Polishing sand wet-in dry-out circulation extruding polishing device

A technology of polishing sand and equipment, which is applied in the field of machinery, can solve the problems of uneven polishing of basic polishing equipment, the inability to realize automatic recycling of materials and automatic addition of logistics, etc., so as to save human resources and work efficiency, improve propulsion efficiency, and benefit society and society. The effect of economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

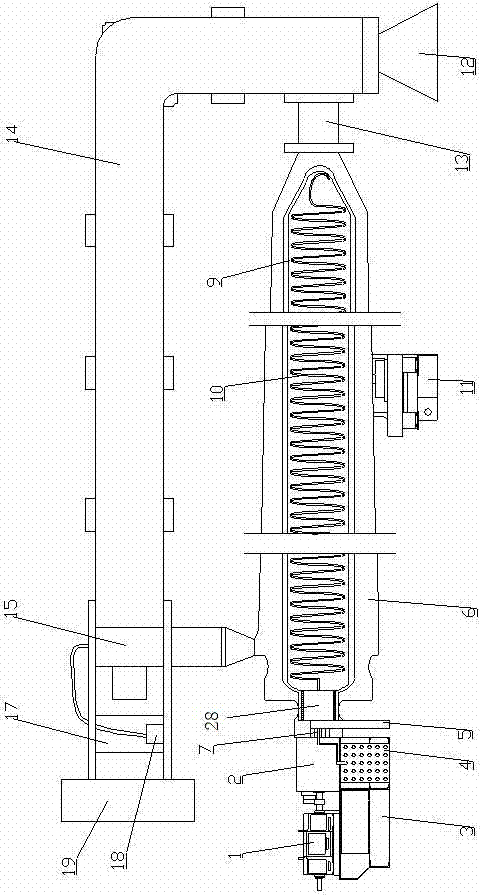

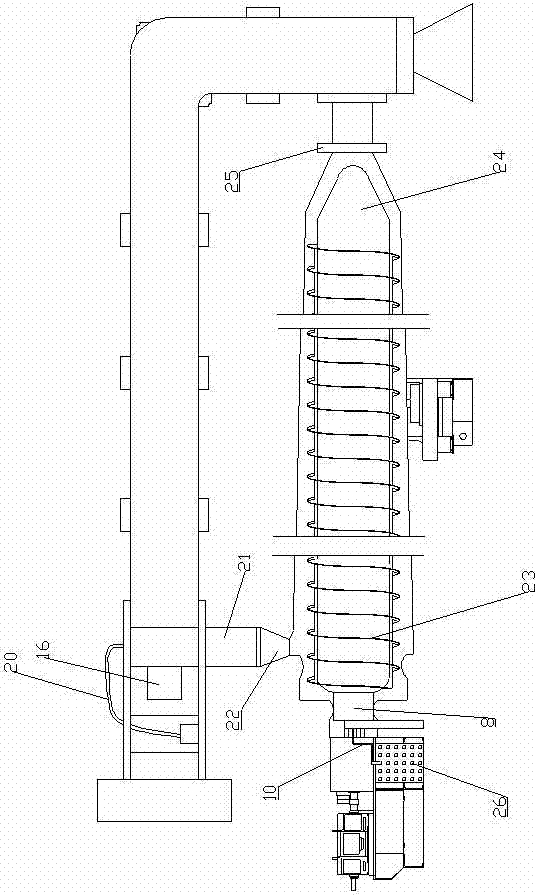

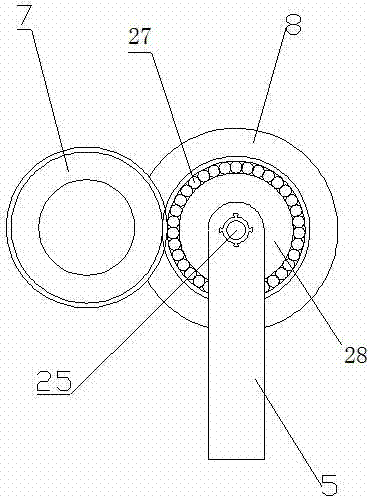

[0017] Such as figure 1 , 2 , 3, and 4, a polishing sand wet-in-dry-out cycle extrusion polishing equipment, including a support 3, a motor 1 fixedly installed on the support 3, a reducer 2 connected to the motor 1, and a reducer 2. The connected drive gear 7, the sleeve 6 fixedly installed on one side of the reducer 2 through the bracket 11, the sleeve 6 is a hollow conical tubular structure with openings at both ends, and moves inside the sleeve 6 A rotating shaft 9 with a hollow tubular structure is installed, and a pusher screw blade 23 is fixedly arranged on the outside of the rotating shaft 9, and a heating coil 10 is arranged inside the rotating shaft 9, and the heating coil 10 and the heater 4 arranged under the reducer 2 connected, the driving gear 7 is connected with the rotating shaft 9 through the hollow gear 8, a fixed disk 28 is fixedly installed inside the hollow gear 8, a steel ball 27 is arranged between the fixed disk 28 and the hollow gear 8, and the sleeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com