Automatic detection device for cylindrical pin machine

An automatic detection and cylindrical pin technology, which is applied in sorting and other directions, can solve the problems of reduced detection efficiency, many mechanical actions, and unsmooth blanking, so as to achieve high detection efficiency, improve accuracy, and avoid low efficiency and errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

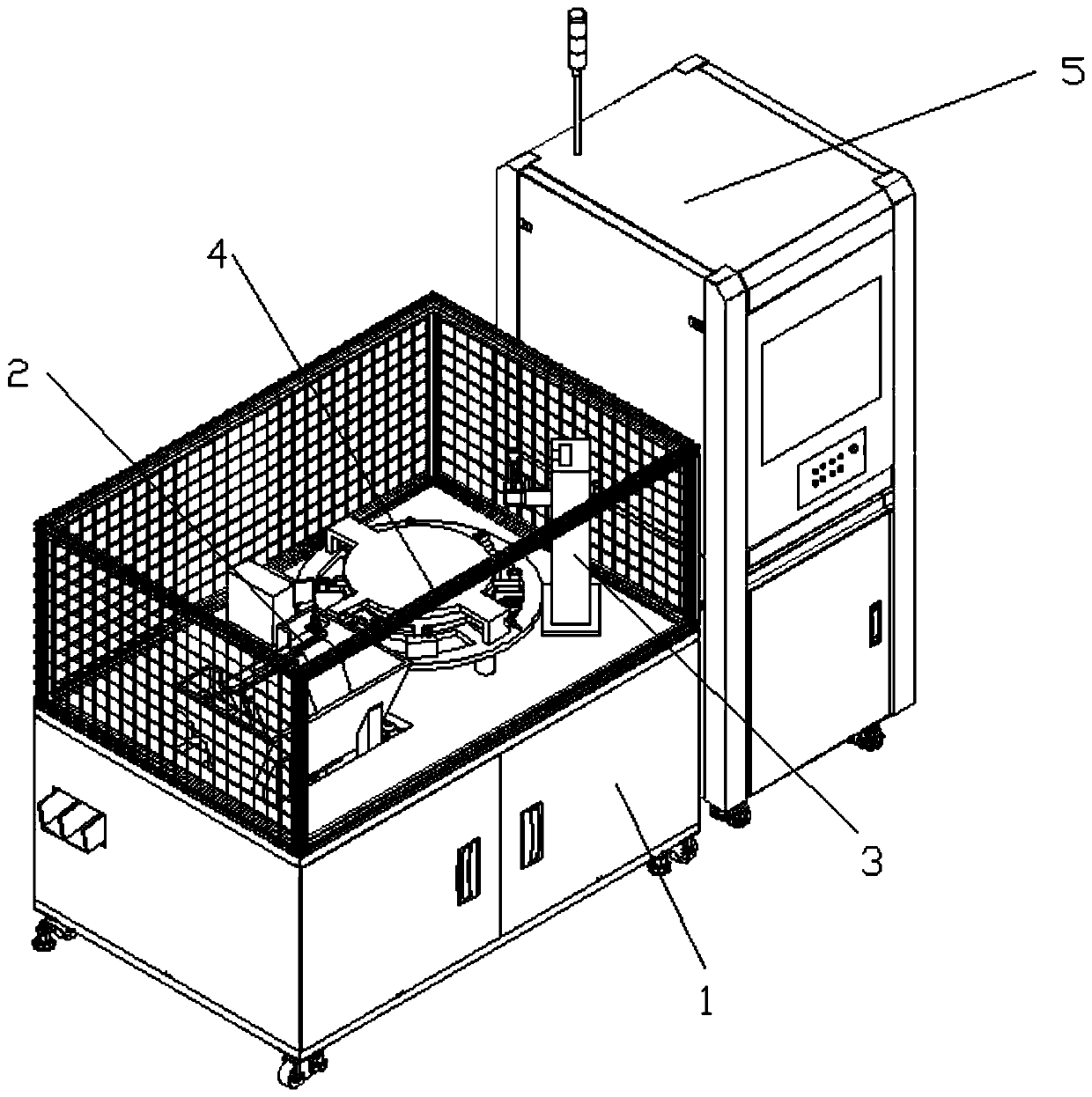

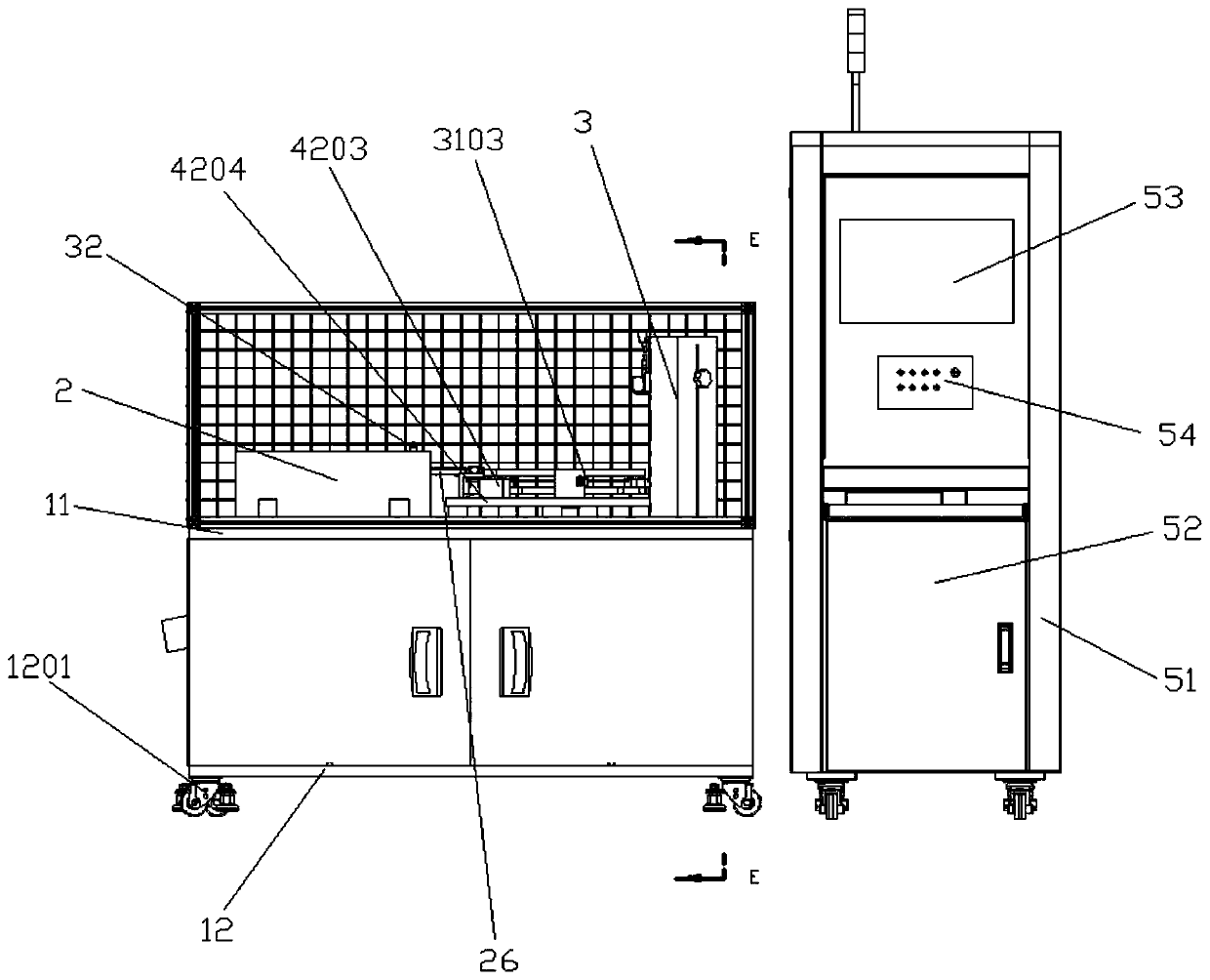

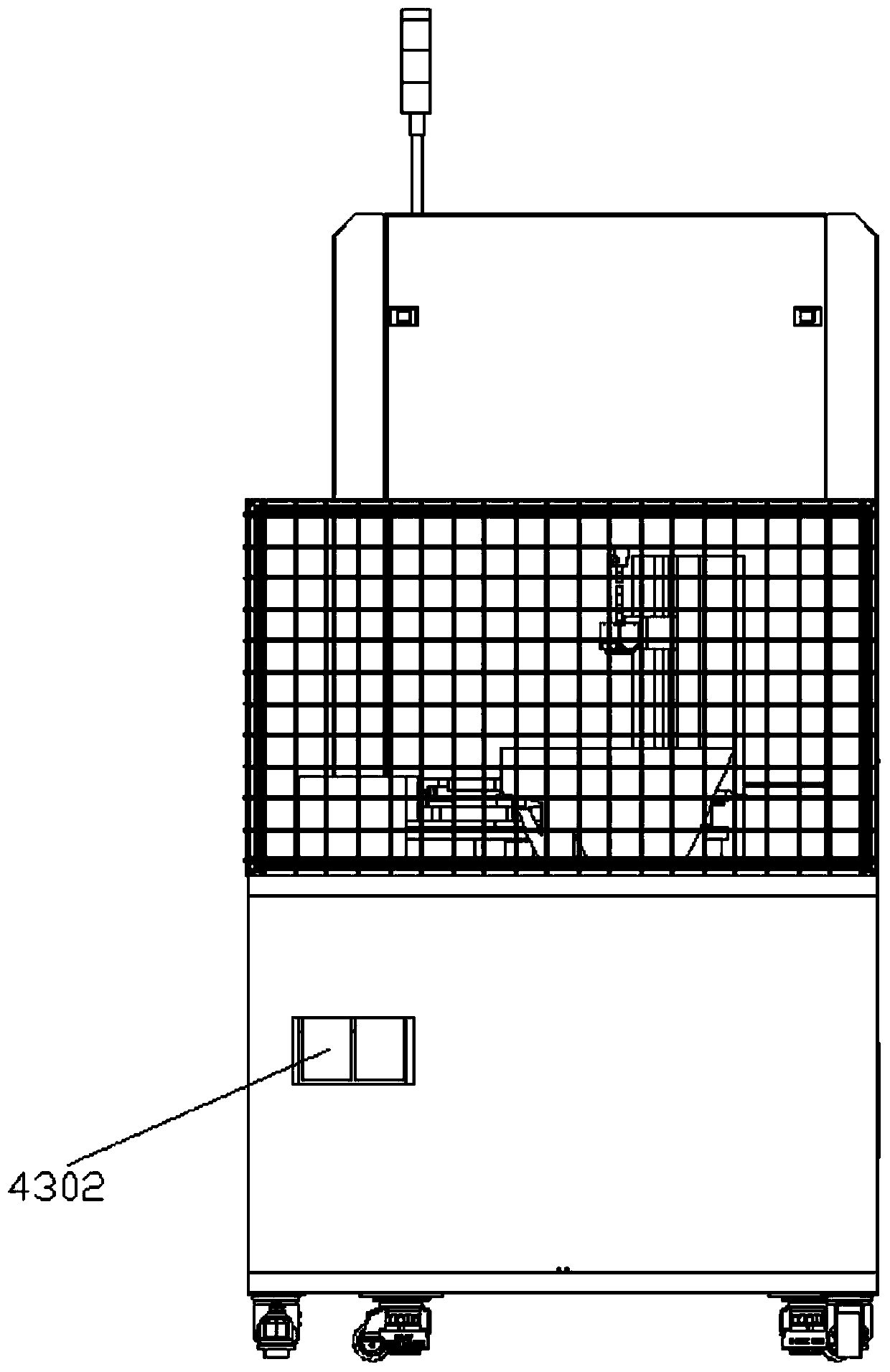

[0039] An automatic detection device for cylindrical pins, comprising a frame 1, a feeding device 2, a detection device 3, a feeding device 4, and a control device 5, the frame 1 includes a top plate 11 and a bottom plate 12, and the bottom of the bottom plate 12 is provided with There are universal wheels 1201 to facilitate movement, the feeding device 2 is arranged on the bottom plate 12 and passes through the top plate 11, the feeding device 4 includes a driving device 41, a rotary device 42, and a feeding device 43. The driving device 41 is arranged on the bottom plate 12, the turning device 42 is arranged on the top plate 11, the unloading device 43 is arranged on the top plate 11, and the driving device 41 communicates with the The rotary device 42 is connected, the unloading device 43 is arranged on one side of the rotary device 42, the detection device 3 is arranged on the top plate 11 and is located on the side of the rotary device 42, and the feeding device 2 passes t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com