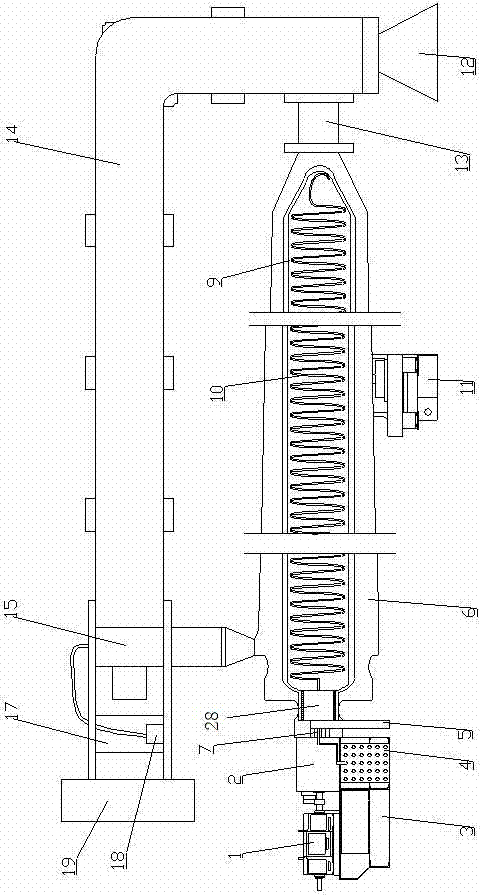

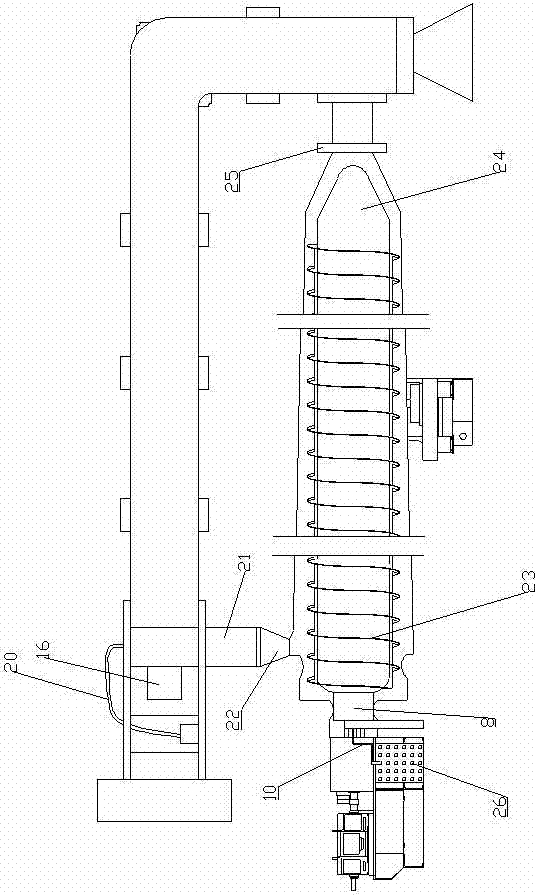

InactiveCN102581914AEliminate manual feedingReduce usageMulti-purpose machinesEconomic benefitsEngineering

An automatic bending and sawing machine relates to production equipment for wood clothes hangers and comprises a framework, a feeding mechanism, a straight saw assembly, a front spherical saw assembly, a rear spherical saw assembly and a movement control mechanism. A guide track is arranged on the framework, the straight saw assembly is mounted at one end of the guide track, the front spherical saw assembly and the rear spherical saw assembly are rotatably mounted on two sides of the other end of the guide track, the movement control mechanism consists of a power output device, a feeding mechanism control device and a straight saw assembly control device, the feeding mechanism control device is connected with the feeding mechanism, and the straight saw assembly control device is connected with the straight saw assembly. A sawing and bending processing route is divided into two arc curves and a straight line, the arc curves and the straight line are automatically processed by the corresponding front spherical saw assembly, the rear spherical saw assembly and the straight saw assembly, accordingly, automatic bending and sawing processing is realized, danger of operation of workers is reduced, simultaneously, productivity is effectively enhanced, and the automatic bending and sawing machine has certain social and economic benefits.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

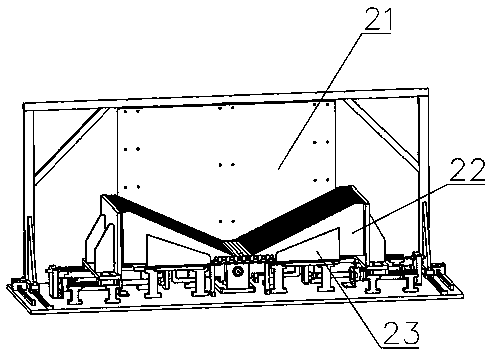

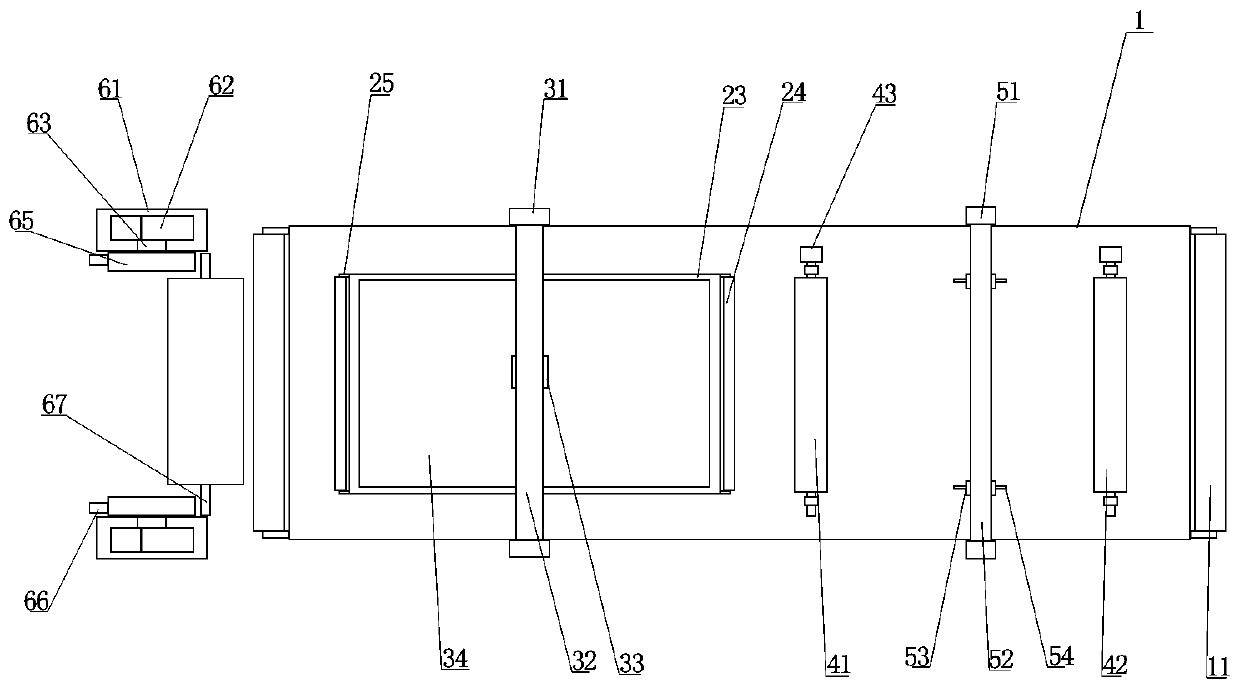

Glass edge grinding system

InactiveCN105234771APrevent left and right movementWon't hurtEdge grinding machinesGrinding feedersRubber ringEngineering

The invention discloses a glass edge grinding machine. Two parallel automatic conveying belts are arranged on the left side and the right side of a base in a spaced mode. A plurality of sets of grinding heads are arranged on the outer side of each automatic conveying belt. The front ends of fixed guiding wheels stretch to the position in front of the automatic conveying belts. The front ends of movable guiding wheels are flush with the front ends of the automatic conveying belts. A line of rubber conveying idler wheels are arranged right in front of the automatic conveying belts. A glass storage frame is arranged right in front of the rubber conveying idler wheels. A line of material receiving rollers which are arranged in the front-and-back direction and can rotate flexibly are arranged right behind the base. The periphery of each material receiving roller is sleeved with a rubber ring. The movable guiding wheels and all the sets of grinding heads located on the right side are installed on the base in the mode of being adjustable in the left-right direction, and the movable guiding wheels and all the sets of grinding heads are adjusted synchronously so as to be adapted to grinding of glass edges with different widths. The glass edge grinding machine has the forward guiding function, so that pieces of glass are aligned before edge grinding is conducted; the glass edge grinding machine can be adapted to processing of glass of different width specifications, and automatic feeding and material receiving are achieved.

