Cereal coarse cereal quality analyzer

A technology for quality analysis and miscellaneous grains, applied in the direction of material analysis, material analysis through optical means, instruments, etc., can solve problems such as low detection efficiency, achieve intuitive display, coherence, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

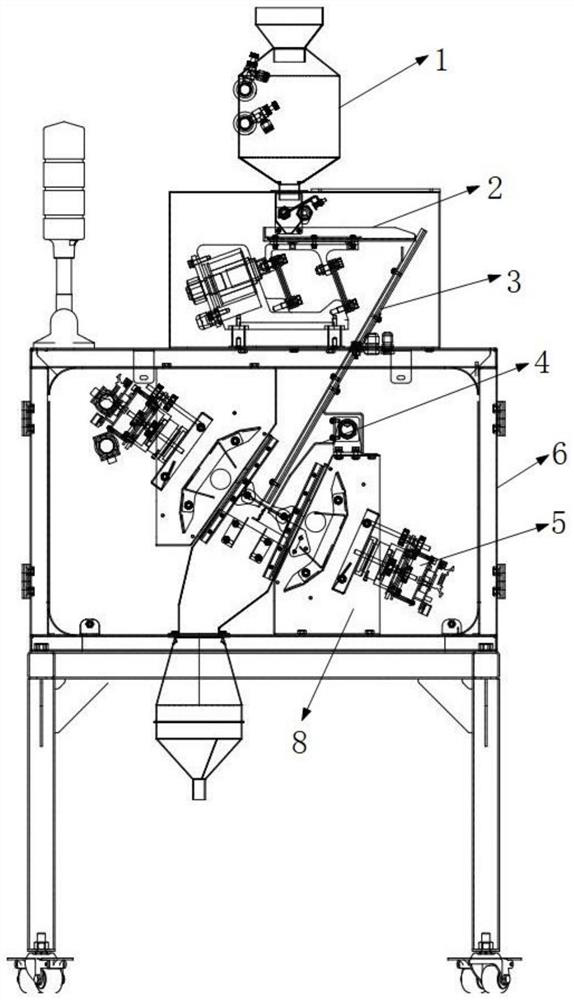

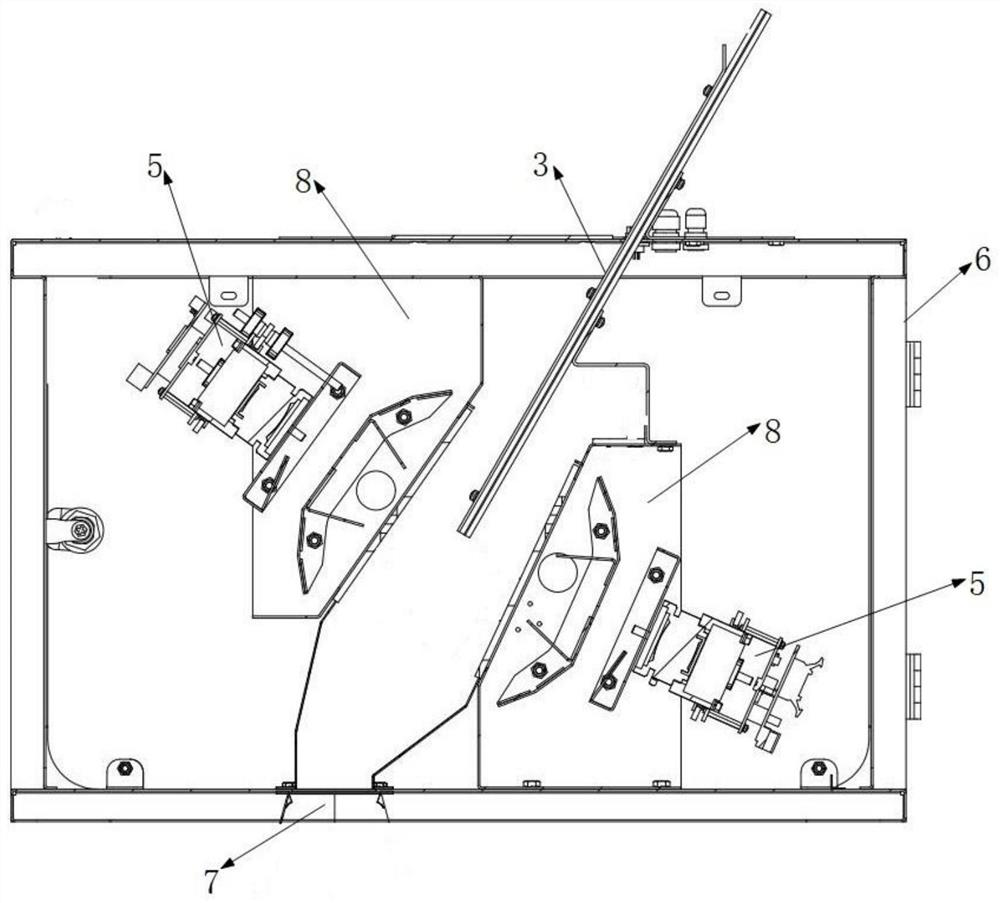

[0042] See figure 2 In a specific embodiment of the present invention, a grain hybrid quality analyzer comprising a quality analysis bun 6, a quality analysis bun 6 includes a box, and a tank is provided with a feed port for a sheet, and the bottom of the box is provided The discharge port 7 of the discharge port 7 can be mounted to collect the collection of rice, and a set of first mounting brackets 8 is provided in the quality analysis bracket 8; the slot assembly 3, the slot assembly 3 passes through The feed port is fixed to the first mounting bracket 8 inside the quality analysis trainer 6; the system assembly 5, including the camera assembly 503 for taking the capture data and the second mounting bracket 502 for fixing the camera assembly 503, a set of The identification system assembly 5 is configured on both sides of the slot assembly 3, and the identification system assembly 5 is provided inside the quality analysis board 6, and is fixed to the first mounting bracket 8; t...

Embodiment 2

[0045] Based on the embodiment 1, the second example of the second embodiment is:

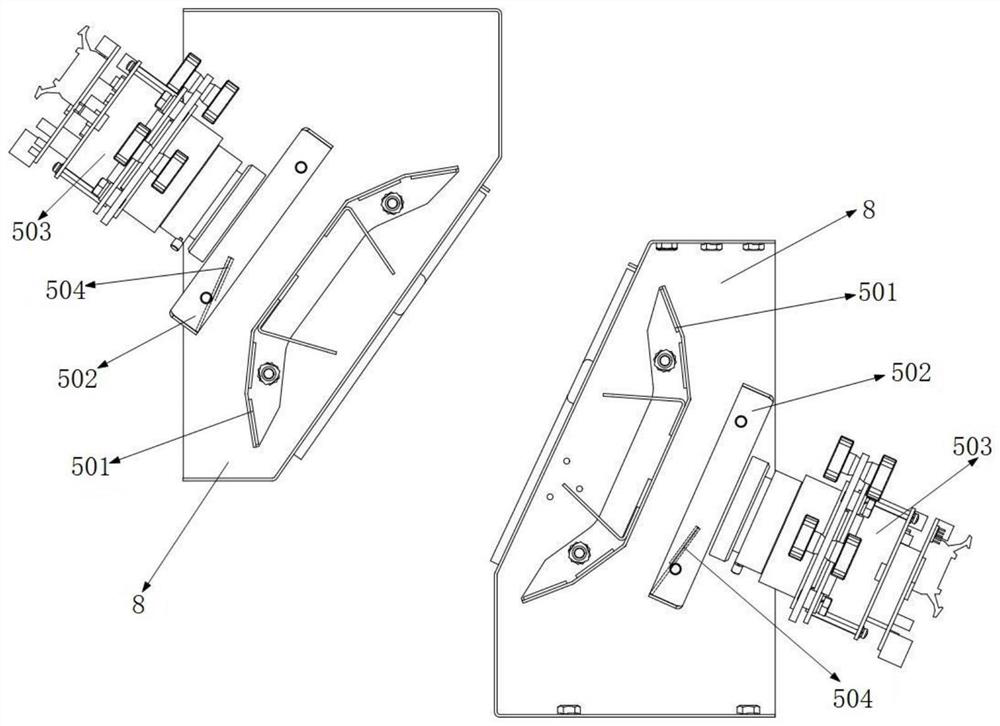

