An automatic drying device for pcb boards

A PCB board and drying device technology, applied in the field of PCB board manufacturing, can solve the problems of long preparation time, secondary wetting of PCB board, high energy consumption of oven, etc., so as to save working hours and labor costs, save manual loading, The effect of accelerating the drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

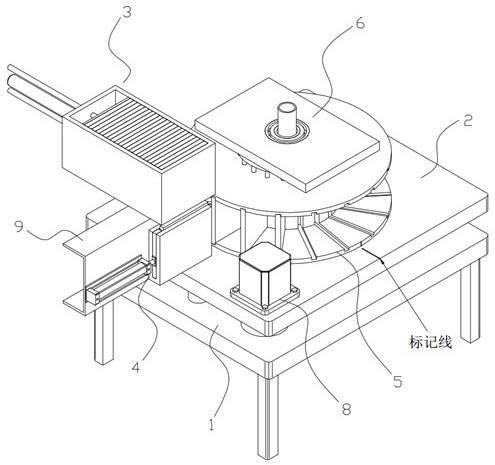

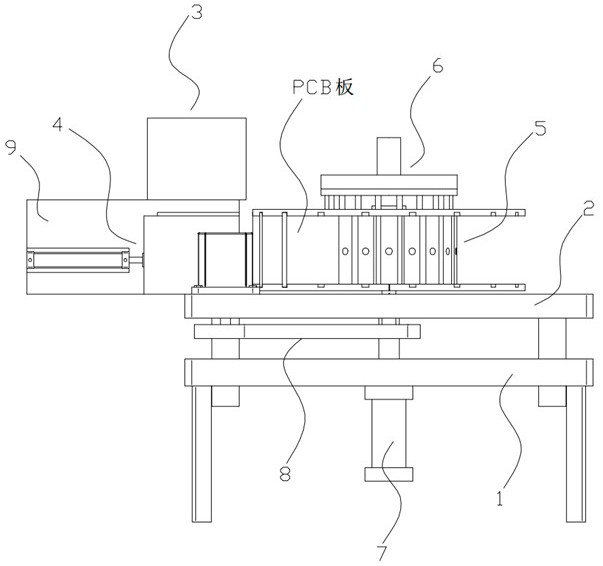

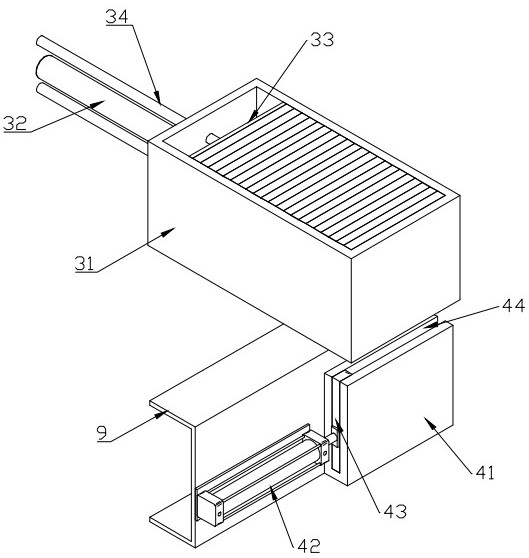

[0028] Such as Figure 1 to Figure 11 As shown, an automatic drying device for PCB boards includes a workbench 1, a base 2, a feeding assembly 3, a lifting assembly 4, a turntable mechanism 5, a positioning mechanism 6, and a lifting assembly 7. The base 2 is slidably connected to On the workbench 1, the adjustment of its height is realized by means of the lifting assembly 7. The feeding assembly 3 is installed on the top of the support plate 9 on the base 2 and can automatically send the PCB board into the ejecting assembly 4. The material assembly 4 is installed on one side of the support plate 9 and is located below the feeding assembly 3. The ejector assembly 4 can send the PCB board into the turntable mechanism 5, and it will be clamped by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com