Owner:CHONGQING FUXIN GLASS

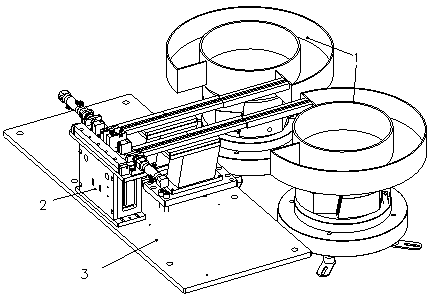

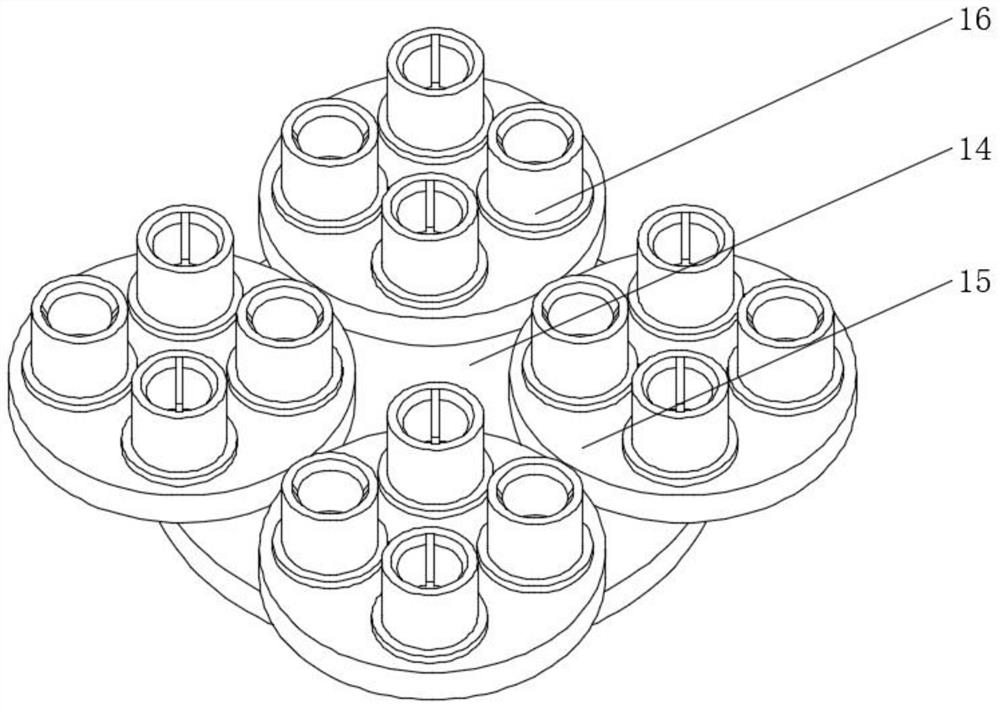

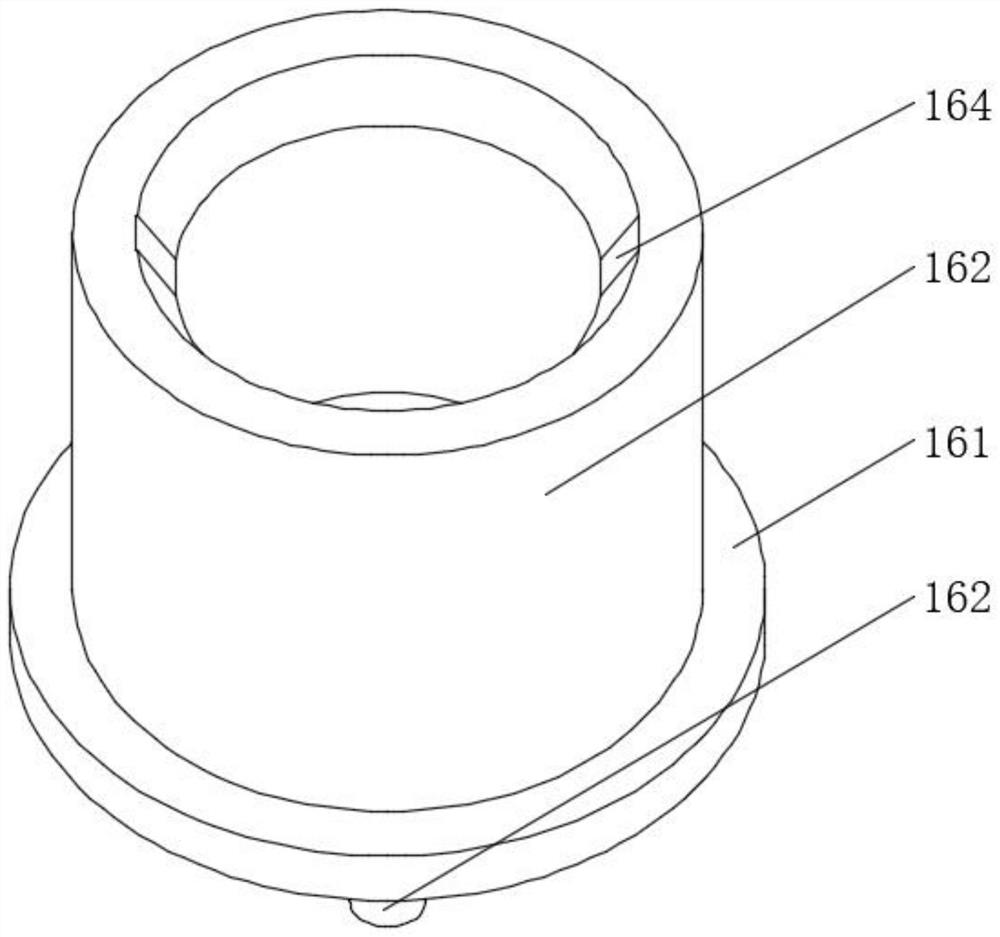

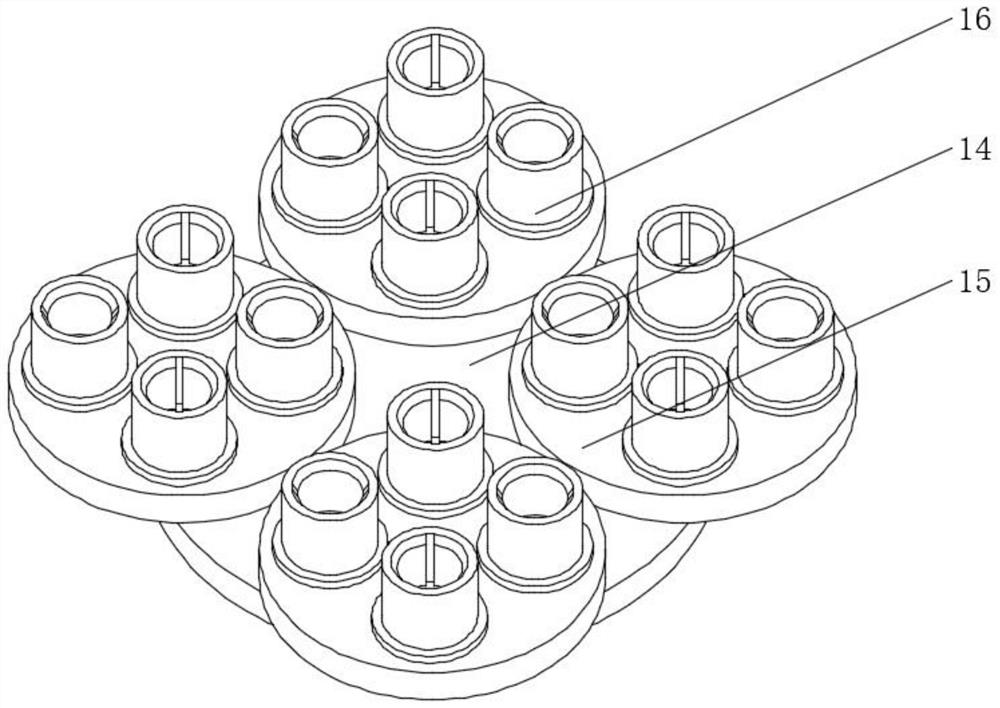

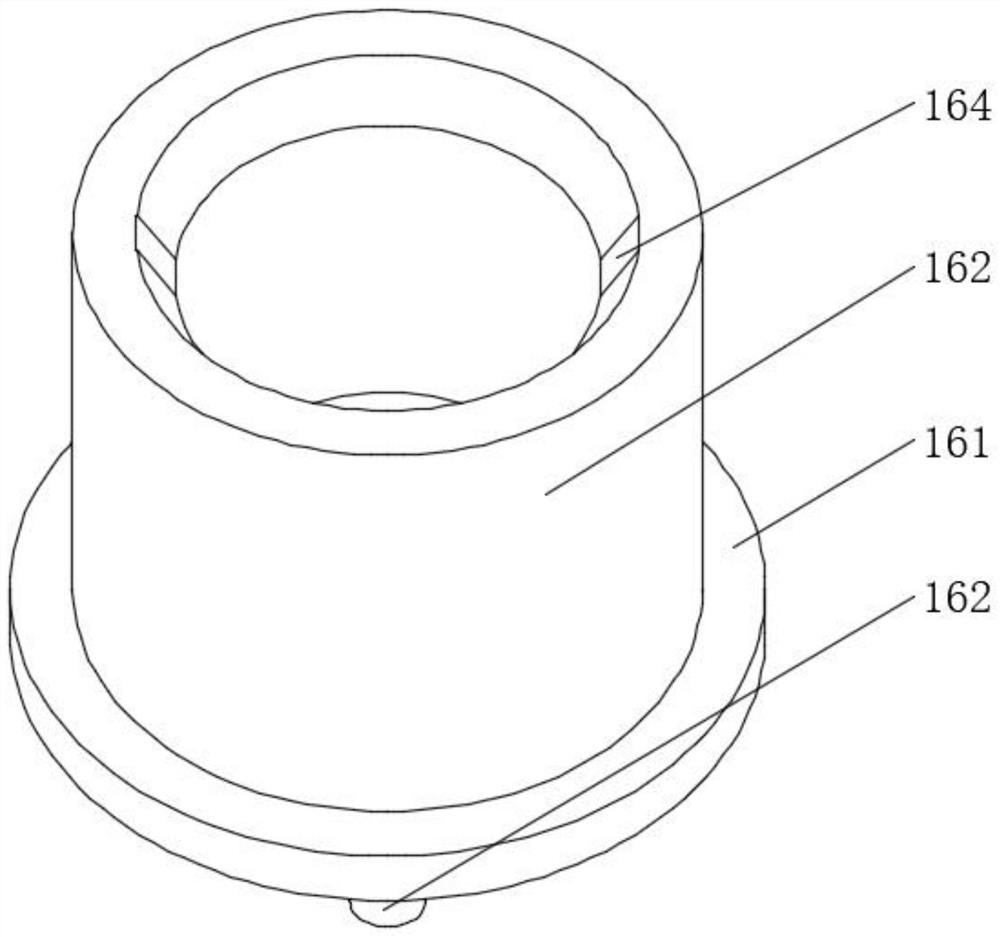

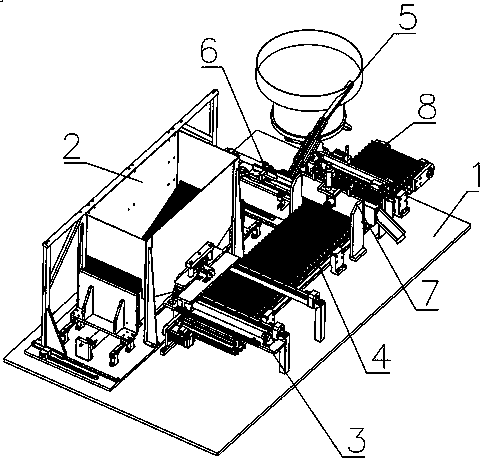

Automatic material separating mechanism for cylinder valve plate

InactiveCN109205279AEasy to dispense at the same timeRealize zero time-consuming changeoverConveyor partsEngineeringCylinder Valve

The invention discloses an automatic material separating mechanism for a cylinder valve plate, comprising a vibration material storage and feeding device, a material separating device and a base plate; the vibration material storage and feeding device is provided with a connecting rod; the upper end of the base plate is symmetrically connected with two groups of vibration disks through the connecting rod; the vibration disks are provided with discharging ports which are connected with straight vibration material channels; the lower ends of the straight vibration material channels are fixedly connected with straight vibrators; the straight vibrators are fixedly installed on the base plate; and the tail ends of the straight vibration material channels are provided with material separating devices. The automatic material separating mechanism provided by the invention has two material separating positions, so that two kinds of valve plates can be separated conveniently and simultaneously;any adjustment is not needed when replacing the type; zero time-consuming model replacing is realized; the automatic material separating mechanism is quicker and more effective; a batch of materials is intensively placed for once by labor, so the labor feeding is saved and the efficiency is improved; meanwhile, the human factor of error feeding is avoided; a valve plate mould block is provided, sothe mechanism is convenient to install and disassemble, quick and simple; and with simple and compact structure, the invention can cooperate with a plurality of feeding mechanisms to finish feeding materials.

Owner:中山精航智能科技有限公司

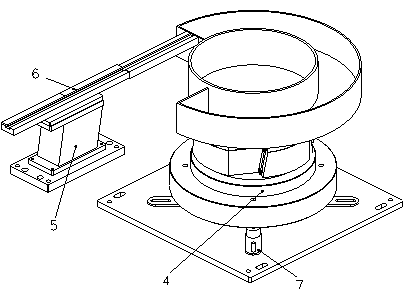

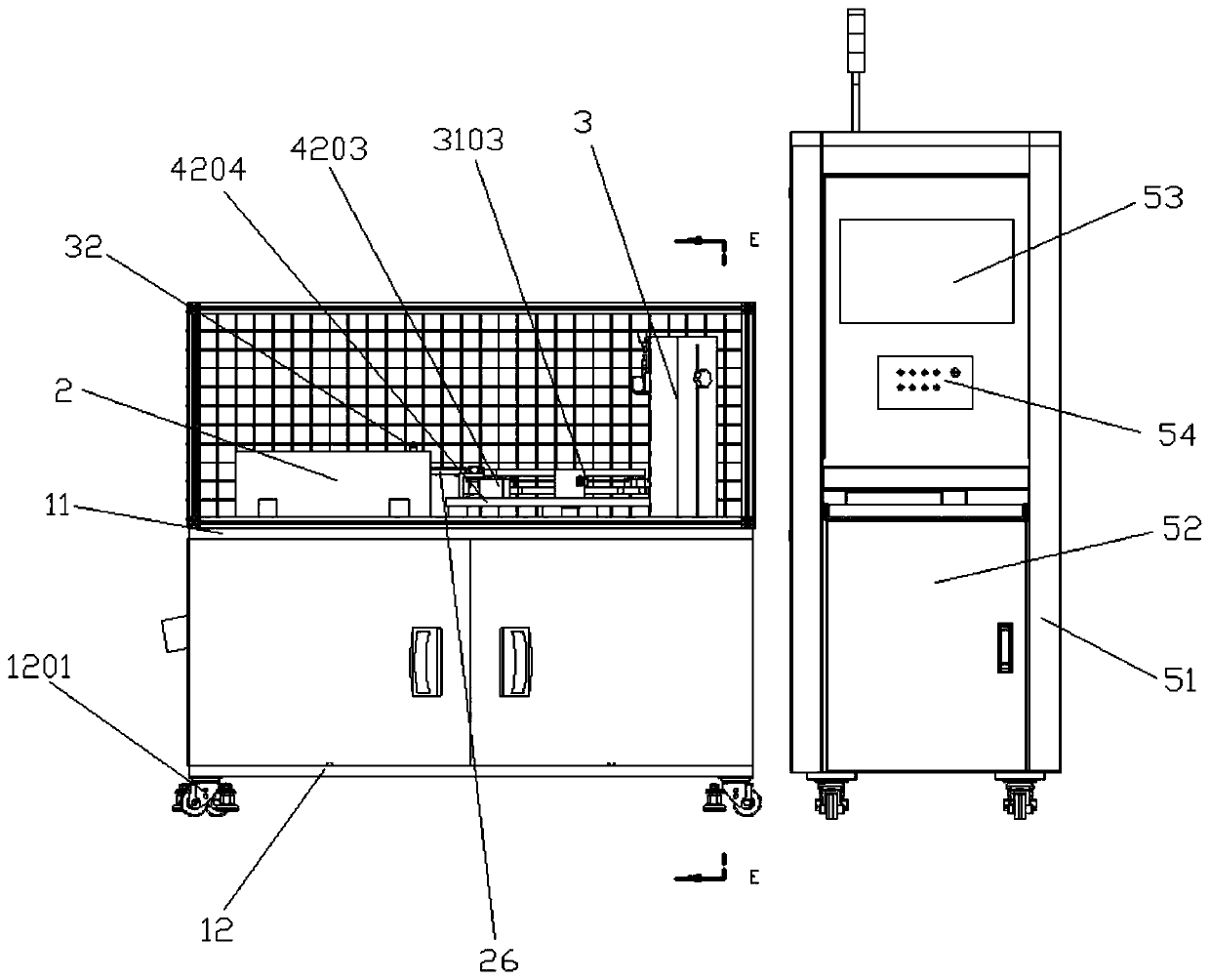

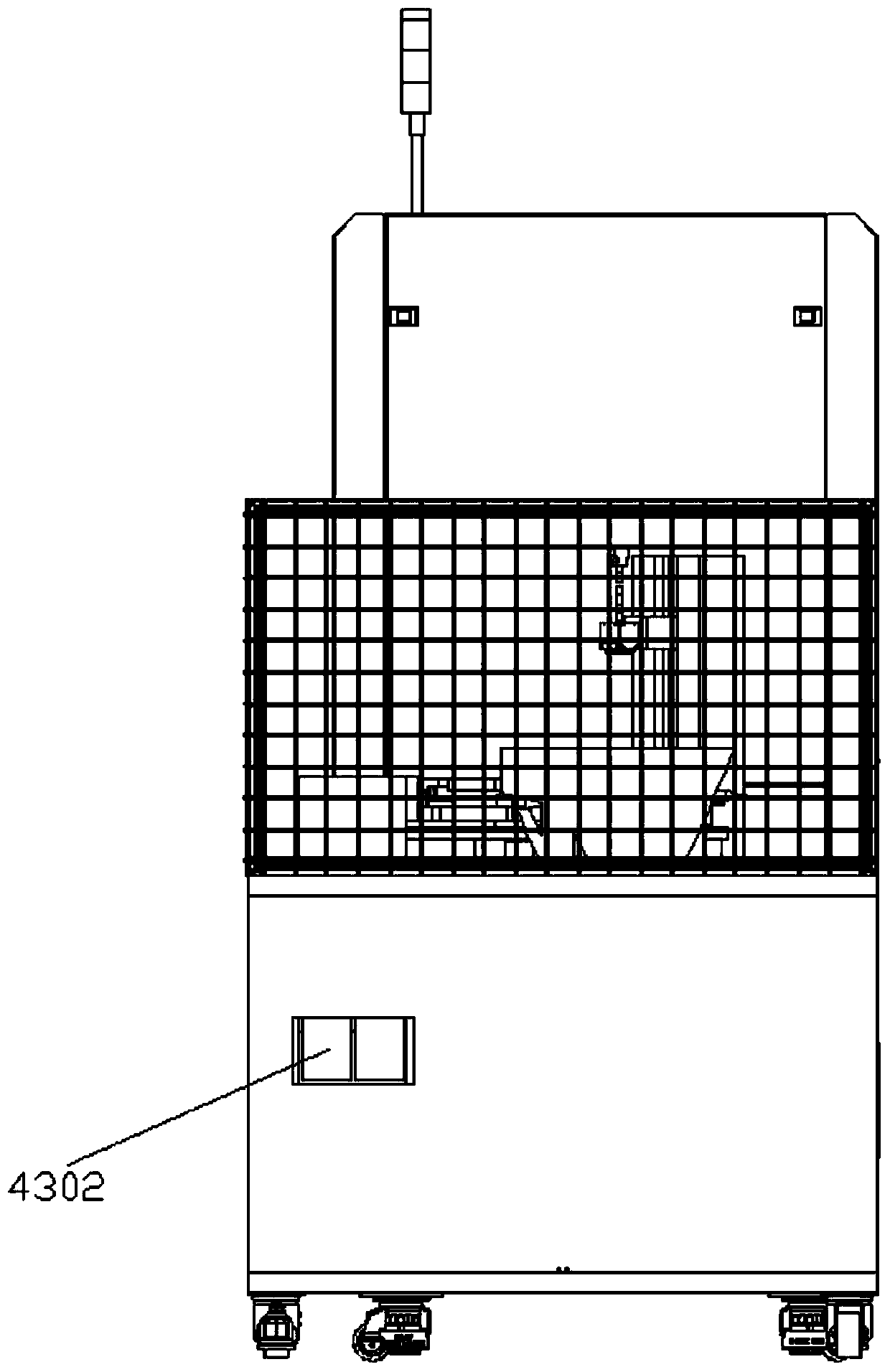

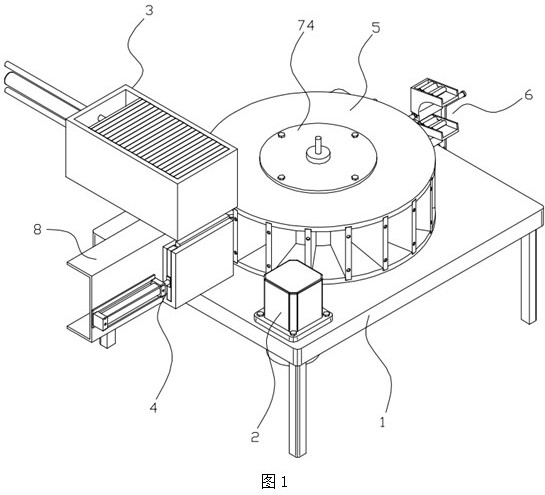

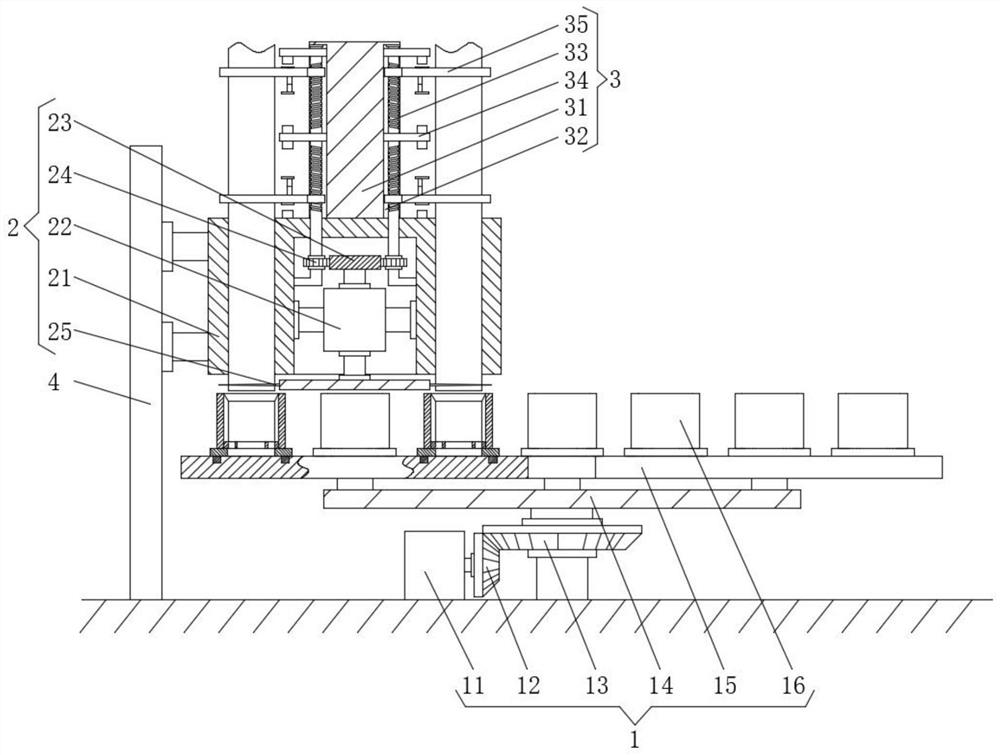

Automatic detection device for cylindrical pin machine

The invention discloses an automatic detection device for a cylindrical pin machine, and relates to the field of mechanical detection. The automatic detection device comprises a rack, a loading device, a detection device, a feeding device and a control device. The automatic detection device is characterized in that the rack comprises a top plate and a bottom plate; the loading device is arranged on the bottom plate and penetrates through the top plate; the feeding device comprises a driving device, a rotating device and a discharging device. The driving device is arranged on the bottom plate;the rotating device is arranged on the top plate; the discharging device is arranged on the top plate; the driving device is connected with the rotating device through a stepping assembly. The discharging device is arranged on one side of the rotating device. The detection device is arranged on the top plate and located on one side of the rotating device. The loading device is connected with the rotating device through a positioning piece. The length and the diameter of the cylindrical pin can be rapidly detected and the detection efficiency is improved.

