Sanding device for high-hardness and high-brightness gold jewelry

A high-brightness, high-hardness technology, applied in the field of sanding machines, can solve the problem of inconvenient sanding, and achieve the effect of saving manual feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

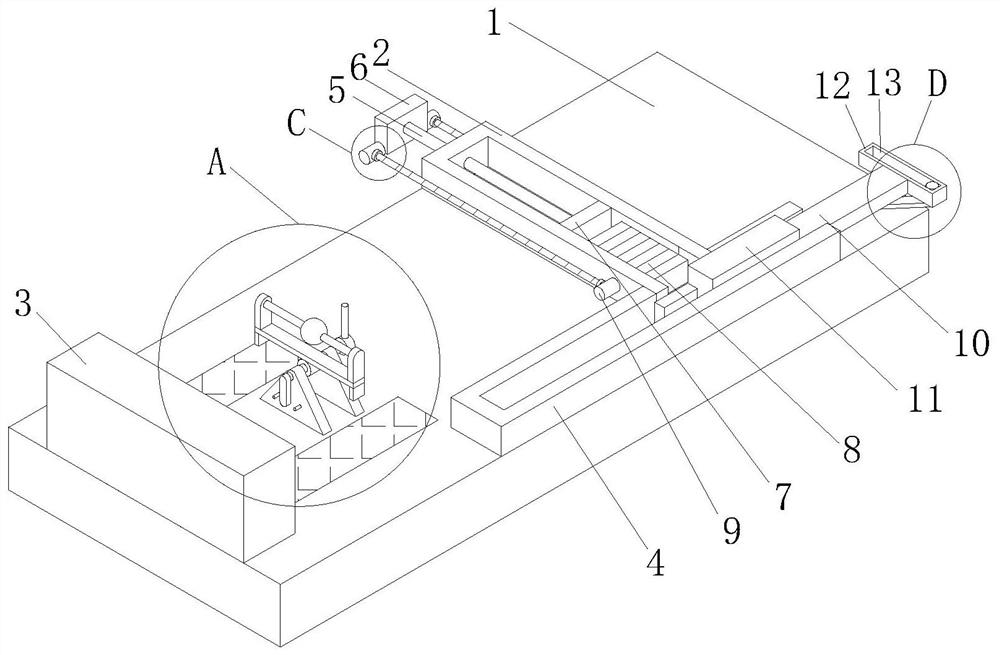

[0030] A sandblasting device for high-hardness and high-brightness gold jewelry, comprising a workbench 1, a pre-storage frame 2 fixedly connected to the top of the workbench 1, a loading frame 4 fixedly connected to the right side of the pre-storage frame 2, the pre-storage frame 2 and the upper The material frame 4 is fixedly connected to the top of the workbench 1 in a "T" shape, the interior of the pre-storage frame 2 and the material loading frame 4 are connected, and the top of the workbench 1 is provided with a sander 3, which is an existing structure , do not do too much description here, the inside of pre-store frame 2 is provided with gold bar 8, when using this device, gold bar 8 is prevented in pre-store frame 2 in advance, when needing to use gold bar 8 to process, gold bar 8 is removed from pre-store Take it out from the frame 2, use the sander 3 to sand the gold bar 8, so that the surface of the gold bar is smooth, the left side of the pre-stored frame 2 is slida...