[0046] Please refer to image 3 Identify system components 5, set with background light group 504, background light group 504 has four dry block light boards, background lamp group 504 fixed to the first mounting bracket 8; also is also provided with material lamp group 501, material lamp group 501 The second mounting bracket 502 is fixedly connected.

[0047] In this embodiment, the light emitted by the background lamp can form a stable and uniform background color, which facilitates the contrast of the material to form a distinct color, improve the recognition accuracy.

Embodiment 3

[0049] Based on the embodiment, the differences of this embodiment are:

[0050] See Figure 4 and Figure 5 : The slot assembly 3 is tilted, and the slot assembly 3 includes: the chute 301, a U-shaped groove is opened on the slot 301 for the rice drop; the slot cover 302 is provided on the front side of the chute 301 and with the chute 301 Secure connection; the slot mount plate is fixed to the back surface of the chute 301. The chute mounting plate includes: the first mounting plate 303, the first mounting plate 303 fixed to the upper surface of the casing; the second mounting plate 304, the second mounting plate 304 is fixed to the first mounting bracket 8.

[0051] In this embodiment, the U-shaped groove is opened on the chute 301, and the rice is slippered from the U tank. The distribution is more uniform, and there is no stacking, the setting of the U-groove, so that the rice is uniform, the accumulation is small, and the photo is more Clear, easy to identify system components...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com