Owner:SHANDONG INST FOR PROD QUALITY INSPECTION

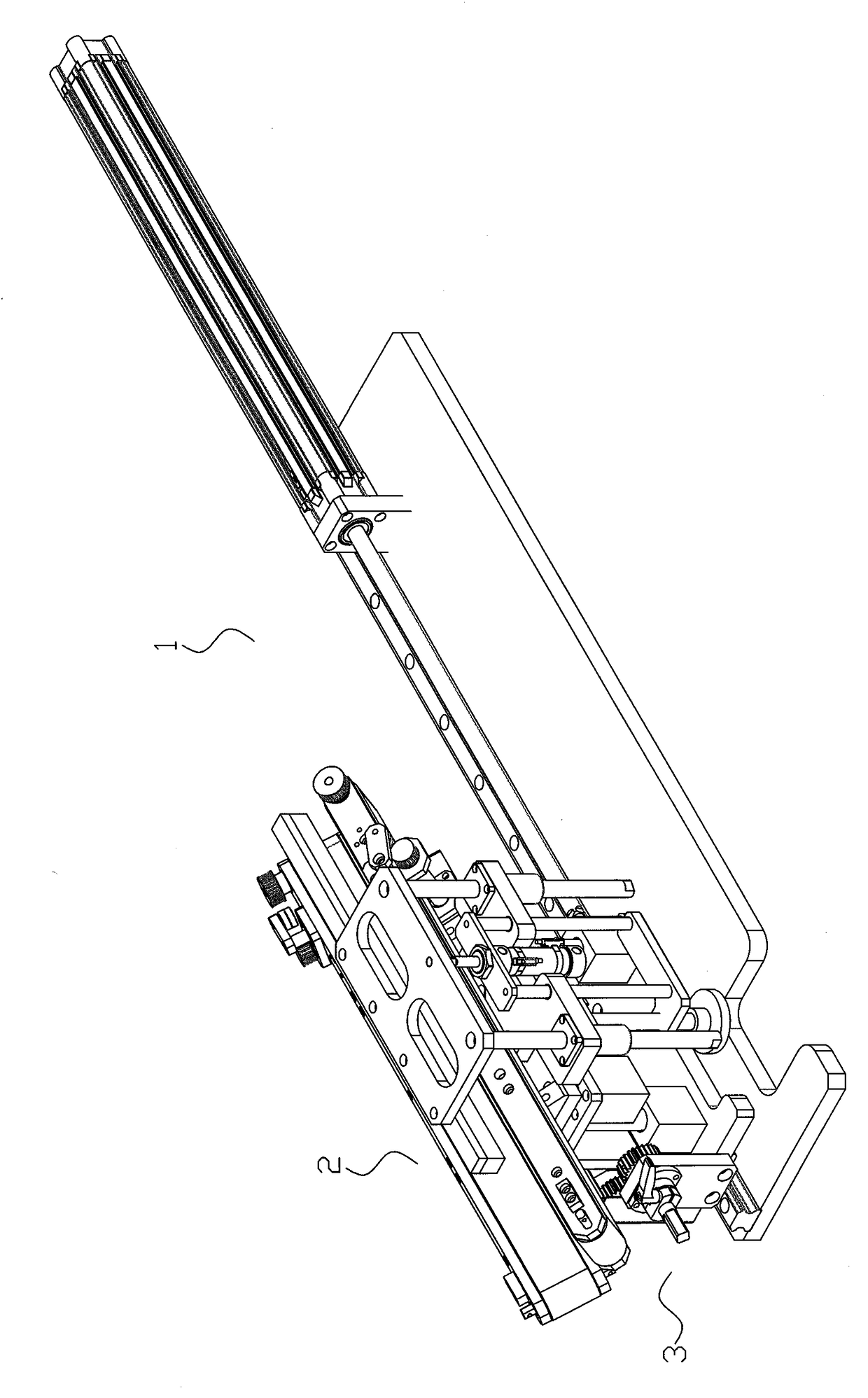

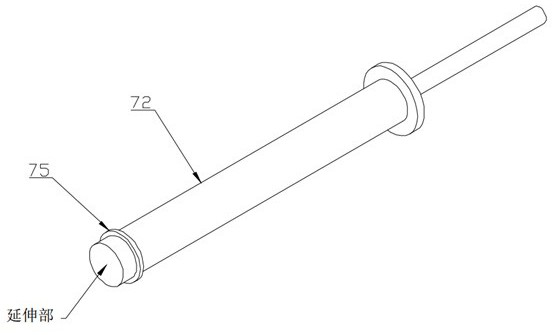

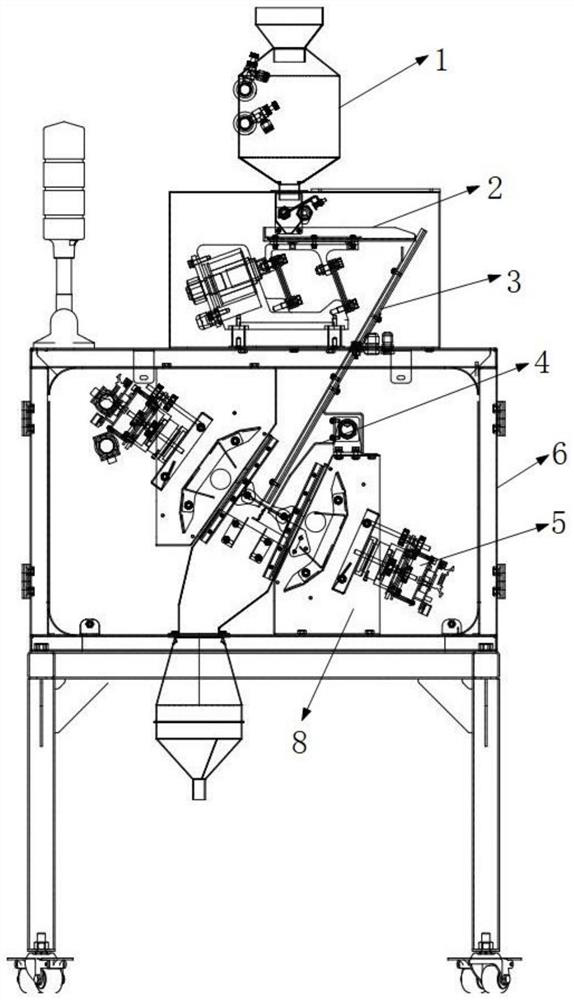

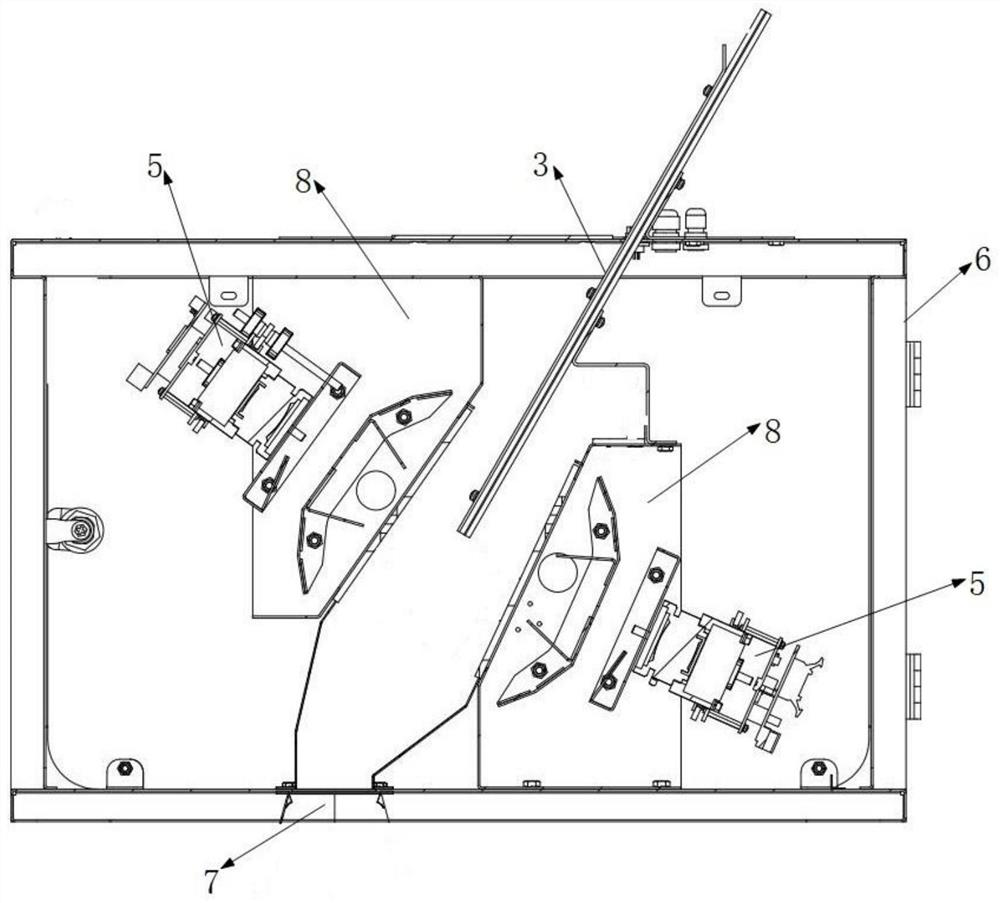

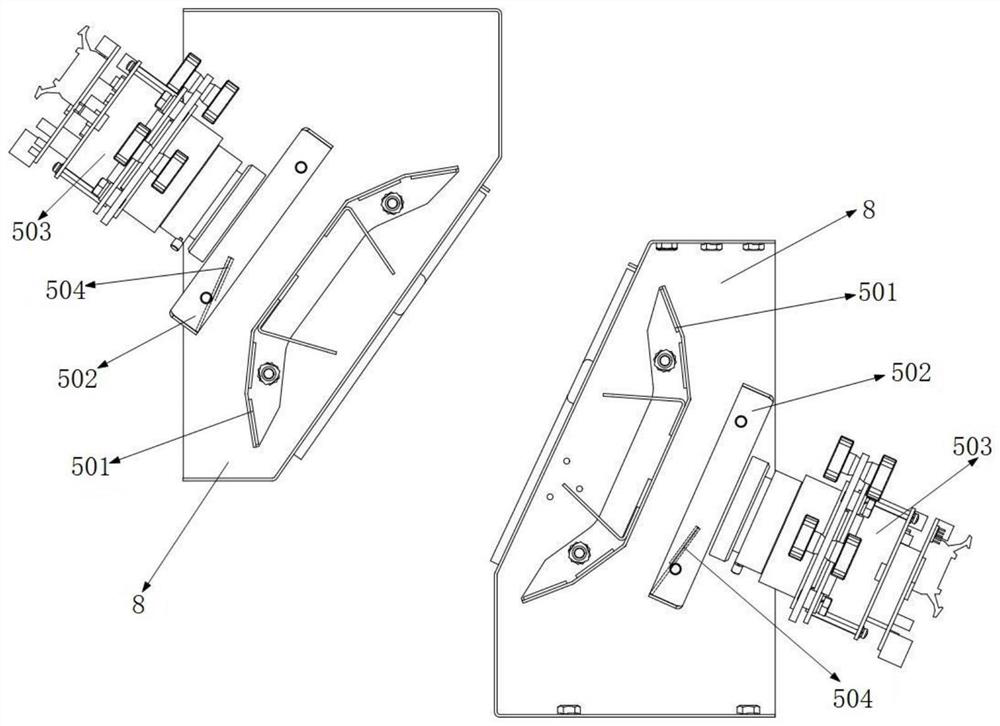

Feeding mechanism of paper tube cores

PendingCN108128650AIncrease productivityEliminate manual feedingWebs handlingPulp and paper industry

The invention discloses a feeding mechanism of paper tube cores. The feeding mechanism comprises a material inlet part and a feeding part for sending the paper tube cores on the material inlet part onto a winding shaft. The feeding mechanism is characterized in that the material inlet part comprises a paper tube core base for placing at least two axial paper tube cores. The feeding part comprisesa power assembly for driving the paper tube core base to move axially. The paper tube core is axially placed on the paper tube core base, the paper tube core base is driven by the power assembly to move axially, the paper tube cores on the paper tube core base are arranged on the winding shaft in a sleeving mode, automatic feeding is achieved, a plurality of paper tube cores can be fed at a time,production efficiency is greatly improved, manual feeding is omitted, and production cost is reduced.

