High-strength steel wire neck-spinning device

A technology of high-strength steel wire and diameter reduction, which is applied in the field of high-strength steel wire outer diameter reduction equipment, can solve problems such as physical damage, manpower consumption, and low relaxation, and achieve the effects of avoiding damage, improving efficiency, and avoiding rigid transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

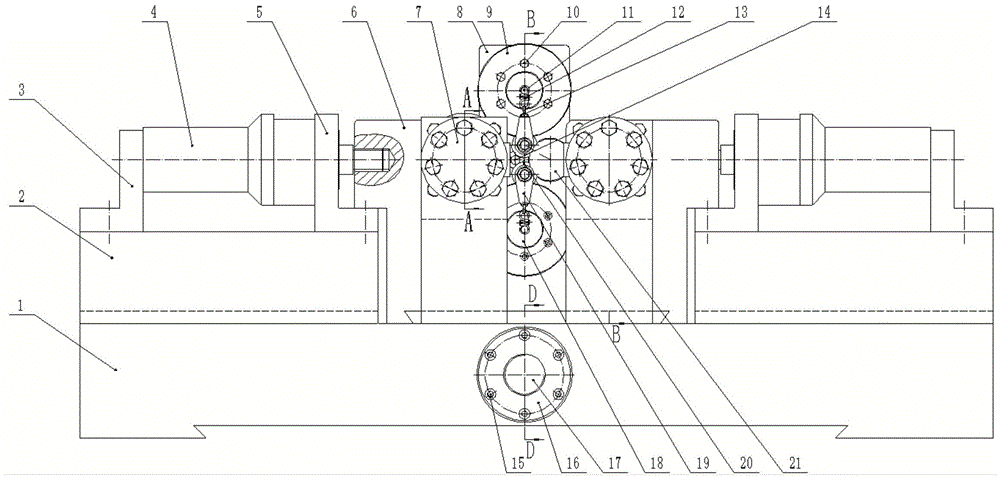

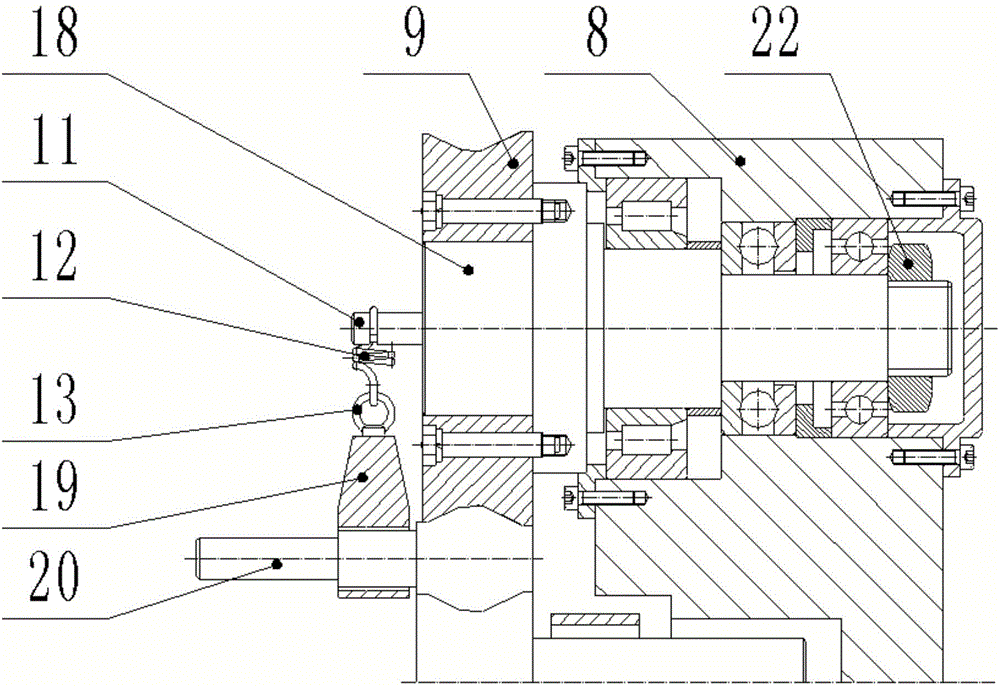

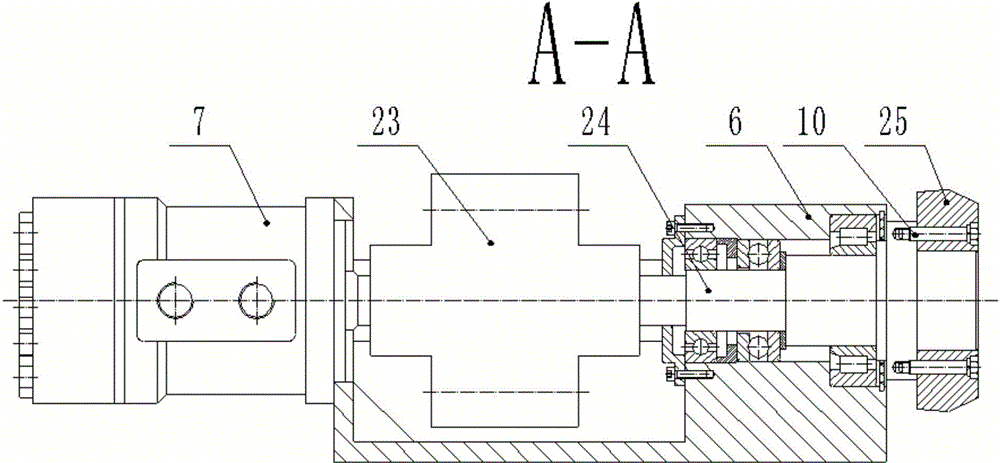

[0021] exist figure 1 and Figure 4 In the schematic diagram of the high-strength steel wire reducing spinning device shown, the radial feeding structure is the same structure of the two mechanisms and is symmetrically arranged on both sides of the lower guide rail block 1. The hydraulic cylinder in the radial feeding structure The guide rail block 2 is installed on the lower guide rail through the dovetail groove and the inclined inlay, the hydraulic cylinder front base 5 and the rear end base 3 are fixed on the hydraulic cylinder guide rail block by bolts 26, and the hydraulic cylinder 4 is fixed on the front and rear end bases.

[0022] The rotation mechanism is symmetrically arranged on the lower guide rail and connected with the radial feed structure. The wheel guide block 6 in the rotation mechanism is installed on the lower guide rail block through the dovetail groove and the oblique insert. One end of the hydraulic cylinder piston is provided with a screw thread. This...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com