Automatic sawing and bending machine

A saw bending machine, automatic technology, applied in the direction of multi-purpose machinery, wood processing equipment, manufacturing tools, etc., can solve problems such as economic loss and personal injury, dangerous working environment, work-related accidents, etc., to avoid work-related accidents and reduce risks , the effect of reducing the amount of usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

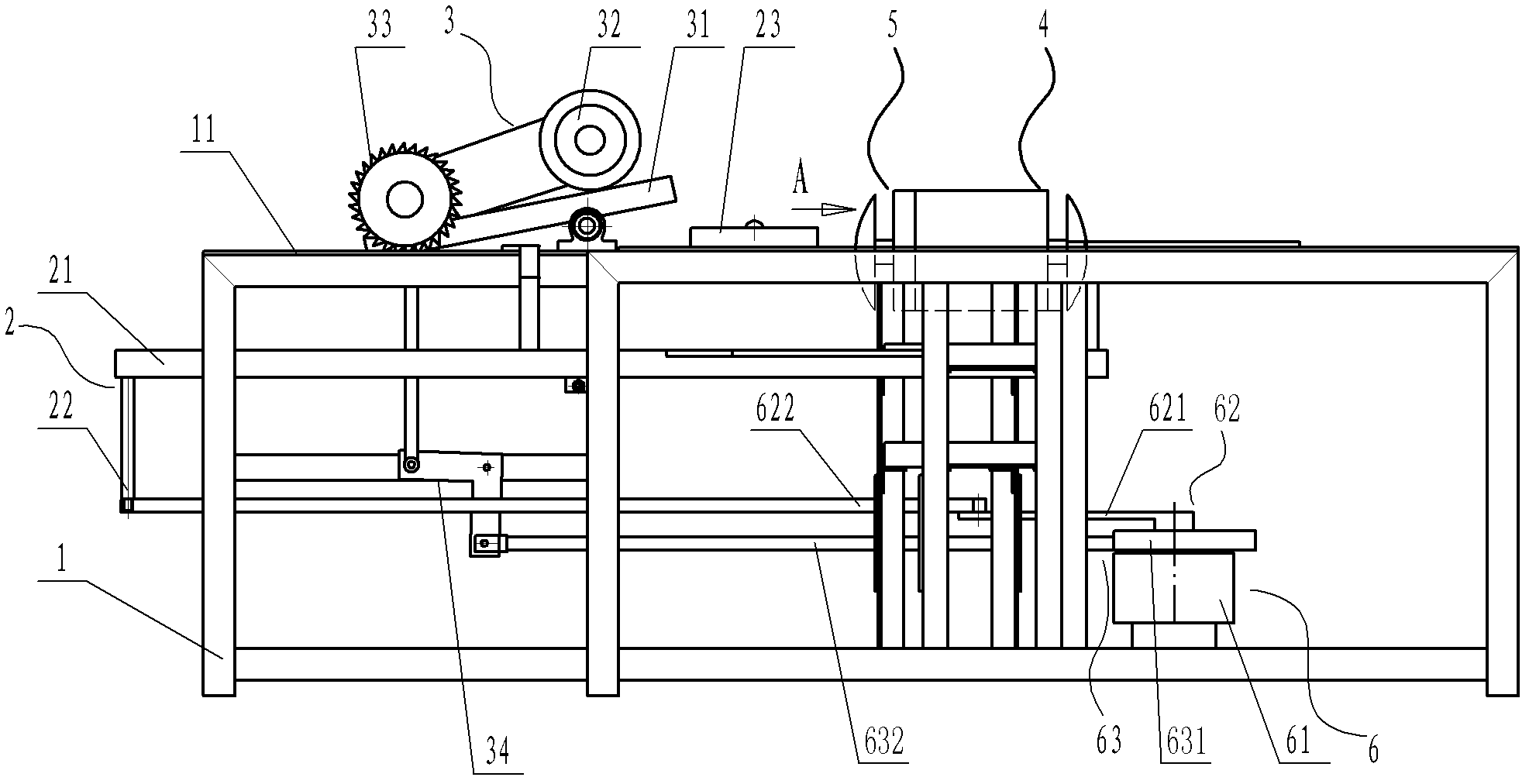

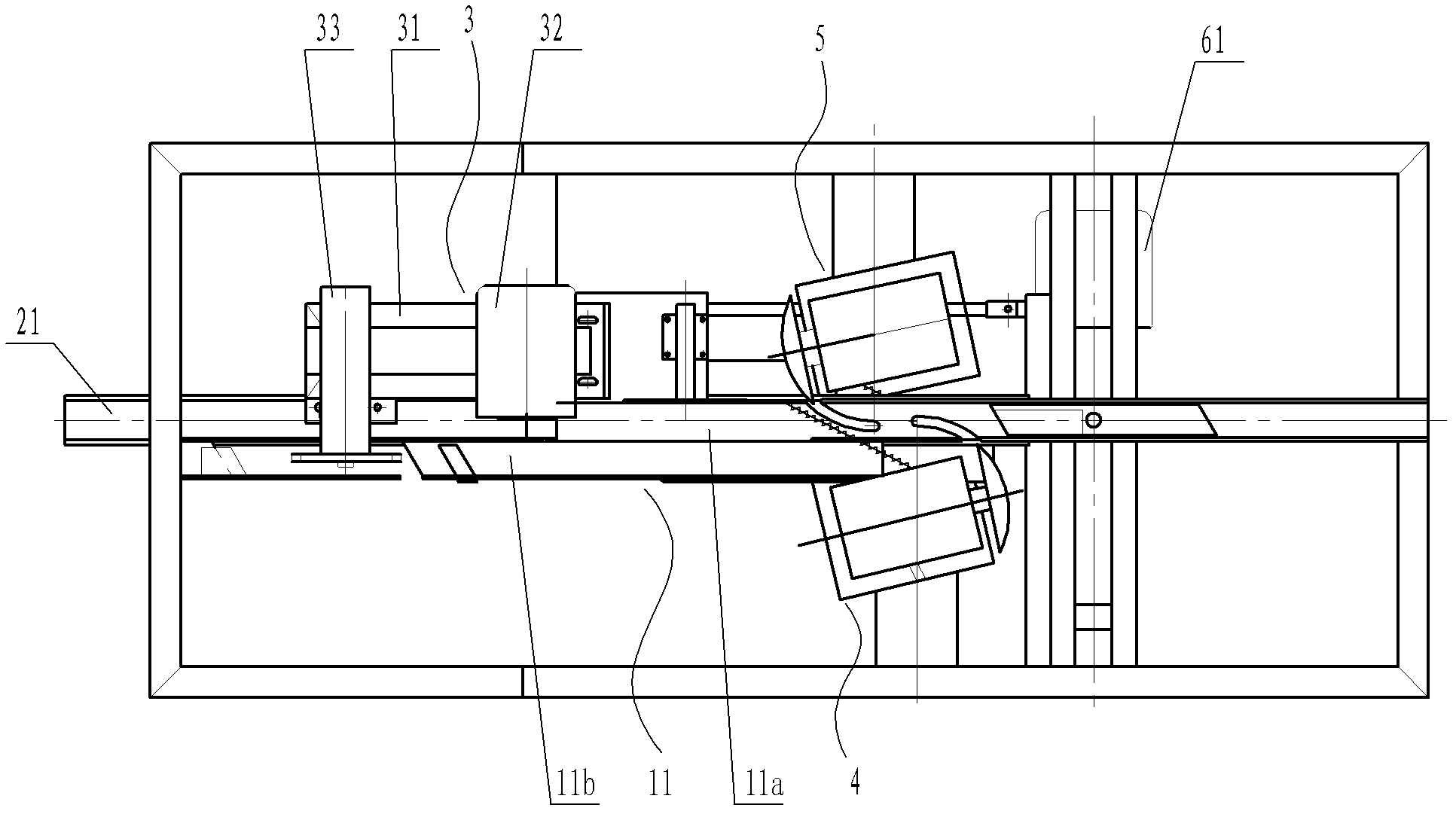

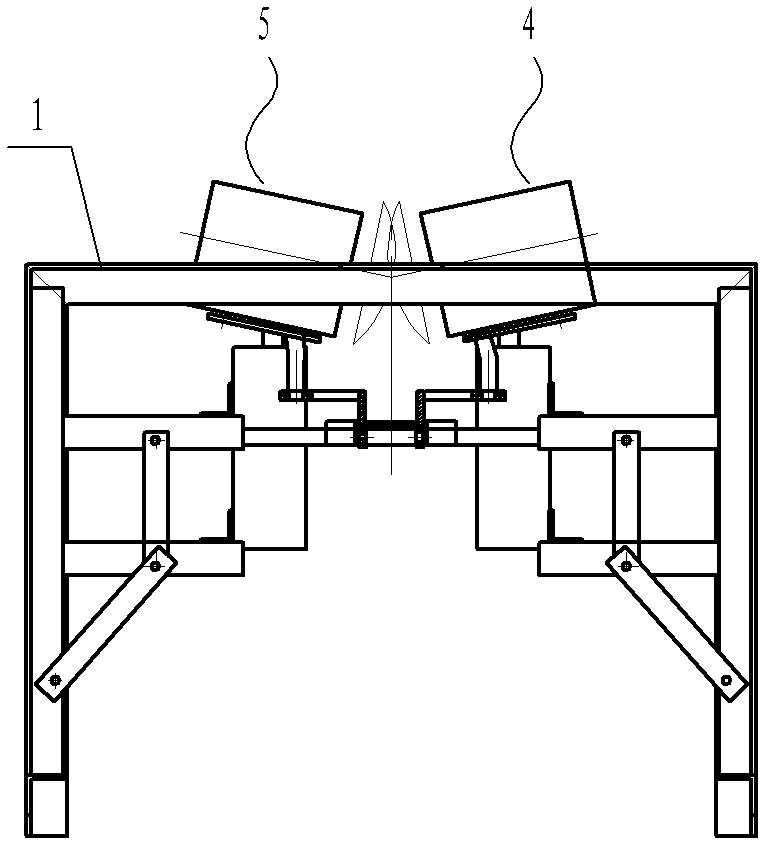

[0037] Figure 1 to Figure 3 Disclosed in is an automatic saw bending machine, including a frame 1, a feeding mechanism 2, a linear saw assembly 3, a front spherical saw assembly 4, a rear spherical saw assembly 5, and a motion control mechanism 6. The frame 1 is provided with guide rail 11, and this guide rail 11 is divided into left guide rail 11a and right guide rail 11b two sections, and described linear saw assembly 3 is installed on one end of right guide rail 11b, front spherical surface saw assembly 4, rear spherical surface saw assembly 5 They are respectively rotatably installed on both sides of the other end of the left guide rail 11a, and the left guide rail 11a and the right guide rail 11b are connected together between the rear spherical saw assembly 5 and the linear saw assembly 3; the motion control mechanism 6 includes a power output device 61, a feeding mechanism control device 62 connected to the power output device 61, and a linear saw assembly control devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com