Owner:瑞安市德冠机械有限公司

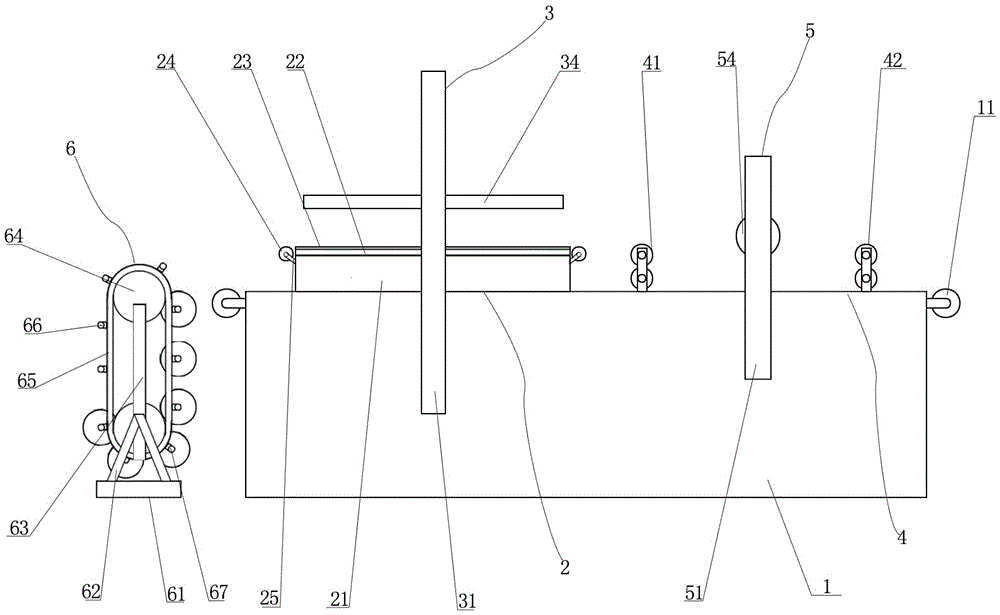

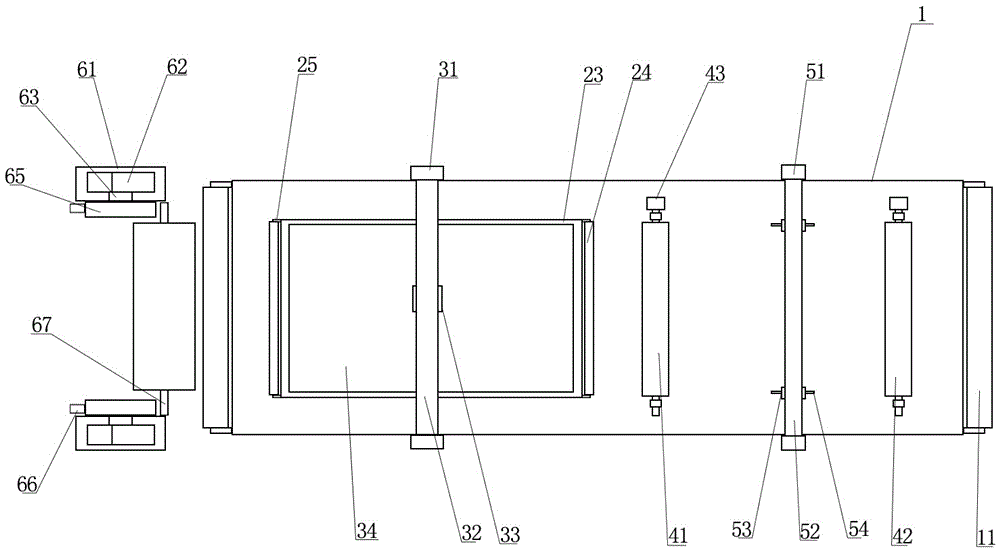

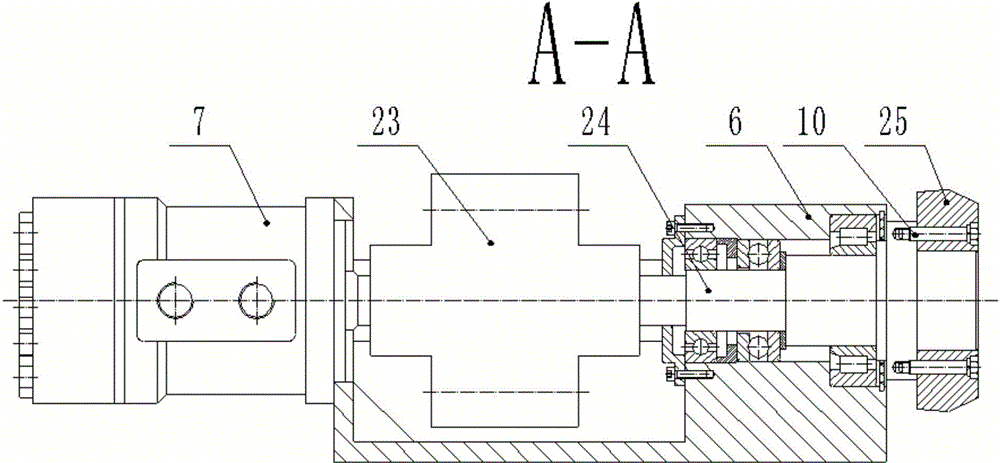

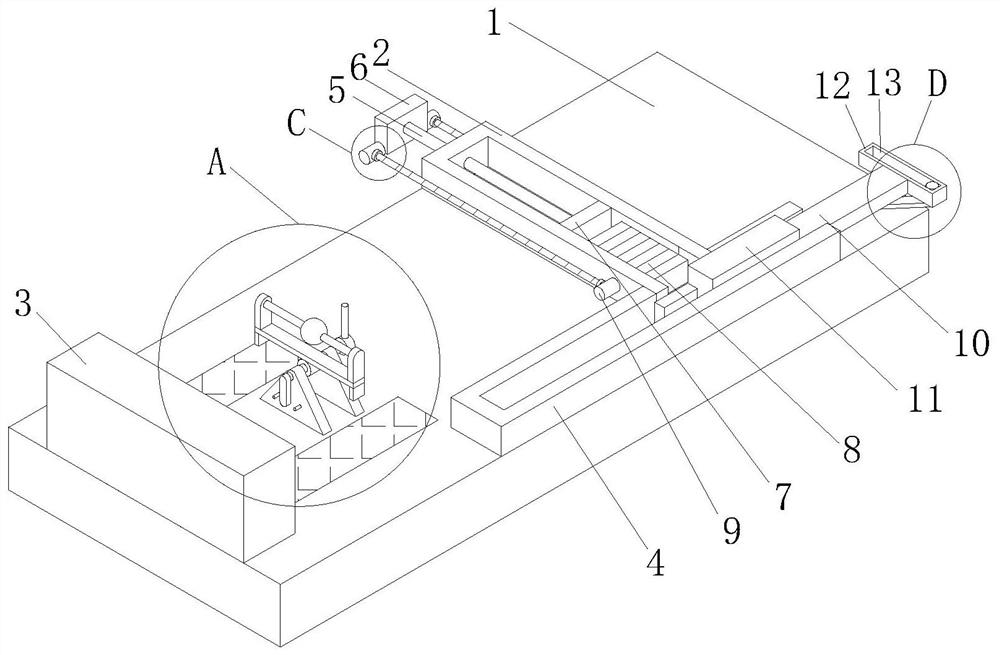

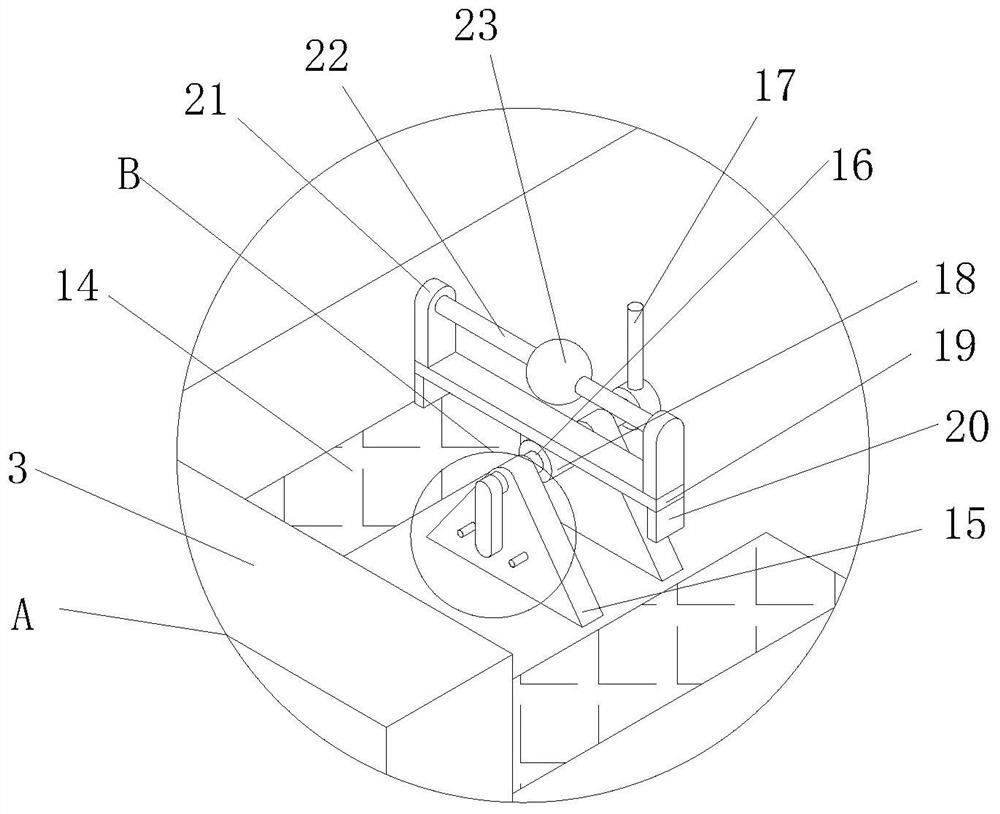

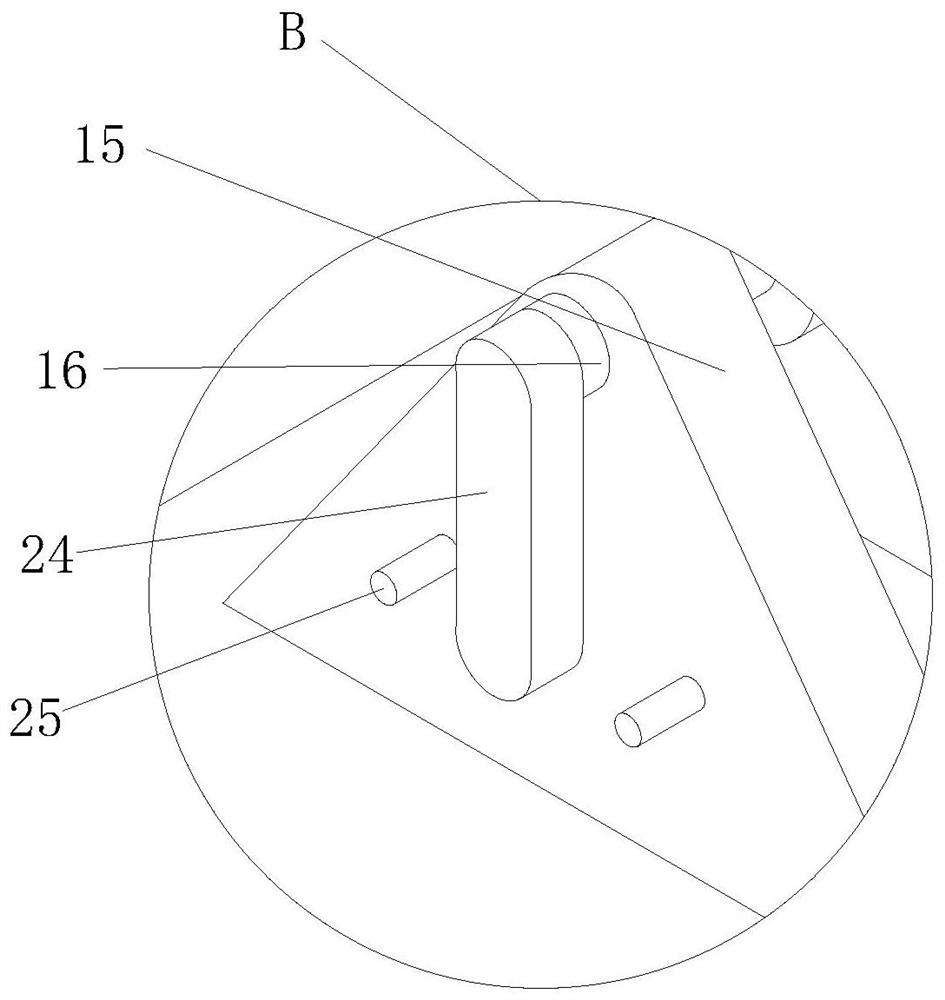

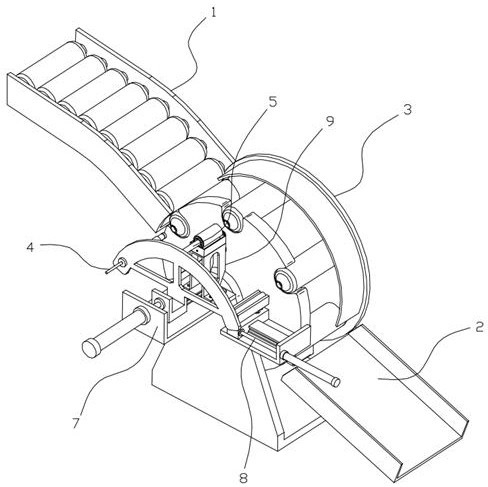

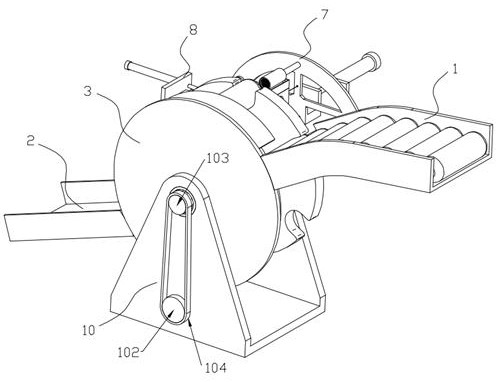

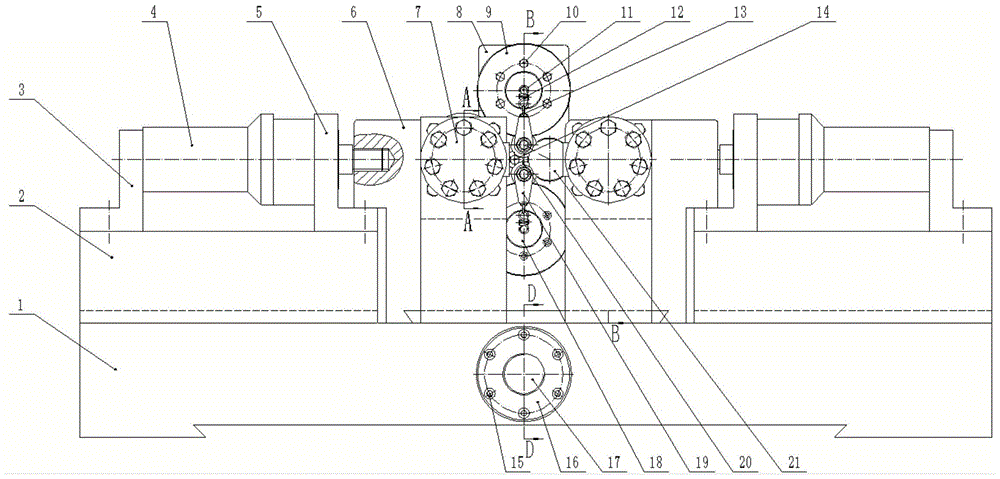

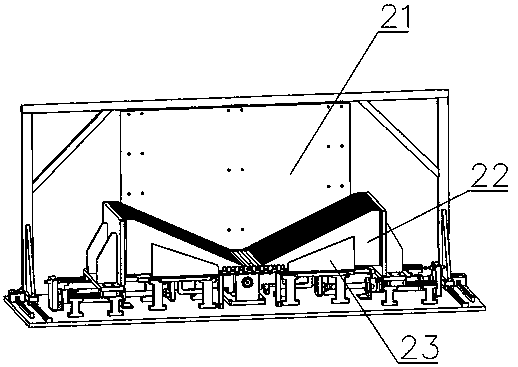

Ramie stem cutting tool wear test bed with changeable supporting state

PendingCN108132195AAvoid damageEliminate manual feedingInvestigating abrasion/wear resistanceEngineeringSingle cycle

The invention discloses a ramie stem cutting tool wear test bed with a changeable supporting state. The ramie stem cutting tool wear test bed comprises a rack, and further comprises a material feedingdevice, a cutting device and an intermittent transmission device which are arranged on the rack, wherein the material feeding device is connected with the cutting device through the intermittent transmission device; under the synergistic effect of the intermittent transmission device, material feeding and cutting are continuously and cyclically performed; in a single cycle process, the intermittent transmission device drives the material feeding device to downwards convey ramie stems, and the cutting device is driven and conveyed to a cutting station at the same time; after the ramie stems are conveyed to the cutting station, the cutting device arrives at the cutting station to execute cutting action; after the cutting action is completed, the intermittent transmission device drives and conveys the cutting device to an avoiding station for staying; a detachable cutting and supporting plate is arranged below the material feeding device. The ramie stem cutting tool wear test bed with the changeable supporting state has the advantages that labor and time are saved, cutting tool wear test data is accurate, and the cutting supporting state is adjustable.

Owner:HUNAN AGRICULTURAL UNIV

Sealed automatic feeding compounding tank

InactiveCN106362613ASave raw materialsImprove work efficiencyTransportation and packagingRotary stirring mixersEngineeringMechanical engineering

The invention discloses a sealed automatic feeding compounding tank. The sealed automatic feeding compounding tank comprises a device body, a gear motor, a stirring shaft, stirring blades, blade scrapers, a right sealing cover, a discharge opening, an observation opening, a waste gas collection barrel, a left sealing cover, a material conveying pipeline, a spiral conveying shaft, a feed opening and a plurality of material conveying branch pipes, wherein the gear motor is arranged on the right side of the device body; the upper side of the gear motor is connected with the stirring shaft; the stirring blades are arranged on the upper side and the lower side of the stirring shaft; the blade scrapers are arranged at the tail ends of the stirring blades; the right side of the device body is connected with the right sealing cover; the discharge opening is formed in the lower side of the right sealing cover; the observation opening is formed in the upper side of the device body; the waste gas collection barrel is arranged at the left side of the observation opening. The sealed automatic feeding compounding tank has the characteristics of being safe and environment-friendly and saving raw materials; the feeding opening is formed in the bottom of the tank body; the raw materials are pushed by a material conveying main pipe with the spiral conveying shaft; the material conveying branch pipes are arranged to bring convenience for adding different types and amounts of the raw materials.