Embodiment 3

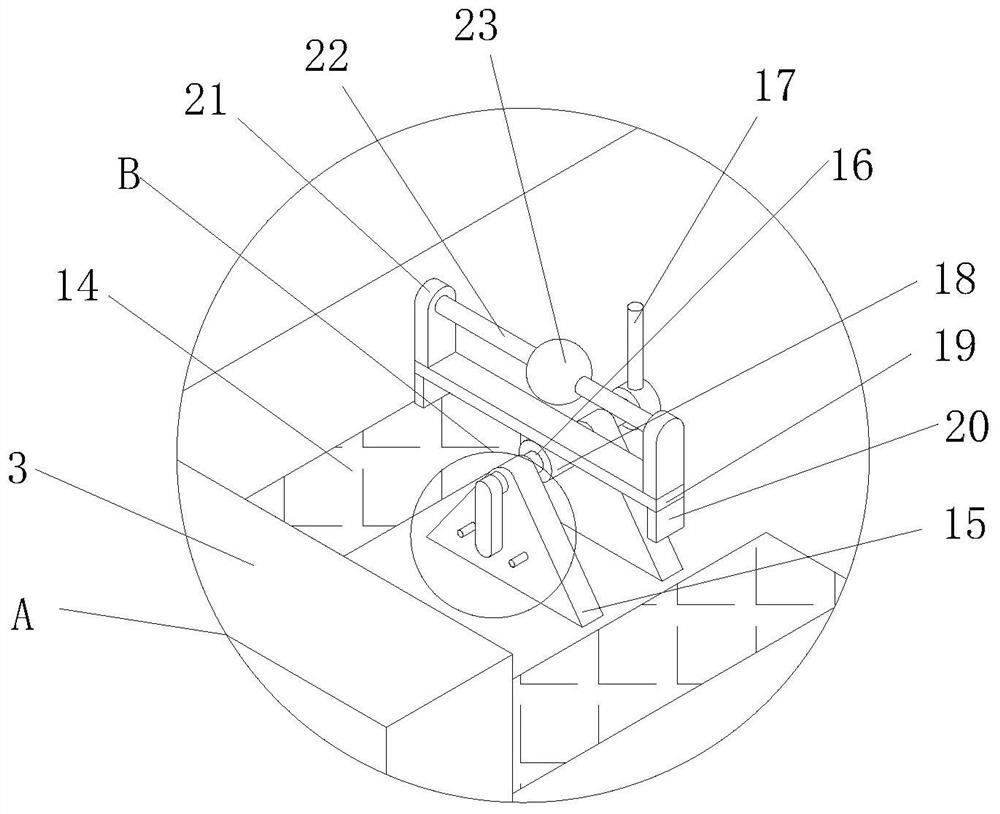

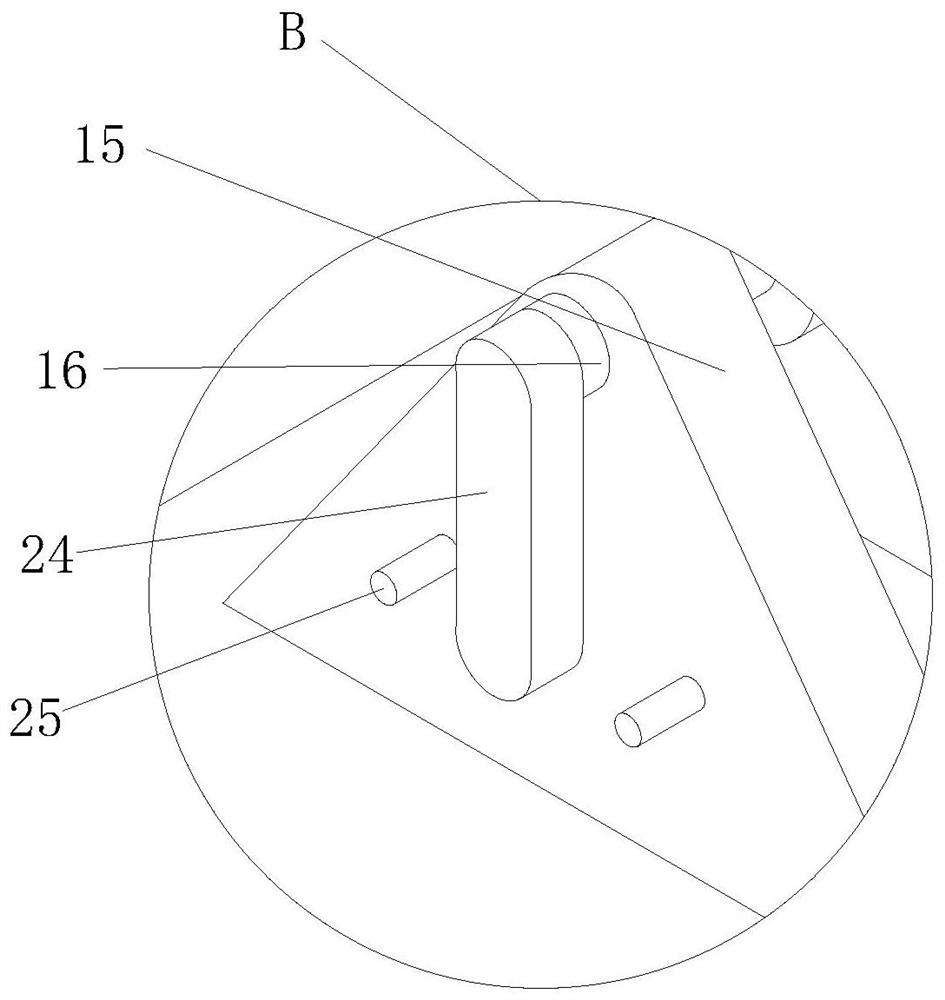

[0032]A sandblasting device for high-hardness and high-brightness gold jewelry, comprising a workbench 1, a pre-storage frame 2 fixedly connected to the top of the workbench 1, a loading frame 4 fixedly connected to the right side of the pre-storage frame 2, the pre-storage frame 2 and the upper The material frame 4 is fixedly connected to the top of the workbench 1 in a "T" shape, the interior of the pre-storage frame 2 and the material loading frame 4 are connected, and the top of the workbench 1 is provided with a sander 3, which is an existing structure , not to be described too much here, the inside of the pre-storage frame 2 is provided with a gold bar 8, and the top of the workbench 1 is fixedly connected with two positioning blocks 15, and the two positioning blocks 15 are located at the rear side of the sand making machine 3 and are not connected with The sand making machine 3 is in contact, and the opposite surfaces of the two positioning blocks 15 are rotated and con...

Embodiment 4

[0034] A sandblasting device for high-hardness and high-brightness gold jewelry, comprising a workbench 1, a pre-storage frame 2 fixedly connected to the top of the workbench 1, a loading frame 4 fixedly connected to the right side of the pre-storage frame 2, the pre-storage frame 2 and the upper The material frame 4 is fixedly connected to the top of the workbench 1 in a "T" shape, the interior of the pre-storage frame 2 and the material loading frame 4 are connected, and the top of the workbench 1 is provided with a sander 3, which is an existing structure , without going into too much description here, the inside of the pre-storage frame 2 is provided with a gold bar 8, the push rod 10 is slidably connected to the loading frame 4, the front end of the push rod 10 is fixedly connected to a slider 11, and the slider 11 is slidably connected to the upper In the material frame 4, the rear end of the push rod 10 is fixedly connected with a connecting rod 12, and the top of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com