Glass edge grinding system

A glass edging and glass technology, applied in grinding machines, machine tools suitable for grinding workpiece edges, grinding feed motion, etc. The effect of high versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with drawings and embodiments.

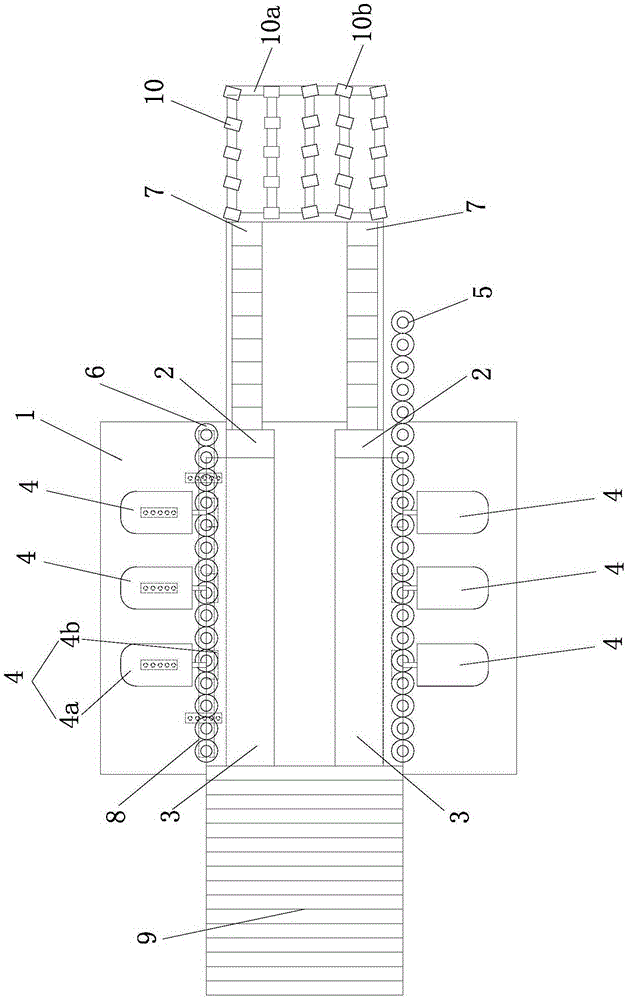

[0010] Such as figure 1 The glass edging system shown is mainly composed of a base 1, two automatic conveyor belts 2, two pressing frames 3, several groups of grinding heads 4, a row of fixed guide wheels 5, a row of moving guide wheels 6, and two rows of rubber conveying rollers 7. The guide wheel support 8, the material receiving roller 9, and the glass placement frame 10 are composed.

[0011] There are two parallel automatic conveyor belts 2 arranged at left and right intervals on the base 1, and a compression frame 3 is arranged above each automatic conveyor belt 2, and the distance between the compression frame 3 and the automatic conveyor belt 2 is just in line with the The thickness of the glass is matched, and the glass passes through the gap between the compression frame 3 and the automatic conveyor belt 2 under the action of the automatic conveyor belt 2. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com