Owner:张庭辉

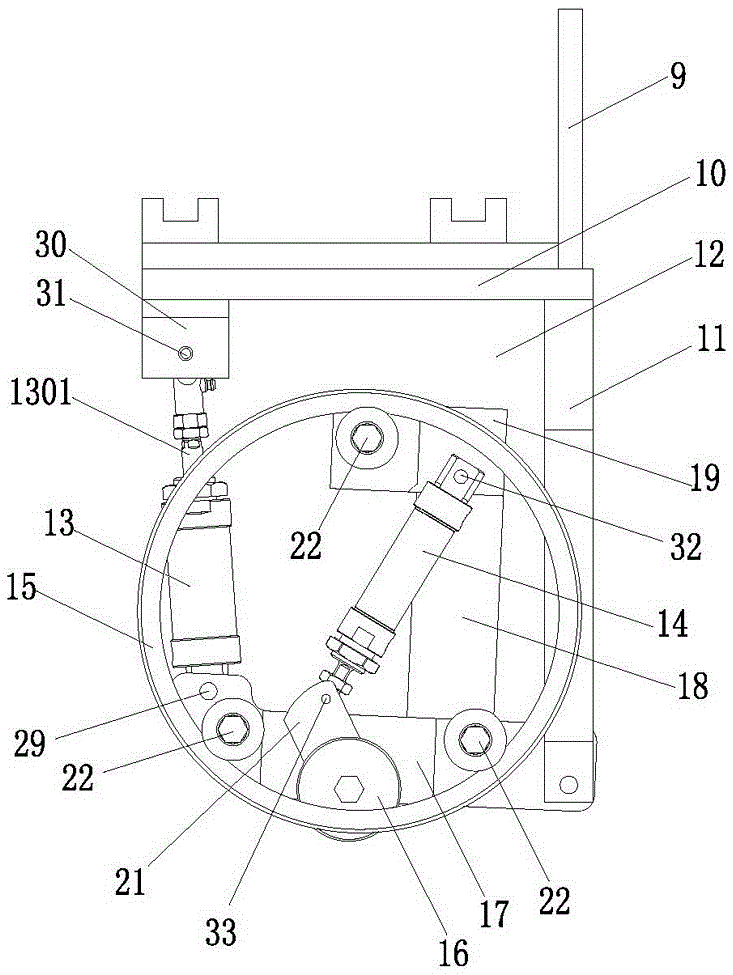

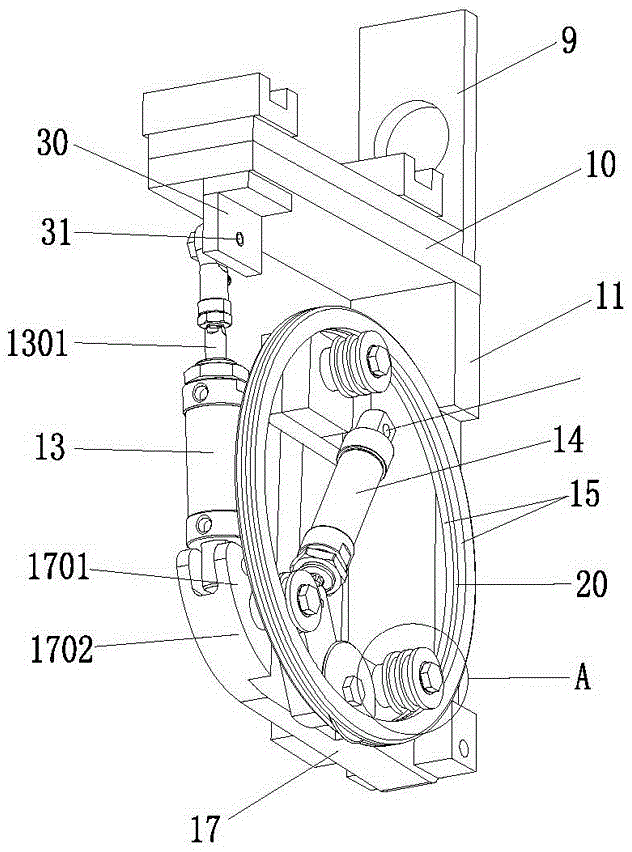

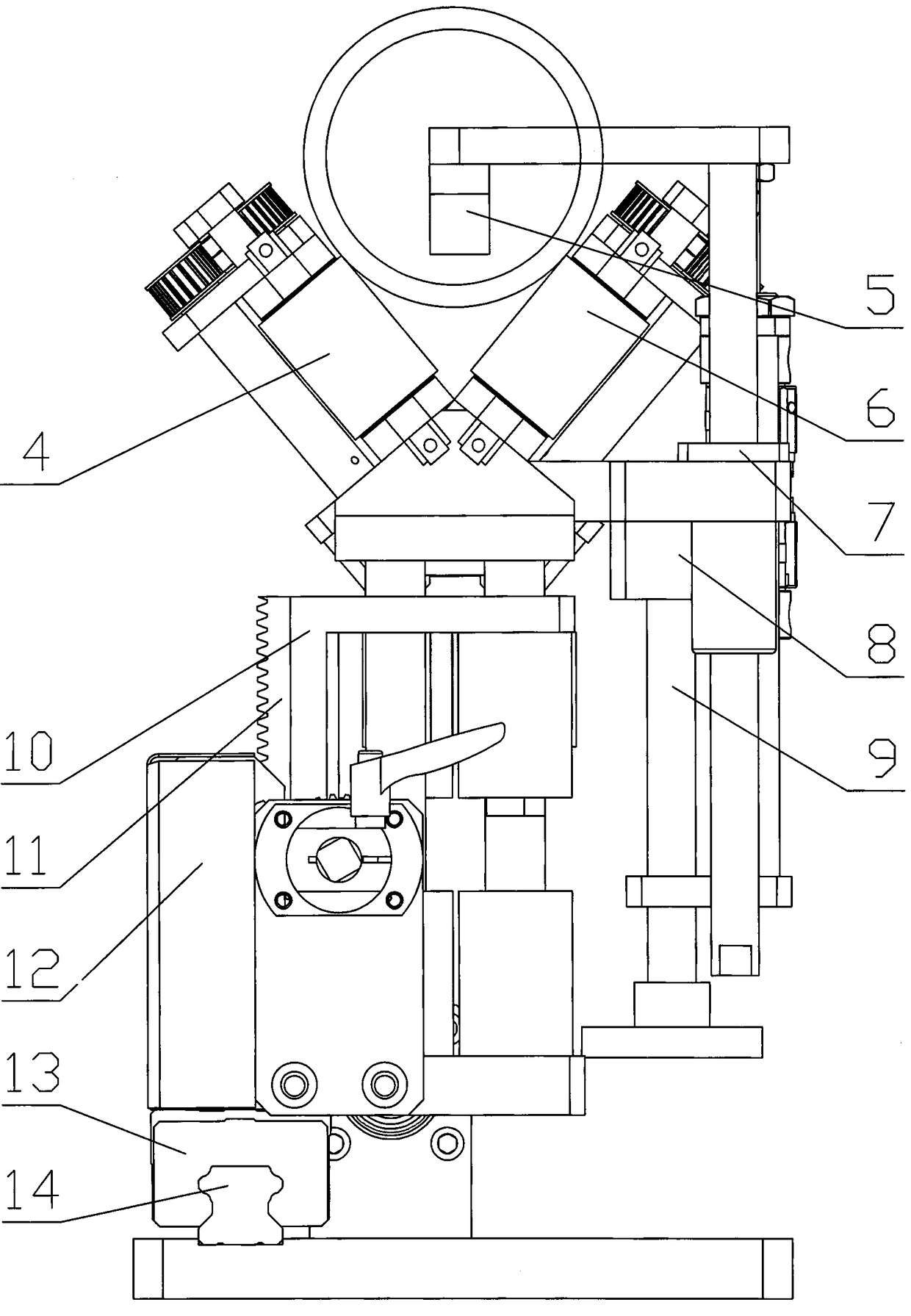

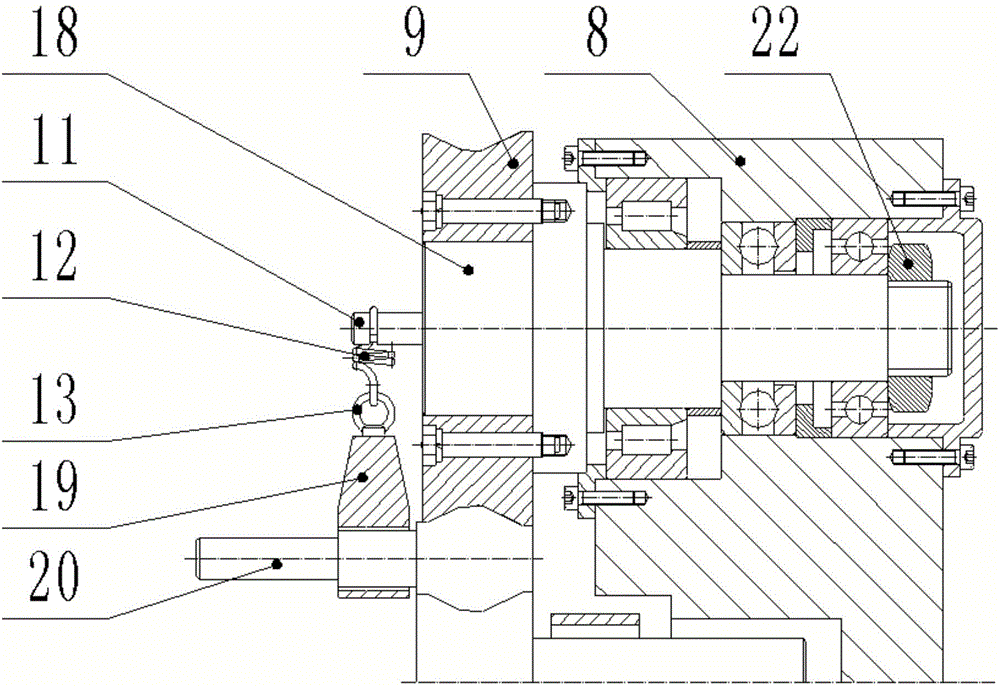

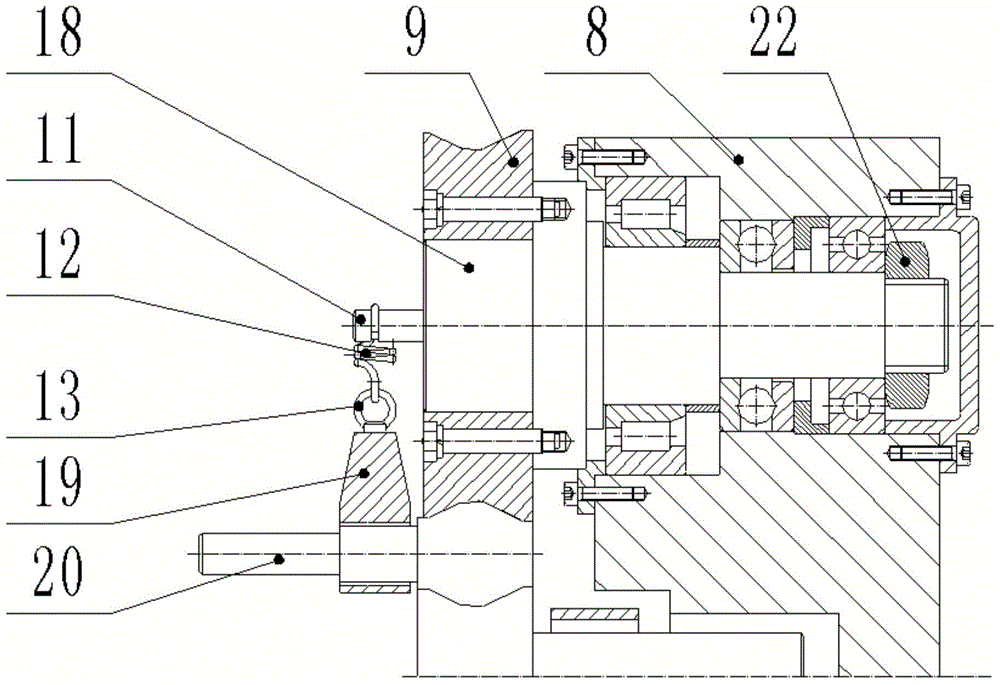

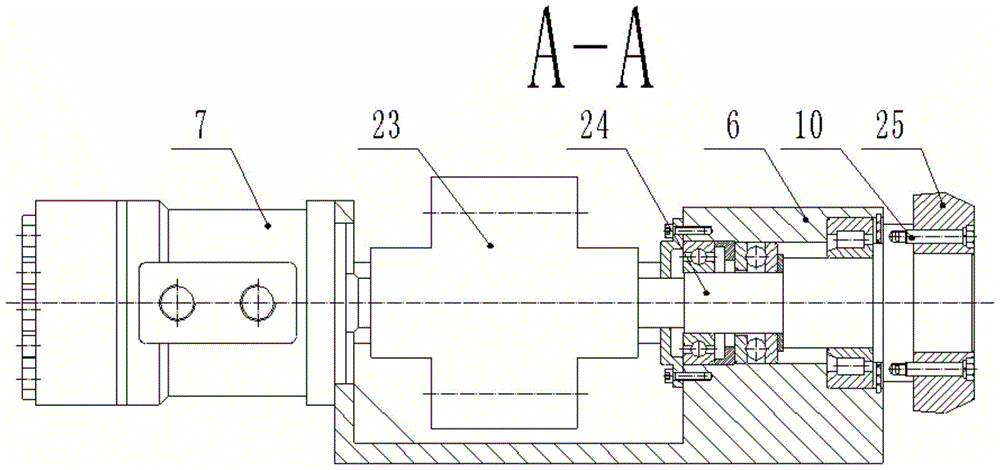

High-strength steel wire neck-spinning device

A high-strength steel wire neck-spinning device comprises a lower guide rail block, a radial feeding mechanism, a rotary mechanism, an outer circle machining mechanism and a ball screw mechanism. The two sides of a steel wire are both provided with a rotary wheel and a supporting wheel of the device, when the steel wire reaches a machining position, a hydraulic cylinder piston stretches to enable the rotary wheels to move in the radial direction, and meanwhile a hydraulic cylinder of the left supporting wheel pushes the rotary wheels to move in the radial direction; when the radial mechanism moves, a motor drives a ball screw to rotate; circumferential movement of the ball screw is converted into axial movement of the guide rail block through a ball and a nut, the rotary wheel and the supporting wheel are rotated due to a motor, the radial mechanism provides rolling reduction of the rotary wheel and provides pressing force for the supporting wheel, an axial feeding mechanism provides axial displacement of a rotary wheel system, the rotary wheel squeezes the steel wire so that the steel wire can generate plastic deformation, and accordingly a steel wire outer circle is machined. By means of the device, the two ends of the steel wire can be machined at the same time, manual feeding is omitted, harm to workers caused by vibration of materials in the machining process is avoided, and steel wire machining efficiency is improved.

Owner:YANSHAN UNIV

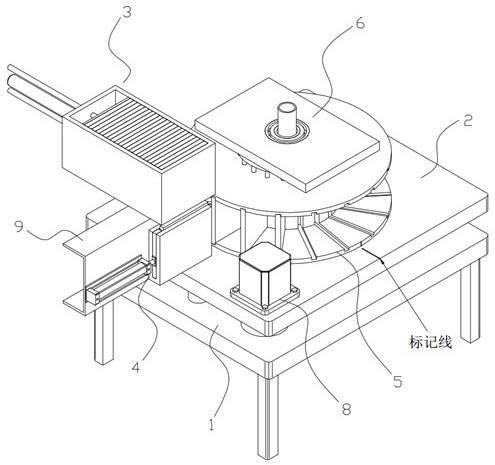

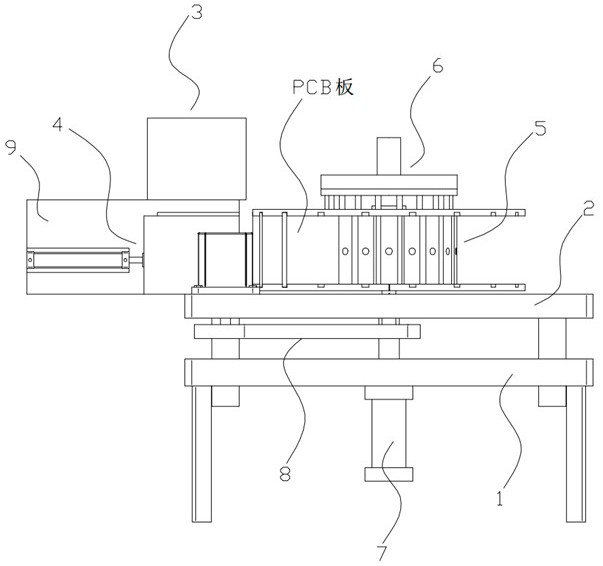

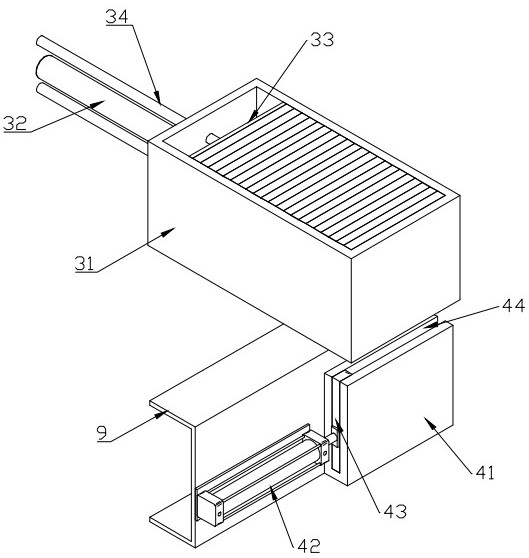

An automatic drying device for pcb boards

ActiveCN110953846BTake away quicklyFast dryingDrying solid materials with heatDrying solid materials without heatEnvironmental engineeringCentrifugal force

The invention discloses an automatic drying device for PCBs, and relates to the technical field of PCB manufacturing. The automatic drying device for the PCBs comprises a workbench, a base, a feedingassembly, an ejection assembly, a rotating disc mechanism, a positioning mechanism and a lifting assembly. According to the automatic drying device for the PCBs, the radical arrangement mode are adopted for the PCBs, firstly, due to the rotation of the PCBs, water in micropores in the PCBs can be thrown out, secondly, due to the fact that the arrangement direction of the PCBs is located in the radical direction of stand columns, the water can be thrown out to the outer side along the surfaces of the PCBs under the action of centrifugal force, meanwhile, under the cooperation of hot air passingthrough every two adjacent PCBs, the water can be quickly taken away, the PCBs are heated and dried, and the drying speed of the PCBs is increased.

Owner:ANHUI TIANBING ELECTRONICS TECH

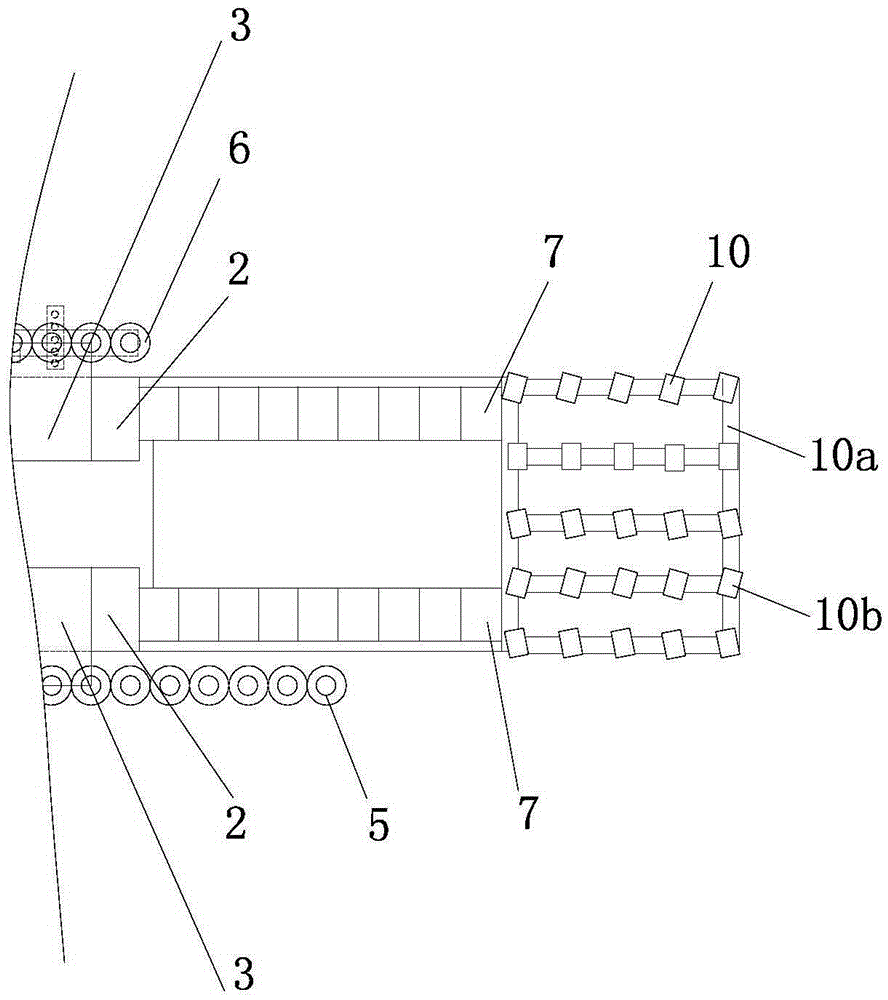

Feeding mechanism of glass edge grinding machine

InactiveCN105234809APrevent left and right movementWon't hurtEdge grinding machinesGrinding feedersIdler-wheel

The invention discloses a feeding mechanism of a glass edge grinding machine. The feeding mechanism of the glass edge grinding machine comprises automatic conveying belts and a pressing frame. A line of fixed guiding wheels are arranged on the outer side of the automatic conveying belt on the left side. A line of movable guiding wheels are arranged on the outer side of the automatic conveying belt on the right side. The gap between the fixed guiding wheels and the movable guiding wheels is just matched with the width of glass passing through the gap. All the movable guiding wheels can be adjusted leftwards and rightwards synchronously to be adapted to grinding of glass edges with different widths. The front ends of the fixed guiding wheels stretch to the position in front of the automatic conveying belts. The front ends of the movable guiding wheels are flush with the front ends of the automatic conveying belts. A line of rubber conveying idler wheels are further arranged right in front of each automatic conveying belt. A glass storage frame is arranged right in front of the rubber conveying idler wheels. The glass storage frame is composed of a welded frame and a plurality of rubber universal idler wheels laid on the top surface of the welded frame. In the feeding process, pieces of glass are aligned, so that the feeding mechanism can be suitable for grinding glass of different width specifications, and the glass can be conveyed into the edge grinding machine easily.

