Testing stand for dynamic airflow response in single/double duct mode switching process

A mode conversion and dynamic response technology, which is applied in aerodynamic tests, jet engine tests, gas turbine engine tests, etc., can solve threats to the engine test piece, the safety of test bench testers, high risk, improper setting of mode conversion rules, etc. problems, to achieve the effect of saving test costs, reducing test risks, and shortening the test cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings.

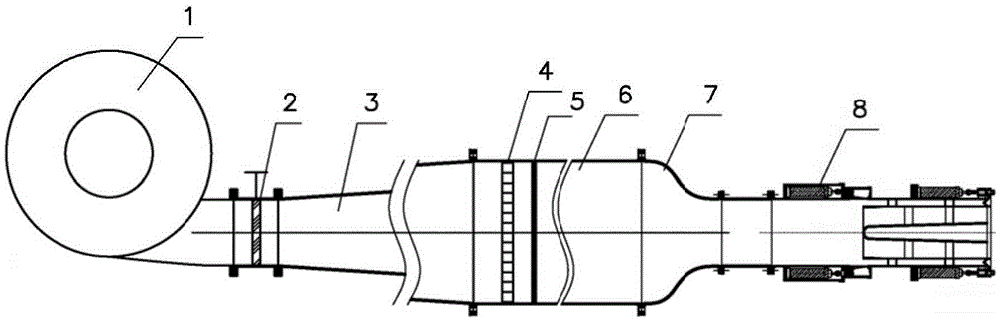

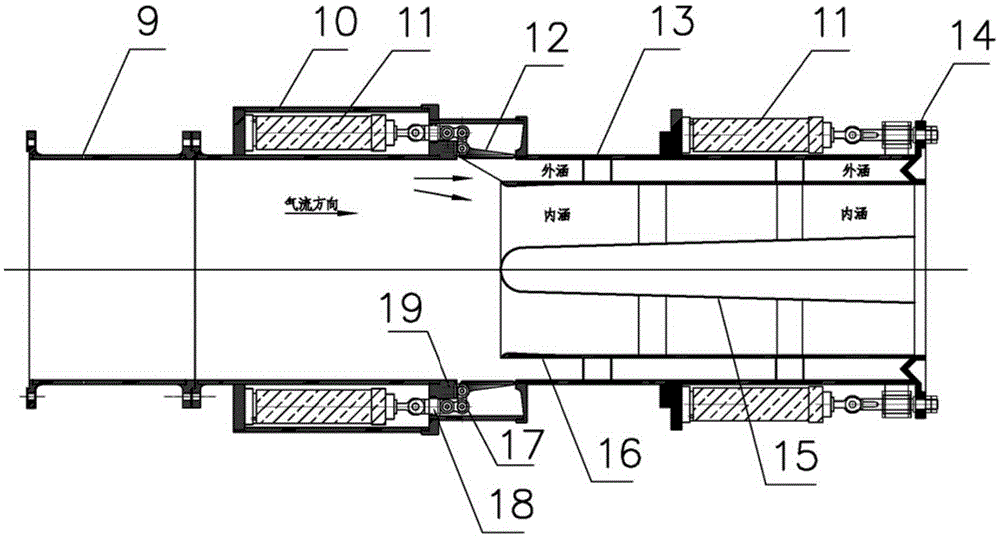

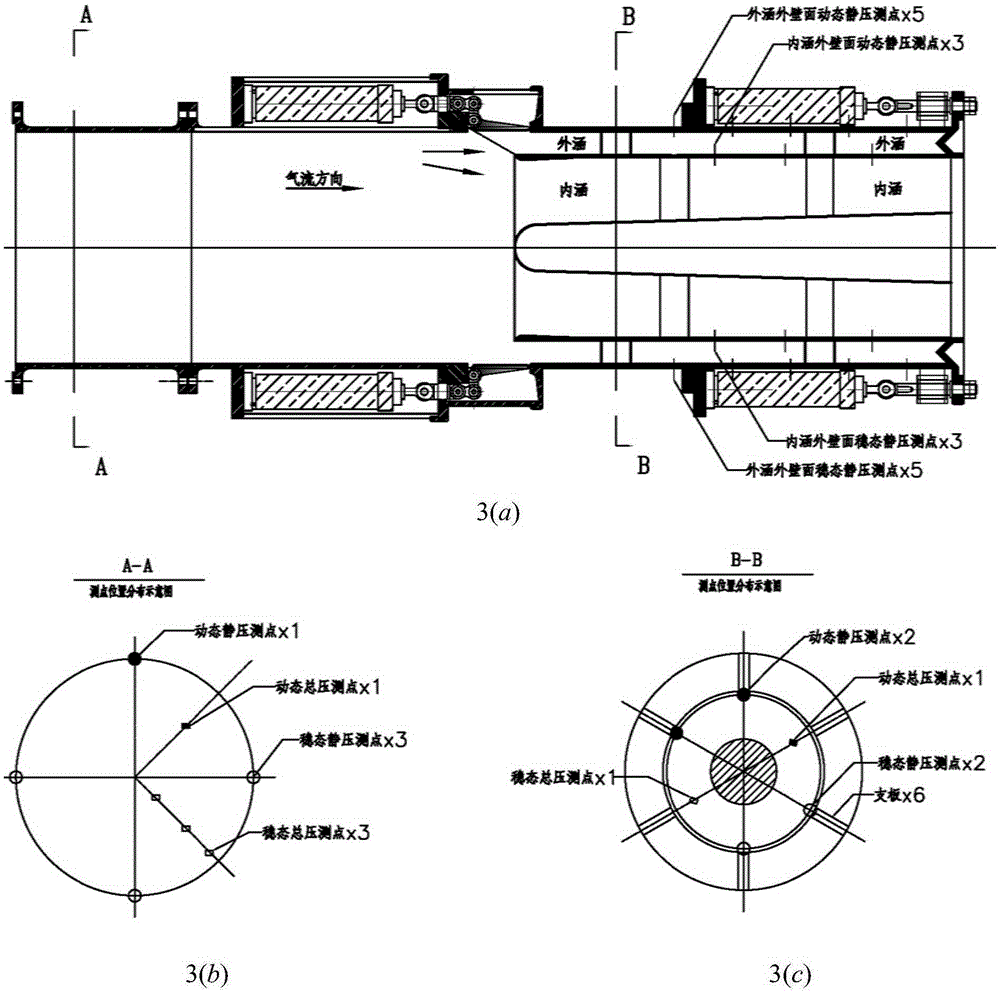

[0036] Such as figure 1 and figure 2Shown is a test bench suitable for studying the dynamic response of airflow during the mode transition process of a variable cycle gas turbine engine. It mainly includes five parts: centrifugal fan 1, expansion section 3, stabilization section 6, contraction section 7 and test section 8. 1 serves as an air source to provide continuous and stable airflow for the test section 8. The airflow from the centrifugal fan 1 first expands through the expansion section 3 and then flows into the stable section 6, then flows into the test section 8 after being contracted by the contraction section 7, and finally exits.

[0037] Such as figure 1 As shown, an electric valve 2 is installed between the centrifugal fan 1 and the expansion section 3, and the air flow flowing into the expansion section 3 is changed by controlling the opening of the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com