Owner:CHONGQING FUXIN GLASS

Sanding device for high-hardness and high-brightness gold jewelry

ActiveCN112757100AAvoid fixationImprove the quality of workGrinding carriagesGrinding machinesEngineeringGold jewelry

The invention relates to the technical field of sanding machines, and discloses a sanding device for high-hardness and high-brightness gold jewelry. The sanding device comprises a workbench, wherein the top of the workbench is provided with a sanding machine, the top of the workbench is fixedly connected with a pre-storage frame, the right side of the pre-storage frame is fixedly connected with a feeding frame, the pre-storage frame and the feeding frame are fixedly connected to the top of the workbench in a T shape, the interior of the pre-storage frame communicates with the interior of the feeding frame, and a gold bar is arranged in the pre-storage frame. The gold bar is placed on the top of a rubber pad, then a holding rod is rotated to drive a fixing sleeve to rotate through a rotating rod, the fixing sleeve drives a balance plate to rotate, a heavy ball slides towards the low end through inclined gravity of a sliding rod, and therefore the gold bar is fixed, hand fixing can be avoided when the gold bar is polished, and therefore, the two hands of a user are liberated, the gold bar can be subjected to sanding treatment through two-hand operation, and the working quality of sanding treatment is improved.

Owner:深圳润福金技术开发有限公司

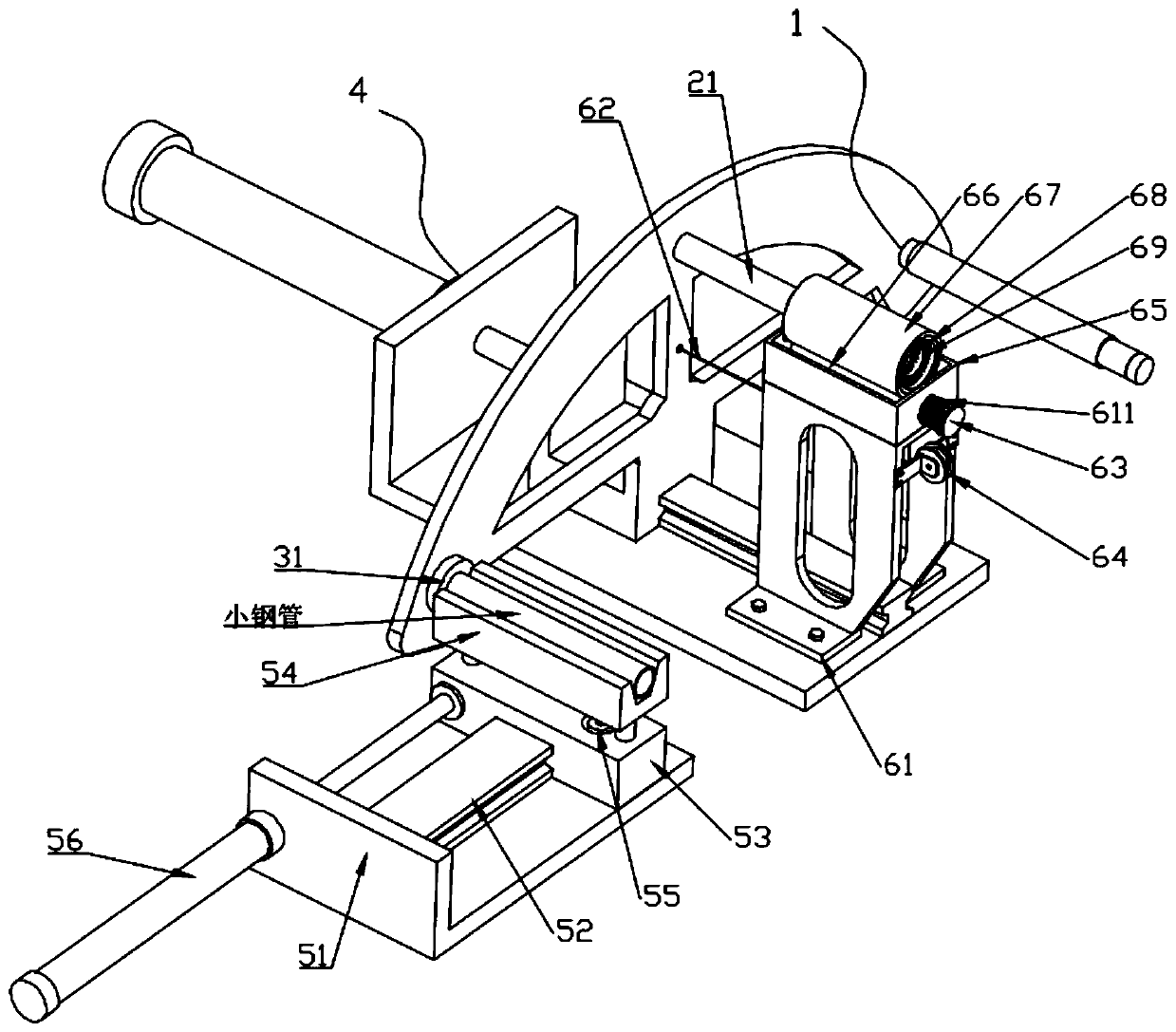

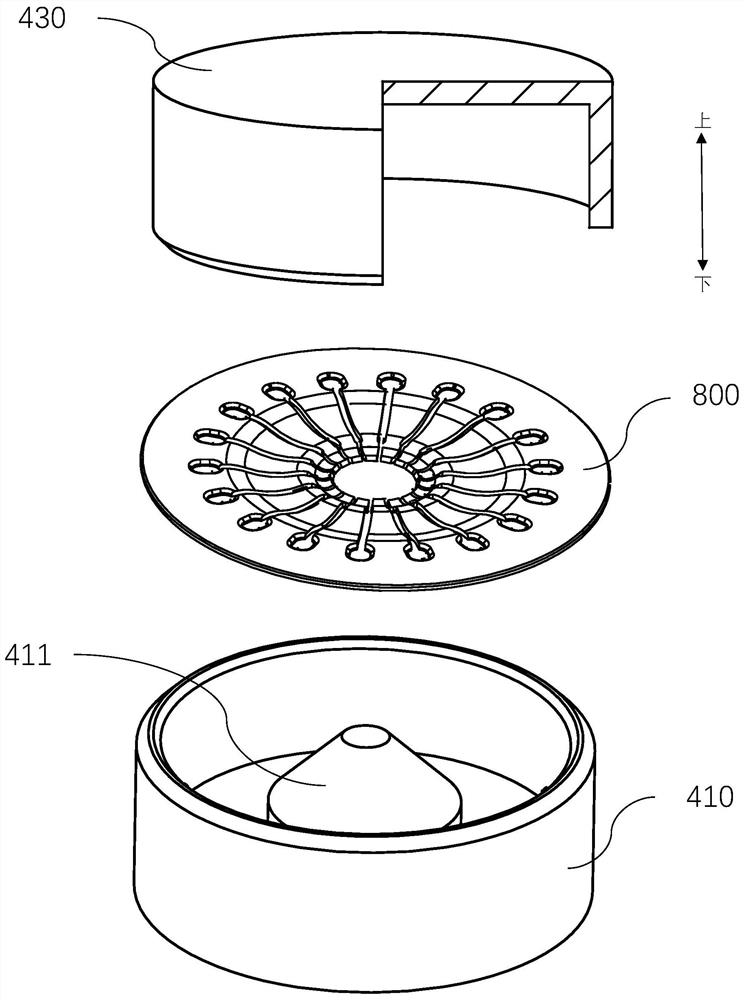

Executing mechanism for silencer steel pipe automatic press fitting equipment

ActiveCN111037257AImprove consistencyImprove accuracyLiquid surface applicatorsCoatingsEngineeringSoldering

The invention discloses an executing mechanism for silencer steel pipe automatic press fitting equipment and relates to the field of automation equipment. The mechanism comprises a detection mechanism, a coating mechanism, a press-fitting mechanism, a press-fitting power mechanism and a soldering flux feeding mechanism. The detection mechanism, the coating mechanism and the press-fitting mechanismare all installed on the press-fitting power mechanism and can move synchronously. Therefore, filter screen detection, soldering flux coating and steel pipe press fitting operation of a silencer bodyare achieved. The soldering flux feeding mechanism can be linked with the press-fitting power mechanism so as to achieve feeding of soldering flux on the coating mechanism. The detection mechanism, the coating mechanism and the press-fitting mechanism are integrated on the press-fitting power mechanism. Three procedures are synchronously performed at three positions, consistency and accuracy of aproduction process are improved, feeding and discharging of the silencer are automatically achieved through gravity, a related power device does not need to be arranged, structural layout is simplified, and equipment cost is reduced.

Owner:芜湖文青机械设备设计有限公司

A machine automatic detection device for straight pins

The invention discloses an automatic detection device for a cylindrical pin machine, and relates to the field of mechanical detection. The automatic detection device comprises a rack, a loading device, a detection device, a feeding device and a control device. The automatic detection device is characterized in that the rack comprises a top plate and a bottom plate; the loading device is arranged on the bottom plate and penetrates through the top plate; the feeding device comprises a driving device, a rotating device and a discharging device. The driving device is arranged on the bottom plate;the rotating device is arranged on the top plate; the discharging device is arranged on the top plate; the driving device is connected with the rotating device through a stepping assembly. The discharging device is arranged on one side of the rotating device. The detection device is arranged on the top plate and located on one side of the rotating device. The loading device is connected with the rotating device through a positioning piece. The length and the diameter of the cylindrical pin can be rapidly detected and the detection efficiency is improved.

Owner:SHANDONG INST FOR PROD QUALITY INSPECTION

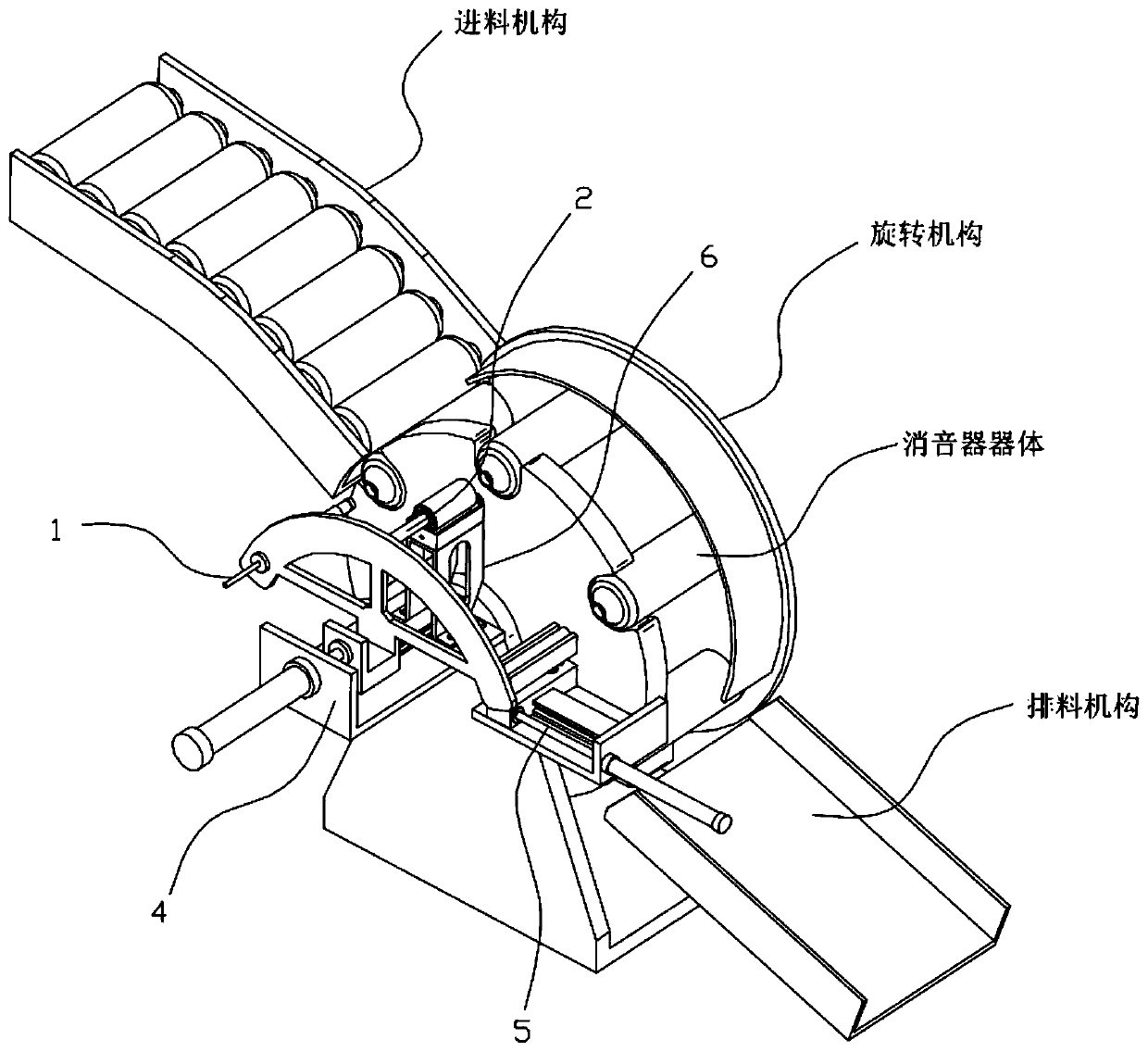

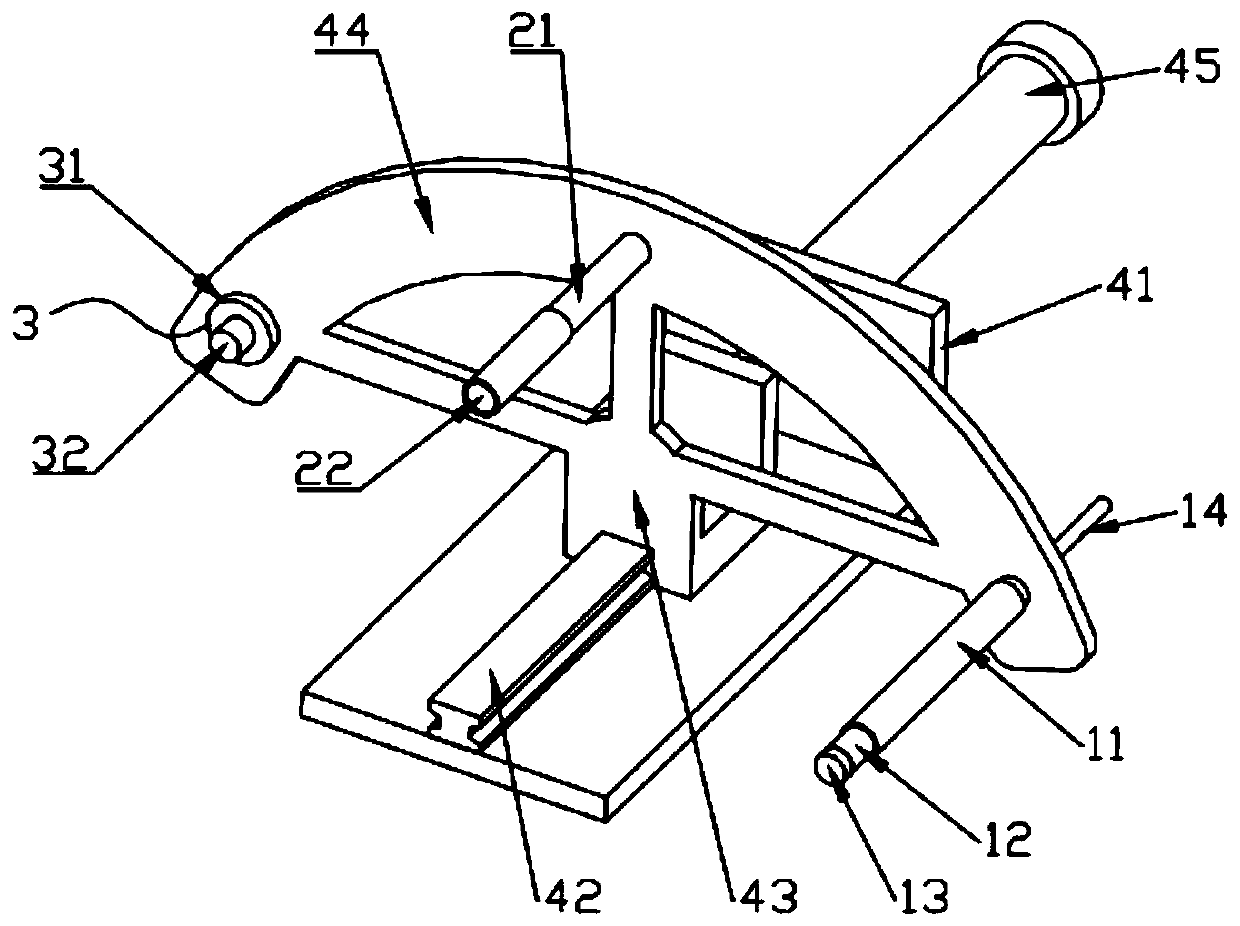

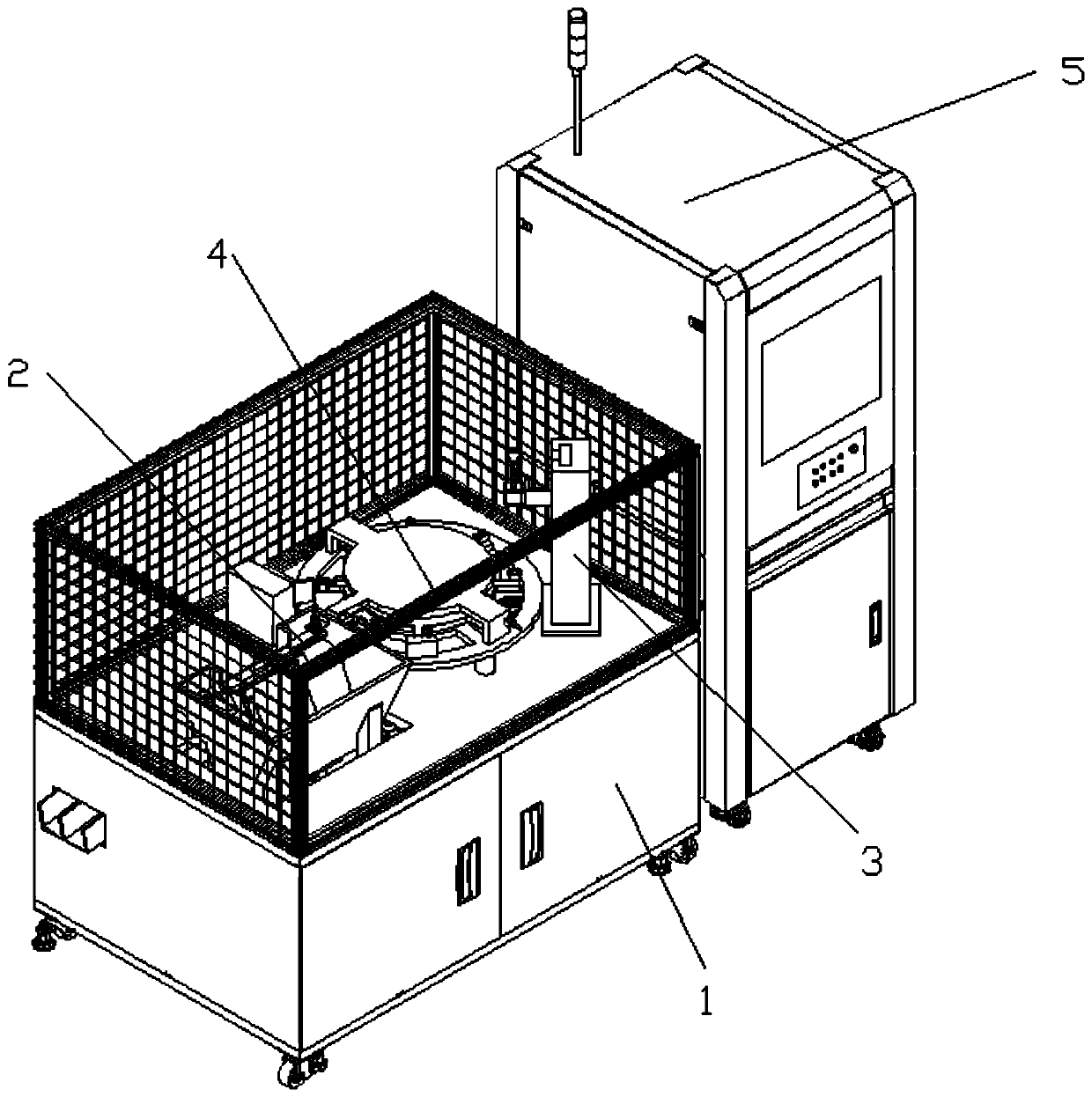

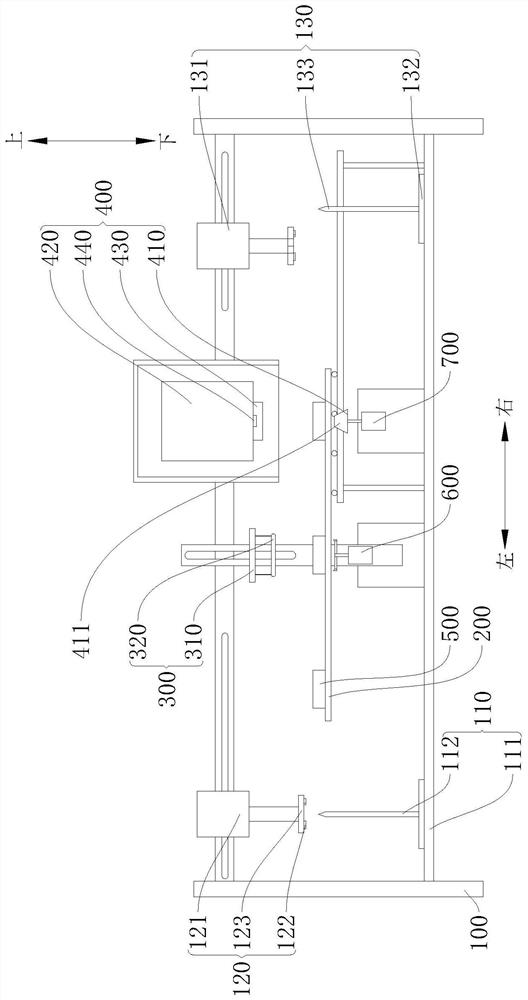

An automatic press-fitting equipment for small muffler steel pipes

ActiveCN111112975BSmall footprintLow costLiquid surface applicatorsCoatingsControl engineeringProcess engineering

The invention discloses an automatic press-fitting equipment for small muffler steel pipes, relating to the field of automation equipment, including a feeding mechanism, a material discharging mechanism, a rotating mechanism, a detection mechanism, a coating mechanism, a pressing mechanism, a pressing power mechanism and a driving mechanism , the detection mechanism, the coating mechanism and the press-fit mechanism are all installed on the press-fit power mechanism and can move synchronously, so as to respectively realize the filter screen detection, flux coating and steel pipe press-fit operation of the muffler body, the present invention The rotating mechanism adopts a rotating feeding method, which significantly reduces the equipment footprint compared with the traditional linear production line. At the same time, the press-fitting power mechanism integrates a detection mechanism, a coating mechanism and a pressing mechanism. Three The process is carried out synchronously at three positions, which improves the consistency and accuracy of the production process. The feeding and discharging of the muffler are automatically realized by its gravity, and there is no need to set up related power devices, which simplifies the structural layout and reduces the cost of production. equipment cost.

Owner:芜湖文青机械设备设计有限公司

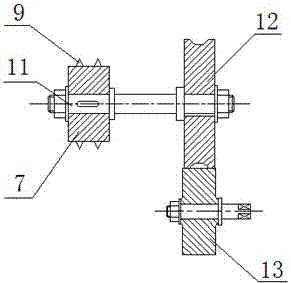

Gravity Self-Contained Welding Feed Mechanism

ActiveCN104191113BGuaranteed uniformityEliminate manual feedingWelding/cutting auxillary devicesAuxillary welding devicesDrive wheelEngineering

The invention discloses a gravity self-feed welding feeding mechanism, and belongs to the field of machines. The gravity self-feed welding feeding mechanism comprises an upper rack, a lower rack, telescopic shafts, springs, shafts, a driving wheel, a driven wheel, anti-slipping teeth, nuts, a rotating shaft, a pulley, a friction wheel, a rope and a weight. The upper rack and the lower rack are provided with rectangular grooves respectively, through holes are formed in each rectangular groove, the telescopic shafts penetrate through the through holes of the rectangular groove in the upper rack or the rectangular groove in the lower rack, one ends of the telescopic shafts are connected with the driven wheel, the other ends of the telescopic shafts are matched with the nuts, the two ends of the rotating shaft are provided with the driving wheel and the pulley respectively, the rotating shaft is assembled on the upper rack or the lower rack, the rope is wound in a groove in the outer edge of the pulley, and the weight is connected with the tail end of the rope. The problem that a copper material is fed unevenly in the existing copper brazing process of a wear plate and a cutting ring is solved, and the gravity self-feed welding feeding mechanism has the advantages of being simple in structure, reasonable in design and easy to manufacture.

Owner:X E S IND JIANGSU CO LTD

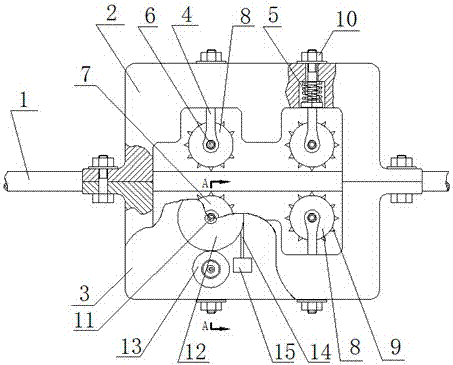

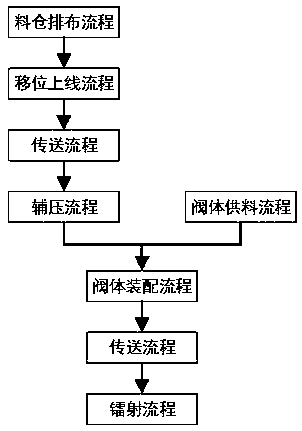

Valve body hose assembly process for water purifier

InactiveCN108971933AGuaranteed stabilityEliminate manual feedingMetal working apparatusLaser beam welding apparatusEngineeringLaser

The invention discloses a valve body hose assembly process for a water purifier. The valve body hose assembly process comprises a silo arrangement process, a shift online process, a transfer process,a valve body feeding process, a valve body assembly process, an auxiliary pressure process and a laser process. The shift online process is carried out sequentially after the silo arrangement process,the transfer process runs through the shift online process, the auxiliary pressure process and the laser process, the valve body assembly process is carried out sequentially after the valve body feeding process, and the valve body assembly process is carried out sequentially after the valve body auxiliary pressure process. The silo arrangement process is used for arranging hoses so that the hosescan be transferred conveniently by the shift online process. The shift online process is used for discharging and transferring the hoses sorted by the silo arrangement process to the transfer processfor transfer. The valve body hose assembly process has high automation degree, realizes continuous production of products, saves labor, saves production cost, increases the qualified rate of productsand has good market application value.

Owner:SHENZHEN JINGFANGYING TECH CO LTD

An automatic assembly device for a liquid cold plate for heat dissipation of microwave components

ActiveCN110860774BImplement assembly processingFully automatedHeat exchange apparatusMetal working apparatusProcess engineeringWorkbench

The invention discloses an automatic assembly device for a liquid cold plate for heat dissipation of a microwave component, relates to the technical field of microwave component manufacturing, and includes a workbench, a workbench, a feeding component, a lifting component, a turntable mechanism, an assembly mechanism and a welding component. The middle liquid cold plate adopts a radial arrangement, which is beneficial to realize the related assembly process of the liquid cold plate through multiple stations. With the help of the assembly mechanism, the installation and welding of the water pipe and the liquid cold plate are realized, which significantly improves Assembly efficiency reduces labor costs.

Owner:ANHUI TIANBING ELECTRONICS TECH

Polishing sand wet-in dry-out circulation extruding polishing device

InactiveCN104259995AFully automatic recyclingIt has the following positive effects: the present invention realizes fully automatic recyclingGrinding/polishing apparatusSteel ballEngineering

The invention relates to a polishing sand wet-in dry-out circulation extruding polishing device. A sleeve is of a hollow conical tubular structure with openings formed in two ends, a rotating shaft of the hollow tubular structure is movably installed on the inner side of the sleeve, material pushing spiral vanes are fixedly arranged on the outside of the rotating shaft, a heating coil is arranged in the rotating shaft, the heating coil is connected with a heater below a reducer, a driving gear is connected with the rotating shaft through a hollow gear, a fixed disc is fixedly installed in the hollow gear, steel balls are arranged between the fixed disc and the hollow gear, a feeding port is formed in the upper portion of the sleeve, a grinding device fixing block is fixedly installed at the tail end of the sleeve, an elevated conveying belt is arranged below the grinding device fixing block, a material receiving bin is arranged at the tail end of the elevated conveying belt, and the material receiving bin is connected with the feeding port through a feeding pipeline. Circulation recycle of the polishing sand is achieved, wet-in dry-out circulation of the polishing sand is achieved, circulation recycle of the polishing material is achieved, polishing material manual feeding is omitted, and the working efficiency is improved.

Owner:HUANGHE S & T COLLEGE

Graphite composite sealing gasket processing system

ActiveCN112008898ARealize automatic feedingEliminate manual feedingWorking accessoriesStone-like material working toolsGear wheelThreaded rod

The invention relates to a graphite composite sealing gasket processing system. The system comprises a collecting device, a cutting device, a feeding device and a vertical plate. The bottom end of thecollecting device is fixedly connected to the ground through a supporting column. The discharging end of the cutting device is located over the corresponding position of one end of the collecting device. The cutting device is fixedly installed at one end of the vertical plate. The bottom end of the vertical plate is fixedly installed on the ground. The feeding device is fixedly installed at the top end of the cutting device. According to the graphite composite sealing gasket processing system, a cutter can be driven through the rotation of fourth gears, the cutter rotates to drive threaded rods to rotate, and therefore the purpose that two clamps in the whole feeding device grab graphite rods in turn to push the graphite rods downwards under the action of rotation of the fourth gears is achieved through the threaded rods, automatic feeding of the graphite rods is achieved, manual feeding is omitted, the labor force is liberated, and the efficiency and the accuracy are also improved.

Owner:佛山市锐昂科技有限公司

PC steel rod reducing spinning device

A high-strength steel wire neck-spinning device comprises a lower guide rail block, a radial feeding mechanism, a rotary mechanism, an outer circle machining mechanism and a ball screw mechanism. The two sides of a steel wire are both provided with a rotary wheel and a supporting wheel of the device, when the steel wire reaches a machining position, a hydraulic cylinder piston stretches to enable the rotary wheels to move in the radial direction, and meanwhile a hydraulic cylinder of the left supporting wheel pushes the rotary wheels to move in the radial direction; when the radial mechanism moves, a motor drives a ball screw to rotate; circumferential movement of the ball screw is converted into axial movement of the guide rail block through a ball and a nut, the rotary wheel and the supporting wheel are rotated due to a motor, the radial mechanism provides rolling reduction of the rotary wheel and provides pressing force for the supporting wheel, an axial feeding mechanism provides axial displacement of a rotary wheel system, the rotary wheel squeezes the steel wire so that the steel wire can generate plastic deformation, and accordingly a steel wire outer circle is machined. By means of the device, the two ends of the steel wire can be machined at the same time, manual feeding is omitted, harm to workers caused by vibration of materials in the machining process is avoided, and steel wire machining efficiency is improved.

Owner:YANSHAN UNIV

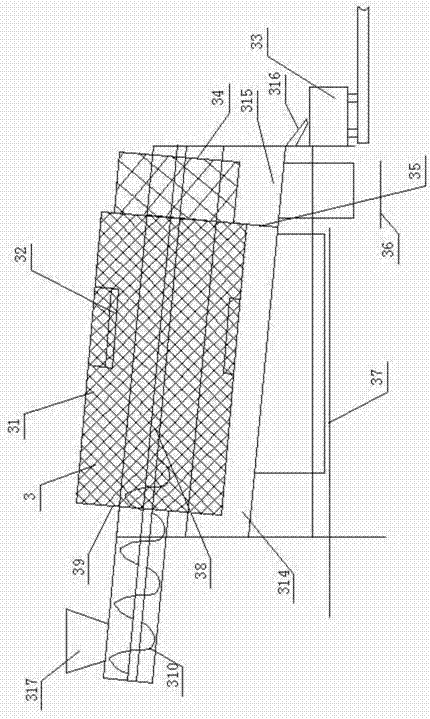

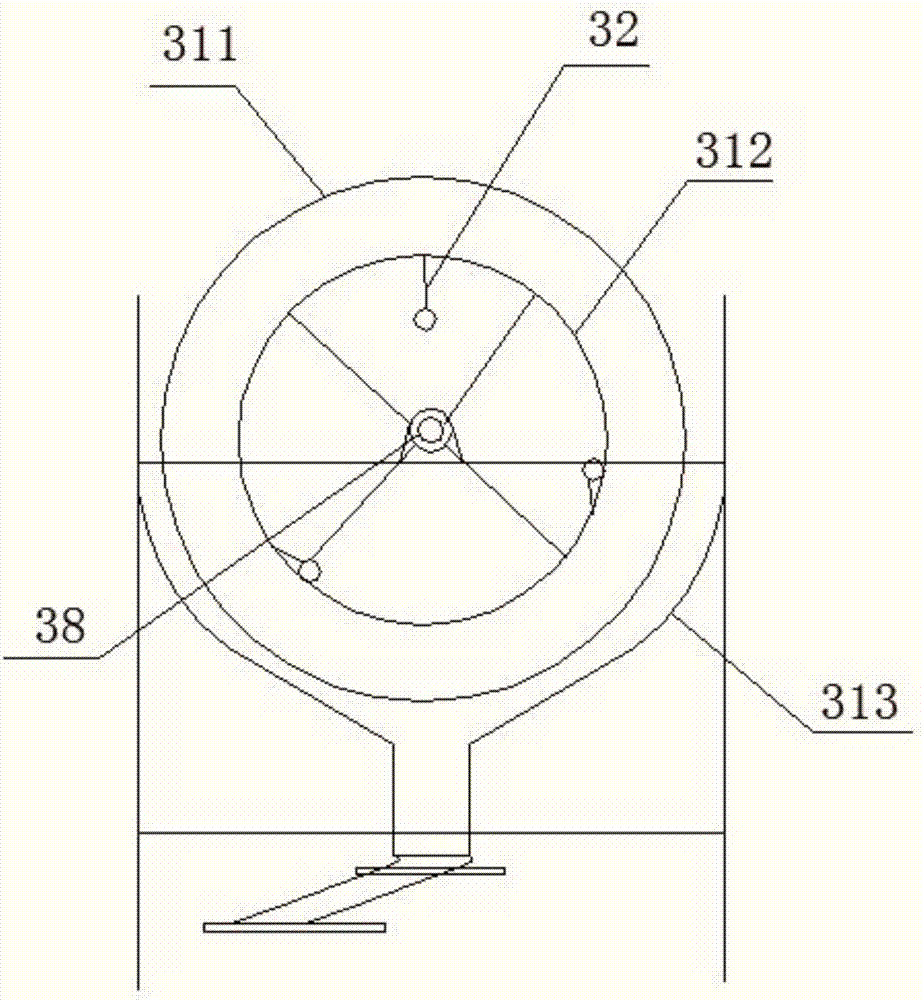

Automatic sawing and bending machine

InactiveCN102581914BEliminate manual feedingReduce usageMulti-purpose machinesEconomic benefitsMovement control

An automatic bending and sawing machine relates to production equipment for wood clothes hangers and comprises a framework, a feeding mechanism, a straight saw assembly, a front spherical saw assembly, a rear spherical saw assembly and a movement control mechanism. A guide track is arranged on the framework, the straight saw assembly is mounted at one end of the guide track, the front spherical saw assembly and the rear spherical saw assembly are rotatably mounted on two sides of the other end of the guide track, the movement control mechanism consists of a power output device, a feeding mechanism control device and a straight saw assembly control device, the feeding mechanism control device is connected with the feeding mechanism, and the straight saw assembly control device is connected with the straight saw assembly. A sawing and bending processing route is divided into two arc curves and a straight line, the arc curves and the straight line are automatically processed by the corresponding front spherical saw assembly, the rear spherical saw assembly and the straight saw assembly, accordingly, automatic bending and sawing processing is realized, danger of operation of workers is reduced, simultaneously, productivity is effectively enhanced, and the automatic bending and sawing machine has certain social and economic benefits.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

A graphite composite sealing gasket processing system

ActiveCN112008898BRealize automatic feedingEliminate manual feedingWorking accessoriesStone-like material working toolsEngineeringHandling system

Owner:佛山市锐昂科技有限公司

Anti-attenuation process of diaphragm springs

ActiveCN113431856AImprove stabilityImprove fatigue strengthCoil arrangementsLeaf springsEngineeringMechanical engineering

The invention discloses an anti-attenuation process of diaphragm springs. The anti-attenuation process comprises the following steps of carrying out adjustment, specifically, adjusting a sliding frame in the left-right direction, and aligning a station at the right end of the sliding frame with a heating device; carrying out feeding, specifically, placing a diaphragm spring on each of the three stations on the sliding frame; carrying out heating, specifically enabling the heating device to heat the diaphragm spring on the station at the right end; carrying out primary transfer, enabling the sliding frame to slide rightwards by a preset distance, enabling the station at the right end to be aligned with a strong pressure measuring device, and enabling the station in the middle to be aligned with the heating device; carrying out heating and strong pressure measuring, specifically, enabling the heating device to heat the diaphragm spring on the station in the middle, and enabling the strong pressure measuring device to carry out strong pressure measuring on the diaphragm spring on the station at the right end; carrying out secondary transfer, enabling the sliding frame to slide rightwards by a preset distance again, enabling the station at the right end to extend out, enabling the station in the middle to be aligned with the strong pressure measuring device, and enabling the station at the left end to be aligned with the heating device; carrying out material taking, specifically, taking down the diaphragm springs subjected to strong pressure from the station at the right end; and carrying out resetting.

Owner:CHINA & CANTON CLUTCH

An actuator used for automatic press-fitting equipment for muffler steel pipes

ActiveCN111037257BImprove consistencyImprove accuracyLiquid surface applicatorsCoatingsEngineeringActuator

The invention discloses an executive mechanism for automatic press-fitting equipment for muffler steel pipes, relating to the field of automation equipment, including a detection mechanism, a coating mechanism, a press-fit mechanism, a press-fit power mechanism and a flux feeding mechanism. Mechanism, coating mechanism and press-fitting mechanism are installed on the press-fitting power mechanism and can move synchronously, so as to respectively realize filter screen detection, flux coating and steel pipe press-fitting operation of the muffler body. The mechanism can be linked with the press-fit power mechanism to realize the feeding of flux on the coating mechanism. The press-fit power mechanism of the present invention integrates the detection mechanism, the coating mechanism and the press-fit mechanism, and the three processes are synchronized at three positions It improves the consistency and accuracy of the production process. The feeding and discharging of the muffler are automatically realized by means of its gravity, without the need to set up related power devices, which simplifies the structural layout and reduces the equipment cost.

Owner:芜湖文青机械设备设计有限公司

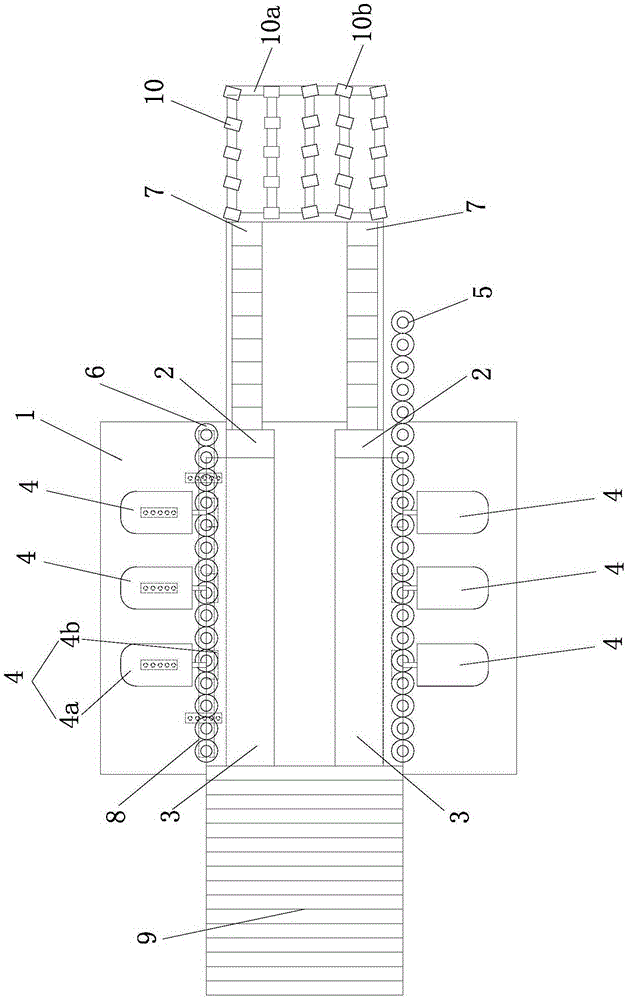

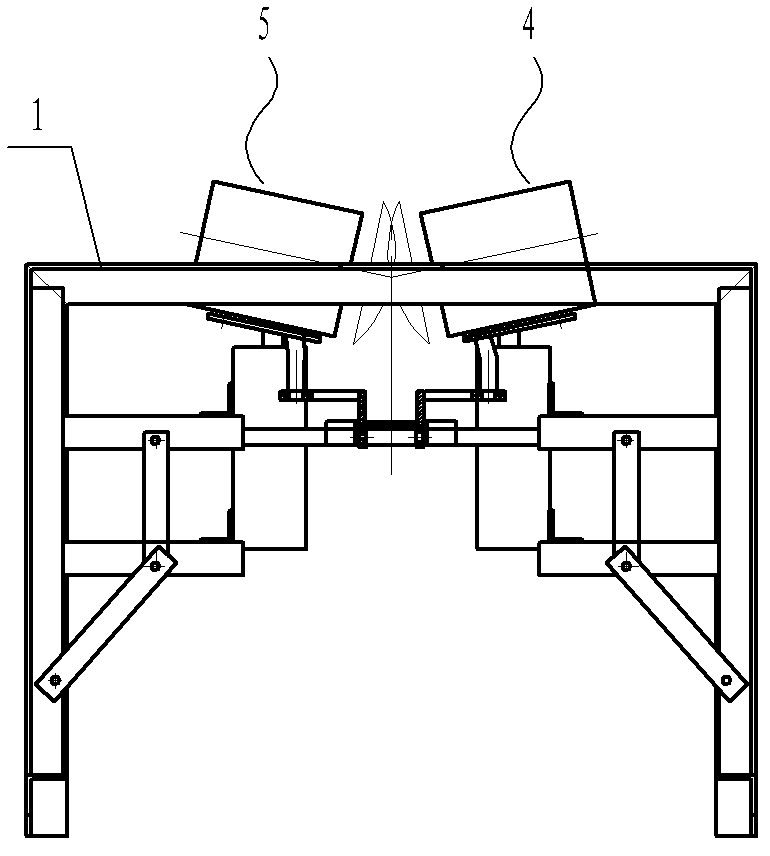

Cereal coarse cereal quality analyzer

PendingCN114199876AComprehensive dataStrong ability to transport materialsInvestigating moving fluids/granular solidsCleaning using toolsAnimal scienceEngineering

The invention discloses a coarse cereal quality analyzer, and relates to the technical field of cereal quality detection. Comprising a quality analysis bin, the quality analysis bin comprises a box body, a feeding port used for feeding is formed in the top of the box body, a discharging port used for discharging is formed in the bottom of the box body, and a set of first mounting supports are arranged in the quality analysis bin; the sliding groove assembly penetrates through the feeding opening and is fixedly connected with a first mounting bracket in the quality analysis bin; each recognition system assembly comprises a camera assembly used for photographing and collecting data and a second mounting bracket used for fixing the camera assembly, the recognition system assemblies are symmetrically arranged on the two sides of the sliding groove assembly, and the recognition system assemblies are fixedly connected with the first mounting bracket; the lower end of the sliding groove assembly is located between the two recognition system assemblies. More materials can be discharged at the same time, the material conveying capacity is higher, more data can be detected in real time, the overall analysis efficiency is high, and the miniaturization design is suitable for more scenes.

Owner:ANHUI ZHONGKE OPTIC ELECTRONICS COLOR SORTER MACHINERY

An automatic feeding wallpaper embossing cutting device

ActiveCN105538785BPaved fastProductivityMechanical working/deformationMetal working apparatusEngineeringMechanical engineering

The invention discloses a wallpaper embossing and cutting device capable of automatically feeding. The wallpaper embossing and cutting device comprises a rack, wherein an embossing part and a cutting part at one side are respectively arranged on the top of the rack; the embossing part comprises a pedestal arranged on the top of the rack; a supporting plate is horizontally arranged on the pedestal; the two sides of the pedestal are in parallel provided with first rollers; the first rollers are as high as the supporting plate; the cutting part comprises a first dual-pressure roller arranged on the top of the rack; the first dual-pressure roller is parallel to the first rollers; one side of the first dual-pressure roller is in parallel provided with a second dual-pressure roller; a loading assembly is arranged at one side of the rack; the loading assembly comprises two supporting bases which are arranged correspondingly; a tripod is arranged on the upper parts of the two supporting bases; a vertical rod is perpendicularly arranged on the tripod; both upper and lower ends of the vertical rod are connected with a rotary shaft respectively; transmission belts are arranged on the upper and the lower rotary shafts; a blocking ring is arranged at the outer side of each transmission belt in an equally-spaced mode; the blocking rings on the two transmission belts are correspondingly arranged; connecting rollers are detachably arranged on the blocking rings; and wallpaper is loaded on the connecting rollers.

Owner:WUJIANG WALLMATE DECORATION MATERIALS

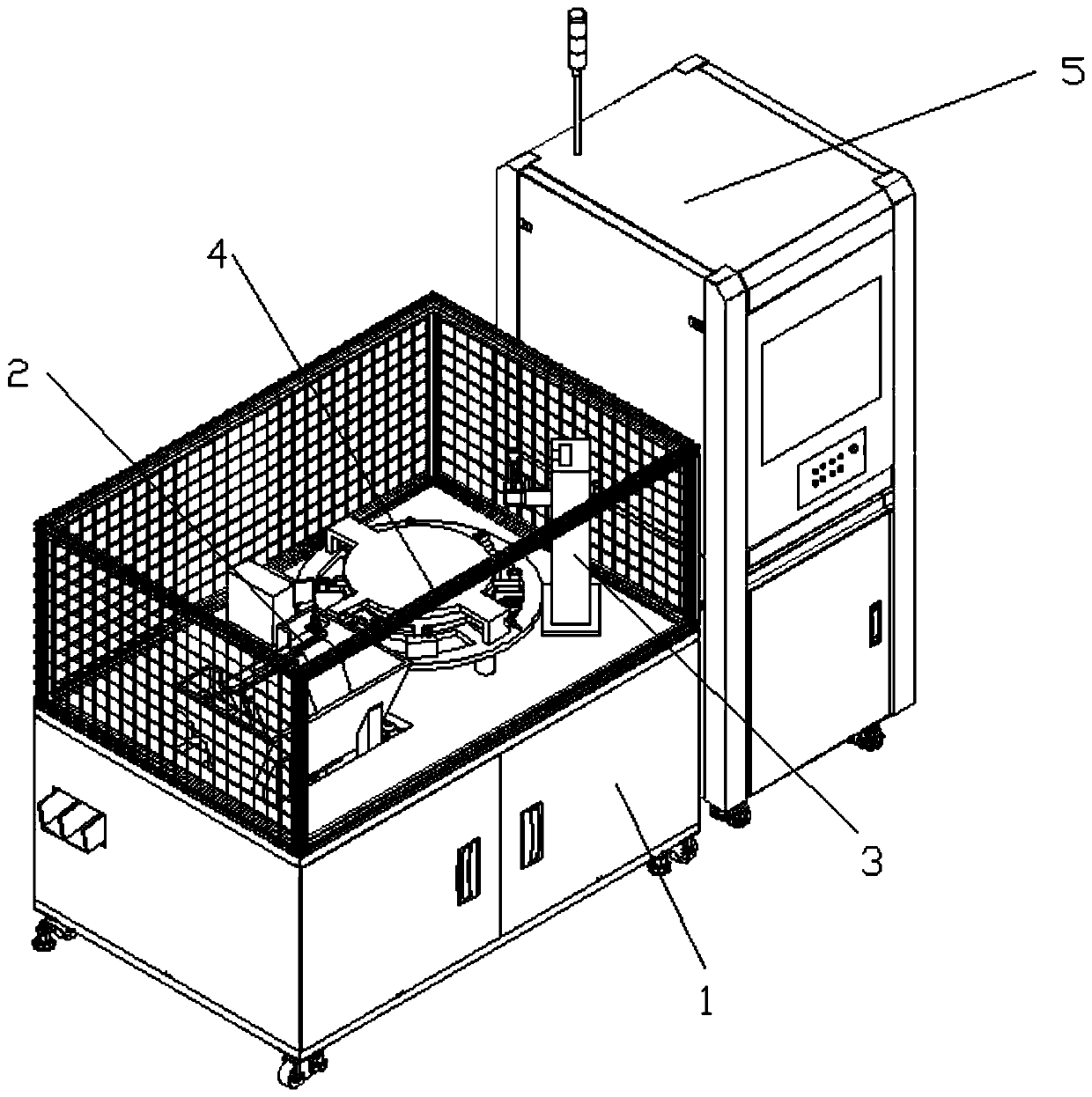

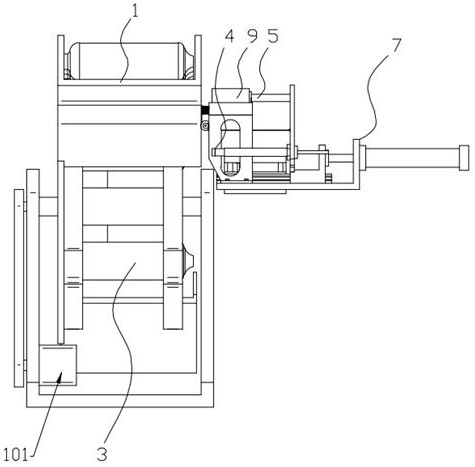

Valve body hose assembly production equipment for water purifier

InactiveCN108942181AGuaranteed stabilityEliminate manual feedingMetal working apparatusContinuous productionAutomation

The invention discloses valve body hose assembly production equipment for a water purifier. The valve body hose assembly production equipment comprises a rack, a stock bin arrangement mechanism, a displacement feeding mechanism, a conveying mechanism, a valve body feeding mechanism, a valve body assembling mechanism, an auxiliary pressing mechanism and a laser mechanism, wherein the material bin arranging mechanism, the shifting feeding mechanism, the conveying mechanism and the valve body assembling mechanism, the auxiliary pressing mechanism and the laser mechanism are all fixed on the top of the rack, the valve body feeding mechanism is fixed beside the machine frame, the conveying mechanism is transversely fixed to the top of the machine frame, a material bin arranging mechanism is fixed beside the head end of the conveying mechanism, the shifting feeding mechanism is fixed to the head end of the conveying mechanism through an upper wire support, and the valve body assembling mechanism is fixed beside the middle of the conveying mechanism. The valve body hose assembly production equipment is high in automation degree, continuous production of products is realized, labor is saved, production cost is saved, the qualified rate of products is improved, and good market application value is achieved.

Owner:SHENZHEN LANSITENG TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com